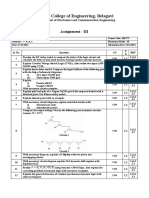

Professional Documents

Culture Documents

Dip-LED in Fridge

Uploaded by

bookslover10 ratings0% found this document useful (0 votes)

30 views9 pagesled

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentled

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views9 pagesDip-LED in Fridge

Uploaded by

bookslover1led

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Refrigerated display case lighting with LEDs

Ramesh Raghavan and Nadarajah Narendran

Lighting Research Center

Rensselaer Polytechnic Institute, Troy, NY 12180

www.lrc.rpi.edu

Copyright 2002 Soci ety of Photo-Optical Instrumentation Engineers.

This paper was published in Solid State Lighting II: Proceedings of SPIE and is made

available as an electronic reprint with permission of SPIE. One print or electronic copy may be

made for personal use only. Systematic or multiple reproduction, distribution to multiple locations

via electronic or other means, duplication of any material in this paper for a fee or for commercial

purposes, or modification of the content of the paper are prohibited.

Refrigerated Display Case Lighting with LEDs

Ramesh Raghavan* and Nadarajah Narendran

Lighting Research Center

Rensselaer Polytechnic Institute, Troy, NY 12180

ABSTRACT

The rapid development of high brightness light emitting diodes (LEDs) has triggered many applications,

especially in the area of display lighting. This paper focuses on the application of white LEDs in

refrigerated display cases. The fluorescent lighting presently used in commercial refrigerators is inefficient

in the application and also it provides poor lighting for merchandising. A laboratory human factors

experiment was conducted to assess the preference for the different lighting systems, namely, fluorescent

and LED. Two refrigerated display cases, one with the traditional fluorescent lighting system and the other

with a prototype LED lighting system, were placed side-by-side in a laboratory setting. Illuminance

measurements made within the two display cases showed that the lighting was more uniform with the LED

system compared to the traditional fluorescent system. Sixteen human subjects participated in this study

and rated their preference for the two lighting systems. The results show that human subjects strongly

preferred the display case with the LED lighting. The authors of this manuscript believe a field study would

be greatly beneficial to further confirm these results and to understand the relationship between preference

and sales. Considering the luminous efficacy of white LEDs presently available in the marketplace, it is

possible to develop a LED based lighting system for commercial refrigerators that is competitive with

fluorescent lighting system in terms of energy use. The LED based lighting would provide better lighting

than traditional fluorescent lighting.

Key Words: LED, White light LED, Display Lighting, refrigerated display cases, uniformity and

preference.

INTRODUCTION

Supermarkets spend nearly half their annual electric cost for refrigeration

[1]

. Studies have shown that

lighting accounts for about 15% of the total energy consumed by commercial refrigerators

[2]

. Although in

this document it is referred to as refrigerators, it includes both refrigerators and freezers. Linear fluorescent

lamp is the most commonly used light source in commercial refrigerators. In general linear fluorescent

lamp is considered energy efficient in applications because as a light source it has very high luminous

efficacy. Rea and Bullough in 2001 showed that high light source efficacy does not mean high application

efficacy

[3]

. Figure 1 shows how the light output of a fluorescent lamp varies as a function of ambient

temperature

[4]

. The light output of a T8 linear fluorescent lamp could drop more than 25% when the

ambient temperature reduces from room temperature, 25

o

C, to refrigeration temperature, 7

o

C. In the case of

freezers the light output could drop even more. In addition the linear fluorescent lamp is typically mounted

near the door hinge with poor optics to redirect the light towards the displayed products. As a result only

about 60% of the light is directed towards the displayed products and the rest is wasted. Therefore, of the

2800 lumens produced by a typical T8 fluorescent lamp with electronic ballast, only about 1260 lumens is

eventually utilized for lighting the products. As a result in the refrigerator lighting application the efficacy

of a T8 fluorescent lamp reduces to 40 lumens per watt (lpw), which is much less than the rated source

efficacy, 90 lpw. Another drawback of fluorescent lighting is that it does not provide for visually appealing

merchandise displays. As shown in Figure 2, the lighting within the display case is very uneven. In most

supermarket display cases it is difficult to see the products that are set behind. This is because the products

in the front obstruct the light and cast heavy shadows.

Considering the energy consumption issue and the poor lighting in commercial refrigerated display cases, it

appears that there is an opportunity for alternate lighting technologies. Surveying the past literature it

became evident that very little work has been done in the area of refrigerator lighting. The few that is out

there have either looked at using optics with the existing fluorescent systems to get the light distributed

deeper into the shelves

[5-7]

or using remote source illumination systems to better distribute the light

[8-9]

.

Although these techniques may address the poor lighting issue they do not address the energy consumption

issue. Over the past few years a new light source technology, light emitting diode (LED), has been rapidly

developing. This new light source technology holds promise for energy savings, low maintenance, and

better lighting for the target application. Therefore the goal of the study presented in this manuscript was to

investigate the use of white light LEDs for commercial refrigerator lighting applications.

Although LEDs were invented during the later part of 1960s it is only after the mid 1990s when the white

light LEDs were developed it became a potential light source for general lighting applications

[10]

. The

initial white LEDs came in the standard 5 mm configuration, typically used for indicator lighting

applications. Each of these LEDs produced very little flux, less than a lumen, and their efficacy was less

than 10 lpw. Furthermore, these 5 mm white LEDs degraded very rapidly and did not hold up to their long

life promise

[11]

. Aggressive product development programs within manufacturing organizations have led

to new commercial white LED packages suitable for illumination applications. These illuminator LEDs

have larger lumen package, 120 lumens, and high luminous efficacy values, of the order of 24 lpw

[12]

.

Also these devices have much less lumen depreciation compared to the traditional 5 mm-white LEDs

[11]

.

Industry experts are predicting the white light LEDs to reach 50 lpw by 2005 and 100 lpw by 2010

[13]

.

Hence a distributed LED system can be a good alternative to the existing fluorescent lighting system.

EXPERIMENT

As mentioned earlier the goal of this study was to investigate the use of white light LEDs for commercial

refrigerator lighting applications. A laboratory human factors experiment was conducted to assess the

preference for the different lighting systems, namely, fluorescent and LED.

Two refrigerated display cases were used in the experiment. Both units had a 4-foot 32-watt 6500K T8

fluorescent lamp. The rated light output for this lamp was 2700 lumens at room temperature, 25 C.

Initially one of the refrigerators was turned on and the light output was continuously monitored until the

temperature inside the case reached its steady state value (7

o

C). The light output of the fluorescent lamp

dropped 25% when the refrigerator reached its operating temperature (7

o

C). This corresponds to about 2200

lumens at 7 C for the fluorescent lamp.

The second refrigerator was retrofitted with a prototype LED lighting system that had two types of LEDs.

The first was a linear array of 5 mm white LEDs, 2 feet long. The second was a high flux illuminator that

had densely packed semiconducting elements. Two of these high flux LEDs were mounted on a flat

aluminum plate. The availability dictated the use of these particular LED packages. Figure 5 illustrates the

LED lighting system formed using the two types of white LEDs. Two such fixtures were mounted to the

bottom side of each shelf, one in the front close to the glass door and the other half way between the glass

door and the back wall. The total flux produced by the LED lighting system was about 1200 lumens and the

CCT was about 5300 K. The number of LEDs used here was based on attaining 500 lux, which is the

recommended vertical illuminance on the face of the displayed products

[14]

.

As shown in Figure 3, both display cases were filled with products typically found in supermarkets. Both

display cases were placed side-by-side in a laboratory setting. The two cases visually looked the same

under the same lighting. The ambient light level in the surrounding area was kept at 530 lux, which is

similar to the illuminance levels in the isles of supermarkets where refrigerated display cases are kept

[15]

.

Illuminance measurements were made at multiple points across the shelves for both display cases, one with

the fluorescent lighting system and the other with the LED lighting system. The shelves were partially

filled with products while taking illuminance measurements. The point of measurement and the

arrangement of products within the shelves were kept the same for both the cases.

Human Factors Experiment

Two refrigerated display cases, one with the traditional 4-ft T8 fluorescent lighting system and the other

with the prototype LED lighting system, were placed side-by-side in a laboratory setting. All subjects were

screened for deficiencies in color vision prior to starting the experiment. Each subject viewed the two

display cases simultaneously and rated their preference on a 1 to 3 scale. The questions asked to the

subjects were based on the overall clarity, overall preference and preferences for four individual products

placed on the shelves. The four products had different packaging and they were predominantly white, red,

blue and green in color. Rating of zero indicated no preference, 1 indicated little preference, and 3 indicated

high preference. The time for making the subjective judgments was not restricted, however, most subjects

rated their preferences within 1 minute.

The first experimental condition observed and rated by human subjects was the null test, in which both

display cases were lit by the fluorescent lighting system and had identical product arrangement and light

levels. Figure 8 illustrates the results of the null test. Statistical analysis of this data showed no significant

preference for either display case, thus the null condition was verified. In the second experiment subjects

rated their preference for the display cases lit by the fluorescent and LED lighting systems; the results are

illustrated in Figure 10. Statistical analysis of this data showed significant preference for the display case

with the LED lighting system. This indicated that human subjects strongly preferred the display case with

the LED lighting system.

Table 1 summarizes the parameters of the two lighting conditions. The lighting in the two display cases,

one with the fluorescent and the other with LEDs, had two main differences, namely, the light distribution

and CCT. Both these parameters could have had an impact on the subjective rating.

Fluorescent LED

Lighting system Single large light source Many small distributed light sources

Illuminance range 200 to 1200 lux 550 to 650 lux

CCT 6500 K 5300 K

CRI 86 82

Therefore to understand the impact of CCT on subject rating, both display cases were lit by fluorescent

lamp. In one of the cases the light was made warm, similar to the CCT of the LED system, using a thin

sheet of theatrical gel. The subject rating results for this experiment is illustrated in Figure 9. Statistical

analysis of this data showed no significant preference for either display case. This indicated that on an

average the human subjects had no preference for the two CCT conditions used here. Therefore form the

three experiments it appears that the lighting distribution had the highest impact on peoples preference.

Table 2 summarizes the light output characteristics and energy use of linear fluorescent and LED lighting

systems. The table also shows projected energy use in 2005 and 2010 for LED lighting systems. It appears

even at the present time a properly constructed LED lighting system for refrigerators would have similar

energy consumption as a fluorescent system. With the proposed advancements in the efficacy of white

LEDs one can expect future LED equipped commercial refrigerators to have better lighting with less

energy consumption.

Lighting system

Light output

(Lumens at 7

o

C)

System Efficacy

(Lumens/watt)

Energy use

(KWhr)

Energy

Savings

32 Watt Fluorescent

2200

68 0.76

LED in 2002

[12]

1200

32 0.91

-18 %

LED in 2010

[13]

1200

100 0.28

62 %

Table 2: System efficacy and energy use projections.

SUMMARY

A laboratory human factors experiment was conducted to assess the preference for the different lighting

systems, namely, fluorescent and LED. Two refrigerated display cases, one with the traditional fluorescent

lighting system and the other with a prototype LED lighting system, were placed side-by-side in a

laboratory setting. Illuminance measurements made within the two display cases showed that the lighting

was more uniform with the LED system compared to the traditional fluorescent system. Sixteen human

subjects participated in this study and rated their preference. The results show that human subjects strongly

preferred the display case with the LED lighting. The authors of this manuscript believe a field study would

be greatly beneficial to further confirm these results and to understand the relationship between preference

and sales. Considering the luminous efficacy of white LEDs presently available in the marketplace, it is

possible to develop a LED based lighting system for commercial refrigerators that is competitive with

fluorescent lighting system in terms of energy use. The LED based lighting would provide better lighting

than traditional fluorescent lighting. Since the LEDs are still in their development phase, at the present time

they are much more expensive than fluorescent systems. However, with the proposed advancements one

can expect lower cost for future LED lighting systems.

ACKNOWLEDGMENTS

Authors gratefully acknowledge the financial support of the U.S. Department of Energy/Oak Ridge

National Laboratories/Foster Miller. We thank Carrier Corporation for donating the refrigerators, B/E

Aerospace Inc. for providing the LED arrays, and Opto Technology Inc. for supplying the high flux LEDs.

REFERENCES

1. Refrigerator display case performance evaluation a report by the Southern California Edison utility

company

2. The energy impact of the food and drug administrations code for reduced storage temperature of

foods services a report by the Southern California Edison utility company

3. Rea, M. S. and J . D. Bullough. Summer 2001. Application efficacy. J ournal of the Illuminating

Engineering Society 30(2): 73-96

4. Dr.Rea M, IESNA Lighting Handbook 2000

5. US patent no.6325523 Display case with lens lighting system

6. US patent no.6179434 Modular lighting system for product display unit

7. US patent no.5879070 Louvered lighting system

8. US patent no.5836669 Remote illumination and light apportionment in appliances

9. US patent no.5508898 Interior lighting apparatus for a refrigerated display case

10. N. Narendran, J . D. Bullough, N. Maliyagoda, and A. Bierman, What is Useful Life for White Light

LEDs? J. Illum. Eng. Soc. Winter 2001, 30(1) 57

11. N. Narendran , N. Maliyagoda, L. Deng, and R. Pysar Characterizing LEDs for General Illumination

Applications: Mixed-color and phosphor-based white sources, SPIE Proceedings, Vol. 4445, 2001.

12. http://www.lumileds.com/pdfs/DS30.PDF; Power light source Luxeon 5 Watt Star Technical Data

DS30

13. Energy Savings Potential of Solid State Lighting in General Lighting Applications a report by Arthur

D. Little Inc to the U.S. Department of Energy

14. IESNA RP-2-01 Recommended practice for Lighting Merchandise Areas

15. LRC publication DELTA Snapshots: Supermarket Lighting, Issue 2 (1997)

* Ramesh Raghavan, email-raghar@rpi.edu, ph 518-687-7100

Figure 2: A typical supermarket refrigerator. The

picture clearly shows the non uniform light

distribution.

Figure 1: Light output versus ambient

temperature curve for a typical

fluorescent system

[4]

.

Fluorescent

lamp

LED fixture

unit

Cross section Cross section LED fixture unit

inside the refrigerator

High flux

diffused

source

Linear

directional

source

Figure 4: Schematic showing the light distribution with

florescent lighting on the left and LED lighting on the right.

Figure 5: Arrangement of the LED fixture

Figure 3: Refrigerated display cases with florescent lighting on the left and LED lighting on the right.

Fluorescent

lamp

LEDs

Figure 6: Illuminance with distance for fluorescent lighting

Figure 7: Illuminance with distance for distributed LED lighting

0

500

1000

1500

2000

2500

0 10 20 30 40 50 60

distance from the front in cms

i

l

l

u

m

i

n

a

n

c

e

i

n

l

u

x

center

right

left

0

500

1000

1500

2000

2500

0 10 20 30 40 50 60

distance from the front in cms

i

l

l

u

m

i

n

a

n

c

e

i

n

l

u

x

center

right

left

5300K Fluorescent | 6500K fluorescent

-3 -2 -1 0 1 2 3

clarity

blue product preference

green product preference

red product preference

white product preference

overall preference

preference scale

Figure 8: Null test results

Figure 9: Color temperature test results

Figure 10: System comparison test results

Fluorescents | Fluorescents

-3 -2 -1 0 1 2 3

clarity

blue product preference

green product preference

red product preference

white product preference

overall preference

preference scale

Fluorescent | LED system

-3 -2 -1 0 1 2 3

clarity

blue product preference

green product preference

red product preference

white product preference

overall preference

preference scale

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PV Questions Arjun - MergedDocument148 pagesPV Questions Arjun - MergedArjun Sankar0% (1)

- Electronic Devices and Circuits - B. Kumar and S. B. Jain PDFDocument163 pagesElectronic Devices and Circuits - B. Kumar and S. B. Jain PDFMrigya Jain0% (1)

- Cornelius Ice MachineDocument28 pagesCornelius Ice Machinebookslover1No ratings yet

- Diego y Paco Del Gastor FalsetasDocument36 pagesDiego y Paco Del Gastor FalsetasJavier Carmona100% (1)

- Mix10 Service InfoDocument8 pagesMix10 Service InfolennythefishNo ratings yet

- Parametric Test 1595249572Document16 pagesParametric Test 1595249572Antonello VannucciNo ratings yet

- Sensory Training Kits: Siebel Institute of TechnologyDocument16 pagesSensory Training Kits: Siebel Institute of Technologydiego jesusNo ratings yet

- Giuliani: 120 Studies For The Right HandDocument15 pagesGiuliani: 120 Studies For The Right HandSjsweet55100% (3)

- MT Report Journal11Document6 pagesMT Report Journal11bookslover1No ratings yet

- MT Report Journal11Document6 pagesMT Report Journal11bookslover1No ratings yet

- MT Report Journal27Document5 pagesMT Report Journal27bookslover1No ratings yet

- 130 Years of Brewing Education: Siebel's World Brewing Academy in ChicagoDocument3 pages130 Years of Brewing Education: Siebel's World Brewing Academy in Chicagobookslover1No ratings yet

- MT Report Journal9Document9 pagesMT Report Journal9bookslover1No ratings yet

- MT Report Journal15Document7 pagesMT Report Journal15bookslover1No ratings yet

- Bitzer DataDocument27 pagesBitzer Databookslover1No ratings yet

- Eng Module 1Document10 pagesEng Module 1bookslover1No ratings yet

- Bitzer DataDocument27 pagesBitzer Databookslover1No ratings yet

- Reece Compressor CatalogueDocument8 pagesReece Compressor Cataloguebookslover1No ratings yet

- Cubigel Brochure 320102MDocument24 pagesCubigel Brochure 320102Mbookslover1No ratings yet

- Beckwith Mech MeasurementCh3Document32 pagesBeckwith Mech MeasurementCh3bookslover1No ratings yet

- Beckwith Mechanical Measurement Ch13Document4 pagesBeckwith Mechanical Measurement Ch13bookslover1No ratings yet

- Beckwith Mech Measuremnt Ch4Document11 pagesBeckwith Mech Measuremnt Ch4bookslover1No ratings yet

- Beckwith Mech Measurement Ch7Document26 pagesBeckwith Mech Measurement Ch7bookslover1No ratings yet

- Beckwith Mech Measurement Ch6Document8 pagesBeckwith Mech Measurement Ch6bookslover1No ratings yet

- Beckwith Mech Measurement Ch5Document10 pagesBeckwith Mech Measurement Ch5bookslover1No ratings yet

- The ChelseaDocument1 pageThe Chelseabookslover1No ratings yet

- Beckwith Mechanical MeasurementCh2Document4 pagesBeckwith Mechanical MeasurementCh2bookslover1No ratings yet

- Fan FactsDocument28 pagesFan FactsmadbakingNo ratings yet

- Psychrometric Chart: Normal Temperature Sea LevelDocument1 pagePsychrometric Chart: Normal Temperature Sea Levelbookslover1No ratings yet

- Dishwasher ManualDocument24 pagesDishwasher ManualtmfinkNo ratings yet

- Dip-Indo Solar IrradiationDocument26 pagesDip-Indo Solar Irradiationbookslover1No ratings yet

- Boston Air Conditioning & RefrigerationDocument1 pageBoston Air Conditioning & Refrigerationbookslover1No ratings yet

- Oil SeparatorDocument7 pagesOil Separatorbookslover1No ratings yet

- Refrigerant Line SizingDocument4 pagesRefrigerant Line Sizingbookslover1No ratings yet

- Datasheet - Live: Continental Device India LimitedDocument3 pagesDatasheet - Live: Continental Device India LimitedMauricio NunesNo ratings yet

- Am 2901Document33 pagesAm 2901SD_DucksoupNo ratings yet

- Aiwa CD Mechanism Cms-b31tg6Document5 pagesAiwa CD Mechanism Cms-b31tg6nanden.fer6973No ratings yet

- The Difference Between NMOSDocument5 pagesThe Difference Between NMOSRey TiburonNo ratings yet

- Fonte Monitor STIDocument1 pageFonte Monitor STISalatiel FirminoNo ratings yet

- Variable Frecuency Drives For Fans PDFDocument15 pagesVariable Frecuency Drives For Fans PDFReyes SanchezNo ratings yet

- Panasonic Th-50phd5 50phw5 CH Gph5d2Document196 pagesPanasonic Th-50phd5 50phw5 CH Gph5d2Jesus MartinezNo ratings yet

- IndexDocument18 pagesIndexSuresh Kumar KongathiNo ratings yet

- PM6 Instructions Manual: S2D/S3DDocument16 pagesPM6 Instructions Manual: S2D/S3DHoracio BerniNo ratings yet

- Janesh RupasingheDocument123 pagesJanesh Rupasingheam_r_lNo ratings yet

- Driver Motor StepperDocument90 pagesDriver Motor Stepperyusron1985No ratings yet

- 1729 Enmed310009enDocument4 pages1729 Enmed310009ensurda123No ratings yet

- Important Questions in PDCDocument2 pagesImportant Questions in PDCManju Reddy PalakolluNo ratings yet

- Fan Speed Control With Temperature Change Using ArduinoDocument7 pagesFan Speed Control With Temperature Change Using Arduinoharshitha harshithaNo ratings yet

- Alat Ukur KapasitorDocument8 pagesAlat Ukur KapasitorsamsulNo ratings yet

- Assignment III VLSIDocument2 pagesAssignment III VLSIAkshaykumar PatilNo ratings yet

- Conductive Polymer Chip Tantalum CapacitorDocument38 pagesConductive Polymer Chip Tantalum CapacitorBrunoNo ratings yet

- DIYAudio DIYAB Honey Badger Build Guide v1.0Document30 pagesDIYAudio DIYAB Honey Badger Build Guide v1.0Danh Pro100% (1)

- SEMIKRONPowerSemiconductors PDFDocument466 pagesSEMIKRONPowerSemiconductors PDFasccorreaNo ratings yet

- 08 Lecture Power Transistors (IGBT)Document22 pages08 Lecture Power Transistors (IGBT)Abid Hasan HimelNo ratings yet

- AT28C256 - Military Grade 256 Kbit (32,768 X 8) Paged Parallel EEPROMDocument33 pagesAT28C256 - Military Grade 256 Kbit (32,768 X 8) Paged Parallel EEPROMAbner FrancoNo ratings yet

- Vaporsens Technical SummaryDocument20 pagesVaporsens Technical SummaryBen RollinsNo ratings yet

- SLG7NT402V: An Ultra-Small 3 MM, 8.5 M, 4 A, Internally-Protected Integrated Power SwitchDocument15 pagesSLG7NT402V: An Ultra-Small 3 MM, 8.5 M, 4 A, Internally-Protected Integrated Power Switchremo meinNo ratings yet

- TL082 EqualizerDocument16 pagesTL082 EqualizerMecabot DzibNo ratings yet

- Colpitts OscillatorDocument15 pagesColpitts OscillatorCaine de Leon0% (1)

- MFJ-969 Deluxe Versa Tuner IIDocument4 pagesMFJ-969 Deluxe Versa Tuner IIAnonymous ycvhCONo ratings yet