Professional Documents

Culture Documents

Introduction To Coiled Tubing Unit Final Touch

Uploaded by

Ovaid MehmoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Coiled Tubing Unit Final Touch

Uploaded by

Ovaid MehmoodCopyright:

Available Formats

Introduction of Coiled Tubing Unit & Its Applications

1

Introduction to Coiled Tubing Unit & Its Applications

While the hunt for the oil and its economical availability goes on, the oil industries are indulged

in an everlasting quest for the more efficient and cost effective works for the exploration and

production jobs to acquire the hydrocarbons with the least expenses. The industry has under gone

many development and revolution that has given this business a new height and fame in every

possible way including the usage of fossil fuel and natural gas in newly arrived industries and for

the growth of recently introduced technologies that has not only eased the capabilities of

different working sectors but also helped many underdeveloped or even undeveloped countries to

make their statement on an international level.

Apart from many revolutions in the worlds most renowned work field, the coiled tubing has

been making its name more and more far and wide ever since it was first used in the late 1960s

and not only it has groomed itself for its working and design but also this technology has added

many other extra and overtime jobs under its name and still it is making its name as a cheap

solution for many drilling and production oriented problems and looks a healthy competitor to

snatch the job of conventional works with its modern working and equipments. Not only this

unit has under gone many developments but also has many of the conventional and

unconventional workings that have been performed by it. Coiled tubing (CT) has become an

important tool regarding to the different well operations due to its ever increasing usage in many

well operations, reduction in the cost and improving reliability, the technology got higher

acceptance all around.

A Brief History

Early coiled tubing (CT) technology can be traced to project PLUTO (Pipe Lines under the

Ocean) which was a top-secret effort to install pipelines across the English Channel during

World War II.

In June 1944, Allied engineers deployed several pipelines across the English Channel to provide

fuel for forces. The lines had 40-ft [12-m] joints of 3-in. inside diameter (ID) and 0.212-in. thick

steel pipe welded together to form 4,000-ft [1,220-m] sections.

End-to-end welding technique was used to join these long pipes and was spooled onto 40-ft

diameter floating drums that were towed behind cable-laying vessels. 23 pipelines ranging in

Introduction of Coiled Tubing Unit & Its Applications

2

length from 30 to 70 miles [48 to 113 km] were successfully deployed that made the stage set for

the usage of coiled tubing in the near future on oil and gas wells.

Modern CT injector heads elements were made because by an innovative idea taken from

Bowen Tools Co. when they deployed radio antennae on to the ocean surface using submarines

submerged as deep as 600 ft. [183 m] in the early 1960s. The antennae were stored on a spool

beneath the injector for easy extension and retrieval.

Afterwards, the first CT unit was built by Bowen Tools and the California Oil Company in 1962,

that included an injector rated for surface loads up to 30,000 lbm [13,608 kg] that ran a

continuous string of 1.315-in. outside diameter (OD). The units 9-ft [2.7-m] diameter storage

reel included a hub with a rotating fluid swivel to allow continuous pumping down the coiled

tubing and it was used for sand wash out, sub-surface valve retrieval and for lifting of the fluids

from the well.

But due to the low yield-strength steels with end-to-end or butt welds, the tubing could not

withstand repeated bending cycles and high tensile loads. As a result, the weld failed and the

equipment broken down that caused operators to lose confidence in this technology.

Bowen Tools, Brown Oil Tools, Uni-Flex, Inc., Hydra Rig Inc. and Otis Engineering, continued

making improvements in CT equipment and injector heads in the 1970s.

In 1980, Southwestern Pipe introduced 70,000-psi (70-kpsi) [483-MPa] high-strength, low-alloy

(HSLA) steel coiled tubing with 112-in. and 134-in. OD

In 1983, Quality Tubing Inc. began using 3,000-ft [914-m] sheets of Japanese steel that reduced

the joints up to 50% and also bias welding was introduced to take over the butt welds. Bias

welding involves cutting flat steel strips diagonally to enhance tubing life by spreading the heat-

affected weld zone spirally around the tube.

In 1990, the first string of 2-in. coiled tubing was milled for a permanent well completion.

Today, coiled tubing is manufactured from steel with high yield strengths of 90, 100, 110 and

120 kpsi [620, 689, 758 and 827 MPa] with corrosion resistant alloys.

Higher strength steel, larger diameters and the need to reduce costs were key factors behind the

CT revolution.

History of Coiled Tubing Drilling

Coiled Tubing Drilling has a history dating back almost 100 years but the first official coiled

tubing drilling rigs were developed in 1964 by the Cullen Research Institute. The first

commercial system was developed in 1976 by the Canadian company, Flex tube. CTD as we

know it today really started to develop in the early 1990s and in the third quarter of 1991 the

Introduction of Coiled Tubing Unit & Its Applications

3

first serious attempt was made to drill horizontally with coil. This was done by Oryx Energy in

combination with a CT company and 3 directional service companies. Throughout the 1990s

CTD became commonplace in Canada and has since been used around the world with particular

growth in the United States, Alaska and Saudi Arabia.

Core Components of Coiled Tubing Unit

The core components of the coiled tubing unit are as follow:

Injector head

Coiled tubing reel

Power Pack

Control Cabin

Pressure Control Equipment

Now by the assistance of the highly qualified and skilled professionals job on the well will have

been accomplished by the integration of these components successfully.

Introduction of Coiled Tubing Unit & Its Applications

4

Injector Head

Injector heads components are driven by the two sets of uninterrupted chain attached in series of

short gripper block and dependent on the size of tubing being used for performing the job. The

load of the coiled tubing reel is detained by the friction of this gripper block. These endless chain

are moved by the help of hydraulic motors which allowing the run in or out of the wellbore.

Injector head is large working equipment and also consist of the very basic components which

include the following:

Drive chains

Gooseneck or guide arch

Weight indicator

Chain tensioners

Hydraulic motors

Drive Chain

The chains consist of links, gripper blocks and roller bearings (conventional chain).

Control Cabin

Coiled tubing reel

Injector head

Figure 1.1: Coiled Tubing Unit of OGDCL

Introduction of Coiled Tubing Unit & Its Applications

5

Gooseneck or Guide Arch

The gooseneck, or guide arch, work as a guide for the tubing, bending it through the angle as the

tubing leaves the reel, to the vertical position as it enters the top of the injector-head chains.

Profiled rollers support the tubing as it is bent over the gooseneck arc.

Weight Indicator

The weight indicator stipulates the tension applied on the tubing hanging from the injector head

chains.

Figure 1.2

2

: Drive Chain Parts

Figure 1.3

3

: Gooseneck or Guide Arch

Introduction of Coiled Tubing Unit & Its Applications

6

Chain Tensioners

As the coiled tubing is run deeper into a well, the injector chain experienced increasing load on

it, therefore requiring an enlarged force to the gripper blocks to sustain enough traction. This is

accomplished by consuming the applied hydraulic pressure in the inside chain tensioner system.

Hydraulic Motor

Hydraulic motor deliver the power to move the tubing in and out of the well during performing

the job.

Coiled Tubing Reel

The tubing is mounted on the coiled tubing reel and the transport, storage of tubing is take place

by this reel and the safe and smooth transport of the tubing from the reel to the injector head is

take place by the aid of the CT reel.

Parts of the CT reel are as follow:

Reel drum

Reel drive system

Levelwind assembly

Reel swivel and manifold

Reel Drum

Thousands feet of reel is wounded on the reel drum. It basically carries the entire reel at the

required location.

The capacity of any reel of the required size of tubing is calculated by the given formulae:

L= (A+C) (A) (B) (K)

Where

L = tubing capacity (ft),

A = tubing stack height (in.),

B = width between flanges (in.),

C = reel drum core diameter (in.), and

K = K value for different tubing sizes.

Reel

Drum

Figure1.3

1

: Coiled Tubing Unit of OGDCL

Introduction of Coiled Tubing Unit & Its Applications

7

Reel Drive System and Level-Wind

In usual practice reel use a chain drive connection of the hydraulic motor straddling on the

support frame to a big sprocket on the side of the drum. The motor use to drive the reel also

helpful in providing dynamic braking during slack off to sustain tension on the CT between the

drum and guide arch. When it is programmed to make CT static the reel brake locks the reel in

the very exact position, but should be avoid during use in dynamic braking. During pull out of

hole the reel drive motor have to apply more torque to the drum than necessary to pace the

injector head pull out speed. To keep the CT reel stretched and stiffens the wraps on the drum

this all provided by the superfluous of torque.

Figure1.5

4

: Fully-loaded CT Reel

Introduction of Coiled Tubing Unit & Its Applications

8

Power Pack and Control Cabin

For efficiently working of the coiled tubing unit the uninterrupted supply of power is provided

by the power pack which provide the hydraulic energy for controlling all the functions of the

coiled tubing unit. Mostly the power pack is fuelled by diesel engine.

Main components of power pack are as below:

Engine

Pumps

Pressure control valves

Hydraulic reserves

Filter and strainers

Heat exchangers

Hydraulic fluid

Figure1.6

5

: Typical CT Reel Level-wind and Mechanical Depth Counter

Introduction of Coiled Tubing Unit & Its Applications

9

Engine

The engine is the main power supply unit for the accomplishment of all jobs. It is either truck

mounted engine or separate engine may be used for power supply purpose.

Hydraulic Pump

The hydraulic pumps are driven by the engine. Engine draws oil from the reservoir and powers it

to flow to the several components of the CTU. Pumps in power packs can contrast because of the

demand of the customer choice. Two types of positive displacement hydraulic pumps are used in

a CTU power pack:

Vane pumps

Piston pumps.

Vane pumps

Vane pumps are the old pump of CTU power pack. Vane pumps are inexpensive than piston

pumps and very reliable. They are fewer complexes to hydraulic oil contamination and run at a

lesser temperature.

Piston pump

Piston pumps are newer models of hydraulic pumps for power pack and more efficient. These

pumps can generate higher pulling forces. A Denison P16 is an example of a piston pump used in

CTU power packs. Piston pumps are, more profound to hydraulic oil contamination and more

expensive than vane pumps.

Figure1.7

6

: Vane pumps

Figure1.8

7

: Piston Pump

Introduction of Coiled Tubing Unit & Its Applications

10

Pressure Control Valves

These valves have installed to maintain the pressure in optimum working limits during

performing of any job. It also has a relive valve for regulating the pressure. Its purpose is to

bounds the pressure in a system to a fixed extreme by diverting some or all of the flow to the

hydraulic fluid reservoir.

Now for the running of the CT operation in a proficient manner a control cabin is required which

contain all the necessary control instruments which guide the angle of gooseneck, the speed of

ruin in or out of the CT reel in the wellbore, the flow rate of the injected fluid through the reel,

control of the BOPs, and so much other minute operations related to the whole coiled tubing

working operations. The control cabin is fixed on the separate skid or may be on the truck

permanently attached.

Pressure Control Equipment

The last and the most deciding component of the coiled tubing unit is the pressure control

equipment, because for safe, reliable and efficient working of the job the influx of unwanted

fluid during the job is only managed and controlled by the use of BOPs.

The basic components associated with the pressure control equipment are:

Stripper

Quad and Combi BOPs

Quad and Combi BOPs comprise the following components:

Blind rams

Shear rams

Pipe rams

Equalizing valves

Top and bottom connection

Side port and pressure port

Stripper

The stripper (stuffing box) between the BOP and the injector head delivers the major effective

seal between pressurized wellbore fluids and the surface environment, during run in or out of

hole with a surface pressure. To provide the necessary stiffness or the seal is accomplished by

revitalizing the stripper packer which forcefully pushes the inserts to seal against the tubing. To

achieve this strengthened force either applied hydraulically and is operated from the operator

control cab.

Introduction of Coiled Tubing Unit & Its Applications

11

Quad and Combi BOPs

Mostly the BOPs are using with the CT assembly having working pressure of 10000-psi and are

also H

2

S resistant. These are operated from the control cabin mostly hydraulically using the BOP

hydraulic circuit and accumulator. For the operation of the BOP a reserve of the hydraulically

energy is provide by the accumulator.

Blind Rams

When there is no tool or the CT reel or tubing inside of the well then to isolate the pressure from

below Blind rams are designed to work in such circumstances. The design of blind rams

integrates a tight seal arrangement which is being helpful by using the well pressure to assist in

Figure1.9

8

: CT Side Door Stripper

Introduction of Coiled Tubing Unit & Its Applications

12

closing of the rams once they have been initiated. Since the rams provide complete separation,

when it is desire to open the rams a pressure equalization system is required to facilitate the

pressure above and below to be balanced.

Shear Rams

In very extreme situation when there is no alternate to loss the part of tubing inside the well

Shear rams are the only solution to operate. This may happen under any uncertain conditions,

and the importance in shearing the tubing is ordinarily to preserve the safety of the well. After

losing the part of tubing in the well the tubing at the surface is wound back to reel and to retrieve

the tubing from the well fishing technique have to adopt. In Combi BOP configurations, the

blind ram and shear ram operate as combined in one ram set.

Slip Rams

Slip rams are fixed with toughened steel inserts which are formed to the profile of the tubing.

When sealed, they hold the CT and are skilled of assistant the weight of the tubing in the well, or

force acting to push the tubing from the wellbore. Slip rams are usually closed in combination

with the pipe or shear rams

Figure1.10

9

: Stewart and Stevenson Quad BOP

Introduction of Coiled Tubing Unit & Its Applications

13

Applications of Coiled Tubing Unit

The approach we have used in this thesis is first precisely explain the abundant worldwide

accepted applications of the coiled tubing unit and then provide reader a profound knowledge of

the applications practiced especially by coiled tubing unit of Oil & Gas Development Company

Pakistan on their oil & gas fields. In oil and gas industry before the invent of coiled tubing unit

many application perform by conventional method which required extraneous labor and much

wastage of time but after the innovation in oil & gas industry many new equipments introduced

by the manufacturer which steadily bring a revolution in this customary industry where it is a

myths that professionals associated with the oil industry were reluctant to adopt the new

equipments and methods but the coiled tubing unit confound all the myths associated with this

industry.

Generally the basic applications of coiled tubing unit are as follow:

Work over and completion application

Drilling applications

Pipeline applications

Permanent installation

Work over and completion application:

CT is usually used as worthwhile solution for frequent work over applications. A fundamental

benefit of CT in this application is the capability to uninterruptedly circulate through the CT

while using CT pressure control equipment to treat a live well. This prevents potential formation

damage associated with well killing operations. The ability to circulate with CT also enables the

use of flow-activated of hydraulic tools. Further basic features of CT for work over applications

contain the in-built stiffness of the CT string. In addition, CT permits much faster trip times as

compared to jointed pipe operations.

Mostly adopted CT Work over Applications

Mechanical Application Pumping Applications

Setting a plug or packer Removing sand or fill from a wellbore

Fishing Fracturing/acidizing a formation

Perforating Unloading a well with nitrogen

Logging Gravel packing

Scale removal (mechanical) Cutting tubular with fluid

Cutting tubular (mechanical) Pumping slurry plugs

Sliding sleeve operation Zone isolation (to control flow profiles

Running a completion Scale removal (hydraulic)

Straddles for zonal isolation Removal of wax, hydrocarbon, or

hydrate plug

Drilling

Introduction of Coiled Tubing Unit & Its Applications

14

Drilling Applications:

The drilling through the CT reel is latest challenge but the highly skilled professionals get

through this challenge and drilled many formations by it. Initially a question mark was put either

the drilling through CT would be possible or beneficial or not but now it experienced and the

answer is Yes. Drilling by CT have many advantages over the conventional drilling method in

definite applications but it also has a number of limitations that a driller engineer must be aware

before compelling the decision of drilling through CT. CT does have distinctive proficiencies

that make it excel in true underbalanced drilling, although overbalanced drilling also take place

with CT, but the specialization of CT is underbalanced drilling.

Pipeline applications:

CT can be used as an effective tool for several pipeline applications, including:

Transportation of inspection tools

Removing organic deposits and hydrate plugs

Removing sand or fill

Placing a patch or liner to repair minor leaks

Setting temporary plugs

Permanent installation:

Regardless of many applications of CT as a unit some applications of CT are little bit unique

because of their conventional methodology of job performing such as the entire permanent

installation of the CT reel in the wellbore for production or injection of fluid. The further

applications include flow lines, velocity strings, and control lines.

The largest market for composite CT is for flow line and pipeline installations. Velocity strings

are the final resting place for many used CT strings. And, control lines are the largest market for

small diameter CRA tubing.

Main objective is of our thesis are the the applications of the coiled tubing unit mostly

executed under the supervision of Pakistan largest exploration & Production stake holder

formerly called Oil & Gas Development Company Limited Pakistan, OGDCL on their fields

This thesis focuses on the work over and completion applications accomplished by the coiled

tubing unit of OGDCL on their fields.

Our determination of selecting this topic is to make a comparative study and explore the

distinctive applications of the coiled tubing unit practiced worldwide and practiced in Pakistan

especially by the OGDCL on their fields and also discover the number of applications mostly

performed by the CT unit of OGDCL on their fields.

Our thesis emphasis on getting answers of the following basic questions regarding the execution

of the jobs of coiled tubing unit.

Introduction of Coiled Tubing Unit & Its Applications

15

In work over and completion category numerous jobs were performed word wide by this coiled

tubing unit, in Pakistan under the supervision of OGDCl which jobs commonly performed by

them.

What is the reason of performing a job on a well?

What results will be expected after the completion of job

What procedure adopted for the entire job performance

What will be the working efficiency, limitations, of the unit?

In drilling applications:

In Pakistan where the drilling is mostly take place by conventional method but in Canada and in

some states of USA expended innovation occur in the field of drilling also, and now coiled

tubing unit also used for drilling a well. Well focus to find out whether in Pakistan any attempt

was made by this coiled tubing unit for drilling purposes. If yes then what are the parameters

which must be fulfilled before taking initiative of drilling a well by this unit. Design of entire

BHA for drilling, WOB for drilling, characteristics of the drilling fluid used, maximum depth

that can be drilled by CT reel, compatible formation for drilling by CT

You might also like

- Resumes & Cover Letters For PHD StudentsDocument25 pagesResumes & Cover Letters For PHD StudentsEsther Fernandez VarelaNo ratings yet

- The Approximate Equation in My KnowledgeDocument3 pagesThe Approximate Equation in My KnowledgeOvaid Mehmood100% (1)

- PTW QuestionareDocument63 pagesPTW QuestionareIshtiaq Ahmad100% (2)

- DEWA Electrical Installation Regulations Section 1 OverviewDocument123 pagesDEWA Electrical Installation Regulations Section 1 Overviewsiva_nagesh_280% (5)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Welltec Corporate Presentation - PDFDocument18 pagesWelltec Corporate Presentation - PDFzapspaz0% (1)

- Hireena Essay AnsDocument2 pagesHireena Essay AnsTasniiem ChandraaNo ratings yet

- Coiled Tubing For Downhole ProcessDocument10 pagesCoiled Tubing For Downhole ProcessCristian BarbuceanuNo ratings yet

- Coiled Tubing & SnubbingDocument4 pagesCoiled Tubing & SnubbingMichael LunaNo ratings yet

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- Coiled Tubing Down Hole ToolsDocument9 pagesCoiled Tubing Down Hole Toolsanthony lakpahNo ratings yet

- CT FatigueDocument29 pagesCT Fatiguefrank vNo ratings yet

- CTU202 ACTE - CH 02b - BJ CT Tools CatalogDocument123 pagesCTU202 ACTE - CH 02b - BJ CT Tools CatalogPaul0% (1)

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- Alternate Path Technology: Higher Production From Gravel-Packed WellsDocument8 pagesAlternate Path Technology: Higher Production From Gravel-Packed WellsNatasha Perez EscobarNo ratings yet

- (Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During PerforatingDocument8 pages(Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During Perforatingjlbarretoa100% (1)

- PPE I PR 005Document11 pagesPPE I PR 005MahanderOadNo ratings yet

- SPE-108284-Sucker RodDocument14 pagesSPE-108284-Sucker RodRuben ChirinosNo ratings yet

- CTHBDocument543 pagesCTHBJose AcostaNo ratings yet

- Why Coiled Tubing Fails and HowDocument56 pagesWhy Coiled Tubing Fails and HowArdita S IrwanNo ratings yet

- 37 Coiled TubingDocument45 pages37 Coiled TubingBrahim LetaiefNo ratings yet

- Seal Assemblies (Locator, Anchor, Latch)Document2 pagesSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanNo ratings yet

- Coil Tubing TractorDocument7 pagesCoil Tubing TractorRamanamurthy Palli100% (1)

- PETE 411 Plugback Cementing LessonDocument42 pagesPETE 411 Plugback Cementing LessonAdhi NugrohoNo ratings yet

- Well Intervention CoilHose A4Document2 pagesWell Intervention CoilHose A4William EvansNo ratings yet

- 6 MandrelsDocument17 pages6 MandrelsEduardoWireNo ratings yet

- Perforation: Omega 2013Document73 pagesPerforation: Omega 2013Igbereyivwe TejiriNo ratings yet

- Buckling Analysis in Deviated Wells A Practical MethodDocument10 pagesBuckling Analysis in Deviated Wells A Practical Methodsabilco13No ratings yet

- MB Coiled Tubing PresentationDocument20 pagesMB Coiled Tubing Presentationcmrig74No ratings yet

- Presentasi Coiled Tubing - Virnando Batu AraDocument20 pagesPresentasi Coiled Tubing - Virnando Batu AraVirnando NainggolanNo ratings yet

- Model E Hydraulic Setting ToolDocument1 pageModel E Hydraulic Setting ToolrezaNo ratings yet

- Tru Tubing TechDocument33 pagesTru Tubing TechPieter HarryNo ratings yet

- 8 Keith Henning - Halliburton PDFDocument21 pages8 Keith Henning - Halliburton PDFAnita Kurniati AbadiyahNo ratings yet

- Maxfire Electronic Firing Systems: Conveyance and Triggering OptionsDocument7 pagesMaxfire Electronic Firing Systems: Conveyance and Triggering OptionsGabriel GonzalezNo ratings yet

- Fracturing StimulationDocument9 pagesFracturing StimulationVlassis SarantinosNo ratings yet

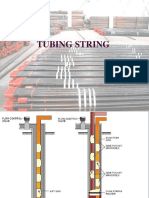

- Tubing StringDocument32 pagesTubing StringKAORU AmaneNo ratings yet

- OptiSleeve Sliding SleeveDocument3 pagesOptiSleeve Sliding SleeveRichard More LeonNo ratings yet

- Pipe - Cut Off MethodsDocument35 pagesPipe - Cut Off MethodsClOudyo VirgílioNo ratings yet

- Recommended Practice for Open Hole Sidetrack DrillingDocument5 pagesRecommended Practice for Open Hole Sidetrack DrillingAdel Ahmed AlkhaligyNo ratings yet

- 29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingDocument6 pages29!541 Transient Aspects of Unloading Oil and Gas Wells With Coiled TubingWaode GabriellaNo ratings yet

- Manual Coiled Tubing p1Document500 pagesManual Coiled Tubing p1Luis Fernando Grajales MorenoNo ratings yet

- Completion ComponentsDocument28 pagesCompletion ComponentsnabiNo ratings yet

- Wellheads 01 PDFDocument12 pagesWellheads 01 PDFLogy Mohamed ElrweedyNo ratings yet

- Squeeze Cementing Techniques for Wellbore RepairDocument41 pagesSqueeze Cementing Techniques for Wellbore RepairMehdi AlizadehNo ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Drilling With Casing Promises Major BenefitsDocument12 pagesDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaNo ratings yet

- Coil TubingDocument15 pagesCoil TubingOgbadiboNo ratings yet

- Coiled Tubing CompletionDocument9 pagesCoiled Tubing Completionreborn2No ratings yet

- Analysis of An Annular Pressure Buildup Failure During Drill AheadDocument6 pagesAnalysis of An Annular Pressure Buildup Failure During Drill AheadJulian OlarteNo ratings yet

- X-Mass Tree & Wellhead Unit 1 Part ADocument46 pagesX-Mass Tree & Wellhead Unit 1 Part AAarzoo Jobanputra100% (1)

- Spe 196232 MSDocument18 pagesSpe 196232 MShijoetigreNo ratings yet

- Coiled-Tubing Desing and OptimizationDocument10 pagesCoiled-Tubing Desing and OptimizationRFVNo ratings yet

- C 06.C Wellhead DesignDocument6 pagesC 06.C Wellhead DesignJose David Hernandez OteroNo ratings yet

- Mandrel Hangers 01Document1 pageMandrel Hangers 01arianaseriNo ratings yet

- 4-06 Tandem Side Loading Stripper PackerDocument14 pages4-06 Tandem Side Loading Stripper PackerDEATH ASSASSIN GAMERNo ratings yet

- PCE Coiled Tubing Dual Action Hydraulic Jar ManualDocument13 pagesPCE Coiled Tubing Dual Action Hydraulic Jar ManualAhmedNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Chinese Uni DetailsDocument3 pagesChinese Uni DetailsOvaid MehmoodNo ratings yet

- Work Schedule Driver's Rest AreaDocument3 pagesWork Schedule Driver's Rest AreaOvaid MehmoodNo ratings yet

- Skiptrace - Export Chattanooga - TN Senior Owner - 10 Yr Owner - 5 Properties or More - Fail Listing-IDocument448 pagesSkiptrace - Export Chattanooga - TN Senior Owner - 10 Yr Owner - 5 Properties or More - Fail Listing-IOvaid MehmoodNo ratings yet

- Sihala Disposal Sheet RFQ Part BDocument1 pageSihala Disposal Sheet RFQ Part BOvaid MehmoodNo ratings yet

- Electrical Safety TrainingDocument2 pagesElectrical Safety TrainingOvaid MehmoodNo ratings yet

- Registration of Partnership FirmDocument3 pagesRegistration of Partnership Firmbilal0% (1)

- Procurement Schedule & Work Mthadology (Watch Tower)Document8 pagesProcurement Schedule & Work Mthadology (Watch Tower)Ovaid MehmoodNo ratings yet

- Description of ItemDocument21 pagesDescription of ItemOvaid MehmoodNo ratings yet

- Work Schedule ChakpiranaDocument16 pagesWork Schedule ChakpiranaOvaid MehmoodNo ratings yet

- Electrical Safety TrainingDocument2 pagesElectrical Safety TrainingOvaid MehmoodNo ratings yet

- Conflict of interest disclosure formDocument1 pageConflict of interest disclosure formOvaid MehmoodNo ratings yet

- Train The Trainer Manual 2Document48 pagesTrain The Trainer Manual 2Khoso AijazNo ratings yet

- Sucker Rod Failure Analysis: A Special Report From NorrisDocument24 pagesSucker Rod Failure Analysis: A Special Report From NorrisOvaid MehmoodNo ratings yet

- Construction Materials Catalogue with PricesDocument21 pagesConstruction Materials Catalogue with PricesOvaid MehmoodNo ratings yet

- Creative Writing PortfolioDocument24 pagesCreative Writing PortfolioAmit KumarNo ratings yet

- EMCompass Note 71 AI Investment TrendsDocument8 pagesEMCompass Note 71 AI Investment TrendsOvaid MehmoodNo ratings yet

- Basic Invoice TemplateDocument21 pagesBasic Invoice TemplateSaorabh KumarNo ratings yet

- Serial No. Item Description Quantity Unit Amount Rs. Rate/Unit Price RsDocument3 pagesSerial No. Item Description Quantity Unit Amount Rs. Rate/Unit Price RsOvaid MehmoodNo ratings yet

- Electrical Safety TrainingDocument2 pagesElectrical Safety TrainingOvaid MehmoodNo ratings yet

- Ministry of Interior: Situation VacantDocument2 pagesMinistry of Interior: Situation VacantEmran ShamNo ratings yet

- British Council Core Skills Nov 2014Document6 pagesBritish Council Core Skills Nov 2014Imran HasanNo ratings yet

- Characterization CyclodextrinDocument13 pagesCharacterization CyclodextrinOvaid MehmoodNo ratings yet

- Change of NameDocument2 pagesChange of NameOvaid MehmoodNo ratings yet

- Emergency Response PlanningDocument8 pagesEmergency Response Planningjr_mcmillinNo ratings yet

- BiomassAtAGlance 11x17Document1 pageBiomassAtAGlance 11x17Gohar AbbasNo ratings yet

- Phone No. 051-9205075 Ext. 385, 377,236,243,241 & 298Document7 pagesPhone No. 051-9205075 Ext. 385, 377,236,243,241 & 298Zafar Islam ZafarNo ratings yet

- Amorphous PolymersDocument17 pagesAmorphous PolymersOvaid MehmoodNo ratings yet

- Handouts Week-01 PDFDocument17 pagesHandouts Week-01 PDFAyesha Chaudry80% (5)

- VIACRYL VSC 6250w/65MP: Technical DatasheetDocument2 pagesVIACRYL VSC 6250w/65MP: Technical DatasheetPratik MehtaNo ratings yet

- Radiant Tube BurnersDocument18 pagesRadiant Tube BurnersRajeshNo ratings yet

- School newspaper report teaches Present PerfectDocument2 pagesSchool newspaper report teaches Present PerfectMiro MiroNo ratings yet

- Ivf Market in IndiaDocument15 pagesIvf Market in IndiaSunil Tak100% (1)

- ExportDocument18 pagesExportDolon MukherjeeNo ratings yet

- Lewis Carrol: Birth: DeathDocument21 pagesLewis Carrol: Birth: DeathmarialuvsjeffNo ratings yet

- DX DiagDocument42 pagesDX DiagVinvin PatrimonioNo ratings yet

- 2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsDocument15 pages2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsSamuel PintoNo ratings yet

- Cambridge IGCSE: 0450/11 Business StudiesDocument12 pagesCambridge IGCSE: 0450/11 Business StudiesGodfreyFrankMwakalingaNo ratings yet

- V Bhebhe PDFDocument63 pagesV Bhebhe PDFVusi BhebheNo ratings yet

- UNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Document6 pagesUNDERSTANDING CULTURE SOCIETY & POLITICS12 - LAS - Week7Bergonsolutions AingelNo ratings yet

- Genigraphics Poster Template 36x48aDocument1 pageGenigraphics Poster Template 36x48aMenrie Elle ArabosNo ratings yet

- Lecturer No 1 - Transformer BasicDocument1 pageLecturer No 1 - Transformer Basiclvb123No ratings yet

- Eco 301 Final Exam ReviewDocument14 pagesEco 301 Final Exam ReviewCảnh DươngNo ratings yet

- 236b3 Esquema Electrico Mini Cargador CatDocument29 pages236b3 Esquema Electrico Mini Cargador Cathenry laviera100% (2)

- Advancements in Organic Rankine Cycle System Optimisation For Combined Heat and Power Applications Components Sizing and Thermoeconomic ConsiderationsDocument14 pagesAdvancements in Organic Rankine Cycle System Optimisation For Combined Heat and Power Applications Components Sizing and Thermoeconomic ConsiderationsGuadalupe Abigail Rueda AguileraNo ratings yet

- Assurance Audit of Prepaid ExpendituresDocument7 pagesAssurance Audit of Prepaid ExpendituresRatna Dwi YulintinaNo ratings yet

- Flow Through Pipes: Departmentofcivilengineering Presidency University, Bangalore-64 BY Santhosh M B Asstistant ProfessorDocument15 pagesFlow Through Pipes: Departmentofcivilengineering Presidency University, Bangalore-64 BY Santhosh M B Asstistant ProfessorSanthoshMBSanthuNo ratings yet

- Booklet English 2016Document17 pagesBooklet English 2016Noranita ZakariaNo ratings yet

- MechanismDocument17 pagesMechanismm_er100No ratings yet

- Goldenberg and Reddy (2017)Document10 pagesGoldenberg and Reddy (2017)Mariana ToniniNo ratings yet

- ZO 503 Physiological Chemistry by Dr.S.S.KunjwalDocument22 pagesZO 503 Physiological Chemistry by Dr.S.S.KunjwalAbhishek Singh ChandelNo ratings yet

- Scrum Quiz - FinalDocument8 pagesScrum Quiz - FinalSangram PandaNo ratings yet

- Working Capital Management (2015)Document62 pagesWorking Capital Management (2015)AJNo ratings yet

- Iwwusa Final Report IdsDocument216 pagesIwwusa Final Report IdsRituNo ratings yet

- Aemses Sof Be LCP 2021 2022Document16 pagesAemses Sof Be LCP 2021 2022ROMEO SANTILLANNo ratings yet

- Bioav 3Document264 pagesBioav 3Sabiruddin Mirza DipuNo ratings yet