Professional Documents

Culture Documents

Additive Manufacturing of Metallic Cellular Materials Via Three-Dimensional Printing

Uploaded by

newkid22020 ratings0% found this document useful (0 votes)

109 views10 pagesCellular materials, metallic bodies with gaseous voids interspersed throughout the solid body, are a promising class of materials that offer high strength accompanied by a relatively low mass. Recent research has focused in the topological design of cellular materials in order to satisfy multiple design objectives. Unfortunately, these design advances have not been met with similar advances in cellular material manufacturing as existing techniques constrain a designer to a predetermined part mesostructure, material type, and macrostructure. In an effort to address these limitations, the authors have developed a manufacturing process chain centered on an augmented three-dimensional printing process. Specifically, metallic cellular materials are made by selectively printing solvent into a bed of spray-dried metal oxide ceramic powder. The resulting green part is then sintered in a reducing atmosphere to chemically convert it to metal. The resultant process has produced maraging steel cellular artifacts featuring a 270-μm wall thickness and angled trusses and channels that are less than 1 mm in diameter

Original Title

Additive Manufacturing of Metallic Cellular Materials via Three-dimensional Printing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCellular materials, metallic bodies with gaseous voids interspersed throughout the solid body, are a promising class of materials that offer high strength accompanied by a relatively low mass. Recent research has focused in the topological design of cellular materials in order to satisfy multiple design objectives. Unfortunately, these design advances have not been met with similar advances in cellular material manufacturing as existing techniques constrain a designer to a predetermined part mesostructure, material type, and macrostructure. In an effort to address these limitations, the authors have developed a manufacturing process chain centered on an augmented three-dimensional printing process. Specifically, metallic cellular materials are made by selectively printing solvent into a bed of spray-dried metal oxide ceramic powder. The resulting green part is then sintered in a reducing atmosphere to chemically convert it to metal. The resultant process has produced maraging steel cellular artifacts featuring a 270-μm wall thickness and angled trusses and channels that are less than 1 mm in diameter

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

109 views10 pagesAdditive Manufacturing of Metallic Cellular Materials Via Three-Dimensional Printing

Uploaded by

newkid2202Cellular materials, metallic bodies with gaseous voids interspersed throughout the solid body, are a promising class of materials that offer high strength accompanied by a relatively low mass. Recent research has focused in the topological design of cellular materials in order to satisfy multiple design objectives. Unfortunately, these design advances have not been met with similar advances in cellular material manufacturing as existing techniques constrain a designer to a predetermined part mesostructure, material type, and macrostructure. In an effort to address these limitations, the authors have developed a manufacturing process chain centered on an augmented three-dimensional printing process. Specifically, metallic cellular materials are made by selectively printing solvent into a bed of spray-dried metal oxide ceramic powder. The resulting green part is then sintered in a reducing atmosphere to chemically convert it to metal. The resultant process has produced maraging steel cellular artifacts featuring a 270-μm wall thickness and angled trusses and channels that are less than 1 mm in diameter

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

ORIGINAL ARTICLE

Additive manufacturing of metallic cellular materials

via three-dimensional printing

Christopher B. Williams & Joe K. Cochran &

David W. Rosen

Received: 4 January 2010 / Accepted: 22 June 2010 / Published online: 17 July 2010

# Springer-Verlag London Limited 2010

Abstract Cellular materials, metallic bodies with gaseous

voids interspersed throughout the solid body, are a

promising class of materials that offer high strength

accompanied by a relatively low mass. Recent research

has focused in the topological design of cellular materials in

order to satisfy multiple design objectives. Unfortunately,

these design advances have not been met with similar

advances in cellular material manufacturing as existing

techniques constrain a designer to a predetermined part

mesostructure, material type, and macrostructure. In an

effort to address these limitations, the authors have

developed a manufacturing process chain centered on an

augmented three-dimensional printing process. Specifically,

metallic cellular materials are made by selectively printing

solvent into a bed of spray-dried metal oxide ceramic

powder. The resulting green part is then sintered in a

reducing atmosphere to chemically convert it to metal. The

resultant process has produced maraging steel cellular

artifacts featuring a 270-m wall thickness and angled

trusses and channels that are less than 1 mm in diameter.

Keywords Additive manufacturing

.

3D printing

.

Cellular materials

.

Designed mesostructure

1 Manufacturing parts of designed mesostructure

1.1 Parts of designed mesostructure

When modern man builds large load-bearing structures, he

uses dense solids; steel, concrete, glass. When nature does

the same, she generally uses cellular materials; wood, bone,

coral. There must be a reason for it [1]. The observations

of cellular materials found in the natural world have

directed more than 50 years of research towards manufac-

turing processes capable of producing metallic cellular

materials. These structures, which feature gaseous voids

interspersed throughout the solid body, are valued for

having high strength accompanied by a relatively low

density [2]. These materials can also offer large stiffness,

improved impact absorption, and thermal and acoustic

insulation to their applications [3].

Recent research has focused in designing the mesoscopic

topology (the geometric arrangement of solid phases and

voids within a material or product on the size range of 0.1

to 10 mm) of cellular materials in order to effectively

support and improve multiple design objectives of the

artifact [4, 5]. Example parts of designed mesostructure

C. B. Williams (*)

Department of Mechanical Engineering,

Virginia Polytechnic Institute and State University,

114F Randolph Hall,

Blacksburg, VA 24061, USA

e-mail: cbwilliams@vt.edu

URL: http://www.me.vt.edu/dreams

J. K. Cochran

School of Materials Science and Engineering,

Georgia Institute of Technology,

Atlanta, GA, USA

D. W. Rosen

School of Mechanical Engineering,

Georgia Institute of Technology,

Atlanta, GA, USA

Int J Adv Manuf Technol (2011) 53:231239

DOI 10.1007/s00170-010-2812-2

include an acetabular cup (Fig. 1a) in which the porosity of

the truss structure has been designed to match the porosity

of the recipients bone so as to encourage bone growth

upon implantation [6] and a trussed robot arm (Fig. 1b) that

has been optimized to minimize mass while meeting

strength and deflection constraints [7].

1.2 Cellular material manufacturing

Unfortunately, traditional cellular material manufacturing

processes prevent the realization of these design improve-

ments. Due to processing limitations, existing processes

limit cellular topology to either a random assortment of

voids (e.g., metal sponging and foaming processes such as

Hydro/Alcan/Combal, Alporas, Formgrip, Gasar, etc. [1, 3])

or an ordered repetition of a unit cell (e.g., joining crimped

sheet metal into a corrugated form [8], bonding metal

textile screen meshes [9], sand/investment casting trussed

lattices [10], etc.[11]). In addition to limiting cellular

topology, the processes also constrain part macrostructure

(most processes only offer planar geometry [12]) and

material selection [1]. While these processes are capable

of producing light-weight and strong cellular materials,

these limitations prevent a designer from tailoring part

mesostructure for specific design intent(s) [4, 13].

There are several research efforts to address the

limitations of traditional cellular material manufacturing

via the use of additive manufacturing (AM) technologies to

create parts of designed mesostructure. Through their

additive, layer-based building process, AM technologies

(a.k.a., rapid prototyping, solid freeform fabrication, or

layered manufacturing) offer the utmost geometric freedom

in the design and manufacture of an artifact.

As previous efforts to use polymer-based AM to

indirectly create metal cellular structures through lost mold

and investment casting techniques resulted in porous parts

with limited cell sizes [14, 15], recent research has focused

in creating metal parts with direct-metal AM techniques.

Generally, the majority of these approaches are generally

not ideal for manufacturing cellular materials due to

limitations from poor resolution, poor surface finish, poor

material properties, limited material selection, and need for

support structures [13].

Ultrasonic consolidation [16] has been used to create

closed aluminum honeycomb panels; however, the technol-

ogy cannot build free-standing, unsupported, and angled

ribs and trusses, thus limiting its ability to create complex

cellular geometries [17]. Selective laser melting [18, 19],

direct-metal laser sintering [20], and electron beam melting

[21] have been successfully used to directly fabricate

metallic cellular materials with designed mesostructure.

While these technologies, which scan an energy source

(e.g., laser or electron beam spot) over a powder bed of

metal, are capable of creating fully dense parts with a small

feature size, they have inherent limitations:

& These processes are generally expensive (e.g., need for

a high-powered energy source) and have slow build

rates (e.g., vector scanning a small energy spot).

& The use of a high-powered energy source can introduce

residual stresses into the part, which arise from the high

thermal gradients present in the material during part

fabrication [22]. This can lead to curling and/or warping

during the build; as such, support structures, which can

be difficult to remove from small cells, must be added

to the part geometry.

& Thermal gradients (and thus warping and residual stresses)

can be reduced by first preheating the powder bed with the

energy source. This technique lightly sinters the powder

bed before reapplying the energy source at an increased

power (and/or decreased scan speed) to fully melt the

powder to create the part [23]. However, pre-sintering the

powder increases its strength, thus making the loose

powder difficult to remove from the part; a feature that

might hamper the fabrication of cellular artifacts.

& Defects on bottom-facing surfaces and an overall poor

surface finish typically arise due to the surface tension

of the molten metal, which dominates at the small sizes

required to achieve good surface finish and creates the

potential for capillary instabilities [24].

& Problems arise when building over loose powder

(which is common when creating overhanging surfaces)

because the conductive heat transport is significantly

Fig. 1 Parts of designed mesostructure: a acetabular cup [6] and b

trussed robot arm [7]

232 Int J Adv Manuf Technol (2011) 53:231239

larger than when building over previously melted

powder [25]. This effect can cause delaminations,

buckling, and warping of cellular mesostructure [26].

In an effort to address the limitations of existing cellular

material manufacturing techniques, the authors have devel-

oped a process for the realization of metal parts with

designed mesostructure. Specifically the authors have

augmented the three-dimensional printing process (3DP)

for the creation of green parts (formed from metal oxide

ceramic powders) that are suitable for conversion to metal

via thermal chemical post-processing.

2 Manufacturing process chain: three-dimensional

printing of metal oxide powders

The manufacturing process chain proposed by the authors is

composed of three steps, as presented in Fig. 2:

a. Material preparation. Fine metal oxide powders are

spray-dried with a binder to form granules suitable for

processing with a 3DP machine.

b. Artifact creation via three-dimensional printing. Cellu-

lar ceramic green parts are fabricated using 3DP.

c. Post-processing. Following the removal of excess pow-

der, the metal oxide green part is sintered in a reducing

atmosphere thus chemically converting it to metal.

As the crux of the overall process is focused in the post-

processing stage, each phase of the process is described in

this section in reverse order.

2.1 Post-processing: chemically converting metal oxide

green parts to metal via reduction

In an effort to circumvent the limitations and difficulties (e.

g., warping, residual stresses, etc.) typically encountered

when directly fabricating metal parts via laser-based AM, the

authors take inspiration from the linear cellular alloy (LCA)

manufacturing process invented by the Georgia Tech Light-

weight Structures Group [27]. In this process, metal oxide

ceramic green artifacts are formed via extrusion and are then

sintered in a reducing atmosphere. The ceramic precursor is

chemically converted to metal, as the reducing agent

typically a gas (e.g., hydrogen or carbon monoxide)reacts

with the oxygen of the green part and forms water vapor,

which is then removed from the system [28].

Cochran and coauthors have used this thermal/chemical

procedure to process a number of transition metal oxides

(Fe, Ni, Co, Cr, N Cu, Mo, W, Mn, and Nb), as well as

many engineering alloys (stainless steel, maraging steel,

Inconel, and Super Invar [29]) that are comparable to

conventionally processed counterparts [27]. The primary

requirement for this process is that the metal oxide must be

reducible at moderate temperatures (below the melting

points of the materials involved) with a partial pressure of

oxygen not lower than 10

16

atm. This requirement

excludes some elements such as Ti and Al because they

are stable under these conditions; hence, they cannot be

introduced into the alloy as an oxide and must be added in

secondary processes.

Cellular materials featuring cell sizes in the range of 0.5

to 2.0 mm with web thicknesses of 50 to 300 m have been

created with the LCA process [27]. These small features are

accomplished, in part, by the shrinkage that is accompanied

with the reduction process (typically on the order of 30% to

70% by volume). This large shrinkage can cause cracks

and/or warping if not controlled carefully [28]; however, it

can be advantageous when fine geometric features are

desired that otherwise would be difficult or expensive to

fabricate [29].

Chemical reduction of metal oxide green parts to metal

has the potential to alleviate many of the limitations found

Step One

Step

Three-Dimensional Printing

Two

Material Preparation

Oxide

Powders

Binder

Drying

Spray Drying

Step Three

Sintering &

H

2

Reduction

Finished Metal Part

Direct Reduction

Roller

Head

Powder Feed

Piston

Built

Piston

Built Object

Binder

Supply

Fig. 2 Three-dimensional print-

ing of spray-dried metal oxide

powder followed by sintering

and reduction

Int J Adv Manuf Technol (2011) 53:231239 233

in direct-metal AM of cellular materials. The thermal/

chemical post-process provides a manner in which to create

metal artifacts without the application of thermal energy in

the forming stage of a manufacturing process chain, thus

avoiding difficulties with thermal transport phenomena

found in current direct-metal AM technologies (Sec-

tion 1.2). Furthermore, implementing this post-processing

technique is economically efficient, as the cost differential

between a metal oxide powder and its metal counterpart is

usually better than a 1-to-10 ratio [29]. Fine oxide powders

are readily available in a pure and stable form. Compared to

pure metal powders, metal oxides are safer as they are

neither carcinogenic nor explosive.

2.2 Artifact creation: three-dimensional printing

As the use of extrusion in the LCA process limits part

geometry to linear macrostructure and an ordered meso-

structure (that is constant throughout the extrusion), the

authors look to combine the material strengths of the post-

process (Section 2.1) with the geometric freedom offered

by AM. Following a structured design process that featured

a conceptual design phase and a formal selection process

[30, 31], the authors determined that 3DP was the most

suitable AM technology for creating green cellular parts

composed of metal oxide ceramic material [32].

3DP features the selective printing of a binder over a bed

of powder via an array of inkjet nozzles [33] (Fig. 3). As

the binder enters the powder bed, it selectively joins

together powder particles to form printed primitives, which

stitch together to form a cross-sectional layer. A roller is

used to add a new layer of powder (at the desired thickness)

onto the previously printed layer. Excess powder from this

recoating process is caught into an overflow container for

reuse.

The authors chose 3DP as a method for creating metal

oxide green cellular parts for the following reasons:

& Speed: The parallel deposition of the multiple nozzles

enables the 3DP technology to deposit entire portions of

a layer in a single pass, thus dramatically increasing its

build speed.

& Cost: The two-dimensional patterning process imple-

mented by 3DP is inherently scalable [34]; unlike laser-

based systems, the quantity of toolheads (i.e., printing

nozzles for 3DP) can be increased with very little

increase in overall cost. One can imagine creating an

array of print heads that would cover the entire width of

the working area, such that only one linear stage is

needed to sweep along the area, and thus increasing the

deposition rate (and therefore reducing build time)

significantly.

& Resolution: The use of an inkjet printing nozzle to

pattern binder provides the 3DP technology the ability

to create parts with high resolution (minimum feature

size of ~0.1 mm), which is a crucial requirement for the

realization of cellular materials. The use of inkjet

printing technology also enables the creation of cross

sections that are characteristic of cellular materials. This

is not true to all AM patterning techniques; extrusion

processes, for example, are unable to satisfactorily

deposit the small, discrete ellipses typically found in

the cross sections of trussed structures (Fig. 4b) due to

pores created by poor optimization of material flow,

filament/roller slippage, liquefier head motion, and

build/fill strategies [35].

& Complex geometry: Many AM technologies must create

support structures to facilitate the construction of

overhanging features (e.g., the trusses in Fig. 4a). Such

structures are not desirable when creating parts with

designed mesostructure because they would be very

difficult to remove from the parts small pores and

channels. The 3DP process eliminates the need for

specialized support structures, as the unpatterned

powder in the bed provides inherent support for the

complex geometry typical of cellular material. Unpat-

terned powder is easily removed from open cells via

careful use of compressed air and a vacuum nozzle. One

drawback of this approach, however, is that unpatterned

Powder Feed

Piston

Build

Piston

Roller Print

Head

Binder

Supply

Built Object

x

z

Fig. 3 Three-dimensional printing Fig. 4 Example a trussed material and its b cross section

234 Int J Adv Manuf Technol (2011) 53:231239

powder cannot be removed from closed cells and can be

troublesome to remove from very small channels.

& Green part density: By working with the powder in its

raw, loose form, 3DP avoids the solids loading and

rheology constraints found in the other ceramic AM

technologies that work with powder/binder suspensions

(e.g., aqueous [36] and hot-melt [37] direct inkjet

printing, extrusion [38], and stereolithography [39]).

Compared to other ceramic AM processes (35 vol.%

solids in direct hot-melt inkjet printing [37], 40 vol.%

solids in extrusion [40]), 3DP has a relatively high

green part solids loading (powder beds with as high as

55 vol.% have been observed [41]).

2.3 Material preparation: spray-dried metal oxide powders

Fine powder particles are preferred over coarse particles in

ceramics processing because they have better sintering

characteristics, resulting in a finished part with a higher

relative density and better material properties. However,

one of the primary limitations with 3DP is its inability to

properly spread fine dry powders with particle size less than

20 m [42, 43]. The authors look to circumvent this

limitation by combining several fine particles into a larger

granule, which is more suitable for the 3DP recoating

process, via spray-drying.

Spray-drying is the process of spraying a slurry, composed

of fine powder particles (15 m) and a binder, into a warm-

drying medium to produce powder granules that are relatively

homogenous [44]. Spray-dried granules are nearly spherical

and typically on the order of 30 m in diameter; therefore,

they flow very well and are easily recoated in the 3DP

process [45]. While the porous nature of spray-dried

powders (60 vol.%) is detrimental in that it slightly decreases

the solids loading possible for a green part, it is beneficial

since smaller primitives result from the increased absorption

of the jetted binder and/or solvent [46].

In addition to enabling 3DP to work with particle sizes

that are typically too small to be spread, spray-drying the

powder eliminates the need for printing a polymeric binder

into the bed as a means of forming primitives (the

traditional 3DP approach, Fig. 5a). Instead, the binder used

to form granules can be activated in the powder bed

through the printing of a solvent. The printed solvent will

partially dissolve and deform the granule surface, creating

printed primitives once dried (Fig. 5b). This approach is

preferred not only because the solvents deformation of the

granule surface will bring the ceramic fine particles

together, but also because it is modularthe same solvent

could be used on various ceramic spray-dried granules

(assuming the same polymer coating is used), thus

eliminating the need to reconfigure the material system.

3 Experimental methods

3.1 Material preparation

While a wide variety of transition metal oxides can be

reduced to metal using this procedure (Section 2.1), the

authors have chosen to work with maraging steel in this

work. Maraging steel features high strength and high

fracture toughness and has uniform, predictable shrinkage

during heat treatment. Finally, its constituents are easily

reduced (Eqs. 13).

Fe

3

O

4

4H

2

! 3Fe 4H

2

O 1

Co

3

O

4

4H

2

! 3Co 4H

2

O 2

NiO H

2

! Ni H

2

O 3

Ametal oxide powder systemthat will chemically convert to

maraging steel (Fe 18.5Ni 8.5Co 5Mo) upon reduction was

Polymer Binder

Metal Oxide Particles

Printed Primitive

Solvent

Spray-dried Granules

Printed Primitive

a

b

Fig. 5 Powder/binder material system options: a coarse particles with

printed binder and b spray-dried fine particles with printed solvent

1400

Sintering

(1300 C)

1200

1000

800

Reduction

(850 C)

600

400

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Binder burnout

(450 C)

200

0

0 5 10 15 20

Time (hr)

Fig. 6 Cycle for reduction and sintering of 3D printed maraging steel

Int J Adv Manuf Technol (2011) 53:231239 235

created by combining iron oxide (Fe

3

O

4

), nickel oxide (NiO),

cobalt oxide (Co

3

O

4

), and molybdenum metal (Mo) powders

and ball milling them for 24 h. Once mixed, the metal oxide

powder system is spray-dried with a 4 wt.% poly-vinyl

alcohol (PVA) solution (Celvol 203, offered by Celanese

Chemicals). This PVA was chosen because it is water soluble

and is a common binder that works well with almost any

oxide ceramic [47]. The powder particles were spray-dried by

Aero-Instant Spray-Drying Services of Brunswick, Georgia.

3.2 Part fabrication

Once spray-dried, the metal oxide granules are processed

using a ZCorp Z402 three-dimensional printer [48].

Printing tests were performed using two different printed

binding mechanisms: (a) ZCorps standard binder (ZB7

binder) and (b) a mild solvent (an 80/20 mixture of distilled

water and isopropyl alcohol (IPA)). The layer thickness was

held constant across all experiments at 100 m as it

provided the highest quality surface upon recoating. Aware

of the porosity of the spray-dried granules, and small

features typical of cellular materials, the saturation level

was set at its maximum value of 2. All other printing

parameters are unchanged from default settings.

Once printing has completed, parts are left in the powder

bed for 20 min (often under an infrared lamp) to allow the

binder to fully dry. The green parts are then transferred to a

depowdering station where unbound powder is carefully

removed from the complex cellular geometry using com-

pressed air and a vacuum nozzle in combination.

3.3 Post-processing

Once depowdered, the green parts are reduced and sintered in

an atmosphere-controlled tube furnace in an Ar10% H

2

environment using the cycle presented in Fig. 6. The

determination of the facets of the sintering scheme were guided

by Cochran and coauthors earlier experimentation in sintering

metal oxide constituents of maraging steel for the production of

linear cellular alloys [27, 28]. The heating cycle is composed

of three phases: debinding of the PVA binder (2C/min ramp

to 450C with 0.5 h hold), reduction of the metal oxide green

part (3C/min ramp to 850C with 6 h hold), and metal

sintering (3C/min ramp to 1,300C with 3 h hold). The hold

duration for the reduction and sintering phases were varied via

experimentation; the final values were chosen as they ensured

that the finished parts would have all oxide phases completely

removed and would be as dense as possible.

4 Results

4.1 Phase identification

X-ray diffraction (completed with molybdenum radiation)

was used to identify the phases present in samples created

by the manufacturing process. Count peaks occur at 2=

Table 1 Density measurements for 4 wt.% granule systems

Granule

binder content

Deposited

binder/solvent

Average

relative density

Average open

porosity

4 wt.% Polymeric

binder (ZB7)

59.15% 36.15%

4 wt.% Solvent

(water + IPA)

62.57% 34.4%

Fi 7b Fig. 7b a c

b

Fig 7c Fig. 7c

z

x

z

x

yy

Fig. 7 a Schematic of sample

and b micrographs of cross-

sectional surfaces perpendicular

to build direction and c parallel

to build direction

236 Int J Adv Manuf Technol (2011) 53:231239

20.155, 28.651, 35.284, 40.97, 46.067, and 50.755. These

results correspond to a BCC iron phase (JADE phase

identification software; powder diffraction file # 00-0006-

0696) with a figure of merit (FoM) of 3.5. From this, it can

be concluded that no oxide phase is present in the finished

parts; thus the parts are fully reduced.

4.2 Density

As discussed in Section 3.2, two primitive creation

principles were tested: one featuring the printing of a

polymeric binder to bind granules, the other featuring the

printing of a solvent to partially dissolve the spray-dried

granules binder. The density and open porosity of multiple

test parts created from both material systems were

calculated using the Archimedes method (assuming marag-

ing steel has a bulk density of 8.2 g/cm

3

). As can be seen in

Table 1, printing a solvent into the powder bed produces

parts with a higher density and a lower open porosity. The

solvent deforms the spray-dried granules, which in turn

brings the enclosed fine particles closer together and leads

to a better sintering performance and a higher part density.

The relatively low density measurement is attributed to a

poor powder bed density (estimated to between 30% and 40%

in these experiments) and an insufficient deformation of the

spray-dried granules. This is a limitation of the authors

specific embodiment; experiments wherein excess solvent

was applied manually to the powder bed resulted in parts with

an average relative density of 81%and an open porosity of 9%

after reduction and sintering.

4.3 Porosity and shrinkage

In order to further evaluate the quality of the parts created by

this manufacturing process, part porosity is investigated by

examining the cross-sectional surfaces of samples (Fig. 7).

Figure 7b provides an opportunity to analyze the porosity

present in a typical cross-sectional layer (xy plane as per

Fig. 7a) fabricated by the process when a solvent is used for

creating primitives. It is observed that the pores are aligned

parallel to the direction of the print head travel (y-axis; left to

right in Fig. 7b), and thus are locations in which printed

bands did not successfully overlap or stitch to one another.

This can be attributed to a clogged print nozzle, but is more

likely due to unoptimized binder characteristics (surface

tension, wetting of granules, viscosity, droplet size, etc.) and

associated process parameters (e.g., printed line overlap).

The cross section presented in Fig. 7c provides an

opportunity to analyze the porosity that exists along the

build direction of the part (yz plane as per Fig. 7a; from

the bottom to the top of Fig. 7c). Again, parallel lines of

porosity are observed. These lines correspond to parts

layers and suggest an inadequate level of solvent saturation

into the powder bed. This problem can be alleviated

through an increase in the amount of solvent deposited by

the print head.

Average linear shrinkage, as measured and calculated

(L/L

o

) across several printed samples between their

green and sintered states, is 45%. This shrinkage is a

result of both the part porosity caused by unoptimized

printing parameters and the act of reducing metal oxide to

Fig. 8 Sample part featuring

intersecting channels: a CAD

model, b metal oxide green part,

and c part after sintering and

reduction

Fig. 9 Cellular material sample

in its various representations

during the manufacturing pro-

cess chain: a CAD model,

b metal oxide green part, and

c part after sintering and

reduction

Int J Adv Manuf Technol (2011) 53:231239 237

metal (Section 2.1). There was slight anisotropic shrinkage

in the parts due to the parallel lines of porosity (Fig. 7); on

average, parts experienced 1% more linear shrinkage in the

direction that is orthogonal to these lines of pores.

4.4 Cellular geometry

Several test parts were created in an effort to characterize

the proposed manufacturing process capability of fabricat-

ing parts of designed mesostructure. Each test part contains

features that are common to geometries typical of cellular

materials: thin walls, small channels, and angled trusses.

& Thin walls: The minimum wall thickness created, as

measured after sintering and reduction, was 270 m. It

should be noted that this is not necessarily the best

possible result of the proposed augmented 3DP process

as printing resolution is primarily dependent on the

printhead of the specific 3DP machine.

& Small channels: The channel size limit that can be

created is not imposed by the resolution and printing

accuracy of the 3DP process. In its current embodiment,

the limit is imposed by the ability of the green part to

withstand the vigorous depowdering that is necessary to

remove the unbound powder trapped within the chan-

nels. Thus far, channels 2 mm in diameter as printed in

the green state (1.1 mm in diameter after sintering and

reduction) have been successfully created, as seen in

Fig. 8.

& Angled trusses: Angled trusses can be difficult to

process in an AM context as the combination of acute

angles, thin trusses, and relatively large layer thick-

nesses can lead to non-overlapping layers. Experiments

have shown that trusses, as small as 1.75 mm in

diameter (green state), can be printed when inclined to

the build plane at angles as low as 20.

With the processs ability to realize the geometrical

building blocks of parts of designed mesostructure verified,

a series of parts featuring complex cellular geometry were

created. An example piece, featuring trusses less than 1 mm

in diameter (post-sintering), is shown in Fig. 9. As can be

seen, the surface roughness is similar to other powder-based

AM processes, which is akin to a sand casting. Additional

parts of designed mesostructure created by this process are

presented in [49].

5 Conclusions

In this paper, the authors present a layer-based additive

manufacturing process for the realization of metal parts

with designed mesostructure. Specifically, metal oxide

green ceramic parts, created by three-dimensional printing,

are sintered and reduced in a hydrogen/argon atmosphere to

chemically convert the part to metal. The green parts are

formed by printing a solvent into a powder bed composed

of spray-dried granules; the solvent deforms the binder-

coated granules, thus pulling the enclosed fine particles

closer together and improving the sintering performance (i.

e., density) of the green part.

The process has been shown to successfully create parts

with designed mesostructure (Fig. 7). In addition to creating

cellular artifacts, it has fabricated walls as thin as 270 m,

channels as small as 1.1 mm in diameter, and angled trusses

less than 1 mm in diameter. Furthermore, the specific

process embodiment used by the authors has produced

finished parts with an average relative density of 63% and

an average linear shrinkage of 45%.

Many opportunities exist for improving the proposed

manufacturing process. Part density could be improved by

exploring techniques for increasing powder bed density, by

increasing solvent deposition, by optimizing the solvent/

powder bed interface, or by depositing a nanoparticle

suspension into the powder bed. Printing resolution (and

thus, part feature size) could be improved through explor-

ing different print head embodiments. A different recoating

solution might enable the use of finer particles, thus

resulting in smaller printed features and an improved final

part density. As a preliminary cost analysis indicates that

metal parts created by the process cost only ~$3/in

3

[49],

the authors believe the process merits further improvement.

Acknowledgments We gratefully acknowledge the funding given

by NSF DMI-0522382. Christopher Williams acknowledges the

financial support provided by the Georgia Tech Technological

Innovation: Generating Economic Results (TI:GER) program (NSF

IGERT-0221600). Dr. Michael Middelmas is acknowledged for his

laboratory assistance during the reduction and sintering post-process

(Section 3.3). The authors would also like to thank Mr. Joe Pechin of

Aero-Instant Spray Drying Services for his generosity and assistance

in preparing the experimental powder system (Section 3.1).

References

1. Ashby MF, Evans AG, Fleck NA, Gibson LJ, Hutchinson JW,

Wadley HNG (2000) Metal foams: a design guide. Butterworth-

Heinemann, Woburn

2. Banhart J, Weaire D (2002) On the road again: metal foams find

favor. Physics Today 55:3742

3. Banhart J (2000) Manufacturing routes for metallic foams. JOM 52

(12):2227

4. Evans AG, Hutchinson JW, Fleck NA, Ashby MF, Wadley HNG

(2001) The topological design of multifunctional cellular metals.

Prog Mater Sci 46:309327

5. Seepersad CC, Kumar RS, Allen JK, Mistree FM, McDowell DL

(2004) Multifunctional design of prismatic cellular materials. J

Comput-Aided Mater Des 11(2):163181

6. Wang HV, Johnston SR, Rosen DW (2006) Design of a graded

cellular structure for an acetabular hip replacement component.

17th Solid Freeform Fabrication Symposium, pp 111123

238 Int J Adv Manuf Technol (2011) 53:231239

7. Wang H, Rosen DW (2002) Computer-aided design methods for

additive fabrication of truss structures. International Conference

on Manufacturing Automation

8. Wadley HNG, Fleck NA, Evans A (2003) Fabrication and

structural performance of periodic cellular metal sandwich

structures. Compos Sci Technol 63:23312343

9. Tian J, Lu TJ, Hodson HP, Queheillalt DT, Wadley HNG (2007)

Cross flow heat exchange of textile cellular metal core sandwich

panels. Int J Heat Mass Transfer 50:25212536

10. Jamcorp Inc. (2004) Jonathon Aerospace Materials website. http://

www.jamcorp.com. Accessed June 2007.

11. Wadley HNG (2002) Cellular metals manufacturing. Adv Eng

Mater 4(10):726733

12. Sypeck DJ, Wadley HNG (2002) Cellular metal truss core

sandwich structures. Adv Eng Mater 4(10):759764

13. Williams CB, Mistree F, Rosen, DW (2005) Investigation of solid

freeform fabrication processes for the manufacture of parts with

designed mesostructure. ASME IDETC Design for Manufacturing

and the Life Cycle Conference, DETC2005/DFMLC-84832

14. Hattiangadi A, Bandyopadhyay A (1999) Processing, character-

ization and modeling of non-random porous ceramic structures.

Solid Freeform Fabrication Symposium, pp 319326

15. Chiras S, Mumm DR, Evans AG, Wicks N, Hutchinson JW,

Dharmasena K, Wadley HNG, Fichter S (2002) The structural

performance of near-optimized truss core panels. Int J Solids

Struct 39:40934115

16. Solidica Inc. (2004) Solidica: direct to metal aluminum tooling for

advanced manufacturing. http://www.solidica.com/technology.

html. Accessed June 2007.

17. Robinson CJ, Zhang C, Janaki Ram GD, Siggard EJ, Stucker B,

Li L (2007) Maximum height to width ratio of freestanding

structures built using ultrasonic consolidation. Solid Freeform

Fabrication Symposium, pp 502516

18. Pham DT, Dimov SS, Ji C, Gault RS (2003) Layer manufacturing

processes: technology advances and research challenges. 1st

International Conference on Advanced Research in Virtual and

Rapid Prototyping, pp 107113

19. Brooks W, Sutcliffe C, Cantwell W, Fox P, Todd J, Mines R (2005)

Rapid design and manufacture of ultralight cellular materials. 16th

Solid Freeform Fabrication Symposium, pp 231241

20. Agarwala M, Bourell D, Beaman J, Marcus H, Barlow J (1995)

Direct selective laser sintering of metals. Rapid Prototyping J 1

(1):2636

21. Cansizoglu O, Cormier D, Harrysson O, West H, Mahale T (2006)

An evaluation of non-stochastic lattice structures fabricateed via

electron beam melting. Solid Freeform Fabrication, pp. 2092119

22. Kruth JP, Froyen L, Van Vaerenbergh J, Mercelis P, Rombouts M,

Lauwers B (2004) Selective laser melting of iron-based powder. J

Mater Process Technol 149(13):616622

23. Cormier D, Harrysson O, West H (2004) Characterization of H13 steel

produced via electron beam melting. Rapid Prototyping J 10(1):3541

24. Rice CS, Mendez PF, Brown SB (2000) Metal solid freeform

fabrication using semi-solid slurries. JOM 52(12):3133.

doi:10.1007/s11837-000-0065-5

25. Kruth JP, Mercelis P, Van Vaerenbergh J, Craeghs T (2007)

Feedback control of selective laser melting. Advanced research in

virtual and rapid prototyping, pp 521527

26. Rehme O, Emmelmann C, Schwarze D (2007) Selective laser

melting of lattice structures in solid shells. Advanced research in

virtual and rapid prototyping, pp 529535

27. Cochran JK, Lee KJ, McDowell DL, Sanders TH (2002)

Multifunctional metallic honeycombs by thermal chemical pro-

cessing. Processing and properties of lightweight cellular metals

and structures (TMS), pp 127136

28. Cochran JK, Lee KJ, Sanders TH (2003) Metallic articles formed

by reduction of nonmetallic articles and method of producing

metallic articles. US 6582651 B1, USA, Georgia Tech Research

Corporation

29. Cochran JK, Lee KJ, McDowell D, Sanders TH, Church B, Clark

J, Dempsey B, Hurysz K, McCoy T, Nadler J, Oh R, Seay W,

Shapiro B (2000) Low density monolithic metal honeycombs by

thermal chemical processing. Fourth Conference on Aerospace

Materials, Processes, and Environmental Technology

30. Williams CB, Mistree F, Rosen DW (2005) Towards the Design of

a layer-based additive manufacturing process for the realization of

metal parts of designed mesostructure. 16th Solid Freeform

Fabrication Symposium, pp 217230

31. Williams CB, Mistree F, Rosen DW (2008) The Systematic Design

of a Layered Manufacturing Process for the Realization of Metal

Parts of Designed Mesostructure. 5th ASME Symposium on

International Design and Design Education, DETC2004/DEC-49457

32. Williams CB, Rosen DW (2007) Manufacturing cellular materials

via three-dimensional printing of spray-dried metal oxide ceramic

powder. 3rd International Conference on Advanced Research in

Virtual and Rapid Prototyping

33. Sachs EM, Haggerty JS, Cima MJ, Williams PA (1993) Three-

dimensional printing techniques. US patent 5 204 055, Massachu-

setts Institute of Technology

34. Carrion A (1997) technology forecast on ink-jet head technology

applications in rapid prototyping. Rapid Prototyping J 3(3):99115

35. Agarwala MK, Jamalabad VR, Langrana NA, Safari A, Whalen

PJ, Danforth SC (1996) Structural quality of parts processed by

fused deposition. Rapid Prototyping J 2(4):419

36. Wright MJ, Evans JRG (1999) Ceramic deposition using an

electromagnetic jet printer station. J Mater Sci Lett 18:99101

37. Seerden KAM, Reis N, Evans JRG, Grant PS, Halloran JW, Derby

B (2001) Ink-jet printing of wax-based alumina suspensions. J Am

Ceram Soc 84(11):25142520

38. Lewis JA (2000) Colloidal processing of ceramics. J Am Ceram

Soc 83(10):23412359

39. Griffith ML, Halloran JW (1996) Freeform fabrication of ceramics

via stereolithography. J Am Ceram Soc 79(10):26012608

40. Grida I, Evans JRG (2003) Extrusion freeforming of ceramics

through fine nozzles. J Eur Ceram Soc 23:629635

41. Utela B, Anderson RL, Kuhn H (2006) Advanced ceramic

materials and three-dimensional printing (3DP). 17th Solid Free-

form Fabrication Symposium, pp 290303

42. Sachs E, Cima MJ, Cornie J, Brancazio D, Bredt J, Curodeau A,

Fan T, Khanuja S, Lauder A, Lee J, Michaels S (1993) Three-

dimensional printing: the physics and implications of additive

manufacturing. CIRP Ann 42(1):257260

43. Yoo, J, Cima MJ, Khanuja S, Sachs EM (1993) Structural ceramic

components by 3D printing. Solid Freeform Fabrication Sympo-

sium, pp 4050

44. Reed JS (1995) Principles of ceramics processing. John Wiley &

Sons, Inc, New York

45. Cima, MJ, Yoo J, Khanuja S, Rynerson M, Nammour D,

Giritlioglu B, Grau J, Sachs EM (1995) Structural ceramic

components by 3D printing. Solid Freeform Fabrication Sympo-

sium, pp 479488

46. Cima MJ, Lauder A, Khanuja S, Sachs EM (1992) Microstructural

elements of components derived from 3D printing. Solid Freeform

Fabrication Symposium, pp 220227

47. Morse T (1979) Handbook of organic additives for use in ceramic

body formulation. Montana Energy and MHD Research and

Development Institute, Butte

48. Z Corporation (2007) 3D printers. http://www.zcorp.com/Products/

3D-Printers/spage.aspx. Accessed 5 November 2007

49. Williams CB (2008) Design and development of a layer-based

additive manufacturing process for the realization of metal parts of

designed mesostructure. Dissertation, Georgia Institute of

Technology

Int J Adv Manuf Technol (2011) 53:231239 239

Copyright of International Journal of Advanced Manufacturing Technology is the property of Springer Science

& Business Media B.V. and its content may not be copied or emailed to multiple sites or posted to a listserv

without the copyright holder's express written permission. However, users may print, download, or email

articles for individual use.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- An Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFDocument7 pagesAn Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFnewkid2202No ratings yet

- Experimental Study Aiming To Enhance The Surface Finish of Fused Deposition Modeled PartsDocument4 pagesExperimental Study Aiming To Enhance The Surface Finish of Fused Deposition Modeled Partsnewkid2202No ratings yet

- An Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFDocument7 pagesAn Experimental Investigation On Surface Quality and Dimensional Accuracy of FDM Components PDFnewkid2202No ratings yet

- A Parametric Study of Part Distortions in Fused Deposition Modeling Using Three-Dimensional Finite Element AnalysisDocument9 pagesA Parametric Study of Part Distortions in Fused Deposition Modeling Using Three-Dimensional Finite Element Analysisnewkid2202No ratings yet

- Design and Analysis of A Compliant Parallel Pan-Tilt Platform 2015Document12 pagesDesign and Analysis of A Compliant Parallel Pan-Tilt Platform 2015newkid2202No ratings yet

- Compliant Manipulators 2014Document72 pagesCompliant Manipulators 2014newkid2202No ratings yet

- An Adaptive Wearable Parallel Robot For The Treatment of Ankle Injuries 2014Document12 pagesAn Adaptive Wearable Parallel Robot For The Treatment of Ankle Injuries 2014newkid2202100% (1)

- A New Approach To The Design and Optimisation of Support Structures in Additive ManufacturingDocument9 pagesA New Approach To The Design and Optimisation of Support Structures in Additive Manufacturingnewkid2202No ratings yet

- An Actuated Finger Exoskeleton For Hand Rehabilitation Following Stroke 2007Document6 pagesAn Actuated Finger Exoskeleton For Hand Rehabilitation Following Stroke 2007newkid2202No ratings yet

- Top-10 Data Mining Case StudiesDocument12 pagesTop-10 Data Mining Case Studiesnewkid2202No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1st Year Physics Notes Chap05Document15 pages1st Year Physics Notes Chap05phoool83% (6)

- Wideband & Multiband Micro Strip Antenna Designs For Project Review FinalDocument71 pagesWideband & Multiband Micro Strip Antenna Designs For Project Review FinallekhaNo ratings yet

- ES MT 0106 - REV1.30 - 24122019 - 6021282 DIAM 4100 Rev 1 30 - EN 2Document64 pagesES MT 0106 - REV1.30 - 24122019 - 6021282 DIAM 4100 Rev 1 30 - EN 2Paix AvousNo ratings yet

- Active Learning Methods For Interactive Image RetrievalDocument78 pagesActive Learning Methods For Interactive Image RetrievalAnilkumar ManukondaNo ratings yet

- Design of Tension MembersDocument11 pagesDesign of Tension MembersWilfharry billyNo ratings yet

- EP 8 CPD20TV8 Parts Manual 20190605 165931Document119 pagesEP 8 CPD20TV8 Parts Manual 20190605 165931Виталий ЧерновNo ratings yet

- The Mostly Complete Chart of Neural NetworksDocument19 pagesThe Mostly Complete Chart of Neural NetworksCarlos Villamizar100% (1)

- Gas Turbine Report RotorDocument10 pagesGas Turbine Report RotorThanapaet RittirutNo ratings yet

- Sampling and Reconstruction of Analog Signals Using VariousDocument11 pagesSampling and Reconstruction of Analog Signals Using VariousChandrahas GodavarthiNo ratings yet

- Chemistry Practical: Class 11Document14 pagesChemistry Practical: Class 11Priyansh GandhiNo ratings yet

- A Brain Tumor Detection Using Image ProcessingDocument5 pagesA Brain Tumor Detection Using Image ProcessingIJRASETPublicationsNo ratings yet

- Radio 2219 PDFDocument2 pagesRadio 2219 PDFdsfasdf dfg100% (1)

- Your Results For - Multiple Choice QuestionsDocument4 pagesYour Results For - Multiple Choice QuestionsHUAWEI HUAWEINo ratings yet

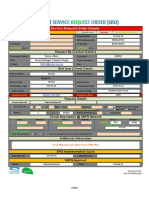

- Service Request Order DetailsDocument4 pagesService Request Order DetailsKashif NaeemNo ratings yet

- Corona Multi Service R410A ManualDocument54 pagesCorona Multi Service R410A Manualfredjbps@gmail.comNo ratings yet

- LR Mobile Diagnostic LogDocument97 pagesLR Mobile Diagnostic LogSalim AlsenaniNo ratings yet

- Warren, J. E. and Root, P. J. The Behavior of Naturally Fractured ReservoirsDocument11 pagesWarren, J. E. and Root, P. J. The Behavior of Naturally Fractured ReservoirsSolenti D'nouNo ratings yet

- Vibration ProblemsDocument18 pagesVibration ProblemsKarthick RamNo ratings yet

- Continuity Assignments Class 12Document3 pagesContinuity Assignments Class 12RiteshNo ratings yet

- II N The L ' ' Ball Typ Which Is N T 3-ph Se Synchronous M T F He F'lyball Head o I T Con Trol The Guide N Pump Driven Maintain 150 Psi B Ea IngsDocument20 pagesII N The L ' ' Ball Typ Which Is N T 3-ph Se Synchronous M T F He F'lyball Head o I T Con Trol The Guide N Pump Driven Maintain 150 Psi B Ea IngsCristian GarcíaNo ratings yet

- JListDocument39 pagesJListsidhanshuNo ratings yet

- SAP BASIS L1 L2 and L3 AtiivtiesDocument9 pagesSAP BASIS L1 L2 and L3 AtiivtieschandarguptaNo ratings yet

- WB Harmonic Shaker Table PDFDocument10 pagesWB Harmonic Shaker Table PDFNagrajThadurNo ratings yet

- 10 1016@j Carbon 2017 07 030Document11 pages10 1016@j Carbon 2017 07 030Adonilson FreitasNo ratings yet

- Mass BalanceDocument55 pagesMass BalanceJoshua Johnson100% (1)

- O Level Physics NotesDocument6 pagesO Level Physics NotesHamza Kahemela83% (6)

- CRT TV Power ProblemDocument15 pagesCRT TV Power ProblemJoy Chowdhury50% (2)

- Modelo Propagacion COST 231Document4 pagesModelo Propagacion COST 231Miguel Andres Vanegas GNo ratings yet

- Unit 3 DSDocument16 pagesUnit 3 DSromeesh jainNo ratings yet

- Associate in Science Degree: Major RequirementsDocument5 pagesAssociate in Science Degree: Major Requirementsjoescribd55No ratings yet