Professional Documents

Culture Documents

Bio Fuel Production in Brazil

Uploaded by

Dee RajanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bio Fuel Production in Brazil

Uploaded by

Dee RajanCopyright:

Available Formats

BIO FUEL

PRODUCTION IN

BRAZIL

DHUWARAHA RAJATHELKAN

Banner ID: B00172276

BEng (Hons) CHEMICAL ENGINEERING

Supervisor: Mr Joseph Heffernan

ENGG 09018 Independent Study

School of Engineering

Page | 2

1 STATEMENT OF AUTHENTICITY

This Individual Study Module Report was prepared by Dhuwaraha Rajathelakan

(B00172276) a student on the Chemical Engineering course at the University of

West of Scotland. This report is my work solely and it has not been submitted

previously for any academic award.

Signed________________________ Date___________________

Page | 3

Table of Contents

1 STATEMENT OF AUTHENTICITY ...................................................................... 2

2 INTRODUCTION ................................................................................................. 4

3 BACKGROUND ................................................................................................... 5

4 HOW ITS MADE ................................................................................................. 6

4.1 GROWING THE SUGARCANE IN THE FIELD ............................................. 8

4.2 TRANSFER OF THE SUGARCANE FROM THE FIELD TO THE MILL ....... 9

4.3 MILLING OF THE SUGARCANE ................................................................ 10

4.4 MIXING AND FILTERING OF THE SUGARCANE ..................................... 10

4.5 DISTILLATION OF THE SUGARCANE ...................................................... 11

4.6 STORAGE OF THE END PRODUCT ......................................................... 11

5 ADVANTAGES AND DISADVANTAGES OF BIO-FUEL IN BRAZIL ................. 12

6 BIO-DIESEL PRODUCTION IN BRAZIL ........................................................... 14

7 BRAZILS ENERGY MATRIX ............................................................................ 16

8 WORLD MARKET OF BIO FUELS .................................................................... 17

9 ETHANOLS LOCAL ENVIRONMENTAL IMPACT ............................................ 19

10 BIO-DIESELS LOCAL ENVIRONMENTAL IMPACT ........................................ 22

11 DISCUSSION .................................................................................................... 22

12 REFERENCE..................................................................................................... 23

Page | 4

2 INTRODUCTION

The purpose of this report is to research about Bio-fuel production in Brazil and

compare it to bio-fuel production around the world consequently meeting the

requirements for a module called Independent Study at the University of West of

Scotland. The aim of this report is to determine whether bio-fuel production in Brazil

is beneficial to the population. This report consists of many sections each discussing

a different aspect of the bio-fuel production such as pros and cons, how its made,

the world market, environmental impact, etc. The research will include a variety of

references from books, journals, internet and articles.

Page | 5

3 BACKGROUND

Bio-fuel is fuel that is made from biological materials and bio-fuel production is a

great way to minimise greenhouse gas emissions. The most commonly used

material of such would be plants and any waste that living things produce. In the past

few years there has been a struggle in the search of a renewable energy due to the

worries of global warming. The sugarcane ethanol industry in Brazil has had a great

advantage due to this. Crops that are grown by farmers are sold to refineries for the

production of bio-fuel. Bio-ethanol and bio-diesel are the two major source of bio-

fuel. Petrol and diesel are fossil fuels which are finite therefore it is very important to

have more renewable and ecological fuels such as bio-ethanol and bio-diesel. By

switching to these fuel types the percentage of carbon footprint can be reduced

because transport is one of the largest greenhouse gas emitters. Bio-diesel is made

from soya beans, oily plants, animal fats, but the most commonly used oil would be

rapeseed oil. Bio-diesel can be used in any diesel operated vehicles without making

any alterations to the engine. On the other hand fermentation of sugar cane is used

in the production of bio-ethanol and other materials such as wheat, corn and other

sugary plants. However unlike diesel engines petrol engines need to be modified

unless it is a modern engine because that can take up to 10 percent of ethanol

without having any alterations being carried out to the engine. United States of

America and Brazil are the worlds largest producers of ethanol fuel and together

lead the industrial production. The most maintainable bio-fuel economy is known to

be in Brazil due to the large amount of lands for agriculture. The sugar cane ethanol

produced has been a great success for transportation which reduces emissions and

acts as a model for many other countries which want to switch to bio-fuel for

development.

Page | 6

4 HOW ITS MADE

The main ingredient used to make bioethanol in Brazil is sugarcane. The whole

process roughly takes about 12 hours and contains 6 main stages. These are:

1. Growing the sugarcane in fields.

2. Transfer of the sugarcane from the field to the mill and unloading it.

3. Milling of the sugarcane.

Page | 7

4. Mixing and filtering of the sugarcane.

5. Distillation of the sugarcane.

6. Storage of the end product.

Page | 8

Figure 4. Cultivator

Figure 2. Cane Cutter

Figure 1. Joint knots

Figure 3.Cane Planter

4.1 GROWING THE SUGARCANE IN THE FIELD

A two row cane cutter is used to cut a field full of sugar cane. Then the canes are cut

in to small pieces at the joint knot (the lines on the cane) and at the end of each of

these joint knots there is an eye which is where the new cane grows out from.

These cut sugarcanes are loaded in to the mechanical cane planter. Before the

sugar cane can be planted the soil has to be prepared. A cultivator is first used to cut

several rows and simultaneously mix compost and fertilizer in to the soil, followed by

a tiller which loosens the soil and helps water reach the roots of the canes.

Thereafter the sugarcane plants are dropped in to the cut rows by a mechanical

cane planter. Labourers then walk by the rows to ensure the sugar canes are in the

open rows. A three row coverer then uses soil to cover up the cut rows filled with the

sugarcanes. Finally rollers pack soil on top of new planted cane. These sugarcanes

will be ready to be harvested in 12 to 24 months. The harvesting periods will range

depending on the region and its climate.

Page | 9

4.2 TRANSFER OF THE SUGARCANE FROM THE FIELD TO THE MILL

In this century there is not many manual loading that take place because machinery

can get the job done faster and cost effectively. Self-propelled push pile loaders and

mobile cranes have replaced labourers resulting in a cut of labour charges. These

machineries are mostly used in large areas of land by the growers of the sugarcanes

to get the load on to the vehicles that are going to transport the sugarcanes from the

fields to the mills. Mobile cranes can load up to 30 tonnes per hour and push pile

loaders are capable of loading 30 to 40 tonnes per hour.

Figure 7. Rollers

Figure 5.Tiller Figure 6. Row

Figure 8. Self-propelled push pile loader

Page | 10

4.3 MILLING OF THE SUGARCANE

In the milling stage the transported sugarcane are unloaded and are sent to a

crushing system via conveyor belts. Rollers are then used to squash the juice out of

the canes and the remaining cane fibre which is a by-product called bagasse is sent

to be burned in the boilers. The bagasse process produces high pressure steam by

heating the water. This steam is used for electricity.

4.4 MIXING AND FILTERING OF THE SUGARCANE

The juice that is collected from the crushing process is then heated and there after

sulphur, lime and thickener are added to that mixture. The next stage is to remove

majority of the impurities which is done by pumping the mixture through rotating

filters. This will help separate most of the impurities. Filter cake is a crumbly residue

which remains from the separating process is then recycled and used as natural

fertilisers on the sugarcane fields.

Figure 9. Shredded Sugarcane being crushed to

extract the juice

Figure 10. By-product Bagasse

Figure 11. Rotating Filters

Page | 11

4.5 DISTILLATION OF THE SUGARCANE

The separated fluid is then sent through two distillation columns to further remove

the water from it by heating the mixture. The product produced by this process is

known as hydrated ethanol which is used as fuel for transport. The by-product that is

formed is called Vinasse. It is recycled and sprayed as a fertiliser in the sugarcane

fields. Hydrated ethanol from the second distillation process gets sent to a third

distillation column to further remove more water. The final product of this process is

known as anhydrous ethanol. This ethanol is used mainly by adapted cars in Brazil

called flex fuel. Flex fuel cars can switch between bio ethanol and gasoline.

4.6 STORAGE OF THE END PRODUCT

The finished product which is bio-ethanol is stored is large tanks. It will then be

shipped off to the markets to sell as fuel for customers.

Figure 12. Flex Fuel car models and bio-ethanol pumps

Figure 13. Pressurised storage tanks for ethanol.

Page | 12

5 ADVANTAGES AND DISADVANTAGES OF BIO-FUEL IN BRAZIL

The main advantage of bio-fuel production is that less carbon dioxide is emitted and

greenhouse gases will also be reduced which is a great benefit for the environment.

The main disadvantage would be that large areas are needed for this production,

therefore rain forests and natural habitats are destroyed. This also would result in

monoculture agriculture; meaning only one kind of crop is grown, lacking on variety.

A large impact on biodiversity will occur. This also means that farmers have to limit

the use of sugarcane for other processes to meet the ethanol industries demands.

Because of this the prices of sugarcane products such as feed, sugar and other

grains will increase. Even though this is a disadvantage, Brazils population would

much rather prefer to depend on their native farmers rather than manufacturers from

foreign countries.

Although bio-fuel sounds like a great idea, firstly the question that needs to be asked

is that; is it really a greener production? Despite the fact greenhouses gases are

reduced, bio-fuel releases nitric oxides which are a cause of acid rain. These

disadvantages should be considered before making a big decision about entirely

converting to the greener side. It is a great difficulty for a nation to be dependent

mainly on bio-fuel because it is not guaranteed that the crops will grow on time, due

to things like soil erosion, droughts, insect damage and many more in which the

plant will be vulnerable in. On the other hand ethanol does burn cleaner compared

to gasoline which is a great advantage. The toxins released by cars that use

gasoline is greater compared to cars that use E85 ethanol. E85 ethanol is a blend of

85% ethanol and 15% gasoline. Gasoline contains lead and benzene which are

cancer causing agents. In this comparison ethanol can be considered as an

substitute or even a replacement to gasoline.

Page | 13

Even supposing that ethanol does less damage to the environment, it is very

corrosive. Since ethanol can contain many impurities by simply absorbing water and

dirt, it can damage the car engine by corroding the inside if the filtering process is

unsuccessful.

Majority of the world population are worried about gasoline prices increasing but if

ethanol is instigated nationwide it would cost more than gasoline but have less

efficiency compared. Drivers would pay more for fuel them would not get them as far

as gasoline would. They would also need to travel further to get E85 ethanol

because only particular gas stations would provide it.

While this may give an idea that there are more disadvantages than advantages to

the public, farmers may find it very beneficial. If their crops are linked to the

transporting and food processing industries it will boost their economic status.

There is also a disadvantage in this situation. If the land used to grow the crops is

well-worn, the soil will become washed-out of nutrients such as minerals. This will

result in a less efficient fuel. The production of the ethanol will cost more than the

savings from buying imported oil from foreign countries. This plan would not be a

profitable income to the country.

It is quite difficult to reach a conclusion on this discussion. Saying so, many countries

are going ahead with the production of bio-fuel because it appears to be the most

common and the first alternative fuel that is controlled and executed on a large scale.

This gives opportunities for bio-fuel industries to advance with the construction of

new facilities which in result encourages farmers to increase the size of their

sugarcane farmlands.

Page | 14

6 BIO-DIESEL PRODUCTION IN BRAZIL

Brazil is already on the top of the market for the energy matrix. Due to the expansion

of the worlds economy, energy demands are on the rise. As a result of this worlds

bio-fuel markets are using raw materials to their advantage and producing bio-diesel

as an alternative energy source along-side bio-ethanol. Fossil fuels are eventually

going to run out which means everyone has to turn to bio-fuels one way or another.

Brazil with its soil and great climate has the potential to produce the biomass needed

for the making of bio-diesel. This program will benefit the farmers that live in the

poorer areas.

In January 2005 bio-diesel was introduced as a new fuel in the energy mix. After 3

years 2% of bio-diesel (B2) was blended to diesel oil. The percentage increased by

another 3% (B5) in 2013. Bio-diesel producers are hoping for blend percentage to

keep increasing until B100 is reached in other words 100% bio-diesel. Based on the

grower, seller, feedstock and other raw materials used to produce the fuel it is said

that the tax has been reduced by 2005.

To manufacture and trade this new fuel, the law in Brazil states that all of the bio-

diesel producers must have a Social Fuel Stamp certificate issued by the Agrarian

Development Ministry. This means that feed stock produced from family owned

farms from the poorer areas must be purchased. The percentage will range from

area to area. For example in the Midwest and North it would be 10%, in the South

east regions it would be 30% and the percentage increases as you move on to the

Northeast areas up to 50%. Bio-fuel producers are also expected to sign agreements

with agricultural producers in those regions concerning costs, delivery times, and

schedules and provide technical assistance.

Page | 15

Bio-diesel manufacturers who use other products such as palm oil or castor oil which

are from the North and Northeast get 100% money back on fuel taxes. These oils

have to be purchased from family farms. If the oils are bought from other farms

which a situated in the same regions they will only get a 32% reduction on tax.

Other feedstock, apart from castor oil and palm oil, is grown on family farms the tax

is reduced to 68%.

One of the important aspects of this bio-diesel project is to provide employment and

income opportunities to the poorest regions in Brazil. Another would be that there are

a variety of feed stocks and raw materials present in Brazil for the production of bio-

diesel. Examples of these would be; cotton, soybean, sunflower, castor beans, palm

oil, radish, animal fat, peanuts, etc. Anyone who wants to manufacture and sell bio-

diesel can produce bio-diesel as long as they are registered under the Brazilian

Petroleum, Gas and Biofuels Regulator and have received authorization from them.

This was put in to place by the government to help out family farms therefore

classifying the company as socially friendly.

Figure 14. Family farms in rural areas of Brazil

Page | 16

Figure 16. Energy supply structure (%) in 2012

7 BRAZILS ENERGY MATRIX

In the 1970s Brazil has imported 80% of its oil consumption but now Brazil stands on

its own two feet and is an energy independent country. This greatly successful

transition of producing green fuel puts Brazil ahead by more than 20% of the rest of

the world and makes it the leader of manufacturing renewable energy.

Brazils largest foundation of renewable energy is the sugarcane. This country is very

privileged to have such a diversity of raw materials to produce renewable energy.

Renewable energy has replaced 40% of gasoline making gasoline the alternative

fuel in Brazil.

Figure 15. Brazilian energy matrix in 2012

Page | 17

8 WORLD MARKET OF BIO FUELS

Bio-fuels play a huge role in the petroleum industry by being the solutions to

economic, environmental and energy securities. Bio-fuel production has increased in

the past 10 years with United States of America and Brazil being popular producers

of bio-ethanol and Europe being known for its production of bio-diesel. Researchers

say that bio-ethanol and bio-diesel has a great chance of replacing gasoline.

It is predicted that the world market of bio-fuels will vastly increase over the next 7 to

10 years. In 2011 the market was worth $82.7 billion (49.02 billion) which in 2021

will double to $185.3 billion (109.85 billion). However, there are many negatives

also present in this industry which could prevent it from meeting government orders.

Researchers from Biofuel markets and technologies suggest that there will be a

stable growth in 2016 which will run into a rapid growth between 2017 and 2021.

Compared to bio-diesel production bio-ethanol has a high demand in the industry

and is projected to reach up to $65.7 billion gallons per year (38.95 billion) by 2021.

Bio-diesels price is clarified at $16.2 billion gallons per year (9.60 billion) but bio-

ethanol is dominating with an enormous $50 billion gallon per year (29.64 billion).

A minimum of 38 countries are joining the production of Greener fuel with Brazil

being the largest market of the world followed by The United States of America and

he European union. These three markets globally produced 85% in 2010. 48% of

this production was steered by North America, while Europe was globally

responsible for 49% of bio-diesel production.

Because of financing difficulties of producing the feedstock for bio-fuel production the

rate of which the market growth depends on might drop and not meet the

requirements by 2021.The estimated rate of $71.8 billion per gallon (42.56 billion)

might not be reached.

Page | 18

Figure 18. Biofuels demand by region, Global Market: 2011-2021

Rather than questioning the validity of the biofuel technology for the failure to meet

the future demand, the world fuel market should be examined. This is because

researchers estimated prices of gasoline and diesel to increase by 2021 by more

than double. The gasoline market will be worth at $375 billion per gallon (222.30

billion) and the diesel market will reach up to $427 billion per gallon (253.13 billion).

The aviation and marine fuel demand will also contribute up to $200 billion gallon per

year (118.56 billion) to the world market.

In 2011 the bio-fuel industry gained $29.4 billion per gallon (17.43 billion). Even if

the current production rates were to be doubled it still would be a tough competition

with the gasoline market because the biofuel industry will only represent 7% of the

fuel market.

Figure 17. Biofuels demand by region, Global Market: 2011-2021

Page | 19

9 ETHANOLS LOCAL ENVIRONMENTAL IMPACT

Brazil has around 50 laws put in place for environmental impact of ethanol

production. The main concern of the ethanol production is the discharge of an acidic

distillation residue called Vinhoto in to rivers and lakes of Brazil. The water pollution

issue was solved with the use of lime to neutralize the acidic distillation residue and

recycle it to use it as fertilizers. This fertilizer replaces the use of mineral fertilizers in

sugarcane plantations. Since the 1970s the use of fertilizers in sugarcane fields has

been kept at a constant rate.

The Brazilian Government are doing all they can to control water pollution. To protect

these water resources the main resourcefulness is to recover river boundaries by

replantation. Farmers are persuaded by law to replant to preserve water.

Most sugarcane plantation farmers depend on the rain to feed plants rather than use

collected water. The government are trying to control the amount of water used in

ethanol production because the rate of water consumed in this process is very high.

In 1990s the water consumption rate was 5.6 cubic meters per tonne cane and this

has been reduced to 1.83 cubic meters per tonne cane in 15 years time. The

ethanol production industries are aiming to reduce the water consumption to a

minimum value of 1 cubic meter per tonne cane and decrease the rate of released

effluent to a value close to zero. This value is aimed to be achieved by the reuse of

water.

Water is usually free around most areas of Brazil for the production of ethanol. In

rural areas charging for water is not known amongst the population. This is not yet a

widespread application.

Conferring with the water opportunity cost each river basin is forming a committee

that are in control of creating a pricelist for the water usage of each ethanol plant.

Page | 20

The cost of water is not constant. It fluctuates from individual river basins. In some

states such as Sao Paulo and Rio de Janeiro the committees have fixed rates for the

level of non-treated water consumed.

It costs R$0.01 per cubic meter for non-treated water collected from major rivers and

a higher rate between R$0.07 and R$0.1 per kilogram for polluted water that has

been discharged through the distillation process. It will be cheaper for industries to

treat the water before discharging it.

An additional environmental impact would be the use of herbicides on sugarcane

estates to get rid of pests. This has been reduced due to the new types of sugarcane

which are more unaffected by pests. Farmers are modifying more sugarcane

through agriculture research. This will decrease the usage of herbicides on

sugarcane plantations.

Pests were controlled through burning sugarcane straws and leaves. This was done

manually by labourers but now that mechanical harvesting has been introduced, it is

not clear how the development of pest resistant sugarcanes would be affected. The

productivity of manual harvesting is higher compared to mechanical harvesting but

the burning of sugarcanes produces large amounts of smoke that pollutes the

environment and spreads to nearby cities. Manual harvesting is also a slow and

difficult process due to the leaves and straws of the sugarcane. The burning of

sugarcane had to be took action on due to pollution issues.

Figure 19. Considering Straw from the production of 360 million tonnes of sugarcane burned for harvesting

Page | 21

Manual harvesting eventually was not as popular as mechanical and most industries

started taking on mechanized harvesting. This was because legislations did not allow

the burning of sugarcane at estates situated near urban areas.

Government have suggested all industries to change from manual to mechanical by

2021 because sugarcane leaf can cut workers which is a health and safety issue.

Normally to prevent the leaves from cutting the labourers it would be burned but

because it is not allowed, labourers are forced to use machinery. Farms that are not

on flat area the fixed deadline to convert from manual to mechanical is not until

2031.

Mechanized harvesting reduces the productivity rate by about 30%, so burning

sugarcane cannot completely be stopped but by replanting sugarcane every year

can increase the rate of productivity.

On the up side, since the 1980 the blend of ethanol in to gasoline has improved in

quality therefore reducing pollution rates. This will balance out the pollution given off

during the burning of sugarcane. The blend of ethanol created now completely

eliminates sulphur oxide and carbon and reduces the percentage of carbon

monoxide by 20%. This change has helped Brazil save up to $500 million per year

(296.49 million).

Figure 20. Burning of sugarcane during harvesting

Page | 22

10 BIO-DIESELS LOCAL ENVIRONMENTAL IMPACT

As I mentioned earlier bio-diesel production is still at its earlier stages compared to

ethanol manufacturing. Government are still researching on the environmental

impacts of bio-diesel production by examining the oily plants used for this invention.

The National Agriculture Research Agency of Brazil is executing a research program

by investigating 24 different oil plant producers. These are 24 plants that are already

in use for the production of bio-diesel. These will be monitored to state the

environmental impact of agriculture activities. This project has not succeeded yet

even though research has been going on for 7 years.

11 DISCUSSION

As mentioned in my report earlier, sugarcane ethanol production in Brazil is taking

over rapidly. The use of flex-fuel cars are becoming more and more popular in Brazil.

This suggests that the sugarcane ethanol will be in demand and will also increase in

price in the next 8 to 10 years. Because ethanol production is becoming so popular

more industries need to be built. This results in the land area needed for the

sugarcane plantation to double. To achieve this, 237 million hectares of pastureland

is being rehabilitated. At the moment there are 2.9 million hectares being used for

sugarcane ethanol production.

The main concerns for the expansion of the sugarcane plantation area is that this

might lead to deforestation. This point has not been proven, so there is no evidence

indicating ethanol production is detrimental.

Although the pastureland is being taken over for new industries, farmers make sure

there is adequate space left for the habitat of cattles. However, due to the

disturbances caused by the workers (e.g. noise pollution) will ultimately cause the

cattle to migrate from its natural habitat to the Amazon. This will encourage the

Page | 23

farmers to invade the empty pastureland. This process will turn in to a vicious cycle

leading to more deforestation, which will ultimately result in the natural habitats of the

Amazon being completely destroyed. This theory is not a major concern at this

moment in time,

because the rate at which the land is increasing is to take approximately 10 years for

any real effect to take place.

12 CONCLUSION

13 REFERENCE

1. Ayhan Demirbas (2009) Biofuels: Securing the planets future energy needs

London Springer

2. Wim Soetaert, ed. Erick Vandamme (2009) Biofuels Oxford Wiley

Page | 24

3. R. B. Gupta and A. Demirbas, Gasoline, Diesel, and Ethanol Biofuels From

Grasses and Plants (Cambridge, 2010)

4. Martha J. Groom, Elizabeth M. Gray, Patricia A. Townsend (2008) Biofuels

and Biodiversity: Principles for Creating Better Policies for Biofuel Production

pages 602-609.

5. http://www.bp.com/en/global/alternative-energy/our-

businesses/biofuels/biofuels-operations-technologies/brazil-ethanol-from-

sugarcane.html

6. http://www.shell.com/global/environment-society/environment/climate-

change/biofuels-alternative-energies-transport/biofuels/raizen/sugar-cane-to-

ethanol-animation.html

7. http://www.nicaraguasugar.com/en/what-we-produce/ethanol/production-

process/

8. http://www.scidev.net/global/policy/feature/sugarcane-ethanol-brazils-biofuel-

success.html

9. http://www.esajournals.org/doi/abs/10.1890/07-1813.1

10. http://sugarcane.org/resource-library/studies?b_start:int=20

11. http://www.bbest.org.br/2011/index.php?option=com_content&view=article&id

=75&Itemid=68

12. http://www.buzzle.com/articles/advantages-and-disadvantages-of-biofuels.html

13. http://www.navigantresearch.com/research/advanced-biofuels-country-

rankings

14. http://www.navigantresearch.com/newsroom/access-to-low-cost-feedstocks-

remains-a-key-barrier-to-wider-adoption-of-biofuels

15. http://dc.itamaraty.gov.br/imagens-e-textos/Biocombustiveis-03ing-

biocombustiveisnobrasil.pdf

16. http://www.internationaltransportforum.org/jtrc/discussionpapers/DiscussionPa

per5.pdf

.

http://www.biotechnologyforbiofuels.com/content/1/1/6

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emom Manual: 25 Kettlebell Conditioning WorkoutsDocument14 pagesThe Emom Manual: 25 Kettlebell Conditioning WorkoutsguilleNo ratings yet

- MATERIAL BALANCE Distillation ColumnDocument9 pagesMATERIAL BALANCE Distillation ColumnRajeev Kumar DohareNo ratings yet

- MATERIAL BALANCE Distillation ColumnDocument9 pagesMATERIAL BALANCE Distillation ColumnRajeev Kumar DohareNo ratings yet

- Urea Manufacturing Plant: CH 4200 - Comprehensive Design ProjectDocument124 pagesUrea Manufacturing Plant: CH 4200 - Comprehensive Design Projectwaqas83% (18)

- Lda AssignmentDocument9 pagesLda AssignmentDee RajanNo ratings yet

- Eulers-Method Best Example of Using Euler Method in Chemical ReactionDocument48 pagesEulers-Method Best Example of Using Euler Method in Chemical ReactionSalma SherbazNo ratings yet

- Design of A Plug Flow Reactor (PFR) : Parameters ValuesDocument10 pagesDesign of A Plug Flow Reactor (PFR) : Parameters ValuesDee RajanNo ratings yet

- Plant Engineering 2 - Compressors 1 The Perfect Gas ModelDocument12 pagesPlant Engineering 2 - Compressors 1 The Perfect Gas ModelDee RajanNo ratings yet

- Electricity and Magnetism Part1Document12 pagesElectricity and Magnetism Part1Dee RajanNo ratings yet

- Bai Tap Tieng Anh Lop 8 (Bai 13)Document4 pagesBai Tap Tieng Anh Lop 8 (Bai 13)nguyenanhmaiNo ratings yet

- Carboset CA-600 - CST600 - CO - enDocument3 pagesCarboset CA-600 - CST600 - CO - enNilsNo ratings yet

- Big 9 Master SoalDocument6 pagesBig 9 Master Soallilik masrukhahNo ratings yet

- Pioneer PDP 5071 5070pu Arp 3354Document219 pagesPioneer PDP 5071 5070pu Arp 3354Dan Prewitt100% (1)

- Those With MoonDocument1 pageThose With MoonRosee AldamaNo ratings yet

- Neuro M Summary NotesDocument4 pagesNeuro M Summary NotesNishikaNo ratings yet

- Chemistry Xi: Short Questions and 20% Long QuestionsDocument3 pagesChemistry Xi: Short Questions and 20% Long QuestionsSyed Nabeel HassanNo ratings yet

- 1A Wound Care AdviceDocument2 pages1A Wound Care AdviceGrace ValenciaNo ratings yet

- Sav4747 PDFDocument49 pagesSav4747 PDFAndres Antonio Moreno CastroNo ratings yet

- WWW Spectrosci Com Product Infracal Model CVH PrinterFriendlDocument3 pagesWWW Spectrosci Com Product Infracal Model CVH PrinterFriendlather1985No ratings yet

- Offender TypologiesDocument8 pagesOffender TypologiesSahil AnsariNo ratings yet

- ATI Respiratory PowerpointDocument90 pagesATI Respiratory PowerpointAnn KelseaNo ratings yet

- Heat Transfer ExampleDocument4 pagesHeat Transfer Examplekero_the_heroNo ratings yet

- Sanctuary Policy PomonaDocument3 pagesSanctuary Policy PomonaGabriel EliasNo ratings yet

- 2020 ROTH IRA 229664667 Form 5498Document2 pages2020 ROTH IRA 229664667 Form 5498hk100% (1)

- A Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceDocument16 pagesA Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceiporrasNo ratings yet

- Anti Stain Nsl30 Super - Msds - SdsDocument8 pagesAnti Stain Nsl30 Super - Msds - SdsS.A. MohsinNo ratings yet

- Feeder BrochureDocument12 pagesFeeder BrochureThupten Gedun Kelvin OngNo ratings yet

- Recruitement Process - Siemens - Sneha Waman Kadam S200030047 PDFDocument7 pagesRecruitement Process - Siemens - Sneha Waman Kadam S200030047 PDFSneha KadamNo ratings yet

- Lab Manual PDFDocument68 pagesLab Manual PDFSantino AwetNo ratings yet

- 6Document2 pages6Min Hsuan HsianNo ratings yet

- Comparison and Contrast Essay FormatDocument5 pagesComparison and Contrast Essay Formattxmvblaeg100% (2)

- Demages Goods RecordDocument22 pagesDemages Goods Recordtariq malikNo ratings yet

- Viscoline Annular UnitDocument4 pagesViscoline Annular UnitjoquispeNo ratings yet

- Phardose Lab Prep 19 30Document4 pagesPhardose Lab Prep 19 30POMPEYO BARROGANo ratings yet

- 2 Dawn150Document109 pages2 Dawn150kirubelNo ratings yet

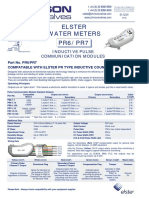

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- RRC Group D Notification 70812Document11 pagesRRC Group D Notification 70812admin2772No ratings yet

- Intershield803 MDSDocument4 pagesIntershield803 MDSSahanNo ratings yet