Professional Documents

Culture Documents

15 - Pipe Thickness Calculations

Uploaded by

rasnowmah2012Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15 - Pipe Thickness Calculations

Uploaded by

rasnowmah2012Copyright:

Available Formats

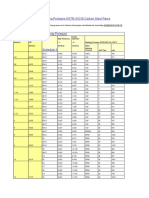

Calculate the Velocity of Gas in 6" Pipeline (Pipeline Rules of Thumb Handbook)

Min Max

v = 1440 * Z * Q * T where : v = velocity of gas, ft/sec 5 30

d

2

* P Z = Compressibility 0.94 0.94

Q = Volume, MMSCFH

T = Operating Temperatur, R 660 660

d = Inside diameter of pipe , inches 6.193 6.193

P = Operating Pressure, psia 600 600

Q = 0.128792073 MMSCFH

3.088538921 MMSCFD Minimum

Q = 0.772752438 MMSCFH

18.53123352 MMSCFD Maksimum

maksimum velocity should be limited to acceptable noise level (60 to 80 ft/s)

minimum velocity should be limited to about 3 - 10 ft/s refer to API RP 14 E if there are solid particles

Hasil perhitungan diatas menunjukan bahwa pipa 6" dapat mengalirkan gas dengan kapasitas maksimum sebesar

37 MMSCFD dan minimum sebesar 3 MMSCFD

Sumur Makmur #25 berada pada satu area dengan sumur-sumur makmur 1, 2, 4, 6, 17 dan 23. Sumur-sumur tersebut

mempunyai zona G-50 series yang kandungan gasnya sangat potensial dan apabila ke-6 sumur tersebut zona gasnya di

produksikan, maka fasilitas 6" trunkline yang diajukan akan dapat menampung gas dari ke-6 sumur tersebut.

Sumur Makmur #25 berada pada satu area dengan sumur-sumur makmur 1, 2, 4, 6, 17 dan 23. Sumur-sumur tersebut

mempunyai zona G-50 series yang kandungan gasnya sangat potensial dan apabila ke-6 sumur tersebut zona gasnya di

produksikan, maka fasilitas 6" trunkline yang diajukan akan dapat menampung gas dari ke-6 sumur tersebut.

Sheet No. : 1 of 3

LINE NO : 121-6-GR-CCD-XXX REV : A

LEGENT : Trunkline Calculation

AFE NO : 08-1318 DATE : 05-Dec-08

TABLE OF CONTENTS

Hal.

1 GENERAL DATA 2

2 Pipe Thickness Calculation 3

0 Sheet No. : 2 of 3

LINE NO : 121-6-GR-CCD-XXX REV : A

LEGENT : Trunkline Calculation

AFE NO : 08-1318 DATE : 05-Dec-08

1. GENERAL DATA

Design Code = ASME B31.8

Design Pressure = 1350 Psi (ANSI 600)

Corrosion Allowance = 1.6 mm

Design Temperatur = 200 F = 93.33 C

MATERIAL = API 5L Gr B Sch 80

Basic Quality Factor For longitudinal weld joints = 0.85

Radiography = Spot

Diameter = NPS 6

Sheet No. : 3 of 3

LINE NO : 121-6-GR-CCD-XXX REV : A

LEGENT : Trunkline Calculation

AFE NO : 08-1318 DATE : 05-Dec-08

2 Thickness Calculation

tm = t + c

1 - u t = P

i

d

o

2 S

mys

E F T

where :

t

m = minimum required thickness

t = pressure design thickness, mm

c = the sum of the mechanical allowance

P

i = internal design pressure, Psi

d

o = outside diameter of pipe, mm

S

mys = Basic allowable Stres forValue

F = Design Factor

E' = longitudinal weld joint factor

T = temperature derating factor

P

i

= 1350 Psi

d

o

= 6.625 inch

c = 0.063 inch

= 0.0362 inch (Accumalation corrosion for 5 years operation) NORSOK-M506

S' = 35000 Psi

E' = 1

F = 0.72

u = 12.5%

T = 1 (Less than 250 F)

Pipe thickness caused by pressure

t = 0.177 inch

Minimum required thickness

t

m

=

0.316 inch

Sch 40 for NPS 6 = 0.280 inch

Sch 80 for NPS 6 = 0.432 inch

Conclusion

We choose Sch 80 NPS 6

Sheet No. : 1 of 3

LINE NO : REV : A

LEGENT : Wellhead Flowline Calculation

AFE NO : AFE 09-1333 DATE : 23-Feb-09

TABLE OF CONTENTS

Hal.

1 GENERAL DATA 2

2 Pipe Thickness Calculation 3

0 Sheet No. : 2 of 3

LINE NO : REV : A

LEGENT : Wellhead Flowline Calculation

AFE NO : AFE 09-1333 DATE : 23-Feb-09

1. GENERAL DATA

Design Code = ASME B31.3

Design Pressure = 1350 Psi (ANSI 600)

Corrosion Allowance = 0.063 inch

Design Temperatur = 200 F = 93.33 C

MATERIAL = A 106 Gr. B, Seamless

Basic Quality Factor For longitudinal weld joints = 1

Radiography = 100%

Diameter = NPS 3

Sheet No. : 3 of 3

LINE NO : REV : A

LEGENT : Wellhead Flowline Calculation

AFE NO : AFE 09-1333 DATE : 23-Feb-09

2 Thickness Calculation

tm = t + c

1 - u t = P

i

d

o

2 (S

.

E + P

i

. Y)

where :

t

m = minimum required thickness

t = pressure design thickness, mm

c = the sum of the mechanical allowance

P

i = internal design pressure, Psi

d

o = outside diameter of pipe, mm

S' = Basic allowable Stres forValue

E' = longitudinal weld joint factor

Y' = coefficient having values ferritic steels

as follow 0.4 up to and including 480C

0.5 for 510C

0.7 for 540C and above

u = mill tolerance

P

i

= 1350 Psi

d

o

= 3.5 inch

c = 0.063 inch

= 0.066 inch 2% of CO2 content

S' = 20000 Psi

E' = 1

Y = 0.4

u = 12.5%

Pipe thickness caused by pressure

t = 0.115 inch

Minimum required thickness

t

m

= 0.279 inch

Sch 40 for NPS 3 = 0.216 inch

Sch 80 for NPS 3 = 0.300 inch

Conclusion

We choose Sch 80 NPS 3

1 GENERAL DATA

Design Code = ASME B31.3

Operating Pressure = 1137 Psi

Working Allowable Pressure = 1350 Psi (ANSI 600)

Corrosion Allowance = 0.063 inch = 1.6 mm

Spesific Gravity = 0.74

Design Temperatur = 200 F = 93.33 C

MATERIAL = API 5L Gr 5 Sch 40

Basic Quality Factor For longitudinal weld joints = 1

Radiography = Spot

Diameter = NPS 4

Sheet No. : 1 of 3

LINE NO : REV : A

LEGENT : Wellhead Flowline Calculation

AFE NO : AFE 09-1306 DATE : 23-Feb-09

TABLE OF CONTENTS

Hal.

1 GENERAL DATA 2

2 Pipe Thickness Calculation 3

0 Sheet No. : 2 of 3

LINE NO : REV : A

LEGENT : Wellhead Flowline Calculation

AFE NO : AFE 09-1306 DATE : 23-Feb-09

1. GENERAL DATA

Design Code = ASME B31.4

Design Pressure = 1350 Psi (ANSI 600)

Corrosion Allowance = 0.063 inch

Design Temperatur = 200 F = 93.33 C

MATERIAL = API 5 L Gr.B, ERW

Basic Quality Factor For longitudinal weld joints = 1

Radiography = 100%

Diameter = NPS 4

Sheet No. : 3 of 3

LINE NO : REV : A

LEGENT : Wellhead Flowline Calculation

AFE NO : AFE 09-1306 DATE : 23-Feb-09

2 Thickness Calculation

tm = t + c P

i

d

o where :

1-u 2 S

mys

E 0.72

t

m = minimum required thickness

u = mill tolerances

c = the sum of the mechanical allowance

P

i = internal design pressure, kPa

d

o = outside diameter of pipe, mm

S' = Specific minimum yield strength

E' = longitudinal weld joint factor

P = 1350 Psi

d

o = 4.5 inch

c = 0.063 inch

S' = 35000 Psi (ASME B31.4 hal 12)

E' = 1 (ASME B31.4 hal 12)

Y' = 0.40

u = 12.50%

t = 0.120535714 inch

t

m

= 0.20976 inch

Thickness 4" Sch 40 = 0.237 inch

t

m

< t

Sch40

The 4" Sch 40 thickness is acceptable

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.4, Code for pipline transportation systems, use the following :

t =

P

i

d

o

2 (S

.

E + P

i

. Y)

where :

t

m

= minimum required thickness

t = pressure design thickness, mm

c = the sum of the mechanical allowance

P

i

= internal design pressure, kPa

d

o

= outside diameter of pipe, mm

S' = Basic allowable Stres forValue

E' = longitudinal weld joint factor

Y' = coefficient having values ferritic steels

as follow 0.4 up to and including 480C

0.5 for 510C

0.7 for 540C and above

P

i

=

1350 Psi

d

o

=

3.5 inch

c = 0.02 inch

S' = 16700 Psi

E' = 1

Y' = 0.4

u = 12.5% t

P

i

d

o

= 0.137 inch

2 (S

.

E + P

i

. Y)

t

m

=

0.174 inch

sch 40 for NPS 4 = 0.237

and the calculation = 0.242 it shows that sch 40 is not adequate

Design thickness calculation indicates that Schedule 80 is appropriate

t =

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.3, Code for pipline

transportation systems, use the following :

tm = t + c + u t =

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.3, Code for pipline

transportation systems, use the following :

tm = t + ca

P

i

d

o

where :

1-a

2 S

mys

E 0.72

t

m

= minimum required thickness

t = pressure design thickness, mm

a = mill tolerances

e = erosion allowance

c = the sum of the mechanical allowance

P

i

= internal design pressure, kPa

d

o

= outside diameter of pipe, mm

S' = Specific minimum yield strength

E' = longitudinal weld joint factor

Y' = coefficient having values ferritic steels

as follow

0.5 for 510C

0.7 for 540C and above

P

i

= 1350 Psi

d

o

= 3.5 inch

c = 0.063 inch

e = 0.02 inch

S' = 35000 Psi (ASME B31.4 hal 12)

E' = 1 (ASME B31.4 hal 12)

Y' = 0.40

a = 12.50%

P

i

d

o

= 0.09375 inch

2 S

mys

E 0.72

t

m

= 0.202 inch

Thickness 4" Sch 80 = 0.337 inch

Thickness 4" Sch 40 = 0.237 inch

Thickness calculation = 0.184 inch

t

m

< t

Sch40

The 4" Sch 40 thickness is acceptable

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.4, Code for pipline

transportation systems, use the following :

0.4 up to and including 480C

t =

t =

pressure design thickness, mm

the sum of the mechanical allowance

Specific minimum yield strength

coefficient having values ferritic steels

0.7 for 540C and above

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.4, Code for pipline

transportation systems, use the following :

0.4 up to and including 480C

tm = t + c

P

i

d

o

where :

1-u

2 S

mys

E F T

t

m

= minimum required thickness

t = pressure design thickness, mm

a = mill tolerances

e = erosion allowance

c = the sum of the mechanical allowance

P

i

= internal design pressure, kPa

d

o

= outside diameter of pipe, mm

S' = Specific minimum yield strength

E' = longitudinal weld joint factor

F = design factor

T = temperature derating factor

P

i

= 1350 Psi

d

o

= 6.25 inch

c = 0.063 inch

= 0.036 inch (Accumalation corrosion for 5 years operation) NORSOK-M506

e = inch

S' = 20000 Psi

E' = 1

F = 0.72

T = 1

a = 12.50%

P

i

d

o

= 0.29296875 inch

2 S

mys

E 0.72

t

m

= 0.448192857 inch

Thickness 4" Sch 80 = 0.337 inch

Thickness 4" Sch 40 = 0.237 inch

Thickness calculation = 0.184 inch

t

m

< t

Sch40

The 4" Sch 40 thickness is acceptable

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.8, Code for Gas Trnamission

and distribution piping systems, use the following :

t =

t =

pressure design thickness, mm

the sum of the mechanical allowance

Specific minimum yield strength

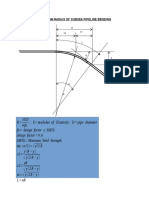

To determine allowable internal working pressure for this wellhead flowline in accordance with ANSI B31.8, Code for Gas Trnamission

and distribution piping systems, use the following :

Gas Flowrate :35.9 Mscfd = 35900 Mscfd

Operating Pressure : 260 Psi

S

1 :

0.858

S

g :

0.65

Fluid Flowrate : 200000 BFPD

V

e

= c = A =

Where :

V

e

: Fluid erosional velocity, feet/second

c : empirical constant, Solid-free Fluids 100 for continuous service,

125 for intermittent service

S

1

: liquid specific gravity

S

g

: gas specific gravity

: Gas or liquid mixture density at flowing pressure and temperature, lbs/ft

3

A : minimum pipe cross sectional flow area

R : gas/liquid ratio, ft/barrel at standard conditions. 0.1795 scfd/bfpd

T : operating temperatur, R

Z : gas compressibility factor

V

e

= 100 A = 9.367

7.314 13.673

= 13.67 = 0.685

= 137.0200476 inch

2

D = 13.21165513 inch

This calculation describe that NPS 14 is appropriate

To determine internal diameter pipe for Walio pipeline in accordance with API RP 14 E (Multiphase Flow)

12409S

l

P + 2.7 RS

g

P

198.7P + RTZ

9.35 + (RTZ/21.25P)

V

e

To determine internal diameter pipe for Walio pipeline in accordance with API RP 14 E (Multiphase Flow)

You might also like

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Reference PDFDocument158 pagesReference PDFAgus YulfizarNo ratings yet

- ASME B31.8 Riser CalcDocument12 pagesASME B31.8 Riser CalcSalz EngineeringNo ratings yet

- Calculation As Per Asme b31.3Document8 pagesCalculation As Per Asme b31.3Rajkumar ANo ratings yet

- Total Length Calcs For Pipes Valves and Fittings RevADocument9 pagesTotal Length Calcs For Pipes Valves and Fittings RevAlutfi awnNo ratings yet

- Hydraulics & Line SizingDocument20 pagesHydraulics & Line SizingM. Faisal Siddiqui100% (10)

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- Pipe Wall Thickness Under External PressureDocument1 pagePipe Wall Thickness Under External PressureAnonymous DJrec2No ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- Pipes. Wall Thickness Calculation According ASME B31.3Document98 pagesPipes. Wall Thickness Calculation According ASME B31.3Saravanan SilambanNo ratings yet

- FittingsDocument50 pagesFittingsashokNo ratings yet

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- Deaerator in A Thermal Power PlantDocument48 pagesDeaerator in A Thermal Power PlantVivek Tiwari100% (1)

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure Calculationrudrakr0% (1)

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocument2 pagesMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Gas Plant - 2Document63 pagesGas Plant - 2viettanctNo ratings yet

- 9.1 Lecture Material - Pneumatic Transport and Slurry TransportDocument51 pages9.1 Lecture Material - Pneumatic Transport and Slurry TransportDondon Irig100% (1)

- BRE 202 LNG ManualDocument69 pagesBRE 202 LNG ManualAlberto Abrajan100% (1)

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- ASME B31.8 Riser CalcDocument23 pagesASME B31.8 Riser Calcisrar khan100% (2)

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Minimum Pipe Wall Thickness and MAWP SI Final ProtectedDocument11 pagesMinimum Pipe Wall Thickness and MAWP SI Final Protectedjsfscibd100% (1)

- Design of Pressure ComponentsDocument34 pagesDesign of Pressure ComponentsYFFernando100% (1)

- New Cut Length CalculatorDocument30 pagesNew Cut Length CalculatorsmdriyazbashaNo ratings yet

- Fluid Mechanics: By: Engr. Ejay P. MarasiganDocument47 pagesFluid Mechanics: By: Engr. Ejay P. MarasiganGodwill Escabel100% (2)

- Info Calculation Pipe Line SizingDocument8 pagesInfo Calculation Pipe Line Sizingrasnowmah2012No ratings yet

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocument1 pagePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540No ratings yet

- Nema CalculationsDocument149 pagesNema CalculationsJ A S JASNo ratings yet

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure CalculationChetan B Kapadia100% (13)

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocument7 pagesPipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiNo ratings yet

- Jitorres - Regression To Experimental PVT DataDocument9 pagesJitorres - Regression To Experimental PVT DataOskr OvalleNo ratings yet

- Deflection Calculation For Over Head PipesDocument6 pagesDeflection Calculation For Over Head PipesRamachandran VenkateshNo ratings yet

- Time To Empty Out Vessel No Dished EndsDocument2 pagesTime To Empty Out Vessel No Dished EndsHeiner PalaciosNo ratings yet

- SampleCalculationspipingB3132008 PDFDocument13 pagesSampleCalculationspipingB3132008 PDFsosatlantiqueNo ratings yet

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTANo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- Permissible Elastic Bend Limit CalculationDocument4 pagesPermissible Elastic Bend Limit Calculationheldermanuel100No ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- 2-Fluid Flow in Porous MediaDocument46 pages2-Fluid Flow in Porous Mediafatma belkacemiNo ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- Trunnion CalculationDocument92 pagesTrunnion CalculationkarunaNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Design of Piping SystemsDocument115 pagesDesign of Piping SystemsDushyant Varshney100% (2)

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Retiring Wall Thickness Calculation For PipeDocument4 pagesRetiring Wall Thickness Calculation For PipeFares JawadNo ratings yet

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDocument1 pageShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanNo ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- GC11 Pipe Thickness CalcDocument1 pageGC11 Pipe Thickness CalcsrinivasanNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Pipe CalculationDocument2 pagesPipe CalculationWijayantoNo ratings yet

- Design of Piping Systems by Tengku SyahdilanDocument115 pagesDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNo ratings yet

- K-4b Perhitungan PipaDocument51 pagesK-4b Perhitungan PipaIndra MaulanaNo ratings yet

- Chapter 4-Simple Vapour Compression Refrigeration SystemDocument40 pagesChapter 4-Simple Vapour Compression Refrigeration Systemm_alodat614450% (2)

- ICH 2101 Mass Transfer 1 ModulesDocument79 pagesICH 2101 Mass Transfer 1 ModulesGrace Lukogho MbafumojaNo ratings yet

- ASME VIII Calc - Shell - HeadsDocument4 pagesASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Minimum Radius Pipe Bending-R1Document4 pagesMinimum Radius Pipe Bending-R1AdvisNo ratings yet

- Gas Line Capacity CalcDocument2 pagesGas Line Capacity CalcMario Mendoza100% (1)

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNo ratings yet

- Pipe Cold Bending (HBG)Document15 pagesPipe Cold Bending (HBG)Haries Bugarin GarciaNo ratings yet

- Pressure & Temperature ClassificationDocument1 pagePressure & Temperature Classificationkeo85100% (1)

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelNo ratings yet

- 1.1 Torispherical Ends Calculation - PZN - DJ03 - DN500: Title Calculation LP Header - 0LBA10BR100Document4 pages1.1 Torispherical Ends Calculation - PZN - DJ03 - DN500: Title Calculation LP Header - 0LBA10BR100pakitingNo ratings yet

- Calculo de Recipientes A PresionDocument2 pagesCalculo de Recipientes A PresionCesar Augusto Castellar OrtegaNo ratings yet

- Info Line SizingDocument110 pagesInfo Line Sizingrasnowmah2012No ratings yet

- Nibco: Material Number NS2920XE, F-607-RWS - Gate Valve - Ductile Iron, Fire Protection, Resilient WedgeDocument1 pageNibco: Material Number NS2920XE, F-607-RWS - Gate Valve - Ductile Iron, Fire Protection, Resilient Wedgerasnowmah2012No ratings yet

- Hardware: Foam ChambersDocument6 pagesHardware: Foam Chambersrasnowmah2012No ratings yet

- Exhibit "?": Sheet 1 of 3 Agreement NoDocument3 pagesExhibit "?": Sheet 1 of 3 Agreement Norasnowmah2012No ratings yet

- Foam ChambersDocument5 pagesFoam Chambersrasnowmah2012No ratings yet

- Tubing SpecificationsDocument5 pagesTubing Specificationsrasnowmah2012No ratings yet

- The Northern Road Stage 3 ScopeDocument158 pagesThe Northern Road Stage 3 Scoperasnowmah2012No ratings yet

- Specification For Road - Rev - Z PDFDocument33 pagesSpecification For Road - Rev - Z PDFrasnowmah2012No ratings yet

- Flange Studs Size Chart PDFDocument2 pagesFlange Studs Size Chart PDFrasnowmah2012No ratings yet

- WHITLIEJO API Certificate 6A-1385Document1 pageWHITLIEJO API Certificate 6A-1385rasnowmah2012No ratings yet

- Nominal Pipe Size: ANSI Flanges Stud and Ring ChartDocument1 pageNominal Pipe Size: ANSI Flanges Stud and Ring Chartrasnowmah2012No ratings yet

- ANSI Pipe SchedulesDocument1 pageANSI Pipe Schedulesrasnowmah2012No ratings yet

- Determination of Vapor PressureDocument5 pagesDetermination of Vapor PressureAbhinav AnandNo ratings yet

- Hydraulics Individual Assignment IDocument5 pagesHydraulics Individual Assignment Ikibrom fishaNo ratings yet

- Gr. 6 Science First Term Revision 2Document19 pagesGr. 6 Science First Term Revision 2sultan alkNo ratings yet

- The Ice Cream Phase Change Lab: Change in Chemical CompositionDocument3 pagesThe Ice Cream Phase Change Lab: Change in Chemical CompositionAllyssa De AmaNo ratings yet

- Swinburne University of Technology School of Engineering: Semester 1, 2019Document8 pagesSwinburne University of Technology School of Engineering: Semester 1, 2019Shehan FernandoNo ratings yet

- CBEN408 06 Field Operations Inlet ReceivingDocument59 pagesCBEN408 06 Field Operations Inlet ReceivingForcus onNo ratings yet

- Pages From COMPRESSIBLE FLOW PDFDocument8 pagesPages From COMPRESSIBLE FLOW PDFashoku2No ratings yet

- A. M. Buri Steam Power Plant Having A Forced Flow Steam Generator Filed May 28, 1956Document4 pagesA. M. Buri Steam Power Plant Having A Forced Flow Steam Generator Filed May 28, 1956Anonymous KzJcjGCJbNo ratings yet

- SHS Sy2021-2022 Q3law W1-2 General-Chemistry-ValidatedDocument8 pagesSHS Sy2021-2022 Q3law W1-2 General-Chemistry-Validatedjohnrobertdeocampo84No ratings yet

- Section 900 Carbon Dioxide and NitrogenDocument20 pagesSection 900 Carbon Dioxide and NitrogenHunterNo ratings yet

- Electro Pneumatic SystemDocument19 pagesElectro Pneumatic SystemPawan JaiswalNo ratings yet

- Feed Water Tanks PDFDocument4 pagesFeed Water Tanks PDFAleksei SukhovNo ratings yet

- List 2021Document25 pagesList 202113Nguyễn Mỹ Hải NgọcNo ratings yet

- Che323 Lecture 1 HumidificationDocument32 pagesChe323 Lecture 1 HumidificationifiokNo ratings yet

- Tutorial 3Document2 pagesTutorial 3sdfsdf3erwtr34tertNo ratings yet

- Siddaganga Institute of Technology, Tumkur - 572 103Document1 pageSiddaganga Institute of Technology, Tumkur - 572 103Sachin Krishna Moger 1si17ch026No ratings yet

- Ideal Gas Notes PDFDocument7 pagesIdeal Gas Notes PDFShahroze Ahmed100% (2)

- Tutorial 1Document4 pagesTutorial 1Kevin TanNo ratings yet

- Proserv Type 5 15k 700cc2Document1 pageProserv Type 5 15k 700cc2Refisal BonnetNo ratings yet

- Microwave SuperconductivityDocument14 pagesMicrowave Superconductivitygayathri ghantajiNo ratings yet