Professional Documents

Culture Documents

Butterfly Damper

Uploaded by

deion290 ratings0% found this document useful (0 votes)

226 views2 pagesButterfly Damper Butterfly Damper Butterfly Damper Butterfly Damper

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentButterfly Damper Butterfly Damper Butterfly Damper Butterfly Damper

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

226 views2 pagesButterfly Damper

Uploaded by

deion29Butterfly Damper Butterfly Damper Butterfly Damper Butterfly Damper

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

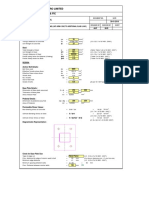

BUTTERFLY DAMPERS

A. Round Fiberglass Reinforced Plastic Dampers

1. All round FRP dampers shall be the butterfly type. FRP fabrication shall

meet the corrosion requirements specified in this Section for FRP duct

work.

2. Leakage shall not exceed 3 cfm/sq. ft at 10 w.g. for balancing, 4.4

cfm/sq. ft at 30 w.g. for medium Isolation and bubble-tight at 30 WC

for full Isolation. Unless otherwise specified on the drawings, all

dampers are assumed to be medium Isolation and be licensed to bear the

AMCA seal

3. Fabrication:

a. Frame and blade: Fire-Retardant vinyl ester resin (Class 1 Flame

Spread). Blade shall fully encapsulate shaft. Blades that bolt to a

single side of the shaft will not be accepted.

b. Shaft: Vinyl ester for all manually actuated dampers below 30

inch diameter and Type 316 stainless steel for all dampers 30

inch diameter and larger.

c. Bearings and bushings: Graphite Impregnated Teflon.

d. All internal hardware: Type 316 stainless steel.

e. Seals:

1) Blade: EPDM for medium isolation and Teflon for O-

ring bubble tight dampers.

2) Shaft: O-ring in FRP Flanged Packing Gland. PVC

fittings used for shaft seal will NOT be accepted.

f. All dampers shall have flanged ends. Flange dimensions to be

similar to fiberglass ductwork.

g. All balancing and Medium Isolation dampers >24" shall be

provided with worm Gear Operators with an epoxy coating.

Dampers 24" and down shall be supplied with hand quadrant

actuators fabricated of Type 316 stainless steel with a 5-stage

locking quadrant Indicator. All balancing dampers shall have a

fully adjustable slot with an extra hole drilled in the handle for

contractor to "drill and pin-in place" once system is balanced so

handle will not vibrate out of position. Drawing may indicate

motorized actuators, if so that shall take precedence. Any

dampers over 6 foot above finished floor shall be furnished with

Chain wheel gear operators. All Positive Seal O-ring dampers

MUST be furnished with Worm gear operators. Manual Hand

levers will not be accepted regardless of size.

h. Approved Suppliers:

1) Balancing and Medium Isolation

a) Belco Manufacturing Model 203

b) Swartwout Model 914

c) Engineer Pre-Qualified AMCA Licensed Equal

2) Bubble-Tight PTFE O-ring dampers

a) Belco Manufacturing Model 204

b) Ershigs Type-B

c) Engineer Pre-Qualified Equal

i. All balancing and medium Isolation dampers provided shall bear

the AMCA seal. Dampers are to have been tested in an AMCA

lab for performance (pressure drop) and leakage. Test results

shall be submitted and confirmed by the engineer. Testing must

have been done in an AMCA lab within the required 3 year

period so that the manufacturer is qualified to apply the AMCA

label.

j. Bubble-Tight dampers should be shop tested. Tests should be

submitted to the engineer and confirmed by full Quality control

documentation. The engineer or representative of the owner

reserves the right to witness this testing or use an independent

inspection firm to confirm test results.

k. Dampers may be tested after installation to confirm compliance.

You might also like

- Manual Sandvik Ds 421-cDocument4 pagesManual Sandvik Ds 421-cchristian100% (1)

- Past Board Exam Problems in DynamicsDocument3 pagesPast Board Exam Problems in DynamicsJoshua MercadoNo ratings yet

- Astm d3567Document8 pagesAstm d3567anastasio53No ratings yet

- Heat Loss From PipeDocument11 pagesHeat Loss From Pipedeion29No ratings yet

- CheatSheet CADocument4 pagesCheatSheet CAAnonymous ypNOeWtsfuNo ratings yet

- Vibration Testing Theory and PracticeDocument31 pagesVibration Testing Theory and PracticeDilara Çınarel0% (3)

- AnexosDocument99 pagesAnexosGustavo GutoNo ratings yet

- SECTION 15861 Air Filters Part 1 - General 1.1 Related DocumentsDocument3 pagesSECTION 15861 Air Filters Part 1 - General 1.1 Related DocumentsfatREVITNo ratings yet

- Sample Specification From Monoxivent Corrosion Composites: SECTION 15800Document4 pagesSample Specification From Monoxivent Corrosion Composites: SECTION 15800Ahmed NabilNo ratings yet

- 2.1 Ducts and Pipes Sizing and Insulation Specification 2.5.1 Duct Size CalculationDocument28 pages2.1 Ducts and Pipes Sizing and Insulation Specification 2.5.1 Duct Size CalculationAllanNo ratings yet

- SECTION 15830 FansDocument6 pagesSECTION 15830 FansfatREVITNo ratings yet

- Kohinoor Square ProjectDocument12 pagesKohinoor Square ProjectAnonymous zIYeDYU7zoNo ratings yet

- Crown Home Consultants: Cleopatra Plaza Tower (Nasr City) Specifications 15861/1 Rev.0 March.2012Document3 pagesCrown Home Consultants: Cleopatra Plaza Tower (Nasr City) Specifications 15861/1 Rev.0 March.2012Waleed Abd El-HamiedNo ratings yet

- Sewers For Adoption - PUMPSDocument25 pagesSewers For Adoption - PUMPSatiNo ratings yet

- HVAC Guide Specifications 39M Total Energy Recovery Wheel SectionDocument7 pagesHVAC Guide Specifications 39M Total Energy Recovery Wheel Sectionhardik033No ratings yet

- General HVAC RequirementDocument10 pagesGeneral HVAC RequirementM GulshairNo ratings yet

- Tube Fitting Technical SpecificationDocument4 pagesTube Fitting Technical Specificationksivakumar09100% (2)

- Duct For Corrosive Fumes ExhaustDocument8 pagesDuct For Corrosive Fumes ExhaustTS WongNo ratings yet

- Axial & Jet Fans SpecificationDocument8 pagesAxial & Jet Fans SpecificationRamakrishnanNo ratings yet

- ITS Installation & Civil Specification & Guidelines-05Document14 pagesITS Installation & Civil Specification & Guidelines-05N V Sumanth VallabhaneniNo ratings yet

- Section 233116Document4 pagesSection 233116Ahmed NabilNo ratings yet

- Section 05110 - Butterfly ValvesDocument6 pagesSection 05110 - Butterfly Valvesse781No ratings yet

- Drainage Inspection Access Details and InstallationDocument6 pagesDrainage Inspection Access Details and InstallationSaif MohammadNo ratings yet

- Tender Specifications-Exhaust SystemDocument6 pagesTender Specifications-Exhaust Systemgullipalli srinivasa raoNo ratings yet

- Specifications - GIF SeriesDocument3 pagesSpecifications - GIF SeriesRodrigo Regla MuñozNo ratings yet

- Series 3100-4100 Accordion SpecificationsDocument4 pagesSeries 3100-4100 Accordion SpecificationsPedro Manuel PérezNo ratings yet

- Fire Tender SpecificationsDocument13 pagesFire Tender Specificationskaranbhadu50% (2)

- TROSTEN Mechanical Specification - AHUDocument6 pagesTROSTEN Mechanical Specification - AHUBalaji JenarthananNo ratings yet

- TS-01 Air - Washer UnitsDocument27 pagesTS-01 Air - Washer UnitsPraveen KumarNo ratings yet

- SECTION 15854 Central Station Air Handling Units Part 1 - General 1.1 General RequirementsDocument7 pagesSECTION 15854 Central Station Air Handling Units Part 1 - General 1.1 General RequirementsfatREVITNo ratings yet

- Technical SpecificationDocument17 pagesTechnical Specificationmohan agasthiNo ratings yet

- Air FiltersDocument4 pagesAir Filtershussam_98No ratings yet

- Sb-Ag-39-Rev-A WING SPAR INSPECTION AND FATIGUE LIFE EXTENSIONDocument14 pagesSb-Ag-39-Rev-A WING SPAR INSPECTION AND FATIGUE LIFE EXTENSIONNathaniel LuraNo ratings yet

- FinalDocument4 pagesFinalggts.99114833No ratings yet

- Technical Specification of Rolling Shutter For ACDFS BuildingDocument10 pagesTechnical Specification of Rolling Shutter For ACDFS BuildingnikkiNo ratings yet

- Annexture N1 427Document14 pagesAnnexture N1 427DEBASISH SARKARNo ratings yet

- Pinch Valves General TechDocument7 pagesPinch Valves General TechPrakashNo ratings yet

- Section 2 15 Hydrant PitDocument2 pagesSection 2 15 Hydrant PitCassy AbulenciaNo ratings yet

- Play Pipes 1Document8 pagesPlay Pipes 1Vuk MarovicNo ratings yet

- MECHANICAL PADS - CIVIL - Construction - Division 23Document23 pagesMECHANICAL PADS - CIVIL - Construction - Division 23JomyJoseNo ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- Power Transformer Manual PDFDocument82 pagesPower Transformer Manual PDFamulya00428No ratings yet

- 0.6. TR-18 Stockbridge Type Vibration DampersDocument10 pages0.6. TR-18 Stockbridge Type Vibration Dampersgiorgis072No ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- Specification Series 20 Ss Sluice GateDocument6 pagesSpecification Series 20 Ss Sluice GatepramodtryNo ratings yet

- Annexure 3486Document8 pagesAnnexure 3486Kamal RajuNo ratings yet

- Continuously Reinforced Concrete PavementDocument7 pagesContinuously Reinforced Concrete PavementtanujpadhyNo ratings yet

- 2 Specification For GRP PipingDocument4 pages2 Specification For GRP Pipinggc_panchaNo ratings yet

- TS-02 Ventilation Fans - Toilet & BasementDocument11 pagesTS-02 Ventilation Fans - Toilet & BasementPraveen KumarNo ratings yet

- FloodBreak 3 Part Specification ROADWAY REV 07-27-2018Document7 pagesFloodBreak 3 Part Specification ROADWAY REV 07-27-2018Bayu Aji PamungkasNo ratings yet

- DESIGN & STANDARD PARAMETERS - PIPING WORKS (Uploaded)Document3 pagesDESIGN & STANDARD PARAMETERS - PIPING WORKS (Uploaded)CNAltNo ratings yet

- Section 151xx-Horizontal Inline Sleeve Valve General 1.1 DescriptionDocument3 pagesSection 151xx-Horizontal Inline Sleeve Valve General 1.1 DescriptionLASCARZAMFIRESCUNo ratings yet

- Specification For Ducting of Ac PlantDocument7 pagesSpecification For Ducting of Ac PlantSubbarayan SaravanakumarNo ratings yet

- 39HQ Guide Specification EN 25022022Document14 pages39HQ Guide Specification EN 25022022Jerome IlaoNo ratings yet

- Strainers Specifications Cod4Document8 pagesStrainers Specifications Cod4Laura AndradeNo ratings yet

- Inspection Check List 3Document22 pagesInspection Check List 3r.devendranNo ratings yet

- 5 Spec For Fume CabinetDocument5 pages5 Spec For Fume CabinetLengNo ratings yet

- Axial & Centifugal Jet Fans SpecificationDocument9 pagesAxial & Centifugal Jet Fans SpecificationRamakrishnan100% (1)

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Document9 pagesElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNo ratings yet

- Soil Nailing and Horizontal Drains 2101 Soil Nailing 2101.1 DescriptionDocument2 pagesSoil Nailing and Horizontal Drains 2101 Soil Nailing 2101.1 DescriptionSABEASNNo ratings yet

- CG 2015238 01 Foam ChambersDocument6 pagesCG 2015238 01 Foam ChambersDavid TjNo ratings yet

- Rola Star CatalogueDocument8 pagesRola Star CataloguemaximghNo ratings yet

- Thermite Rail Welding Caltrain StandardDocument7 pagesThermite Rail Welding Caltrain StandardPeem'zPlNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Fischer Tropsch SynthesisDocument18 pagesFischer Tropsch Synthesisdeion29No ratings yet

- Pump TrainingDocument15 pagesPump TrainingdalayeliNo ratings yet

- ConversionDocument1 pageConversionCosmin CinciNo ratings yet

- Air Consumption ChartDocument1 pageAir Consumption Chartdeion29No ratings yet

- Performance Guarantee NormalisasiDocument5 pagesPerformance Guarantee Normalisasideion29No ratings yet

- Inerting & BlanketingDocument5 pagesInerting & Blanketingbksree100% (1)

- 4 PO 14 SekiguchiDocument10 pages4 PO 14 Sekiguchideion29No ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Process Design Basis Process Design BasisDocument17 pagesProcess Design Basis Process Design Basisdeion29100% (3)

- Terminal User ManualDocument51 pagesTerminal User Manualdeion29No ratings yet

- Air Consumption ChartDocument1 pageAir Consumption Chartdeion29No ratings yet

- Air Consumption ChartDocument1 pageAir Consumption Chartdeion29No ratings yet

- Se Se Se 616Document2 pagesSe Se Se 616deion29No ratings yet

- Up Up AwayDocument1 pageUp Up Awaydeion29No ratings yet

- HYSYS Depressurisation ExampleDocument2 pagesHYSYS Depressurisation ExampleMuhammad Saquib67% (3)

- Heating Value of Common FuelsDocument1 pageHeating Value of Common Fuelsscience4uNo ratings yet

- Hot Oil System GuideDocument56 pagesHot Oil System GuideleelaramaNo ratings yet

- Forced ConvectionDocument5 pagesForced Convectionsadiqchem179No ratings yet

- Algorithm of MainDocument1 pageAlgorithm of Maindeion29No ratings yet

- Undangan Sharing EngDocument1 pageUndangan Sharing Engdeion29No ratings yet

- Whitepaper - Piping Connection ConsiderationsDocument11 pagesWhitepaper - Piping Connection ConsiderationsblindjaxxNo ratings yet

- Level Technology Comparison: 4-20 Ma W/ HART, F Fieldbus, Profibus PaDocument1 pageLevel Technology Comparison: 4-20 Ma W/ HART, F Fieldbus, Profibus Padeion29No ratings yet

- Pump Sizing (Si Units) : Equipment Number Service Fluid Pumped DutyDocument2 pagesPump Sizing (Si Units) : Equipment Number Service Fluid Pumped Dutydeion29No ratings yet

- Proxy 1 November 2013Document60 pagesProxy 1 November 2013deion29No ratings yet

- Insulated PipeDocument54 pagesInsulated Pipedeion29No ratings yet

- Torp Ship Based LNG RegasificationDocument1 pageTorp Ship Based LNG Regasificationdeion29No ratings yet

- Water Hammer Pressure/ Surge Pressure Calculation : Developed by Engr. Abiodun AsadeDocument2 pagesWater Hammer Pressure/ Surge Pressure Calculation : Developed by Engr. Abiodun Asadecoolsummer1112143100% (1)

- Tricks N Hacks N TipsDocument6 pagesTricks N Hacks N Tipsdeion29No ratings yet

- Airplane Flight Manual Z 242 LDocument40 pagesAirplane Flight Manual Z 242 LFeksesNo ratings yet

- FICHA - ARMSTRONG Recirculadores Series S y H EspecificacionesDocument4 pagesFICHA - ARMSTRONG Recirculadores Series S y H EspecificacionesSalvador RiveraNo ratings yet

- 2-1TS-60T0-R0 Alloy VerificationDocument17 pages2-1TS-60T0-R0 Alloy VerificationArooba AroojNo ratings yet

- Hiace Techstream 1st RunDocument3 pagesHiace Techstream 1st RunStephen MasemoNo ratings yet

- Assignment On Revision of Statics & Strength of Materials 20 21Document2 pagesAssignment On Revision of Statics & Strength of Materials 20 21Yishak AmanuelNo ratings yet

- 02 - List HeDocument22 pages02 - List Heahmadalfan662No ratings yet

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- XXL Leser PSV ObsoleteDocument28 pagesXXL Leser PSV ObsoleteMuhammad RidwanNo ratings yet

- Project Report On Winter Internship IIT KharagpurDocument39 pagesProject Report On Winter Internship IIT KharagpurTech broNo ratings yet

- Robex 210LC 7 Manual de Partes PDFDocument1,312 pagesRobex 210LC 7 Manual de Partes PDFmohammed barghothiNo ratings yet

- J54-100 Parte1Document45 pagesJ54-100 Parte1angel gabriel perez valdezNo ratings yet

- Design of Base Plate LKP Arm 4-F-30.01.2018Document5 pagesDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaNo ratings yet

- European Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Document16 pagesEuropean Codes - Steel Design To Eurocode 3 (EN 1993-1-1:2005)Nicoleta cristianNo ratings yet

- Performance Evaluation of RC Buildings by Time History AnalysisDocument6 pagesPerformance Evaluation of RC Buildings by Time History AnalysisAica M. AtendidoNo ratings yet

- 08 Plasticity 03 Yield CriteriaDocument21 pages08 Plasticity 03 Yield Criteria한종훈100% (1)

- Stability-Calculation For PipelineDocument2 pagesStability-Calculation For PipelineGeorge100% (1)

- Elevador Rotary LiftDocument120 pagesElevador Rotary LiftMiguel Eliezer SequeiraNo ratings yet

- Most Common Types of Welding DefectsDocument23 pagesMost Common Types of Welding DefectsRommel GocotanoNo ratings yet

- 4.classification of Tensometry MethodsDocument3 pages4.classification of Tensometry MethodsМурад ГусейнзадеNo ratings yet

- Centroid - Centre of Gravity - Mechanical Engineering (MCQ) Questions and AnswersDocument5 pagesCentroid - Centre of Gravity - Mechanical Engineering (MCQ) Questions and AnswersNitik Kumar0% (1)

- Chapter 2 - Lubrication (Added)Document32 pagesChapter 2 - Lubrication (Added)Najip TalibinNo ratings yet

- Juki HZL-FDocument35 pagesJuki HZL-FjinkysuzykayeNo ratings yet

- B62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDocument15 pagesB62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDiego CamargoNo ratings yet