Professional Documents

Culture Documents

Hydraulic Specific Ennergy1

Uploaded by

Anonymous EPSHB9tXZCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Specific Ennergy1

Uploaded by

Anonymous EPSHB9tXZCopyright:

Available Formats

Home

Fluid Machinery

CHAPTERS

Home

Topics

Chapter 1 : General Concepts

Chapter 2 : Pelton Turbine

Chapter 3 : Francis and Kaplan Turbine

Chapter 4 : Centrifugal Pumps

Chapter 5 : Similarity Relations and Performance Characteristics

Chapter 6 : Reciprocating Pumps

Chapter 7 : Hydraulic devices and Systems

Home

Chapter 3 : Francis and Kaplan Turbine

Share this

Q. 1. Discuss briefly the guide mechanism in reaction turbines.

Ans. It consists of a stationary circular wheel all round the runner of the turbine. The stationary guide

vanes are fixed on guide mechanism The guide vanes allow the water t strike the vanes fixed on the

runner without shock at inlet. The width between two adjacent vanes of guide mechanism can be

altered so that the amount of water striking the runner can be varied.

Q. 2. List the advantages of Kaplan Turbine over Francis Turbine.

Ans. Advantages of Kaplan turbine over Francis turbine

(i) Runner vanes are adjustable in Kaplan turbine while in Francis turbine run vanes are not adjustable.

(ii) There is less resistance offered as the number of vanes are fewer in Kaplan turbine (in) Specific speed

range 250-850 m Kaplan turbine In Francis turbine specific speed range is 5o250.s

Q. 3. Draw velocity triangles at inlet and outlet of typical Francis turbine vane.

Ans. There are three types of velocity triangles for. inlet and outlet in Francis turbine. Triangles are made

for slow runner, medium runner and fast runner.

Fig. Slow runner

Fig. Medium Runner

Fig. Fast Runner

Q. 4. Define degree of reaction and Eulers Head.

Ans. The degree of reaction (R) is defined as a ratio of change of pressure energy in the runner to the

change of total energy in the runner per kg of water.

Eulers Head: It is defined as energy transfer per unit weight.

Q.5. Why is the efficiency of Kaplan turbine nearly constant irrespective of speed variation under load?

Ans. Kaplan turbines has the concept of adjusting the runner vanes in the face of changing load

conditions on the turbine, with proper adjustment of blades during its running the Kaplan turbine is

capable of giving a constant and high efficiency for a wide range of load conditions. The pitch of the

blades is also automatically adjusted by the governor through the action of a servo meter.

Q. 6. Define specific speed of a turbine and write down its expression.

Ans. The specific speed of a turbine may be defined as the speed of an imaginary turbine, identical with

the given turbine which will develop a unit power under a unit head.

It is given by

N = Speed of the runner in r.p.m.

H =Head of water

P = Power produced.

Q. 7. Sketch different types of draft tubes.

Ans. Following are the important types of draft tubes which are commonly used.

1. Conical draft tubes

2. Simple elbow tubes

3. Moody spreading tubes

4. Elbow with circular inlet and rectangular outlet.

Fig. Types of draft tubes

Q. 8. List the various functions of surge tanks.

Ans. Surge tanks have the following functions:

1. To control the pressure variations, due to rapid changes in the pipeline flow, thus eliminating water

hammer possibilities.

2. To regulate the flow of water to the turbines.

3. To reduce the distance between the free water surface and turbine, thereby reducing the water

hammer effect on penstock.

4. It protects up stream tuner from high pressure rises.

Q. 9. Explain (i) Hydraulic efficiency (ii) Mechanical efficiency (iii) Overall efficiency of turbines.

Ans. (i) Hydraulic Efficiency-It is the ratio of work done on the wheel to the head of rater (or energy)

actually supplied to the turbine i.e.

(ii) Mechanical Efficiencyit is the ratio of actual work available at the turbine to e energy imparted to

the wheel.

(iii) Overall Efficiencyit is a measure f the performance of a turbine and is the 120 of power produced

by the turbine to the energy actually supplied to the turbine.

Q. 10. Differentiate between Francis and Kaplan turbine.

Ans.

Q. 11. List the unit quantities as applied to turbo-machines.

Ans. (i) Unit power (ii) Unit speed (iii) Unit discharge.

Unit Power-The powered developed by a turbine working under a head of 1 meter, is known as unit

power:

P =Power developed,

H =Head of water

Unit Speed-The speed of turbine, working under a head of 1 meter, is known as unit speed

N = speed of turbine,

H = Head of water

Unit Discharge-The discharge of a turbine, working under a head of 1 meter, is known as unit discharge.

Q = Discharge,

= Head of water

Q. 12. List the factors/criteria to choose a turbine.

Or

How to decide whether Kalpan, Francis or a pelton type tupe turbine would be used in a hydro project?

Ans. The selection of turbines depend on the following considerations.

1. Operating Head Pelton turbine - Greater than 400 m

Francis turbine - 50-400 m

Kaplan turbine - Less than 50 m

2. Specific speed-Turbine having high specific speed is selected. High speed means a smaller size of the

turbine. Francis turbines run at higher speeds (50250) than those of pelton wheels (850), Kaplan

turbine have the greatest specific speed (2501000).

3. Cavitation- Cavitation occurs when the pressure at the runner outlet equals vapour pressure. Francis

turbines can not be used for very high heads because of cavitation. Pelton turbines are free from

cavitation because the pressure at runner outlet is the atmospheric.

4. Performance characteristicsTurbines should be selected in such a way that their efficiencies do not

fall appreciably when operating under part load. Francis turbines operate efficiently between half and

full load. Kaplan turbines are more efficient at low heads.

5. Overall costThe plant should be designed for the minimum cost as cost is the prime consideration in

designing a plant

6. Number of unitsIt is better to go in for a larger unit as far as possible, but there must be at least two

units at any particular site so that one unit is always available.

Q. 13. What is the importance of a draft tube in a Francis turbine 7 Discuss different types of draft tubes.

Ans. It is a pipe, which connects the turbine and outlet or tail race, through which the water exhausted

from the runner, flows to the outlet channel.

It also act as a water conduit.

Draft tube has the following important function:

1. It makes the installation possible above the tail race level without the loss of head.

2. Water velocity at runner outlet is very, high. By using draft tube the velocity can be lowered. Loss of

kinetic energy is converted into pressure energy.

3. Draft tube prevents the splashing of water coming out of the runner.

Different types of draft tubes used are:

(1) Conical draft tubes

(2) Simple elbow tubes

(3) Moody spreading tubes

(4) Elbow with circular inlet and rectangular outlet.

Fig. Types of draft tubes

(1) Conical Draft TubesThis is known as tapered draft tube and used in all reaction turbines where

conditions permit. It is preferred for low specific speed and Francis turbine. The maximum cone angle is

8 (a = 40). The hydraulic efficiency is 90%.

(2) Simple Elbow Tubes-The elbow type draft tube is often preferred in most of the power plants. If the

tube is large in diameter; it may be necessary to make the horizontal portion of some other section. A

common form of section used is over or rectangular. It has low efficiency around 60%.

(3) Moody Spreading Tubes-This tube is used to reduce the whirling action of discharge water when

turbine runs at high speed under low head conditions. The draft tube has efficiency around 85%.

(4) Elbow with circular inlet and rectangular outletThis tube has circular cross- section at inlet and

rectangular section at outlet. The change from circular section to rectangular section take place in the

bend from vertical leg to the horizontal leg. The efficiency is about 85%.

Q. 14. Derive the expression for specific speed of turbine. What is the range of specific speed for

reaction turbine?

Ans. Power available at turbine shaft

Since and w are constant: (1)

The tangential velocity u, the flow velocity the absolute velocity v and the head H on the turbine are

related as

Now

Also

Substituting this value in expression (1)

(2)

Where k is constant of proportionality

Now taking H =1, P= 1, then (specific speed)

Expression (ii) may be written as

Specific speed,

Specific speed for Francis turbine = 50 250.

Specific speed for Kaplan turbine = 250 850.

Q. 15. Show that in a given turbine v

H = available head, u tangential velocity, Q = discharge, P power developed.

Ans. (i) We know that

Absolute velocity v

(1)

Also tangential velocity, (2)

So from (1) and (2)

(ii) Q = Area of flow x Velocity

So

(iii)

so (hence proved).

Q. 16. Define draft tube efficiency. Give mathematical expression.

Ans. The efficiency of the draft tube is defined as the ratio of actual conversion of kinetic head into

pressure head in the draft tube to the kinetic head at the inlet of the draft tube.

Mathematically, = =

Q .17. Why the draft tube is not used for Pelton turbine?

Ans. In case of pelton turbine all the K. E. is lost and draft tube is not used because the pressure value is

just the atmospheric so there is no requirement of draft tube.

Q .18. What is the function of scross casing in reaction turbines?

Ans. Scroll casing provides the limited area around the runner to maintain the constant velocity of water

flow around the runner The material of scroll casing may be cost steel, cast iron, concrete or concrete

and steel.

Q.19. Explain with neat sketch the operation of Kaplan turbine, governing of Kaplan turbines and their

performance characteristics.

Ans. Kaplan Turbine The figure shows a schematic diagram of Kaplan turbine The function of the guide

vane is same as in case of Francis turbine Between the guide vanes and the runner, the fluid in a

propeller turbine turns through a right-angle into the axial direction and then passes through the

runner. The runner usually has four or six blades and closely resembles a ships propeller Neglecting the

frictional effects, the flow approaching the runner blades can be considered to be a free vortex with

whirl velocity being inversely proportional to radius, while on the other hand, the blade velocity is

directly proportional to the radius The take care of this different relationship of the fluid velocity and the

blade velocity with the changes in radius, the blades are twisted. The angle with axis is greater at the tip

that at the root.

Performance Characteristics of Reaction Turbine:

It is not always possible in practice, although desirable, to run a machine at its maximum efficiency due

to changes in operating parameters. Therefore, it becomes important to know the performance of the

machine under conditions for which the efficiency is less than the maximum It is more useful to plot the

basic dimensionless performance parameters (Fig 1) as derived earlier from the similarity principles of

fluid machines Thus one set of curves, as shown in Fig 1, is applicable not just to the conditions of the

test, but to any machine in the same homologous series under any altered conditions.

Fig.I: Performance characteristics of a reaction turbine in dimensionless parameters)

Figure 2 is one of the typical plots where variation in efficiency of different reaction turbines with the

rated power is shown.

Fig. 2 Variation of efficiency with load

Governing of Reaction Turbines- Governing of reaction turbines is usually done by altering the position

of the guide vanes and thus controlling the flow rate by changing the gate openings to the runner. The

guide blades of a reaction turbine are pivoted and connected by levers and links to the regulating ring.

Two long regulating rods, being attached to the regulating ring at their one ends, are connected to a

regulating lever at their other ends. The regulating lever is keyed to a regulating shaft which is turned by

a servomotor piston of the oil.

Q. 20. Write note on Surge tanks.

Ans. A surge tank is a storage reservoir fitted at some opening made on a long penstock to receive the

rejected flow when the penstock is suddenly closed by a value fitted at its steed end. Surge tanks,

relieves the pipe line of excessive pressure produced due to closing of the penstock, thus eliminating

positive water hammer effect by admitting in it a large mass of water which would have flown out of the

pipe line.

It is also used in a large pumping plant to control variations resulting from rapid changes in the

flow.

Functions of surge tanks:

(1) To control the pressure variations by reliving the line of excessive pressure.

(2) Regulation of flow in power plants and pumping plants.

(3) Regulation of turbine speed.

Location of surge tank: Theoretically it should be located close to a power or pumping plant. It is

generally located at the junction of pressure tunnel and penstock or on the side of the mountain.

Types of surge tanks:

(1) Single surge tanks

(2) Restricted orifice type

(3) Differential type.

Q. 21. Write short note on design of runner for reaction turbine.

Ans. Suppose, H = Head

N = Running Speed

P = Power Output

The design Procedure is given as follows.

1. Assume probable values of

Hydraulic efficiency.

Overall efficiency

n, Ratio of width to diameter

Flow ratio

2. Find Discharge by using

Shaft Power

3. Area through which water enters

Where and are entrance diameter and width.

is effect for the vanes.

4. Find tangential velocity

5. Find Flow Velocity,

6. Obtain and by using

Assume

Use continuity equation

(1) Net Head, H =

(2) Hydraulic efficiency,

(3) Discharge through Kaplan turbine:

Problem 1. A Francis turbine works under a head of 25 m producing 3675 kW at 150 r.p.m. Determine

the (a) Unit power and unit speed of the turbine (b) Specific speed of the turbine and (c) Power

developed by this turbine if the speed is reduced to 100 r.p.m.

Solution. P= 3675 kW

H=25m

N = 150 r.p.m.

Unit power and unit speed

Unit power:

Unit speed:

Specific speed of the turbine

= 162.66

=163 r.p.m.

Power developed if the speed reduced to 100 r.p.m.

We know that

Also

Problem. 2. A Kaplan turbine runner is to be designed to develop 7357.5 kW shaft power. The net

available head is 5.50 m. Assume that the speed ratio is 2.09 and flow ratio is 0.68 and the overall

efficiency is 60%. The diameter of the boss is rd of the diameter of the runner. Find the diameter of the

runner, its speed and its specific speed.

Solution: Given:

Shaft power P = 7357.5 kW

Head H = 5.50m

Speed ratio

Flow ratio

Overall efficiency, = 60% = 0.60

Diameter of boss,

Using relation

0.60 =

We have

6.788m

And 6.788 = 2.262 m

Using

= 61.08 r.p.m.

Specific speed is given by

= 622 r.p.m.

Problem. 3. The following data pertains to an inward flow reaction turbine Net head = 60 m, speed = 650

r.p.m., Brake power = 275 kW Ratio of wheel width to wheel diameter at inlet = 0.10 Ratio of inner

diameter to outer diameter = 0.5 Flow ratio = 0.17, = 0.95 and = 0.85. The flow velocity remains

constant and the discharge is radial. Neglecting area blockage by blades, work out the main dimensions

and blade angles of the turbine.

Solution:

Flow velocity==5.83m/s

=5.83m/s

Power available from the turbine shaft = w Q H x

275 x = (9810 x Q x 60) x 0.85

Discharge through the turbine,

= 0.55/s

Also

0.55 =x 0.1 d x 5.83

Diameter of wheel at inlet, = 0.5486m = 54.86cm

Width of wheel at inlet, = 0.1 x 54.86 = 5.486 cm.

Diameter of wheel at outlet, = 0.5 d = 0.5 x 54.86 = 27.43 cm

Since the discharge of water at inlet and outlet tips is same,

Width of wheel at outlet, = 0.1097 m = 10.97 cm

Angles at inlet:

Peripheral velocity at inlet, = 18.66 m/s

Hydraulic efficiency,

0.9 5

Angles at outlet:

0.6248,

Problem 4. A Francis turbine with an overall efficiency of 75% is required to produce 14825 kW power. It

is working under a head of 7.62 m. The peripheral velocity = 0.26 and the radial velocity of flow at inlet

are 0.96. The wheel runs at 150 r.p.m. and the hydraulic losses in the turbine are 22% of the available

energy. Assume Radial discharge, determine

(i) The guide blade angle

(ii) The wheel vane angle at inlet

(iii) Diameter of the wheel at inlet, and

(iv) Width of the wheel at inlet.

Solution: Overall efficiency, =

Power produced = 148.25 kW

Head = 7.62 m

Peripheral velocity,

= 3.179 m/s

Velocity of flow at inlet,

= 11.738 m/s

Speed, N = 150 r.p.m.

Hydrauls losses = 22% of available energy

Discharge at outlet = Radial

Hydraulic efficiency is given as

=0.78

=0.78

= 18.34 m/s

1. The guide blade angle, a

=0.64

0.64 = 32.619

2. The wheel vane angle at inlet,

=0.774

0.774 = 37.74

3. Diameter of wheel at inlet

=0.4047m

4. Width of the wheel at inlet

w.P.

= 2.644

Using

2.644 = x 0.4047 xx 11.738

= 0.177m

Problem 5. A hydro-turbine is required to give 25 mW at 50 m heat and 90 r.p.m. runner speed. The

laboratory facilities available permit testing of 20 kW model at 5m head. What should be the model

runner speed and model prototype scale ratio?

Solution: = 25 mW =20 kW

= 90 r.p.m. =5 m

=50m

Scale ratio ==6.29

=90x6.29x=179r.p.m.

Problem 6. In an inward flow reaction turbine having vertical shaft, water enters the runner from the

guide blades at an angle of 155 with the runner blade angle at entry being 100. Both these angles are

measure from the tangent at runner periphery drawn in the direction of runner rotation. The flow

velocity through the runner is constant, water enters the draft tube from tile runner without whirl and

the discharge from the draft tube into the tail race takes place with a velocity of 2.5 m/s. The runner has

the dimensions of 40 cm external diameter and 3.8 cm inlet width. The turbine works with a net head of

35m and the loss of head in the turbine due to fluid n is 4m of water. Draw vector diagrams and

calculate:

1. Speed of the runner

2. Runner blade angle at a point on the outlet edge where the radius of rotation is 9 cm.

3. Power generated by the turbine and its specific speed.

4. Inlet diameter of the draft tube.

Solution. Velocities at inlet and exit are related by the expression:

From the inlet velocity triangle

= (180155) =25

= (180 100) = 800

Since the discharge is in radial direction,

Work done == 0.43

From the energy balance,

Head supplied

= (work done) + (kinetic heat at exit) + (losses in the runner)

3.5 + +4

= 8.45m/s

= 1.968= 1.968 x 8.45 = l6.63m/s

1. ;1663=

N == 794 r.p.m.

2. From outlet velocity triangle:

=8.45m/s

Peripheral velocity of the outer edge at 9 cm radius

= 16.63 x= 7.48 m/s

= 1.13 ; vane angle at outlet, =

Discharge through the turbine, Qx 0.4 x 0.038 x 8.45

= 0.4035

3. Power developed by the turbine,

= 9810 x 0.4035 x 0.43121.5 x W = 121.5 kW

Assume a mechanical efficiency of 98%

4. Power available at turbine shaft = 121. 5 x 0.98 = 119.07

Specific speed of the turbine, Ns= 101.77

5. Inlet area of draft tube === 0.04775

If d is the inlet diameter of the tube,

=0.04775

d==0.246m

Problem.7. Francis turbine develops 365 kW at an overall efficiency of 80%. When working under a static

head of 5 m, the draft tube being cylindrical and of diameter 2.5 m. What increase in power and

efficiency of the turbine would you expect if a tapered draft tube having an inlet diameter of 4m and

efficiency of conversion of 90% is substituted for the cylindrical one? It maybe presumed that head,

speed and discharge remain constant.

Solution Power available = wQH

365 x= (9810 x Q x 5) x 0.8

Q=

When the draft tube is tapered one velocity of water at inlet to draft tube

=1.89m/s

velocity of water at outlet of draft tube

=0.74m/s

Heat gained = xO.9 = 0.14 m

Increase in efficiency == 0.028 = 2.8%

Increase in power = increase in efficiency x original power

= 0.028 x (9810 x 9.30 x 5)

=12773W=12.77kW

Problem.8. An inward flow reaction turbine discharges radially and the velocity of flow is constant and

equal to the velocity of discharge from the turbine. Show that the hydraulic efficiency can be expressed

by

Where a and are respectively the guide vane angle and wheel vane angle at Intel.

Solution. From the inlet velocity triangle

For radical discharge at outlet

Thus

Or

Substituting the value of , we get

Also substituting the value of u from above, we get

Now =

Or =

Or

Problem.9. The velocity of whirl at inlet to the runner of an inward flow reaction turbine is (3.15) m/s

and the velocity of flow at inlet is (1.05) m/s. The velocity of whirl at exit is (0.22) m/s in the same

direction as at inlet and the velocity of flow at exit is (0.83) where H is the head in meters. The inner

diameter of the runner is 0.6 times the outer diameter. Assuming hydraulic efficiency of 80%, compute

the angles of the runner vanes at inlet and exit.

Solution.

From inlet velocity triangle, we have

1.9091

= 6221

From outlet velocity triangle, we have

=0.6194

=3146

Problem.10. The inlet and the outlet runner blade angles of a propeller turbine are and 25 respectively

to the tangential direction of the runner. The inlet guide vane angle is 30. The speed of the turbine 30

rpm. The mean diameter of the runner blades is 3.6 m and the area of flow is 30. Assuming that the

velocity of flow is constant throughout, determine (1) Discharge (ii) Power developed (iii) Hydraulic

efficiency (iv) Specific speed.

Solution.

=3.6m

N =30 r.p.m.

= 90

= 25

a = 30

Flow area, a =

Runner blade angle at inlet is radial

As velocity of flow is constant so

= 5.65 m/s

Also

= 5.65 m/s

From inlet velocity triangle

=5.65xtan30

=3.262m /s

=5.65m/s

From outlet velocity triangle,

tan 25

+ 5.65 ==7 m/s

= 7 - 5.65 = 1.35 m/s

=3.529 m/s

We have,

[5.65 x 5.65 1.35 x 5.65]

H = 2.47 + 0.634 3.104 m

(1)Hydraulic efficiency is given by

=0.798 = 79.8%.

(2)Discharge through turbine, Q = Area of flow x Velocity of flow

=30x3262=97.86

(3)Power developed by turbine

Weight of water

x 1000 x 9.81 x 97.86

= 2378 kW

(4)Specific speed is given by355.08 rpm

Problem.11. In a Francis turbine of very low specific speed, the velocity of flow from inlet to exit of the

runner remains constant. If the turbine discharges radially, show that the degree of reaction p can be

expressed as

where a and are the guide and runner vane angles respectively and the degree of reaction p is equal to

the ratio of pressure drop to the hydraulic work done in the runner, assuming that the losses in the

runner are negligible.

Solution. Applying Bernoullis equation between the inlet and exit of the runner and neglecting the

potential difference, we get

(for radial discharge)

Where and are the pressure heads at the inlet aid the exit of the runner respectively.

Thus pressure head drop due to hydraulic work done in the runner is given by

Now

Or

Or (1)

For radical discharge

Also

Or u =V [cos a-sin a cot]

And

Thus, introducing these values in equation (i) above and simplifying it, we get.

Problem.12. A Francis turbine supplied through a 6 m diameter penstock has the following particulars.

Output of installation 63500 kW

Flow 117

Speed 150 r.p.m.

Hydraulic efficiency 92%

Mean diameter of turbine at entry 4 m

Mean blade height at entry 1 m

Entry diameter of draft tube 4.2 m

Velocity in tail race 2.4 m/s

The static pressure head in the penstock measured before entry to the runner is 57.4 m. The point of

measurement is 3 m above the level of the tail race. The loss in the draft tube is equivalent to 30% of the

velocity head at entry to it. The exit plane of the runner is 2 m above the tail race an the flow leaves the

runner without swirl. Determine:

1. The overall efficiency,

2. The direction of flow relative to the runner at inlet,

3. The pressure head at entry to the draft tube.

Solution.

(a)The net head H for the turbine is given by equation

And 2.4 m/s.

Thus by substitution, we get

= 60.98 m

The overall efficiency is given by

= 0.907 or 90.7%

(b) Neglecting the vane thickness, the velocity of flow at inlet i given by equation

B=1m; and D=4m

Thus by substitution, we get

= 9.31 m/s

31.42 m/s

Or 0.92

17.52 m/s

The direction of flow relative to the runner at inlet is given by

=0.6698

(c) The pressure head at entry to the draft tube is given by equation

2m =8.44m/s; =2.4m/s

And =1.09 m

Thus by substitution, we get

+1.0904.25m

Problem.13. A model of Francis turbine one-fifth of full size, develops 3 kW at 306 r.p.m. under a head

of 1.77 m. Find the speed and power of full size turbine operating under a head of 5.7 m, if (a) the

efficiency of the model and the full size turbine are same, (b) the efficiency of the model turbine is 76%

and the scale effect is considered.

Solution: (a) For the same efficiency of the model and the prototype

Or

=109.8 r.p.m.

Further

Or

=433.43kW

(b) According to Moodys equation,

Or

Or

=114.5 r.p.m.

We know that

Or

=491.09 kw

Problem.14. Show that in a turbine, with radial vanes at inlet and outlet, the hydraulic efficiency is given

by:

Where is the guide blade angle. Assume the flow velocity to remain constant.

Solution. Neglecting losses with in the runner, the energy balance gives:

Head supplied = (work done or head utilized) + (kinetic head at exit)

For radial vanes at inlet and outlet

Hydraulic efficiency,

Problem.15. A Kaplan turbine develops 2250 kW under a net head of 5.5 m and with overall efficiency

87 percent. The draft tube has a diameter of 2.8 m at its inlet and has an efficiency of 78 percent. In

order to avoid cavitation, the pressure head at entry to the draft tube must not drop more than 4.5 m

below atmosphere. Calculate the maximum height at which the runner may be set above the tail race

level.

Solution. Power available from the turbine shaft,

P = wQH x

2250 = (9810 x Q x 55) x 0.87;

Q = 47.93

Now =7.79 m/s

Given: = 4.5m

=4.5-

Draft tube efficiency,

0.78 =

= 4.5 - x 0.78 = 2.087

Problem.16. An inward flow pressure turbine has runner vanes which are radial-at the inlet and inclined

backward at 45 to the tangent at discharge. The guide vanes are inclined at 15 to tangent at inlet and

velocity of water leaving the guides in 24 m/sec. Determine correct speed for runner and absolute

velocity of water at point of discharge if diameter at entry is twice that at discharge and width at entry is

0.6 times that at discharge.

Solution.

Fig. Input and outlet velocity triangle

Given =15

= 24 m/s

In outlet velocity triangle

= m/s Ans.

We know

x33.94

x 33.94 = 28.28 m/s

(For radial discharge)

= 105.94 m/s Ans.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mercedes Trucks MR Fault Codes List Truckmanualshub - Com-1Document23 pagesMercedes Trucks MR Fault Codes List Truckmanualshub - Com-1frank mutale100% (5)

- NX Series Oil-Injected Rotary Screw Compressors Parts ListDocument28 pagesNX Series Oil-Injected Rotary Screw Compressors Parts ListrobertNo ratings yet

- Pelton Turbine (FM62)Document6 pagesPelton Turbine (FM62)Mintesnot Abera100% (4)

- Major Components and Types of Compressed Air SystemsDocument4 pagesMajor Components and Types of Compressed Air SystemsMuhammad Shahir100% (1)

- Zero FlareDocument9 pagesZero FlareJohn RongNo ratings yet

- Process Simulation Cases Flash SeparationDocument23 pagesProcess Simulation Cases Flash Separationahmed atwaNo ratings yet

- Deficit 2Document1 pageDeficit 2Anonymous EPSHB9tXZNo ratings yet

- Parent Child Communication Tool - 5Document2 pagesParent Child Communication Tool - 5Anonymous EPSHB9tXZNo ratings yet

- Deficit 3Document1 pageDeficit 3Anonymous EPSHB9tXZNo ratings yet

- Deficit 4Document1 pageDeficit 4Anonymous EPSHB9tXZNo ratings yet

- Parent Child Communication Tool - 4Document2 pagesParent Child Communication Tool - 4Anonymous EPSHB9tXZNo ratings yet

- Product Catalogue 2018Document19 pagesProduct Catalogue 2018Anonymous EPSHB9tXZNo ratings yet

- Authority To Travel Off Site For Permit Holder-29.07.21-AdminDocument1 pageAuthority To Travel Off Site For Permit Holder-29.07.21-AdminAnonymous EPSHB9tXZNo ratings yet

- Deficit 1Document1 pageDeficit 1Anonymous EPSHB9tXZNo ratings yet

- What Are The Economic Implications of Budget Deficit and Budget SurplusDocument1 pageWhat Are The Economic Implications of Budget Deficit and Budget SurplusAnonymous EPSHB9tXZNo ratings yet

- Designing Shotcrete As Primary Support in Tunnels: July 2011Document7 pagesDesigning Shotcrete As Primary Support in Tunnels: July 2011Anonymous EPSHB9tXZNo ratings yet

- Pre-sanded Cemwash decorative cement paintDocument1 pagePre-sanded Cemwash decorative cement paintTonderai RusereNo ratings yet

- Parent Child Communication Tool - 2Document2 pagesParent Child Communication Tool - 2Anonymous EPSHB9tXZNo ratings yet

- Proposed new playground under $40kDocument2 pagesProposed new playground under $40kAnonymous EPSHB9tXZNo ratings yet

- Mix Design Hints For Shotcrete - tcm45-345148Document2 pagesMix Design Hints For Shotcrete - tcm45-345148yosephinnukeNo ratings yet

- Shotcrete or Guniting - Advantages and Disadvantages PDFDocument1 pageShotcrete or Guniting - Advantages and Disadvantages PDFAnonymous EPSHB9tXZNo ratings yet

- Shotcrete Mix Designs - Civil EngineerDocument3 pagesShotcrete Mix Designs - Civil EngineerAnonymous EPSHB9tXZNo ratings yet

- Case Studies ImpairmentDocument3 pagesCase Studies ImpairmentAnonymous EPSHB9tXZNo ratings yet

- Parent Child Communication Tool - 6 PDFDocument2 pagesParent Child Communication Tool - 6 PDFAnonymous EPSHB9tXZNo ratings yet

- Phase 2 MarkerDocument1 pagePhase 2 MarkerAnonymous EPSHB9tXZNo ratings yet

- Case Studies ImpairmentDocument3 pagesCase Studies ImpairmentAnonymous EPSHB9tXZNo ratings yet

- Autocad Issues PDFDocument1 pageAutocad Issues PDFAnonymous EPSHB9tXZNo ratings yet

- Parent Child Communication Tool - 1Document2 pagesParent Child Communication Tool - 1Anonymous EPSHB9tXZNo ratings yet

- Book1 PDFDocument1 pageBook1 PDFAnonymous EPSHB9tXZNo ratings yet

- Appendix DDocument1 pageAppendix DAnonymous EPSHB9tXZNo ratings yet

- Westfall Heights Sanitary Sewer Feasibility Study - FINAL DRAFT - 201405131036012131Document46 pagesWestfall Heights Sanitary Sewer Feasibility Study - FINAL DRAFT - 201405131036012131Anonymous EPSHB9tXZNo ratings yet

- Appendix DDocument1 pageAppendix DAnonymous EPSHB9tXZNo ratings yet

- Section 11 - Gravity Sewer ConstructionDocument13 pagesSection 11 - Gravity Sewer ConstructionAnonymous EPSHB9tXZNo ratings yet

- MPA111 Public Administration Course OutlineDocument1 pageMPA111 Public Administration Course OutlineAnonymous EPSHB9tXZNo ratings yet

- Intoduction To Public Finance and Taxation TheoryDocument21 pagesIntoduction To Public Finance and Taxation TheoryAnonymous EPSHB9tXZNo ratings yet

- Public FinanceDocument9 pagesPublic FinanceAnonymous EPSHB9tXZNo ratings yet

- Gas Form C Main Particulars: 2.1 PreambleDocument8 pagesGas Form C Main Particulars: 2.1 PreambleKeyur B ShrimaliNo ratings yet

- Winglets AirfoilDocument10 pagesWinglets AirfoilJohn SmithNo ratings yet

- Bebidas CarbonatadasDocument5 pagesBebidas CarbonatadasVanessa PenaNo ratings yet

- Gas Turbine ProtectionDocument29 pagesGas Turbine ProtectionMohammed Hamza Ahmed100% (1)

- Chem Feed - C-600-p - Datos TecnicoDocument1 pageChem Feed - C-600-p - Datos TecnicomazzingerzNo ratings yet

- ASTM D323-08 (Metodo de Prueba Estandar para Presión de Vapor de Productos Del Petroleo Método REID) PDFDocument10 pagesASTM D323-08 (Metodo de Prueba Estandar para Presión de Vapor de Productos Del Petroleo Método REID) PDFDaniel FelipeNo ratings yet

- Healthcare Pin Index Cylinder Instruction Guide LeafletDocument4 pagesHealthcare Pin Index Cylinder Instruction Guide LeafletAlemuNo ratings yet

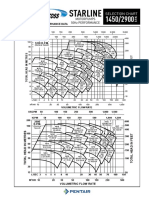

- Starline centrifugal pump performance chartDocument122 pagesStarline centrifugal pump performance chartThomas KamongNo ratings yet

- Multiple Choice: Choose The Letter of The Best Answer.: B. Inversely ProportionalDocument7 pagesMultiple Choice: Choose The Letter of The Best Answer.: B. Inversely ProportionalClarence Mike BorjaNo ratings yet

- 5 Pump ControlersDocument22 pages5 Pump ControlersJose Manuel Barroso PantojaNo ratings yet

- Solucioonario Manometros 7ma Edicion - Termodinamica - CengelDocument12 pagesSolucioonario Manometros 7ma Edicion - Termodinamica - CengelVictorNo ratings yet

- Technical Information Series C General Description: Check ValvesDocument3 pagesTechnical Information Series C General Description: Check ValvesPeter StanleyNo ratings yet

- 1 s2.0 S2667312622000414 MainDocument6 pages1 s2.0 S2667312622000414 MainWahidNo ratings yet

- InternshipDocument17 pagesInternshipShivam TiwariNo ratings yet

- Calculating The Pump Head - PDF - Extract PDFDocument1 pageCalculating The Pump Head - PDF - Extract PDFVISHALNo ratings yet

- Va1 Dec 2Document15 pagesVa1 Dec 2Xuân Định LêNo ratings yet

- z9611BR - Norgren Process Fluid Control - EN - LRDocument32 pagesz9611BR - Norgren Process Fluid Control - EN - LRShigueo EnamotoNo ratings yet

- Glass sterilization hydraulic designDocument16 pagesGlass sterilization hydraulic designSamuel OrozcoNo ratings yet

- Subject Index: Refinery Engineering: Integrated Process Modeling and Optimization, First EditionDocument15 pagesSubject Index: Refinery Engineering: Integrated Process Modeling and Optimization, First EditionzironelNo ratings yet

- Section 8001: Specifications, Troubleshooting, Inspections and Hydraulic Pressure SettingDocument52 pagesSection 8001: Specifications, Troubleshooting, Inspections and Hydraulic Pressure SettingHelioNo ratings yet

- Lecture 3 - 2 - Fire Tube BoilersDocument26 pagesLecture 3 - 2 - Fire Tube BoilersFEALABREPORTSNo ratings yet

- Controlled Atmosphere StorageDocument9 pagesControlled Atmosphere StorageAnaniah BlessingNo ratings yet

- CNG Bike PDFDocument15 pagesCNG Bike PDFKrishnaNo ratings yet