Professional Documents

Culture Documents

Manual 0am PDF

Uploaded by

Carlos Garcia Godoy100%(7)100% found this document useful (7 votes)

5K views72 pagesVolkswagen Group of America, Inc., its affiliated companies and its licensors reserve the right to make changes at any time without notice. No part of this document may be reproduced, stored in a retrieval system, or transmitted by any means, electronic, mechanical, photocopying, recording or otherwise. For maintenance and repair procedures, always refer to the latest electronic service information.

Original Description:

Original Title

Manual-0Am.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVolkswagen Group of America, Inc., its affiliated companies and its licensors reserve the right to make changes at any time without notice. No part of this document may be reproduced, stored in a retrieval system, or transmitted by any means, electronic, mechanical, photocopying, recording or otherwise. For maintenance and repair procedures, always refer to the latest electronic service information.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(7)100% found this document useful (7 votes)

5K views72 pagesManual 0am PDF

Uploaded by

Carlos Garcia GodoyVolkswagen Group of America, Inc., its affiliated companies and its licensors reserve the right to make changes at any time without notice. No part of this document may be reproduced, stored in a retrieval system, or transmitted by any means, electronic, mechanical, photocopying, recording or otherwise. For maintenance and repair procedures, always refer to the latest electronic service information.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 72

Service Training

Self Study Program 850123

The 7-speed Double-Clutch Transmission 0AM

Design and Function

Volkswagen Group of America, Inc.

Volkswagen Academy

Printed in U.S.A.

Printed 08/2012

Course Number 850123

2012 Volkswagen Group of America, Inc.

All rights reserved. All information contained in this manual

is based on the latest information available at the time of

printing and is subject to the copyright and other intellectual

property rights of Volkswagen Group of America, Inc., its

afliated companies and its licensors. All rights are reserved

to make changes at any time without notice. No part of this

document may be reproduced, stored in a retrieval system,

or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording or otherwise, nor

may these materials be modied or reposted to other sites

without the prior expressed written permission of the

publisher.

All requests for permission to copy and redistribute

information should be referred to Volkswagen Group of

America, Inc.

Always check Technical Bulletins and the latest electronic

repair information for information that may supersede any

information included in this booklet.

Trademarks: All brand names and product names used in

this manual are trade names, service marks, trademarks,

or registered trademarks; and are the property of their

respective owners.

iii

Contents

This Self-Study Program provides information

regarding the design and function of new

models.

This Self-Study Program is not a Repair Manual.

This information will not be updated.

For maintenance and repair procedures,

always refer to the latest electronic

service information.

Note Important!

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Selector Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transmission Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mechatronic Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrohydraulic Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Oil Circuit Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transmission Management System . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Knowledge Assessment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Page intentionally left blank

1

Introduction

The New 7-Speed Double-Clutch Transmission from Volkswagen

The 7-speed double-clutch transmission 0AM is based on the 02E DSG transmission. It offers the same comfort

and shifting characteristics of the 02E DSG. It has been designed for engines with a torque of up to 184 lb/ft

(250 Nm) of torque.

The DSG transmission economy is on a par with manual transmission vehicles. The DSG transmission has

succeeded in reducing fuel consumption below that of manual transmissions using technical innovations. This

reduction in fuel consumption makes a signicant contribution towards lowering emissions.

In this SSP, you will learn how the new 0AM double-clutch transmission functions and the technical highlights

that help to reduce fuel consumption.

We hope you enjoy reading it.

Application in the Jetta Hybrid

Although Volkswagen has used this transmission in vehicles for many years, the rst application for the North

American market is the 2013 Jetta Hybrid. Some aspects of this SSP are different for hybrid applications, and this

SSP does not cover those differences.

Please refer to ElsaWeb for the specic changes for use in the Jetta Hybrid.

2

Introduction

S390_060

The new 0AM DSG is the:

First transverse 7-speed transmission

First double-clutch transmission with dry double clutch

The dry double clutch has an extensive impact on the entire transmission concept. In comparison with the direct-

shift transmission 02E, efciency has been considerably improved. This improved efciency makes a signicant

contribution towards lowering consumption and emissions.

Mechatronic Unit

Double Clutch

3

Introduction

Design Features

S390_003

Mechatronic Unit

Double Clutch

Modular design of the transmission: The clutch, mechatronic unit and transmission each form one unit

Dry double clutch

Separate oil circuit, mechatronic unit and mechanical transmission, with lifetime llings

Seven speeds on four shafts

No oil/water heat exchanger

Technical Data

Designation 0AM

Weight Approx. 154 lb (70 kg) including clutch

Torque 184 ft lbs (250 Nm)

Gears Seven Forward Speeds, One Reverse =Ggear

Spread 8.1

Operating Mode Automatic and Tiptronic Modes

Transmission Fluid Volume 1.7L - G 052 171

Mechatronic Unit Fluid Volume 1.0L Central Hydraulic/Power Steering Box Fluid G 004 000

4

Selector Lever

S390_005

Actuation

The selector lever is the same as in normal

automatic transmission vehicles. The double-clutch

transmission also offers the option of shifting using

Tiptronic.

As with automatic transmission vehicles, the selector

lever has with a selector lever lock and an ignition key

withdrawal lock.

The selector lever positions are:

P - Park

To move the selector lever from this position, the

ignition must be ON and the foot brake must be

depressed. The release button on the selector lever

must also be pressed.

R - Reverse Gear

The release button must be pressed to engage this

gear.

N - Neutral Position

In this position, the transmission is in neutral. If the

selector lever is set to this position for a long time,

the foot brake must be depressed again to move it

from this position.

D - Drive Position

In this drive position, the forward gears are shifted

automatically.

S - Sport

Automatic gear selection is carried out according to

a "sporty" characteristic curve, which is stored in the

control module.

Release Button

5

Selector Lever

S390_007

Design of the Selector Lever

E313 Selector Lever

Hall sensors in the selector lever register the selector

lever position and make this information available to

the mechatronic unit via the CAN bus.

N110 Shift Lock Solenoid

The solenoid locks the selector lever in the "P" and

"N" positions. The solenoid is controlled by the J587

Selector Lever Sensor System Control Module.

F319 Selector Lever Park Position Lock Switch

If the selector lever is in the "P" position, the signal is

sent to the J527 Steering Column Electronics Control

Module. The control module requires this signal to

control the ignition key withdrawal lock.

E313

Locking Pin Latch "N"

Hall Senders for Detecting

the Selector Lever Position

N110

F319

Locking Pin Latch "P"

6

Selector Lever

S390_009

S390_008

S390_010

N110

Compression

Spring

Locking Pin Locking Pin

Latch for "P"

Locking Pin

Latch for "N"

N110 Shift Lock Solenoid

How It Works:

Selector Lever Locked in "P" Position

If the selector lever is set to "P", the locking pin is

located in locking pin latch "P". This prevents the

locking lever from being moved unintentionally.

Selector Lever Released:

After switching on the ignition and actuating the

foot brake, the J587 Selector Lever Sensor System

Control Module supply the N110 Shift Lock Solenoid

with current. As a result of this, the locking pin is

withdrawn from the locking pin latch "P".

The selector lever can now be moved to the drive

position.

Selector Lever Locked in "N" Position

If the selector lever is set to the "N" position for

longer than 2 sec., the control unit supplies the

solenoid with current. As a result of this, the locking

pin is pressed into locking pin latch "N". The selector

lever can no longer be unintentionally moved into a

gear. The locking pin is released when the brake is

actuated.

7

Selector Lever

S390_011

Emergency Release

If the voltage supply to the N110 Shift Lock Solenoid

fails, the selector lever cannot be moved because

selector lever lock "P" remains activated in the event

of a power failure.

By mechanically "pressing in" the locking pin with

a narrow object, the lock can be released and the

selector lever can be "emergency released" to the "N"

position.

The vehicle can be moved again.

8

Selector Lever

S390_013

S390_012

Ignition Switch Key Lock Solenoid

The ignition key withdrawal lock prevents the ignition

key from being turned back to the removal position if

the parking lock is not engaged.

It functions electromechanically and is controlled

by the J527 Steering Column Electronics Control

Module.

The J527 detects the open switch. The N376

Ignition Switch Key Lock Solenoid is not supplied

with current. The compression spring in the solenoid

pushes the locking pin into the release position.

N376

Compression Spring

Locking Pin

"Ignition Off"

Retaining Lug

How It Works:

With the selector lever in park position the ignition is switched off. If the selector lever is set to the park position,

the F319 Selector Lever Park Position Lock Switch is opened.

9

Selector Lever

S390_014

How It Works:

Selector lever in drive position the ignition is

switched on.

If the selector lever is set to the drive position, the

F319 Selector Lever Park Position Lock Switch is

closed.

The steering column electronics control unit then

supplies the N376 Ignition Switch Key Lock Solenoid

with current.

The locking pin is pushed into the locked position

because the solenoid overcomes the force of the

compression spring.

In the locked position, the locking pin prevents the

ignition key from being turned back and withdrawn.

Only when the selector lever is pushed into the park

position does the selector lever locked in position

"P" switch open and the control unit switches off the

current supply to the solenoid.

The locking pin is then pressed back by the

compression spring. The ignition key can be turned

further and can be removed.

N376

"Ignition On"

10

Transmission Design

S290_015

Basic Schematic

Output Shaft 2

Output Shaft 3

Gear Train Half 2

Drive Shaft 2

Engine Torque

Drive Shaft 1

Gear Train Half 1

Output Shaft 1

1

2

3

4

5

6

7

R

K2

K1

Basic Principle

In principle, the double-clutch transmission consists

of two independent halves.

In terms of function, each half is designed as a

manual transmission. A clutch is assigned to each

half.

The two clutches are dry clutches. They are opened

and closed and controlled by the mechatronic unit

depending on the gear to be shifted.

Gears 1, 3, 5 and 7 are shifted via clutch K1 via gear

train half 1 and output shaft 1. Gears 2, 4, 6 and

reverse gear are actuated via clutch K2 and gear train

half 2 and output shafts 2 and 3.

One gear train half is always connected. The next

gear can already be shifted in the other gear train

half, because the clutch for this gear is still open.

A conventional, manual transmission synchronizer

and shift unit is assigned to each gear.

11

Transmission Design

S390_064

Torque Input

Torque is transferred from the dual-mass ywheel, which is secured to the crankshaft, to the double clutch. The

dual-mass ywheel is equipped with inner teeth that engage in the outer teeth on the double clutch carrier ring.

From there, the torque is transmitted to the double clutch.

Drive Shafts 1 and 2

Double Clutch

Dual-Mass Flywheel

Carrier Ring

Outer Teeth

Inner Teeth

12

Transmission Design

S390_016

Double Clutch and Torque Curve

The double clutch is located in the bell housing. It consists of two conventional clutches, which combined form a

double clutch. During the remainder of this SSP, the clutches are referred to as K1 and K2.

Clutch K1 transfers the torque to drive shaft 1 via splines. From drive shaft 1, the torque for gears 1 and 3 is

transferred to output shaft 1, and the torque for gears 5 and 7 is transferred to output shaft 2.

Clutch K2 transfers the torque to drive shaft 2 via splines. It transfers the torque for gears 2 and 4 to output shaft

1 and the torque for 6th gear and reverse gear to output shaft 2. Using the reverse gear intermediate gear R1,

the torque is then passed on to reverse gear R2 on output shaft 3.

All three output shafts are connected to the differential nal drive gear.

Dual-Mass Flywheel

Clutch K1

Clutch K2

Output Shaft 3

Output Shaft 2

Output Shaft 1

1 7 = 1st to 7th gears

R1 = reverse gear intermediate gear

R2 = reverse gear

Final Drive Gear

Differential

Drive Shaft 2

Drive Shaft 1

13

Transmission Design

S390_065

S390_067

Double Clutch Drive Plate

From the carrier ring, the torque is transferred to the drive plate in the double clutch. For this to take place, the

carrier ring and drive plate are joined rmly together. The drive plate is mounted on drive shaft 2 as an idler gear.

How It Works:

If one of the two clutches is actuated, the torque

is transferred from the drive plate onto the relevant

clutch plate and onwards onto the corresponding

drive shaft.

Carrier Ring

Drive Plate

Dual-Mass Flywheel

Clutch K1

Clutch K2

Drive Shafts 1 and 2

Carrier Ring

14

Transmission Design

S390_017

Drive Shaft 1

Clutches

Two independent, dry clutches operate in the double clutch. They each transfer the torque to one gear train half.

Two clutch positions are possible:

When the vehicle is stopped and idling, both clutches are open.

During vehicle operation, only one of the two clutches is ever closed.

Clutch K1

Clutch K1 conducts the torque for gears 1, 3, 5 and 7 to drive shaft 1.

Clutch K1 Not Actuated

15

Transmission Design

S390_066

S390_087

How It Works:

To actuate the clutch, the engaging lever presses the engagement bearing onto the diaphragm spring. At several

contact points, this compression movement is transformed into a tension movement.

As a result, the pressure plate is pulled onto the clutch plate and the drive plate. The torque is then transferred to

the drive shaft.

The engaging lever is actuated via N435 Sub-Transmission 1 Valve 3 by the hydraulic clutch actuator for K1.

Clutch K1 Actuated

Engagement

Bearing

Pressure Plate

Diaphragm Spring

Drive Plate

Clutch Plate

Engaging Lever

Diaphragm

Spring

16

Transmission Design

S390_018

Clutch K2

Clutch K2 transfers the torque for gears 2, 4, 6 and R to drive shaft 2.

Drive Shaft 2

17

Transmission Design

S390_088

How It Works:

Clutch K2

If the engaging lever is actuated, the engagement bearing presses against the pressure plate diaphragm spring.

Because the diaphragm spring is supported by the clutch housing, the pressure plate is pressed against the drive

plate and the torque is transferred onto drive shaft 2. The engaging lever is actuated via N439 Sub-Transmission 2

Valve 3 by the hydraulic clutch actuator for K2.

Clutch K2 Actuated

Pressure Plate

Drive Plate

Clutch Plate

Engaging Lever

Engagement

Bearing

Diaphragm Spring

Support Point

18

Transmission Design

S390_046

S390_019

Drive Shaft 2

Drive Shaft 1

Ball Bearing

Spline

Drive Shafts

The drive shafts are located in the transmission

housing. Each drive shaft is connected to a clutch

via splines. These transfer the engine torque onto

the output shafts according to the gear which is

engaged.

Drive shaft 2 is hollow. Drive shaft 1 runs through

hollow drive shaft 2. Ball bearings are mounted in

the transmission case.

19

Transmission Design

S390_020

S390_021

Please note that a strong magnet may destroy the impulse wheel for drive shaft 1.

Drive shaft 1 is connected to clutch K1 via splines. It is used to shift gears 1, 3, 5 and 7. To record the

transmission input speed, this shaft has the impulse wheel for G632 Transmission Input Speed Sensor 1.

Drive Shaft 1

Drive Shaft 2

Due to its installation position, we will cover drive shaft 2 before drive shaft 1.

Drive shaft 2 is a hollow shaft. It is connected to K2 via splines. Drive shaft 2 is used to shift gears 2, 4, 6 and R.

To record the transmission input speed, this shaft has the gear for G612 Transmission Input Speed Sensor 2.

Bearing Gear for G612

2nd/R Gears

4th/6th Gears

G632

Bearing

1st Gear

5th Gear

3rd Gear

7th Gear

20

Transmission Design

S390_022

S390_023

Output Shafts

The transmission has three output shafts.

Depending on the gear which is engaged, the engine

torque is transferred from the drive shafts to the

output shafts.

An output gear is located on each output shaft.

Output Shaft 1

Installation Position in the

Transmission

(View from the left shown elongated)

The following are located on output shaft 1:

The selector gears for gears 1, 2 and 3; the 3 gears are 3xs synchromeshed.

The selector gear for 4th gear; the 4th gear is 2xs synchromeshed.

1st Gear

3rd Gear

4th Gear

2nd Gear

Output Gear

Bearing

Sliding Sleeve,

Gears 2/4

Sliding Sleeve,

Gears 1/3

Bearing

21

Transmission Design

S390_024

S390_025

Installation Position in the

Transmission

(View from the left shown elongated)

Output Shaft 2

The following are located on output shaft 2:

The 2-fold synchromeshed selector gears for gears 5, 6 and 7, and

The intermediate gears R gear 1 and R gear 2 for reverse gear.

5th Gear

7th Gear

6th Gear

R Gear 2

Output Gear

Sliding Sleeve,

Gears 6/R

Sliding Sleeve,

Gears 5/7

R Gear 1

22

Transmission Design

Installation Position in the

Transmission

(View from the left shown elongated)

Output Shaft 3

The following are located on output shaft 3:

The 1-fold synchromeshed selector gear for R gear

The parking lock gear

S390_026

S390_027

Bearing

Parking Lock Gear

Gear Wheel for R Gear

Output Gear

Bearing

Sliding Sleeve

23

Transmission Design

S390_029

Installation Position in the

Transmission

(View from the left shown elongated)

Differential

The differential transfers the torque onwards to the vehicle wheels via the drive shafts.

S390_028

Final Drive Gear

24

Transmission Design

S390_030

Parking Lock

A parking lock is integrated into the DSG to ensure that a parked vehicle does not roll away.

The locking pin is engaged purely mechanically via a Bowden cable between the selector lever and the parking

lock lever on the transmission.

The Bowden cable is used exclusively to actuate the parking lock.

Return Spring for

Locking Pin

Locking Pin

Connection Ball for Parking

Lock Bowden Cable

Hold-Down Device

Detent Spring

Actuation Pin

Pre-Tensioning Spring

Parking Lock Gear

25

Transmission Design

S390_063

S390_062

S390_061

Function

Parking Lock Not Actuated,

(Selector Lever Position R, N, D, S)

When the parking lock is not actuated, the cone of

the actuation pin lies on the holding-down device and

the locking pin.

The parking lock is held in the non-actuated position

by a locking device.

Parking Lock Sctuated, Locking Pin Not Engaged

(Selector Lever Position P)

By actuating the parking lock, the cone of the

actuation pin is pressed against the hold-down

device and the locking pin. As the hold-down device

is stationary, the locking pin moves down. If it

encounters a tooth on the parking lock gear, the pre-

tensioning spring is tensioned.

The actuation pin is held in this position by the

locking device.

Parking Lock Actuated, Locking Pin Engaged

(Selector Lever Position P)

(Locking Pin Engaged)

If the vehicle continues to move, the parking lock

gear also rotates.

As the actuation pin is pre-tensioned, it automatically

pushes the locking pin into the next tooth space on

the parking lock gear.

Locking Pin

Hold-Down

Device

Detent Spring

Actuation Pin

Locking Device

Pre-Tensioning Spring,

Relaxed

Tooth of

Locking Pin Engaged

in Parking Lock Gear

Actuation Pin

in End Position

Pre-Tensioning Spring,

Tensioned

26

Transmission Design

S390_082

S390_081

Gear Synchronization

A synchromesh with locking pieces is used for all gears to synchronize the different speeds when changing

gears. Depending on the shifting load, the gears are synchronized between one and three times.

Gear Synchromesh Synchronizer Ring Material

1st to 3rd Three synchronizers Brass with molybdenum coating

4th Two synchronizers Brass with molybdenum coating

5th to 7th One synchronizer Brass with molybdenum coating

R One synchronizer Brass with molybdenum coating

The gure shows the synchromesh design for 2nd, 4th and R gears.

Selector Fork

Firmly Connected

(Welded)

Selector Gear

4th Gear

Clutch Splines

Synchronizer Ring

(inner)

Intermediate Ring

Synchronizer Ring

(outer)

Sliding Sleeve

Synchronising Hub

Locking pieces

Synchronizer

Ring

(outer)

Outer ring

(intermediate

ring)

Synchronizer

Ring

(inner)

Selector gear

2nd gear

Selector Gear R Gear

Synchronizer Ring

Locking Pieces

Synchronising Hub

Sliding Sleeve

27

Transmission Design

S390_034 S390_033

Power Transmission in the Gears

Torque is transmitted into the transmission by either clutch K1

or K2. Each clutch drives a drive shaft. Drive shaft 1 is driven by

clutch K1 and drive shaft 2 is driven by clutch K2.

Power is transmitted to the differential via:

output shaft 1 for gears 1, 2, 3, and 4,

output shaft 2 for gears 5, 6 and 7, and

output shaft 3 for reverse gear and the parking lock.

1st Gear

Clutch K1

Drive Shaft 1

Output Shaft 1

Differential

R Gear

Clutch K2

Drive Shaft 2

Output Shaft 3

Differential

The change in rotational direction for reverse gear is

carried out by output shaft 3.

For greater clarity, power transmission is shown schematically in "elongated" form.

28

Transmission Design

S390_037

S390_036

S390_035

2nd Gear

Clutch K2

Drive Shaft 2

Output Shaft 1

Differential

4th Gear

Clutch K2

Drive Shaft 2

Output Shaft 1

Differential

3rd Gear

Clutch K1

Drive Shaft 1

Output Shaft 1

Differential

29

Transmission Design

S390-040

S390_039

S390_038

5th Gear

Clutch K1

Drive Shaft 1

Output Shaft 2

Differential

6th Gear

Clutch K2

Drive Shaft 2

Output Shaft 2

Differential

7th Gear

Clutch K1

Drive Shaft 1

Output Shaft 2

Differential

30

Mechatronic Module

S390_041

J743 DSG Transmission Mechatronic

The mechatronic unit controls all transmission functions. It combines the electronic control unit and the

electrohydraulic control unit into a single component.

The mechatronic unit is an autonomous unit. It has a separate oil circuit, which is independent of the oil circuit

for the mechanical transmission.

The advantages of this autonomous, compact unit

are:

All sensors (except one) and actuators are

contained in the mechatronic unit.

The hydraulic uid is specically adapted to the

requirements of the mechatronic unit.

Due to the separate oil circuit, no foreign material

from the mechanical transmission enters into the

mechatronic unit.

Good low-temperature behavior, as no

compromise has to be made with the

requirements of the transmission in terms of

viscosity behavior.

Mechatronic Unit

31

Mechatronic Module

S390_042

S390_083

The electornic control unit is the central transmission control unit. All sensor signals and all signals from other

control units come together here, and all actions are performed and monitored by it. Eleven sensors are

integrated into the electronic control unit; only the G182 Transmission Input Speed Sensor is located outside of

the control unit. The electronic control unit hydraulically controls and regulates eight solenoid valves for shifting

the seven gears and for actuating the clutch.

The electronic control unit learns (adapts) the positions of the clutches and the positions of the gear selectors

when a gear is engaged and takes what has been learned into consideration for operation of these components.

Sensor Locations

G270 Hydraulic Pressure

Sensor

G617 Clutch Pedal Position Sensor 1 for K1

G618 Clutch Pedal Position Sensor 2 for K2

G488 Gear Position

Distance Sensor 2

(gears 1/3)

Electronic Control Unit with

Integrated Sensor System

G632 Transmission

Input Speed Sensor 1

G489 Gear Position Distance

Sensor 3 (Gears 5/7)

G510 Temperature

Sensor in Control

Module

G490 Gear Position Distance

Sensor 4 (Gears 6/R)

G612 Transmission

Input Speed Sensor 2

Vehicle connector

G487 Gear Position Distance

Sensor 1 (Gears 4/2)

G182

32

Electrohydraulic Control Unit

Electrohydraulic Control Unit

The electrohydraulic control unit is integrated into the mechatronic module. It generates the oil pressure which is

required to shift the gears and to actuate the clutches.

Oil Pressure Generation and Control

The oil pressure is generated by the hydraulic pump motor. An oil pressure accumulator ensures that sufcient

oil pressure is always present at the solenoid valves.

S390_043

N437 Sub-Transmission

2 Valve 1

Gear Selector Valve 2/4

N439 Sub-Transmission

2 Valve 3

Clutch Valve K2

N440 Sub-Transmission

2 valve 4

Gear Train Half

Pressure regulator

N438 Sub-Transmission

2 Valve 2

Gear Selector Valve 6/R

Hydraulic Pump

Oil Pressure

Accumulator

Motor for

Hydraulic Pump V401

N433 Sub-Transmission

1 Valve 1

Gear Selector Valve 1/3

N436 Sub-Transmission

1 Valve 4

Gear Train Half

Pressure Regulator

N434 Sub-Transmission

1 Valve 2

Gear Selector Valve 5/7

Gear Selector Valve

Valve 3 in Gear Train

Half 1 N435

Clutch Valve K1

To Clutch K2

To Clutch K1

Electrohydraulic Control Unit

33

Oil Circuit - Hydraulic System

S390_080

Oil Circuit

The double clutch transmission operates with two independent oil circuits using two different oils:

Oil circuit for mechanical transmission

Oil circuit for mechatronic module

Each oil circuit contains a specic oil.

Oil Circuit for Mechanical Transmission

Mechatronic Module

Oil Circuit - Mechanical Transmission

The oil supply to the shafts and gears of the

mechanical transmission is the same as in a normal

manual transmission.

The oil volume in the mechanical transmission

is 1.7 L.

Oil Circuit - Mechatronic Module

The oil supply for the mechatronic unit is separate

from the oil circuit for the mechanical transmission.

An oil pump delivers pressurized oil so that the

hydraulic mechatronic unit components can function.

The oil volume in the mechatronic unit is 1.1 L.

For the volumes and capacities, always refer to the service information

34

Oil Circuit - Hydraulic System

S390_ 098

Oil Circuit Flow Chart

Basic Oil Circuit

Non-Return Valve

Hydraulic Pump

Hydraulic Pressure Sender

Pressure Accumulator

Pressure Limiting Valve

Filter

V401 Hydraulic Pump Motor

35

Oil Circuit - Hydraulic System

S390_071

S390_043

Hydraulic Pump

The hydraulic pump unit is located in the mechatronic

module. It consists of a hydraulic pump and an

electric motor.

The motor for the hydraulic pump is a brushless

DC motor. It is actuated by the mechatronic units

electronic control unit depending on pressure

requirements. It drives the hydraulic pump through a

coupling.

The hydraulic pump operates just like a gear pump.

It pulls in hydraulic oil and pumps it into the oil circuit

at a pressure of approximately 70 bar.

The hydraulic oil is pumped from the intake side to

the pressure side between the walls of the pump

housing and the tooth gaps.

V401 Hydraulic

Pump Motor

Hydraulic Pump

Intake Side

Housing

Pressure Side

Driving Gear

36

Oil Circuit - Hydraulic System

V401 Hydraulic Pump Motor

Design

Like conventional, smaller DC electric motors, the

brushless DC motor has a stator and a rotor. While

the stator consists of permanent magnets and the

rotor of electromagnets in the conventional, smaller

electric motor, the opposite is true in the case of the

brushless DC motor.

The rotor consists of six permanent magnet pairs.

The stator has six electromagnet pairs.

How It Works

In the conventional DC motor, commutation (current

direction change-over) takes place via ring contacts.

Commutation in the brushless DC motor is carried

out by the mechatronic unit's electronic control unit

and is contact-free.

The stator coils are actuated to that a rotating

magnetic eld occurs in the stator coils. The rotor

follows this magnetic eld and is rotated.

Thanks to contact-free commutation, the DC motor

runs entirely wear-free, with the exception of bearing

wear.

Torque to the

Hydraulic pump

Rotor with Permanent

Magnets

Electrical Connection

Electromagnet Pole Pairs

Stator

Stator

Rotor

S390_089

S390_085

37

Oil Circuit - Hydraulic System

Electrical Actuation

The mechatronic unit controls switching between the individual poles to ensure smooth rotational movement.

This changes the magnetic eld. As a result, the rotor is rotated.

The schematic shows the design of the circuit using

the example of a wound coil.

Legend

1st phase positively switched

2nd phase negatively switched

3rd phase - open

Wound Coil

S390_086

Supply Voltage

Mechatronic Unit

Control Unit

3

r

d

P

h

a

s

e

1

s

t

P

h

a

s

e

2

n

d

P

h

a

s

e

38

Oil Circuit - Hydraulic System

G270 Hydraulic Pressure

Sensor and Pressure Limiting

Valve

The hydraulic pump pumps the hydraulic oil through

the lter towards the pressure limiting valve, the

pressure accumulator and the hydraulic pressure

sender.

When the hydraulic oil pressure at the pressure

limiting valve and the hydraulic pressure sender

reaches approximately 70 bar, the control unit turns

the electric motor and hydraulic pump off. The bypass

ensures that the system functions if the lter channel

is clogged.

Pressure Accumulator

The pressure accumulator is designed as a gas

pressure accumulator.

It provides the hydraulic system with oil pressure

when the hydraulic pump is turned off. Its storage

volume is 0.2 litres.

S390_096

S390_100

Hydraulic Pressure Sender

Pressure Limiting Valve

Pressure Accumulator

39

Oil Circuit - Hydraulic System

Oil Circuit Flow Chart

Working Pressure

Legend

N433 Valve 1 in Gear Train Half 1

N434 Valve 2 in Gear Train Half 1

N435 Valve 3 in Gear Train Half 1

N436 Valve 4 in Gear Train Half 1

N437 Valve 1 in Gear Train Half 2

N438 Valve 2 in Gear Train Half 2

N439 Valve 3 in Gear Train Half 2

N440 Valve 4 in Gear Train Half 2

The clutch safety valves enable the clutches to be drained and therefore opened in the event of a fault.

KS

KS

Clutch Actuator K2

Gear Selector 6 - R

Gear Selector 4 - 2

Clutch Actuator K1

Gear Selector 5 - 7

Gear Selector 1 - 3

S390_048

Return

Controlled Working Pressure

KS =

Clutch Safety Valve

40

Oil Circuit - Hydraulic System

Solenoid Valves

Gear Train Half 1

Pressure Control

Valve

Gear Train Half 2

Pressure Control

Valve

Gears 5/7

Gears 1/3

Gears 6/R

Gears 2/4

K1

K2

S390_101

S390_102

S390_103

Gear Train Half Pressure Control Solenoid Valves

The gear train half pressure control solenoid valves

control the oil pressure for gear train halves 1 and 2.

If a fault is detected in a gear train half, the pressure

control solenoid valve can shut off the corresponding

gear train half.

Gear Selector Solenoid Valves

The gear selector solenoid valves control the volume

of oil to the gear selectors. Each gear selector shifts

two gears. If no gear is engaged, the gear selectors

are held in the neutral position via oil pressure.

In selector lever position "P" and when the ignition is

switched off, 1st gear and reverse gear are engaged.

Clutch Actuator Solenoid Valves

The clutch actuator solenoid valves control the

volume of oil to the clutch actuators. The clutch

actuators actuate clutches K1 and K2.

When not supplied with current, the solenoid valves

and the clutches are open.

41

Oil Circuit - Hydraulic System

Shifting the Gears

As with conventional manual transmissions, the

gears are shifted using selector forks. Each selector

fork shifts two gears.

The selector forks are mounted on both sides in the

transmission housing.

S390_058

Selector Fork

Gears 2/4

Selector Fork

Gears 1/3

Selector Fork

Gears 5/7

Selector Fork

Gears 6/R

42

Oil Circuit - Hydraulic System

Gear Selector

Movement Sensor

Shifting the Gears

When changing gears, the selector forks are moved

by the gear selectors integrated into the mechatronic

unit.

Gear Selectors and Selector Forks

The gear selector piston is connected to the selector

fork. To change gears, oil pressure is applied to the

gear selector piston. When it moves, it also moves

the selector fork and the sliding sleeve. The sliding

sleeve actuates the synchronising hub and the gear

is engaged.

The mechatronic unit detects the new position of the selector fork via the permanent magnet and the gear

selector movement sensor.

S390_107

S390_056

Gear Selector Cylinder

Gear Selector Piston

Sliding Sleeve

Synchronising Hub

Selector Fork

Permanent Magnet

Gear Selector

Gears 2 and 4

Gear Selector

Gears 1 and 3

Gear Selector

Gears 5 and 7

Gear Selector

Gears 6 and R

43

Oil Circuit - Hydraulic System

Gear Changes

Just like the 02E DSG, the selector forks are actuated hydraulically. To change the gears, the mechatronic unit

actuates the correct gear selector solenoid valve.

How It Works

This is an example of changing into 1st gear:

Initial Position

The gear selector piston is held in neutral position

"N" via the oil pressure controlled by N433 Sub-

Transmission 1 Valve 1 for gears 1 and 3. No gear is

engaged.

N436 Sub-Transmission 1 Valve 4 controls the oil

pressure in gear train half 1.

S390_057

Gear Selector Cylinder

Gear Selector Piston

Sliding Sleeve

Selector Fork

N433

N436

Piston Chamber

Mechatronic Unit

44

Oil Circuit - Hydraulic System

Gear Selector Cylinder

Gear Selector Piston

Sliding Sleeve

Selector Fork

N433 Sub-

Transmission 1

Valve 4

Piston Chamber

Mechatronic Unit

S390_097

Changing to 1st Gear

To change to 1st gear, the gear selector valve increases the oil pressure in the left piston chamber and pushes

the gear selector piston to the right. As the selector fork and the sliding sleeve are connected to the gear

selector piston, they also move to the right.

Because of the movement of the sliding sleeve, 1st gear is engaged.

45

Oil Circuit - Hydraulic System

S390_092

Engaging

Lever

Dust

Protection

Bellows

Piston Rod

Clutch Actuator Piston

Boot

Permanent Magnet

Clutch Actuator K1

Clutch Actuator Cylinder

Support Ring

Guide Ring

Clutch Actuator K2

Clutch Actuators

Clutches K1 and K2 are actuated hydraulically. To achieve this, the mechatronic unit contains a clutch actuator for

each clutch.

A clutch actuator consists of a clutch actuator cylinder and a clutch actuator piston. The clutch actuator piston

actuates the clutch engaging lever. The clutch actuator piston is equipped with a permanent magnet, which is

required by the clutch travel sender to detect the piston position.

To prevent detection of the piston position from being impaired, the actuator cylinder and the actuator piston are

not magnetic.

46

Oil Circuit - Hydraulic System

Clutch Operation

To actuate the clutches, the mechatronic electronic

control unit actuates the solenoid valve

N435 Sub-Transmission 1 Valve 3 for clutch K1 and

N439 Sub-Transmission 2 Valve 3 for clutch K2.

How It Works

Actuation of K1 is shown here as an example.

Clutch Not Actuated

The clutch actuator piston is in the resting position.

The N435 is open in the return ow direction. The oil

pressure from the N436 Sub-Transmission 1 Valve 4

ows into the mechatronic unit oil reservoir.

N435

Clutch Actuator K1 in Resting Position

S390_093

47

Oil Circuit - Hydraulic System

N435

Clutch Actuator K1 Actuated

S390_094

Clutch Actuated

If clutch K1 is to be actuated, the N435 Sub-

Transmission 1 Valve 3 is actuated by the electronic

control unit. When actuated, it opens the oil channel

to the clutch actuator, and oil pressure is built up

at the rear of the clutch actuator piston. The clutch

actuator piston moves and actuates the K1 clutch

engaging lever. Clutch K1 is closed. The control unit

receives a signal regarding the precise position of the

clutch via G167 Rear Infrared Sensor.

The speed difference between the transmission input

speed and drive shaft speed (clutch slip), is controlled

by N435 by controlling the oil pressure between the

clutch actuator and the return ow.

48

Transmission Managment System

Overview of the System

Sensors

G182 Transmission Input Speed Sensor

G632 Transmission Input Speed Sensor 1

G612 Transmission Input Speed Sensor 2

G617 Clutch Pedal Position Sensor 1

G618 Clutch Pedal Position Sensor 2

G487 Gear Position Distance Sensor 1

G488 Gear Position Distance Sensor 2

G489 Gear Position Distance Sensor 3

G490 Gear Position Distance Sensor 4

G270 Hydraulic Pressure Sensor

G510 Temperature Sensor in Control Module

E389 Steering Wheel Tiptronic Switch

J743 DSG Transmission

Mechatronic

Diagnostic Connector

49

Transmission Managment System

E313 Selector Lever

J285 Instrument Cluster Control Module

CAN

Actuators

V401 Hydraulic Pump Motor

N435 Sub-Transmission 1 Valve 3

N439 Sub-Transmission 2 Valve 3

N436 Sub-Transmission 1 Valve 4

N440 Sub-Transmission 2 Valve 4

N433 Sub-Transmission 1 Valve 1

N434 Sub-Transmission 1 Valve 2

N437 Sub-Transmission 2 Valve 1

N438 Sub-Transmission 2 Valve 2

S390_053

50

Transmission Managment System

Sensors

G617 Clutch Pedal Position Sensor 1,

G618 Clutch Pedal Position Sensor 2

The clutch pedal position sensors are located in the

mechatronic unit above the clutch actuators.

The double clutch control system requires reliable

and precise recording of the current clutch actuation

status.

For this reason, contact-free sensor technology is

used to record clutch travel. Contact-free position

recording increases the reliability of the sensor

functions. Measured value falsication caused by

wear and vibrations is avoided.

Signal Use

The control unit requires these signals to control the

clutch actuators.

Effects of Signal Failure

If G617 fails, transmission path 1 is shut off. Gears 1,

3, 5 and 7 can no longer be engaged.

If G618 fails, gears 2, 4, 6 and R can no longer be

engaged.

G617/G618

S390_050

51

Transmission Managment System

Clutch Pedal Position Sensors

Design

A clutch pedal position sensor consists of:

The primary coil is wound around an iron core

Two secondary evaluation coils

A permanent magnet, located on the clutch

actuator piston, and

The sensor electronics

How It Works

An alternating voltage is applied to the primary

coil and a magnetic eld is built up around the iron

core. If the clutch is actuated, the clutch actuator

piston moves through the magnetic eld with

the permanent magnet. Voltage is induced in the

secondary evaluation coils.

The level of the voltage induced in the left and right

evaluation coils depends on the position of the

permanent magnet. The sensor electronics detect

the position of the permanent magnet and the

position of the clutch actuator piston by the level of

the voltage in the left and right evaluation coils.

S390_091

Applied Alternating Voltage

Iron Core

Primary Coil

Secondary

Evaluation Coil

Clutch Actuator Piston

Permanent Magnet

Evaluation Voltage

Sensor Electronics

52

Transmission Managment System

G182 Transmission Input Speed Sensor

The transmission input speed sensor is a Hall sensor that is inserted into the transmission housing. It is the

only sensor located outside of the mechatronic unit. It electronically scans the starter ring gear and records

the transmission input speed. The transmission input speed is identical to the engine speed.

Signal Use

The control unit requires the transmission input

speed signal to control the clutches and to calculate

slip. It compares the signals from the G182 before

the clutches with the signals from G612 and G632

Transmission Input Speed Sensor 1 and 2, which

transmit speed signals from the drive shafts.

Effects of Signal Failure

The control unit uses the engine speed signal as

a substitute signal. It obtains this signal from the

engine control unit over the CAN bus.

S390_073

G182

53

Transmission Managment System

G632 Transmission Input Speed Sensor 1

G612 Transmission Input Speed Sensor 2

Both input speed sensors are Hall sensors that are

located in the mechatronic unit.

G632 scans an impulse wheel located on drive

shaft 1.

From this signal, the control unit calculates the

speed of drive shaft 1.

G612 scans a gear on drive shaft 2. From this

signal, the control unit calculates the speed of

drive shaft 2.

Signal Use

The speed signals from drive shafts 1 and 2 are

used by the control unit to control the clutch and to

calculate clutch slip.

Effects of Signal Failure

If G632 fails, gear train half 1 is shut off. The vehicle

can then only be driven in gears 2, 4, 6 and R.

If G612 fails, gear train half 2 is shut off. The vehicle

can then only be driven in gears 1, 3, 5 and 7.

S390_049

G612

G632

54

Transmission Managment System

G510 Temperature Sensor in Control Module

The temperature sensor is located directly in the mechatronic unit's electronic control unit.

Hot hydraulic oil constantly ows around the control unit, heating it. Severe heating may impair the functions of

the electronics.

G510

S390_074

Signal Use

The temperature sensors signal is used to check the

mechatronic unit's temperature.

At a temperature of 139 C, engine torque will be

reduced.

Effects of Signal Failure

In case of signal failure, the control unit uses an

internally available substitute value.

55

Transmission Managment System

G270 Hydraulic Pressure Sensor

The hydraulic pressure sensor is integrated into the mechatronic unit hydraulic oil circuit. It is a diaphragm

pressure sender.

G270

S390_075

Signal Use

The control unit uses the signal to control the motor

for the V401 Hydraulic Pump Motor.

At a hydraulic oil pressure of approximately

60 bar, the motor is shut off according to the

pressure sensor signal, and is switched on again at

approximately 40 bar.

Effects of Signal Failure

If the signal fails, the motor for hydraulic pump runs

continuously.

The hydraulic pressure is determined by the pressure

control valve.

56

Transmission Managment System

Signal Use

The control unit requires the precise position of

the gear selectors to control the gear selectors for

changing gears.

Effects of Signal Failure

If a movement sensor fails, the control module

cannot detect the position of the corresponding gear

selector. As a result, the control unit is unable to

recognise whether or not a gear has been changed

using the gear selector and the selector fork. To

prevent damage to the transmission, half of the

transmission with this failure will be disabled.

G487 to G490 Gear Position Distance Sensor 1 - 4

The gear selector movement sensors are located in

the mechatronic unit.

In combination with the solenoids on the selector

forks, the sensors generate a signal that the control

module uses to determine the precise position of the

gear selectors.

S390_051

G489

G490

G487

G488

57

Transmission Managment System

E313 Selector Lever

The selector lever sensor system and the control system for the selector lever lock solenoid are integrated

into the selector lever. The selector lever positions are detected by Hall sensors, which are integrated into the

selector lever sensor system. The selector lever position signals and the Tiptronic signals are transmitted over the

CAN bus to the mechatronic unit and to the control unit in the dash panel insert.

Signal Use

Based on the signals, the control unit detects the

selector lever positions. It uses the signals to

implement the driver D-R-S or Tiptronic command

and to control starter release.

Effects of Signal Failure

If the control unit detects no selector lever position,

both clutches are opened.

Hall Sensors for

Detecting the

Selector Lever Position

Hall Sensors for

Tiptronic Position

S390_052

58

Transmission Managment System

Actuators

Clutch Actuator Solenoid Valves

N435 Sub-Transmission 1 Valve 3,

N439 Sub-Transmission 2 Valve 3

The clutch actuator solenoid valves are located in

the mechatronic unit's hydraulic module. They are

actuated by the electronic transmission control unit.

They are used to control the oil volume for actuating

the clutches.

N435 controls the oil volume for clutch K1

N439 controls the oil volume for clutch K2

Effects of Signal Failure

If a solenoid valve fails, that half of the transmission will be disabled.

S390_076

N439

N435

59

Transmission Managment System

Gear Train Half Pressure Control Valves

N436 Sub-Transmission 1 Valve 4,

N440 Sub-Transmission 2 Valve 4

Both sub-transmission valves are solenoid valves, and

are located in the mechatronic unit hydraulic module.

Valve 4 in gear train half 1 controls the hydraulic

oil pressure to the gear selectors and to the clutch

actuator in gear train half 1.

Gear train half 1 is used to shift gears 1, 3, 5 and

7. Valve 4 in gear train half 2 controls the hydraulic

oil pressure to the gear selectors and to the clutch

actuator in gear train half 2.

Effects of Signal Failure

If one solenoid valve fails, that half of the trnamsisison will be disabled, and only the gears assigned to the other

transmission half can be engaged.

S390_077

N440

N436

60

Transmission Managment System

Gear Selector Solenoid Valves

N433 Sub-Transmission 1 Valve 1,

N434 Sub-Transmission 1 Valve 2,

N437 Sub-Transmission 2 Valve 1,

N438 Sub-Transmission 2 Valve 2

The gear selector solenoid valves are located in the

mechatronic unit's hydraulic module. They are used

by the transmission control unit to control the oil

volume to the gear selectors and for changing gears.

N433 Sub-Transmission 1 Valve 1

N434 Sub-Transmission 1 Valve 2

N437 Sub-Transmission 2 Valve 1

N438 Sub-Transmission 2 Valve 2

Effects of Signal Failure

If a solenoid valve fails, that half of the transmission will be disabled.

S390_078

N437 N433

N434

N438

61

Transmission Managment System

Effects of Signal Failure

If the motor cannot be actuated, the hydraulic pressure drops and the clutches open independently due to the

spring force of the pressure plates.

V401 Hydraulic Pump Motor

The motor for the hydraulic pump is integrated into

the mechatronic unit hydraulic module. It is actuated

by the transmission control unit.

The control unit shuts off the motor when the

hydraulic pressure in the system has reached 60 bar,

and turns it on again when the pressure drops to 40

bar.

V401

S390_079

62

Transmission Managment System

Functional Diagram

E313 Selector Lever

E438 Tiptronic Upshift Button on Steering Wheel

E439 Tiptronic Downshift Button on Steering Wheel

F319 Selector Lever Park Position Lock Switch

G182 Transmission Input Speed Sensor

G270 Hydraulic Pressure Sensor

G487 Gear Position Distance Sensor 1

G488 Gear Position Distance Sensor 2

G489 Gear Position Distance Sensor 3

G490 Gear Position Distance Sensor 4

G510 Temperature Sensor in Control Module

G612 Transmission Input Speed Sensor 2

G617 Clutch Pedal Position Sensor 1

G618 Clutch Pedal Position Sensor 2

G632 Transmission Input Speed Sensor 1

J119 Multifunction Indicator

J285 Instrument Cluster Control Module

J453 Multifunction Steering Wheel Control Module

J519 Vehicle Electrical System Control Module

J527 Steering Column Electronics Control Module

J533 Data Bus on Board Diagnostic Interface

J681 Terminal 15 Power Supply Relay 2

J743 DSG Transmission Mechatronic

N110 Shift Lock Solenoid

N433 Sub-Transmission 1 valve 1

N434 Sub-Transmission 1 valve 2

N435 Sub-Transmission 1 valve 3

N436 Sub-Transmission 1 valve 4

N437 Sub-Transmission 2 valve 1

N438 Sub-Transmission 2 valve 2

N439 Sub-Transmission 2 valve 3

N440 Sub-Transmission 2 valve 4

V401 Hydraulic Pump Motor

Y6 Selector Lever Position Display

Diagnosis Connector

63

Transmission Managment System

S390_054

Input Signal

Output Signal

Bi-directional

Positive

Ground

CAN Data Bus

64

Transmission Managment System

CAN Data-bus Connection

The schematic shown below symbolically shows the

integration of the mechatronic unit for direct shift

transmission into the vehicle CAN data bus structure.

J104 ABS Control Module

J248 Diesel Direct Fuel Injection Engine Control

module

J285 Instrument Cluster Control ModuleJ

J519 Vehicle Electrical System Control Module

J527 Steering Column Electronics Control Module

J533 Data Bus on Board Diagnostic Interface

J587 Selector Lever Sensor System Control Module

J623 Engine Control Module

J743 DSG Transmission Mechatronic

Diagnostic connector

"Powertrain" CAN data bus

CAN "convenience" data bus

S390_055

65

Knowledge Assessment

Special Tools

When removing the transmission, a new special

tool is available for aligning transmission support

3282 of engine and transmission jack V.A.G 1383 A.

Adjustment plate 3282/59

S390_095

Page intentionally left blank

67

Knowledge Assessment

An on-line Knowledge Assessment (exam) is available for this Self-Study Program.

The Knowledge Assessment may or may not be required for Certication.

You can nd this Knowledge Assessment at:

www.vwwebsource.com

For Assistance, please call:

Volkswagen Academy

Certication Program Headquarters

1-877-791-4838

(8:00 a.m. to 8:00 p.m. EST)

Or, E-mail:

concierge@volkswagenacademy.com

Volkswagen Group of America

2200 Ferdinand Porsche Drive

Herndon, VA 20171

August 2012

You might also like

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Ignition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.From EverandIgnition, Timing And Valve Setting: A Comprehensive Illustrated Manual of Self-Instruction for Automobile Owners, Operators, Repairmen, and All Interested in Motoring.Rating: 3 out of 5 stars3/5 (4)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Fuel Supply System - Petrol Engines-TouranDocument59 pagesFuel Supply System - Petrol Engines-TouranCarlos Garcia GodoyNo ratings yet

- ZF8HP RebuildDocument62 pagesZF8HP RebuildKhristina Stefanova94% (16)

- Essential Scooter Maintenance for the Absolute BeginnerFrom EverandEssential Scooter Maintenance for the Absolute BeginnerNo ratings yet

- Manual Transmision 0GC PDFDocument246 pagesManual Transmision 0GC PDFCarlos Garcia Godoy80% (5)

- Manual 09G 09M InglesDocument66 pagesManual 09G 09M InglesOmar Xicotencatl100% (7)

- OB5 Transmission InfoDocument98 pagesOB5 Transmission InfoRobert Moreau95% (21)

- Pps 951703 Audi 09d Transmission EngDocument79 pagesPps 951703 Audi 09d Transmission EngQuattro-Sports Auto-Transmission EANo ratings yet

- Pickup TruckDocument51 pagesPickup TruckJosé Peguero100% (3)

- 2011 08 001 002 enDocument49 pages2011 08 001 002 enAlex Maceira Graterol100% (3)

- DSG 02e SSP - 308 PDFDocument64 pagesDSG 02e SSP - 308 PDFcataroxi100% (1)

- VW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFDocument68 pagesVW-AUDI - SSP - 372 - Shiftmatic Gearbox Eng PDFlucafelicianioanNo ratings yet

- ZF6HP28 TG PDFDocument94 pagesZF6HP28 TG PDFИгорь Наумов100% (8)

- SSP+227+++3 3L+V8+TDI+common+rail+injection+systemDocument36 pagesSSP+227+++3 3L+V8+TDI+common+rail+injection+systemĐức HòangNo ratings yet

- The V8-5V Engine: Construction Features and FunctionsDocument52 pagesThe V8-5V Engine: Construction Features and Functionssheba1023100% (2)

- Manual Motores Audi A3Document74 pagesManual Motores Audi A3Carlos Garcia GodoyNo ratings yet

- SSP+411+++2 8l+and+3 2L+FSI+engines+with+Audi+valvelift+systemDocument64 pagesSSP+411+++2 8l+and+3 2L+FSI+engines+with+Audi+valvelift+systemgbeszeNo ratings yet

- Manual 8vel 0BK Audi-A7-Q5-Q7Document215 pagesManual 8vel 0BK Audi-A7-Q5-Q7Carlos Garcia Godoy100% (3)

- Touareg 6 SpeedautotrannyDocument56 pagesTouareg 6 SpeedautotrannyGlbrt Elizondo100% (1)

- DiagramaAudiTT2015 UpDocument773 pagesDiagramaAudiTT2015 UpCarlos Garcia GodoyNo ratings yet

- Mercedes 722.1 722.2 Transaxle Service Manual - ATSG Automatic Transmission Service GroupDocument113 pagesMercedes 722.1 722.2 Transaxle Service Manual - ATSG Automatic Transmission Service Grouposcar100% (2)

- 7-Speed 0am VW TrainingDocument15 pages7-Speed 0am VW Trainingeddix96% (26)

- Semi-Active Suspension Control Design for VehiclesFrom EverandSemi-Active Suspension Control Design for VehiclesRating: 5 out of 5 stars5/5 (1)

- 09a, B 1 PDFDocument72 pages09a, B 1 PDFdevfin100% (1)

- DSGDocument66 pagesDSGTM12550% (2)

- 0B5 7-Speed Dual ClutchDocument24 pages0B5 7-Speed Dual ClutchKeldo Gliana94% (93)

- ZF6HP26 TransmissionDocument69 pagesZF6HP26 TransmissionMirsa Garcia100% (3)

- DSG Clutch Removal Tool Set Eng Printer PDFDocument16 pagesDSG Clutch Removal Tool Set Eng Printer PDFMohammed MochrifNo ratings yet

- Info For 0B5 GearboxesDocument2 pagesInfo For 0B5 GearboxesCatalin Belea100% (2)

- Audi VW 1.9 Tdi Pumpe Duse EngineDocument60 pagesAudi VW 1.9 Tdi Pumpe Duse EngineGabriel Latis100% (3)

- Audi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Document9 pagesAudi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Keldo Gliana100% (3)

- 7 Speed Dual Clutch Transmission 0gcDocument30 pages7 Speed Dual Clutch Transmission 0gcAntónio Fernandes100% (1)

- Manual VW Polo 2018+ PDFDocument326 pagesManual VW Polo 2018+ PDFCarlos Nuñez100% (2)

- D D D Direct S S S Shift G G G Gearbox 02E: Self-Study Programme 308Document64 pagesD D D Direct S S S Shift G G G Gearbox 02E: Self-Study Programme 308Jonathan Joel100% (1)

- 02E (DQ250) 0BH OBT (DQ500) OB5 (DL501) Inf Tec PDFDocument7 pages02E (DQ250) 0BH OBT (DQ500) OB5 (DL501) Inf Tec PDFFrankkelly Bonilla Frankkelly Bonilla85% (20)

- SSP 232 5sp Auto 09a-09bDocument72 pagesSSP 232 5sp Auto 09a-09bภูเก็ต เป็นเกาะNo ratings yet

- Manual Transmision 0DL PDFDocument216 pagesManual Transmision 0DL PDFCarlos Garcia Godoy100% (1)

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Rating: 1 out of 5 stars1/5 (3)

- TranmisiiDocument15 pagesTranmisiiCătălin-Ionuţ Cioabă100% (2)

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Manual Fre No SQ 52017Document216 pagesManual Fre No SQ 52017Carlos Garcia GodoyNo ratings yet

- SSP 556 The Development-goal-For-The 7 Speed-Dual Clutch Gearbox-0GC VWDocument32 pagesSSP 556 The Development-goal-For-The 7 Speed-Dual Clutch Gearbox-0GC VWFarid Mch100% (3)

- Manual Monitoreo Presion LLantas VagDocument36 pagesManual Monitoreo Presion LLantas VagCarlos Garcia Godoy100% (1)

- SSP 390 7 Speed Double Clutch Gearbox 0AMDocument76 pagesSSP 390 7 Speed Double Clutch Gearbox 0AMEdgar Oswaldo Hinojosa Mayoral100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- SSP.390-DSG-7 Gearbox 0AM PDFDocument0 pagesSSP.390-DSG-7 Gearbox 0AM PDFspiros23100% (8)

- Dl501 0b5 Repair ServiceDocument13 pagesDl501 0b5 Repair ServiceAlex Maceira Graterol100% (1)

- The 8-Speed Automatic Transmission 09P: Self Study Program 850193Document37 pagesThe 8-Speed Automatic Transmission 09P: Self Study Program 850193Allan Cancino100% (1)

- DSGDocument64 pagesDSGWiki Andy100% (1)

- D4B8047B934-4-Cylinder Injection Engine (1 4 L 4V EA211 Turbocharger)Document326 pagesD4B8047B934-4-Cylinder Injection Engine (1 4 L 4V EA211 Turbocharger)Carlos Garcia GodoyNo ratings yet

- DSG TransmissionDocument69 pagesDSG TransmissionOvidiu Bir100% (12)

- 7 Speed Dual Clutch Gearbox 0bh EngDocument138 pages7 Speed Dual Clutch Gearbox 0bh EngAlex Maceira Graterol100% (7)

- 0aw Manual VWDocument4 pages0aw Manual VWJoaquim Lemos67% (3)

- 0b5 TransmisionDocument6 pages0b5 TransmisionAnonymous NzJUyHq4100% (3)

- D4B8048F894-6-Speed Dual Clutch Gearbox 0DD Hybrid VehiclesDocument106 pagesD4B8048F894-6-Speed Dual Clutch Gearbox 0DD Hybrid VehiclesCarlos Garcia Godoy100% (1)

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004From EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Rating: 3 out of 5 stars3/5 (1)

- CareerPath SupplyChainDocument27 pagesCareerPath SupplyChainShobhit PareekNo ratings yet

- D4B8048BC6A-4-Cylinder Injection Engine (1 4 L Direct Injection Engine Turbocharger and Supercharger)Document245 pagesD4B8048BC6A-4-Cylinder Injection Engine (1 4 L Direct Injection Engine Turbocharger and Supercharger)Carlos Garcia Godoy100% (1)

- Manual Fre No SQ 52008Document196 pagesManual Fre No SQ 52008Carlos Garcia GodoyNo ratings yet

- The 8-Speed Automatic Transmission 0C8 Design and Function: Self Study Program 850103Document48 pagesThe 8-Speed Automatic Transmission 0C8 Design and Function: Self Study Program 850103jorge Angel Lope50% (2)

- Running Problems - Restricted Functions - Audi 0B5 GearboxDocument4 pagesRunning Problems - Restricted Functions - Audi 0B5 GearboxKeldo Gliana100% (3)

- SM 22 UnlockedDocument126 pagesSM 22 UnlockedSebastian Gomez Gomez100% (2)

- Manual Informacion Q5 HibridaDocument60 pagesManual Informacion Q5 HibridaCarlos Garcia Godoy100% (1)

- 4871 - 399 Electromechanical Steering With Parallel Assist VWDocument40 pages4871 - 399 Electromechanical Steering With Parallel Assist VWVibhav Sridharan100% (2)

- AC Electric Motors Control: Advanced Design Techniques and ApplicationsFrom EverandAC Electric Motors Control: Advanced Design Techniques and ApplicationsFouad GiriNo ratings yet

- SSP 390 7 Speed Double Clutch Gearbox 0AMDocument76 pagesSSP 390 7 Speed Double Clutch Gearbox 0AMYüksel DoğrulNo ratings yet

- The Electromechanical Parking BrakeDocument36 pagesThe Electromechanical Parking BrakeDragos1993100% (2)

- 9 PMP - ProcurementDocument14 pages9 PMP - Procurementdrsuresh26No ratings yet

- Functional Level StrategyDocument32 pagesFunctional Level StrategyAmit Yadav100% (2)

- Audi A5 - SuspensionDocument56 pagesAudi A5 - SuspensionCarlos Garcia GodoyNo ratings yet

- Audi A5 - SuspensionDocument56 pagesAudi A5 - SuspensionCarlos Garcia GodoyNo ratings yet

- SSP 512 Automated 5 Speed Manual Gearbox 0CTDocument36 pagesSSP 512 Automated 5 Speed Manual Gearbox 0CTossoski100% (3)

- MC 10156073 9999Document72 pagesMC 10156073 9999Даниел АбонеевNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- A005A120020-Basic Equipment (L0L) From April 2010Document1,105 pagesA005A120020-Basic Equipment (L0L) From April 2010Carlos Garcia GodoyNo ratings yet

- Manual-0BW Hybrid Front-Wheel DriveDocument146 pagesManual-0BW Hybrid Front-Wheel DriveCarlos Garcia GodoyNo ratings yet

- ASSP0043120-Nr 431 Audi RS 6Document44 pagesASSP0043120-Nr 431 Audi RS 6Carlos Garcia GodoyNo ratings yet

- ActualizacionSoftwareIVT KiaForte2019 2021Document12 pagesActualizacionSoftwareIVT KiaForte2019 2021Carlos Garcia GodoyNo ratings yet

- ASSP0045620-Nr 456 The Audi A8 '10Document96 pagesASSP0045620-Nr 456 The Audi A8 '10Carlos Garcia GodoyNo ratings yet

- DiagramaAudiA72010 UpDocument1,558 pagesDiagramaAudiA72010 UpCarlos Garcia GodoyNo ratings yet

- D4B8038282A 1 Speed Gearbox 0CZDocument52 pagesD4B8038282A 1 Speed Gearbox 0CZCarlos Garcia GodoyNo ratings yet

- Self-Study Programme 256: ServiceDocument32 pagesSelf-Study Programme 256: ServiceMohd FairusNo ratings yet

- AudiA42016 Up DiagramasElectricos PDFDocument843 pagesAudiA42016 Up DiagramasElectricos PDFCarlos Garcia GodoyNo ratings yet

- 1402810632V-Nr 244 Audi RS 6 PDFDocument60 pages1402810632V-Nr 244 Audi RS 6 PDFCarlos Garcia GodoyNo ratings yet

- Information Systems Analysis: Topic 7: Process-Oriented IS MethodologiesDocument24 pagesInformation Systems Analysis: Topic 7: Process-Oriented IS MethodologiesAkuzike NgukuNo ratings yet

- A Power Line Communication Tutorial Challenges andDocument17 pagesA Power Line Communication Tutorial Challenges andzeeshanmianNo ratings yet

- Modelling and Simulation PV Station VRTDocument4 pagesModelling and Simulation PV Station VRTDaniel ManjarresNo ratings yet

- D ch07Document50 pagesD ch07mullai03No ratings yet

- A Survey of VPN Performance EvaluationDocument5 pagesA Survey of VPN Performance EvaluationEditor IJRITCCNo ratings yet

- DMC 550Document45 pagesDMC 550Pandu Sandi PratamaNo ratings yet

- Manual Tecnico InglesDocument6 pagesManual Tecnico InglesyuleysNo ratings yet

- Gda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Document17 pagesGda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Vũ Khánh Trang BùiNo ratings yet

- Clevo W950SU2 - 6-71-W5S20-D03Document94 pagesClevo W950SU2 - 6-71-W5S20-D03Francisco Teixeira100% (2)

- Subhajit Sen ResumeDocument2 pagesSubhajit Sen ResumeSubhajit SenNo ratings yet

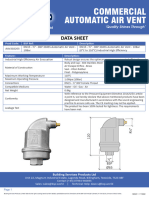

- BSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022Document1 pageBSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022j.iqubalNo ratings yet

- Security Issues in EcommerceDocument12 pagesSecurity Issues in EcommerceDBS MANFESTNo ratings yet

- Design approach analysis for inset-fed rectangular microstrip patch antennaDocument4 pagesDesign approach analysis for inset-fed rectangular microstrip patch antennaNam TàoNo ratings yet

- MDS Report for PTFE TubeDocument3 pagesMDS Report for PTFE TubeyatheendravarmaNo ratings yet

- ANALYSISTABS Sample Dashboard Sales DataDocument232 pagesANALYSISTABS Sample Dashboard Sales Datapuran1234567890No ratings yet

- C GraphicsDocument31 pagesC GraphicsArnav DasNo ratings yet

- Siebel 8.1 Integration With Avaya IC 7.2Document3 pagesSiebel 8.1 Integration With Avaya IC 7.2Shipra JainNo ratings yet

- Um m1114 61298 en 1412 PDFDocument55 pagesUm m1114 61298 en 1412 PDFJFco VANo ratings yet

- Physics 03-04 PowerDocument2 pagesPhysics 03-04 PowerMacmillanNo ratings yet

- Islanding in Power Systems: Hybrid Detection MethodsDocument18 pagesIslanding in Power Systems: Hybrid Detection MethodsSK YadavNo ratings yet

- The Antennagate Crisis ManagementDocument7 pagesThe Antennagate Crisis ManagementMenghui DaiNo ratings yet

- Chapter 22 Transport LayerDocument25 pagesChapter 22 Transport LayerAnonymous ey6J2bNo ratings yet

- Endress Houser TMRDocument20 pagesEndress Houser TMRAndriana Teja PermanaNo ratings yet

- 3HAC049194 AM Lincoln ArcLink Interface and Weld Editor-EnDocument48 pages3HAC049194 AM Lincoln ArcLink Interface and Weld Editor-EnRosmery MilagrosNo ratings yet

- Objective: TH STDocument3 pagesObjective: TH STAmzal AhamedNo ratings yet

- Bank of Baroda BankingApplicationDocument45 pagesBank of Baroda BankingApplicationprateekNo ratings yet

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-1-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)