Professional Documents

Culture Documents

KLM Intro Process Control Rev 3

Uploaded by

FA AyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KLM Intro Process Control Rev 3

Uploaded by

FA AyCopyright:

Available Formats

KLM

Technology Group

Practical Engineering Guidelines

for Processing Plant Solutions

Page 1 of 6

Rev 1.0

#02-12 Block Aronia Phone + 60 07-421-8396

Jalan Sri Perkasa 2 Email: info@klmtechgroup.com

Taman Tampoi Utama Internet: www.klmgtechgroup.com

81200 Johor Bahru, Malaysia Internet: www.kolmetz.com

Introduction to Regulatory

and Advanced Process Control Course

Introduction

The success of every company depends of each employee's understanding of the

business's key components. Employee training and development will unlock the

companies' profitability and reliability. When people, processes and technology work

together as a team developing practical solutions, companies can maximize profitability

and assets in a sustainable manner.

Understand Regulatory and Advanced Process Control (APC) is a key to optimized plant

operations. A way to improve an existing plants operating cost or to reduce a new

distillation systems operating cost is to improve the efficiency and operations by correct

equipment selection, process optimization and control.

Course Objective

This course will guide the participates to develop key concepts and techniques to operate

design and troubleshoot a process control system. These key concepts can be utilized to

make design and operating decisions. Training and development is an investment in

future success - give yourself and your employees the keys to success.

Product recoveries, purities and energy utilization can be improved in most process

systems. This cannot be achieved without first an understanding of principles and design.

These principles need to be understood in advance of designing, operating and trouble

shooting a process for the operator, designer, or problem solving to be effective.

KLM

Technology Group

Practical Engineering Guidelines

for Processing Plant Solutions

Page 2 of 6

Rev.1

#02-12 Block Aronia Phone + 60 07-421-8396

Jalan Sri Perkasa 2 Email: info@klmtechgroup.com

Taman Tampoi Utama Internet: www.klmgtechgroup.com

81200 Johor Bahru, Malaysia Internet: www.kolmetz.com

What You Can Expect To Gain;

The operation, control and trouble shooting of a process control systems and its

associated equipment,

An overview of process control, practical solutions as well as theory

An understating of essential process control concepts,

Valuable practical insights for trouble free design and field proven techniques for

commissioning, start up and shutdown of process operations.

The fundamental knowledge of process and distillation control.

To tailor your approach to specific design, analysis and trouble shooting

problems.

KLM

Technology Group

Practical Engineering Guidelines

for Processing Plant Solutions

Page 3 of 6

Rev.1

#02-12 Block Aronia Phone + 60 07-421-8396

Jalan Sri Perkasa 2 Email: info@klmtechgroup.com

Taman Tampoi Utama Internet: www.klmgtechgroup.com

81200 Johor Bahru, Malaysia Internet: www.kolmetz.com

Course Syllabus

The goal of the course would be to refresh the knowledge of those who have a basic

understanding of process control and to build a foundation to those who are new to the

process control. In the introduction course the basic fundamentals will be covered in

detail and the advanced topics will be reviewed. In the advanced course the basic

fundamentals will be reviewed and the advanced topics will be covered in detail.

Typical Course Outline

1. Introduction to Petrochemical Key Concepts

A. Overview of the Petrochemical Industry

B. Safety in the Petrochemical Industry

2. Introduction to Regulatory Control

A. Process Control

1. Parts of the typical control loop

2. Process & Instrument Diagrams (P&ID's)

3. Commonly used process control signals

B Automatic Control

C Definitions

D Block Diagram

E. Open and Closed Loop Systems

F Feedback and Feed forward Control

2. Typical controlled and manipulated process variables

A Level

B Pressure

C Composition

D Temperature

F Flow

KLM

Technology Group

Practical Engineering Guidelines

for Processing Plant Solutions

Page 4 of 6

Rev.1

#02-12 Block Aronia Phone + 60 07-421-8396

Jalan Sri Perkasa 2 Email: info@klmtechgroup.com

Taman Tampoi Utama Internet: www.klmgtechgroup.com

81200 Johor Bahru, Malaysia Internet: www.kolmetz.com

3 Process Dynamics:

A Input Changes

B Process Representation

C First Order System

D Higher Order System

E Process Identification

F Sensor and Control Valve Dynamics

4 On-Off Controller

5. PID Controller:

A Proportional

B Integral

C Derivative

D PID Controller

E Industrial PID Controller

F Direct and Reverse Action

6. Cascade Control:

A. Operations

B. Initialization

7. Ratio Control

8. Tuning of Controllers:

A Ultimate Method

B Reaction Curve Method

C Minimum Error Integral Methods

D Practical Considerations

KLM

Technology Group

Practical Engineering Guidelines

for Processing Plant Solutions

Page 5 of 6

Rev.1

#02-12 Block Aronia Phone + 60 07-421-8396

Jalan Sri Perkasa 2 Email: info@klmtechgroup.com

Taman Tampoi Utama Internet: www.klmgtechgroup.com

81200 Johor Bahru, Malaysia Internet: www.kolmetz.com

9 Distributed Control System:

A I/O Module

B Control Module

C Computer Module

D Operator Station

10. Distillation Column Control

A. Functions of Process Control

B Characteristics of a Continuous Process

C Select appropriate composition and column pressure control schemes

D Process settings during column operation

11. Advanced Process Control

A Introduction to APC

B. Fundamental and terminology

C Overview of current APC technologies

D Typical steps of an APC project.

12. Installation

A. Common column installation mistakes

B. List tasks to insure a proper installation

KLM

Technology Group

Practical Engineering Guidelines

for Processing Plant Solutions

Page 6 of 6

Rev.1

#02-12 Block Aronia Phone + 60 07-421-8396

Jalan Sri Perkasa 2 Email: info@klmtechgroup.com

Taman Tampoi Utama Internet: www.klmgtechgroup.com

81200 Johor Bahru, Malaysia Internet: www.kolmetz.com

Who Should Attend

People who are making day to day decisions regarding operation, design,

maintenance, and economics of process industry plants.

1. 1

st

Line Operations personnel,

2. Operation Supervisors,

3. 1

st

Line Maintenance personnel,

4. Maintenance Supervisors,

5. Senior Plant Supervisors,

6. Operations Engineers

7. Process Support Engineers,

8. Design Engineers,

9. Cost Engineers

An operator or engineer who must troubleshoot and solve problems in a plant or

an engineering office.

Technical Engineers, Operating Engineers, Process Support Personnel, and

Managers

Engineering graduates/technologists who will be using process control in their

daily work.

Technical Process engineers doing process design and optimization projects and

studies that need who need advanced skills for more complex modeling tasks.

Plant Operation Support Engineers checking plant performance under different

operating conditions, and who are involved in design of new facilities or revamps

of existing facilities.

Ideal for veterans and those with only a few years of experience who want to

review or broaden their understanding of process safety.

Other professionals who desire a better understanding of the subject matter.

You might also like

- M Alkalinity and P AlkalinityDocument3 pagesM Alkalinity and P AlkalinityFA AyNo ratings yet

- FluxDocument10 pagesFluxRJG0409No ratings yet

- Instrument QuestionsDocument71 pagesInstrument QuestionsFA AyNo ratings yet

- Boiler Feedwater DeaerationDocument5 pagesBoiler Feedwater DeaerationFA AyNo ratings yet

- Mech Seals Selection Guide 2Document6 pagesMech Seals Selection Guide 2taghdirimNo ratings yet

- NOx Booklet MarkedDocument19 pagesNOx Booklet MarkedFA AyNo ratings yet

- Burner SystemDocument1 pageBurner SystemFA AyNo ratings yet

- TDLS200 CombustionDocument4 pagesTDLS200 CombustionFA AyNo ratings yet

- Weyer Group Engineering ConsultingDocument2 pagesWeyer Group Engineering ConsultingFA AyNo ratings yet

- Classification of PolymersDocument14 pagesClassification of PolymersFA Ay67% (6)

- Polymerization Techniques Advantages and DisadvantagesDocument1 pagePolymerization Techniques Advantages and DisadvantagesFA Ay100% (6)

- FormulaDocument6 pagesFormulaanon-963224100% (5)

- Saudi Aramco's Guide to Compressed Air SystemsDocument29 pagesSaudi Aramco's Guide to Compressed Air SystemsFA Ay100% (1)

- SIM4ME ThermodynamicsDocument137 pagesSIM4ME ThermodynamicsFA AyNo ratings yet

- KLM Intro Process Control Rev 3Document6 pagesKLM Intro Process Control Rev 3FA AyNo ratings yet

- Saudi Aramco's Guide to Nitrogen and Inert Gas SystemsDocument32 pagesSaudi Aramco's Guide to Nitrogen and Inert Gas SystemsFA Ay100% (1)

- CHE10209 Couplings Seals BearingsDocument36 pagesCHE10209 Couplings Seals BearingsFA AyNo ratings yet

- Centrifugal Pump AnalysisDocument69 pagesCentrifugal Pump AnalysisFA AyNo ratings yet

- Heat Exchanger PerformanceDocument31 pagesHeat Exchanger PerformanceFA AyNo ratings yet

- Heat Exchangers Design DOEDocument25 pagesHeat Exchangers Design DOEPedro DiazNo ratings yet

- Engineering Encyclopedia: Saudi Aramco Desktop StandardsDocument12 pagesEngineering Encyclopedia: Saudi Aramco Desktop StandardsFA Ay100% (1)

- Liquid Process Piping: Part 5: ValvesDocument23 pagesLiquid Process Piping: Part 5: ValvesFA AyNo ratings yet

- Astral Attack and DefenseDocument21 pagesAstral Attack and DefenseFA AyNo ratings yet

- Intro To Steam Boilers and Turbines For Power PlantsDocument57 pagesIntro To Steam Boilers and Turbines For Power PlantsFA AyNo ratings yet

- KLM Process Furnace Rev 3Document5 pagesKLM Process Furnace Rev 3FA AyNo ratings yet

- Flow Measurement in Pipes and DuctsDocument24 pagesFlow Measurement in Pipes and DuctshozipekNo ratings yet

- ENGINEERING DESIGN GUIDELINE - Flare Rev1.1Document19 pagesENGINEERING DESIGN GUIDELINE - Flare Rev1.1ashutosh_mishra_9No ratings yet

- Engineering Design Guideline - HX Rev 3Document24 pagesEngineering Design Guideline - HX Rev 3axle_ramNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ISGEC Heavy Engineering Limited: Checklist For Equipment InspectionDocument43 pagesISGEC Heavy Engineering Limited: Checklist For Equipment Inspectionallu arunNo ratings yet

- PTV09 Series - 9 MM Potentiometer: FeaturesDocument4 pagesPTV09 Series - 9 MM Potentiometer: FeaturesMuabdib AtreidesNo ratings yet

- Wifi Controlled Light Using Esp32: Products Learning Center My AccountDocument6 pagesWifi Controlled Light Using Esp32: Products Learning Center My AccountbejaouiNo ratings yet

- Data Center SOP UPS Transfer To Maintenance Bypass v3Document5 pagesData Center SOP UPS Transfer To Maintenance Bypass v3Dev MonitorNo ratings yet

- Important Note (S) :-To Participate in The Online Auction, There Is Need To Obtain Digital Signature Certificate (DSC) - Bidders Can Date andDocument5 pagesImportant Note (S) :-To Participate in The Online Auction, There Is Need To Obtain Digital Signature Certificate (DSC) - Bidders Can Date andRunveer SurwadeNo ratings yet

- EN Enelex Analyzers GEDocument4 pagesEN Enelex Analyzers GEManoj PaneriNo ratings yet

- Online Bike ShowroomDocument11 pagesOnline Bike ShowroomsandipNo ratings yet

- Erdt EssayDocument2 pagesErdt EssayJuan Carlos Dela CruzNo ratings yet

- CV Igor Chiriac enDocument2 pagesCV Igor Chiriac enigorash17No ratings yet

- Avid Codecs 2.3.7 Download: Codec PackagesDocument5 pagesAvid Codecs 2.3.7 Download: Codec PackagesjairmrfNo ratings yet

- Vivado Basic TutorialDocument30 pagesVivado Basic Tutorial8885684828No ratings yet

- ScadaDocument3 pagesScadaAkira SatoNo ratings yet

- Machine Learning Approach To 5G Infrastructure Market Optimization - Bega Et Al. 2019Document16 pagesMachine Learning Approach To 5G Infrastructure Market Optimization - Bega Et Al. 2019Evenso NdlovuNo ratings yet

- Ventilation Calculation 1591013185963Document8 pagesVentilation Calculation 1591013185963mak ksaNo ratings yet

- ModbusTCP PDFDocument2 pagesModbusTCP PDFGeorge GaitanakisNo ratings yet

- 1.03-Exabit/skm Seven-Core Fiber TransmissionDocument3 pages1.03-Exabit/skm Seven-Core Fiber TransmissionWaddah SaeedNo ratings yet

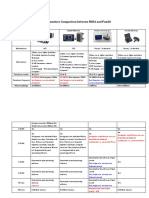

- Main Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayDocument3 pagesMain Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayAsep RifkyNo ratings yet

- HTTP API Guide for SMS and Number InsightsDocument35 pagesHTTP API Guide for SMS and Number InsightsIvan WalulyaNo ratings yet

- Transient Performance of CVTsDocument3 pagesTransient Performance of CVTsajaysitaula8478No ratings yet

- Spring Festival Events and CompetitionsDocument10 pagesSpring Festival Events and Competitions45.thiên ýNo ratings yet

- The Function of Transport TerminalsDocument3 pagesThe Function of Transport TerminalsRiot Ayase0% (1)

- Subaru Diesel - TuningDocument28 pagesSubaru Diesel - TuningEdwinNo ratings yet

- Project SpecificationDocument8 pagesProject SpecificationYong ChengNo ratings yet

- List of Presentation Topics For Class XIDocument1 pageList of Presentation Topics For Class XIchandni1972No ratings yet

- Newlester PhilipsDocument49 pagesNewlester PhilipsCarlos D MauroNo ratings yet

- Faculty-Student Innovation Program GuidelinesDocument8 pagesFaculty-Student Innovation Program GuidelinesPratik PatilNo ratings yet

- Inspection ControlDocument10 pagesInspection ControlIvan D. RiveraNo ratings yet

- Scientific Recruitment With ResearchGateDocument16 pagesScientific Recruitment With ResearchGateMuhammad OktaviansyahNo ratings yet

- Example To Manually Check and Create EDIFACT Signatures 2022-11-18Document10 pagesExample To Manually Check and Create EDIFACT Signatures 2022-11-18ralucaNo ratings yet

- p0335 Nissan Sentra 2003 2.5Document7 pagesp0335 Nissan Sentra 2003 2.5DirciosNo ratings yet