Professional Documents

Culture Documents

Ref Batch Management

Uploaded by

justine_fabian2Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ref Batch Management

Uploaded by

justine_fabian2Copyright:

Available Formats

Toc G-1

IM 33S01B30-01E

CS 1000/CS 3000

Reference

Batch Management

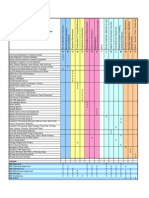

CONTENTS

17th Edition : Jul.14,2008-00

IM 33S01B30-01E 17th Edition

PART-G Batch Management

G1. Overview of Batch Management .......................................................... G1-1

G1.1 ISA S88.01 and Batch Management ............................................................. G1-2

G1.2 What is a Recipe? ......................................................................................... G1-5

G1.3 Hierarchy of Procedure ................................................................................ G1-9

G1.4 Application Capacity .................................................................................. G1-12

G2. Recipe Management ............................................................................. G2-1

G2.1 Master Recipes ............................................................................................. G2-2

G2.1.1 Header ........................................................................................... G2-3

G2.1.2 Procedure....................................................................................... G2-9

G2.1.3 Formula ........................................................................................ G2-15

G2.1.4 Equipment Requirements ............................................................. G2-24

G2.1.5 Handling Master Recipe File ......................................................... G2-26

G2.2 Recipe Group and Train.............................................................................. G2-28

G2.3 Common Block ........................................................................................... G2-33

G2.4 Engineering of Unit Common Block .......................................................... G2-43

G2.4.1 Engineering on System View ........................................................ G2-45

G2.4.2 Engineering on Recipe View ......................................................... G2-47

G2.5 Recipe View................................................................................................. G2-51

G2.6 Recipe Data Backup ................................................................................... G2-62

G3. Process Management ........................................................................... G3-1

G3.1 Batch Execution Management ..................................................................... G3-2

G3.2 Recipe Setup ............................................................................................... G3-17

G3.3 Batch-Related Messages............................................................................ G3-28

G3.4 Batch Result Data ....................................................................................... G3-31

G3.5 Duplicating Control Recipe ........................................................................ G3-40

G3.6 Exporting Formulas .................................................................................... G3-46

G3.6.1 Exporting Formulas Manually ....................................................... G3-47

G3.6.2 Exporting Formulas Automatically ................................................. G3-53

G3.7 Security Settings of Process Management ............................................... G3-55

G3.8 Dual-Redundancy ....................................................................................... G3-62

IM 33S01B30-01E

Toc G-2

10th Edition : Dec.18,2003-00

G3.9 Batch Related Trend Management ............................................................. G3-67

G3.9.1 Batch Related Trend File .............................................................. G3-68

G3.9.2 Batch-Related Trend Window ....................................................... G3-76

G4. Unit Supervision under Batch Management........................................ G4-1

G4.1 Nonresident Unit Instrument ........................................................................ G4-2

G4.2 Operation....................................................................................................... G4-5

G5. Production Planning and Scheduling Interface .................................. G5-1

G5.1 Overview of Production Planning and Scheduling Interface ..................... G5-2

G5.2 Schedule Expansion..................................................................................... G5-4

G5.3 File Format of Fixed Schedule File............................................................... G5-8

G6. Production Information Management .................................................. G6-1

G6.1 Overview of Production Control Information Management ........................ G6-2

G7. Product-Related Windows ................................................................... G7-1

G7.1 Architecture of Product-Related Windows.................................................. G7-2

G7.2 Product Overview Window........................................................................... G7-8

G7.2.1 Elements of Product Overview Window ........................................ G7-10

G7.2.2 Dialog Boxes Extended from Product Overview Window .............. G7-15

G7.3 Product Control Window ............................................................................ G7-35

G7.3.1 Elements of Product Control Window............................................ G7-37

G8. Engineering when Connecting Multiple Projects................................ G8-1

G8.1 Connecting CS 3000 and CS 1000................................................................ G8-6

G8.1.1 Engineering of the Upper-Level Project (CS 3000) .......................... G8-7

G8.1.2 Engineering of the Lower-Level Project (CS 1000) ........................ G8-14

G8.2 Unilateral Connection between CS 3000s ................................................. G8-19

G8.2.1 Engineering of the Upper-Level Project (CS 3000) ........................ G8-20

G8.2.2 Engineering of the Lower-Level Project (CS 3000) ........................ G8-27

G8.3 Bilateral Connection between CS 3000s.................................................... G8-32

G8.3.1 Common Engineering ................................................................... G8-35

G8.3.2 Engineering of Recipe Group in which the Self Project Becomes

the Upper-Level Project ................................................................ G8-37

G8.3.3 Engineering of Recipe Group in which the Self Project Becomes

the Lower-Level Project ................................................................ G8-43

G8.4 Connecting CS 3000 and CS ...................................................................... G8-47

G8.4.1 Engineering of the Upper-Level Project (CS 3000) ........................ G8-48

G8.4.2 Engineering of the Lower-Level Project (CS) ................................ G8-55

<G1. Overview of Batch Management> G1-1

IM 33S01B30-01E

G1. Overview of Batch Management

This chapter gives an overview of Batch Management.

10th Edition : Dec.18,2003-00

G1-2 <G1.1 ISA S88.01 and Batch Management>

IM 33S01B30-01E

G1.1 ISA S88.01 and Batch Management

The ISA SP88 is a working group for international standard on Batch Control under

the ISA (Instrument Society of America) in the U.S.. One of the publications they put

together is Batch Control Part 1: models and terminology, which was published in

1997 as IEC/61512-1.

This section describes the relationship between ISA S88.01 and Batch Management.

Physical Model

In ISA S88.01, a Physical Model (equipment support model) comprised of 7 levels is

defined. With CS 1000/CS 3000 Batch Management, the system can be hierarchically

constructed in a manner different from the actual physical hierarchy by using unit instru-

ments, operations and control blocks (PID blocks, etc.) that correspond to units, equipment

modules (equipment) and control modules (instrument), respectively.

G010101E.EPS

ISA S88.01 Physical Model Batch Management

Train

Recipe group

Unit instrument

Regulatory control block

SEBOL

Sequence table

Logic chart

SFC block (operation)

Enterprise

Site

Area

Process Cell

Unit

Equipment Module

Control Module

Figure Physical Model and Batch Management

10th Edition : Dec.18,2003-00

<G1.1 ISA S88.01 and Batch Management> G1-3

IM 33S01B30-01E

Control Activity Model

To control batch manufacturing, a Management Activity Model consisting of 7 activities is

defined in ISA S88.01as follows. Unit supervision occupies a position of supervising pro-

cess management.

G010102E.EPS

Production planning

and scheduling

Production information

management

Recipe management (*1)

Process management

Unit supervision (*2)

Process Control

(Function block)

Scopes of Batch Management

Personnel and

Environmental Protection

(*3) (*4)

Figure Control Activity Model and Batch Management

*1: The recipe management defined in ISA S88.01 includes General Recipe, Site Recipe, Master Recipe and Control

Recipe. Batch Management functions supports Master Recipe and Control Recipe.

*2: Unit supervision is included in the FCS basic control functions. Unit supervision can be operated by itself without being

combined with the Batch Management Recipe Management and process management.

*3: The Batch Management uses the production planning and scheduling interface as an interface between the Process

Management and the Production Planning and Scheduling.

*4: The Batch Management uses an OPC interface as an interface between the Process Management and the Production

Information Management.

10th Edition : Dec.18,2003-00

G1-4 <G1.1 ISA S88.01 and Batch Management>

IM 33S01B30-01E

Procedural Control Model

In a batch process, operating procedures and manufacturing procedures are changed

according to the product to be made. The S88 Procedural Control Model indicated below is

a hierarchical representation of these procedures. With Batch Management, phases and

other levels below them are assigned to SEBOL, sequence tables, and logic charts and

operations are executed by the SFC blocks, based on the ISA S88.01 model. Unit proce-

dures are executed by the unit instruments to perform overall control of the operations.

G010103E.EPS

Blending

Reaction

Process

Procedure

Unit Procedure

Operation

Initialization

Charge of catalyst

Component A

Initialization

Sequence

Table

G010103E.EPS

Component B

Logic chart

Phase

SEBOL

Charge A

Heating

Procedure

Unit Procedure

Operation

Phase

ISA S88.01 Batch Management

Figure Procedural Control Model and Batch Management

10th Edition : Dec.18,2003-00

<G1.2 What is a Recipe?> G1-5

IM 33S01B30-01E

G1.2 What is a Recipe?

The recipes controlled in Batch Management prescribe the manufacturing proce-

dures, parameters and units used in producing a particular product.

Types of Recipes

In the ISA SP88.01, recipes are divided into four types as shown in the diagram below,

depending on what needs to be done and which resources are required to manufacture the

product.

Of these, the CS Batch 1000/CS Batch 3000 handles master recipes and control recipes.

The Process Management handles control recipes and the Recipe Management handles

master recipes.

G010201E.EPS

General Recipe

Site Recipe

Master Recipe

Control Recipe

Recipe management

Process management

Figure Types of Recipes

10th Edition : Dec.18,2003-00

G1-6 <G1.2 What is a Recipe?>

IM 33S01B30-01E

General Recipe

General recipes do not specify a plant to be used. Instead, they deal with production plans

and other activities that involve a company as a whole. Thus, quantities handled in formu-

las are defined primarily by a development group (researchers, etc.) in a testing lab or at a

pilot plant. The purpose of general recipes is to separate general descriptions regarding the

chemical processing, manufacturing processing, and processes required to manufacture

the product, from specific information on the plant and units. By doing this, those who

develop general recipes can do so without knowledge of the specific units. The Batch

Management does not handle general recipes.

Site Recipe

Site recipes contain information that have been changed to match the conditions at a

specific manufacturing site and are necessary for long-term production schedules at the

site level. The site refers to a physical, geographical or logical entity as determined by each

company. As is the case with general recipes, Batch Management does not handle site

recipes.

Master Recipe

Master recipes are the modified recipes for meeting plant conditions. With the Batch

Management, the components in a master recipe are specified as absolute quantities.

When using a master recipe as a control recipe, actual parameters must be determined in

accordance with the unit used to process the batch and the batch size executed by the unit.

With Batch Management, master recipes are handled by the Recipe Management.

Control Recipe

Control recipes clarify the items required for producing a specified batch of a particular

product. Control recipes contain detailed information necessary for minute-by-minute

operation of the plant. The detailed information provided by a control recipe has been

modified to account for the quality of actual raw materials and the actual equipment used.

With Batch Management, control recipes are handled by the Process Management.

10th Edition : Dec.18,2003-00

<G1.2 What is a Recipe?> G1-7

IM 33S01B30-01E

Structure of Recipe

In general, a single recipe consists of the following items:

Header

Equipment

requirements

Procedure

Other

information

Formula

Recipe

G010202E.EPS

Figure Structure of Recipe

Header

Indicates information used to manage recipes such as recipe name, version and date/time

of creation.

Procedure

The procedure specifies procedure for manufacturing a product in process production.

Procedures prescribe the order of actions that should be taken for a specific purpose or the

manufacturing procedures and control methods in a given batch process, and are de-

scribed in the SFC (Sequence Function Chart).

Formula

The formula is a set of parameters used to manufacture the product defined by the recipe

procedure. These parameters define the values of process variables and the types and

quantities of components.

Equipment Requirements

The equipment requirements define conditions for units and other equipment necessary for

manufacturing a product.

Other Information

Information excluded from the other parts of the recipe that supports the batch process falls

into this category. This information includes laws and regulations to comply with, product

safety information, process flows, packaging, labeling, etc.

10th Edition : Dec.18,2003-00

G1-8 <G1.2 What is a Recipe?>

IM 33S01B30-01E

Recipes and Unit Recipes

A recipe is composed of unit recipes to run on a particular unit, and a common block that

stores data for use in a recipe. A unit is in a one-to-one relationship with a particular unit if a

product is transferred form one unit to another before it its finished.

The diagram below shows the relationship between units and unit recipes.

The unit recipe of Batch Management contains a recipe unit procedure that runs on a

particular unit. Formulas are not owned by a unit recipe but located in the common block, or

a shared areas, so that they can be referenced/set by every recipe unit procedure.

G010203E.EPS

Recipe

Unit recipe 1

Recipe unit procedure

Unit recipe 2

Recipe unit procedure

Unit recipe 3

Recipe unit procedure

Shared area

(Common block)

Formula

Unit 1

Unit instrument

Unit 2

Unit instrument

Unit 3

Unit instrument

Figure Units and Unit Recipes

10th Edition : Dec.18,2003-00

<G1.3 Hierarchy of Procedure> G1-9

IM 33S01B30-01E

G1.3 Hierarchy of Procedure

In a batch process, operating procedures and manufacturing procedures are changed in

order as products are made. These procedures have a hierarchical structure and can be

broken down as shown in the diagram below. The operations at each hierarchical level are

executed sequentially or in parallel.

The functions used to execute sequence procedures are provided by the corresponding

process management, unit instrument, operation, SEBOL, sequence table block, and logic

chart blocks.

G010301E.EPS

Procedure

Control action

Control step

Phase

Operation

Unit procedure

procedure

control action

control step

(Corresponding functions)

phase

operation

unit procedure

Process management

SEBOL

Sequence table

Logic chart

Operation

Unit instrument

Figure Procedure Model

G010302E.EPS

Recipe Procedure Master Recipe Recipe Unit Procedure Equipment Operation Phase

Polymerize 1

Dry PVC 3

Recover PVC 2

Preparation 1

React 3

Charge 2

Add Catalyst 1

Heat to 55 3

Add VCM 2

Add VCM 4

Sequence

Table

Logic Chart

Make PVC

SEBOL

Recipe Management Unit Supervision

Figure Hierarchy of Procedure

10th Edition : Dec.18,2003-00

G1-10 <G1.3 Hierarchy of Procedure>

IM 33S01B30-01E

Recipe Procedure

A recipe procedure reflects the relationships among the equipment entities (units). Recipe

procedure determines the order of recipe unit procedure execution.

Recipe Unit Procedure

A recipe unit procedure is a unit procedure controlled as a recipe. Recipe unit procedure

determines the process procedures and control methods corresponds to an equipment

entity (unit).

When a part of manufacturing methods vary with processes, a recipe unit procedure may

be applied. Thus this part of manufacturing methods may be defined as a recipe unit

procedure and downloaded to an FCS. Then this procedure can be executed by a unit

instrument.

Operation

An operation defines a process sequence for switching the running status from one to the

other based on chemical or physical process changes.

An operation may be started from a recipe unit procedure. Generally speaking, in a con-

tinuous process, one unit only requires one operation to be executed in a unit instrument. In

a batch process, multiple operations may be required to run in one unit instrument as the

operating sequence.

Some of the basic operations in a batch process are not specific to a recipe but can be

shared.

In the following example, the cleaning sequence is a shared operation.

G010303E.EPS

Recipe unit procedure B

Initialization B

Cleaning

Charge B

2

3

1

Cleaning

sequence

Recipe unit procedure A

Operations specific to the unit

Initialization A

Cleaning

Charge A

2

3

1

Initialization A

sequence

Charge A

sequence

Initialization B

sequence

Charge B

sequence

Operation can be shared

Operations specific to the unit

Figure An Example of Operation

10th Edition : Dec.18,2003-00

<G1.3 Hierarchy of Procedure> G1-11

IM 33S01B30-01E

Phase

In an operation, a phase refers to a processing or operation that is associated with a

process event.

Normally, a phase is determined in consideration of the discontinuation point of a process

in a logical sense or the point of a process where operator intervention is practicable in

view of safety.

For the sequences that enable a phase to run, the set of operating steps is selected in such

a manner that the requirements for repetitive operation and external factors are fulfilled.

For example, the following phases are selected for use with an operation, such as a charge

sequence or reaction sequence.

Operation Phase

Charge sequence Charge of component A

Charge of component B

Agitation

Charge of component C

Reaction sequence Heating

Charge of component D

Thermal insulation

Discharge sequence Cooling

Transfer

G010304E.EPS

Figure An Example of Operations and Corresponding Phases

Some applications may treat a process over an extended period of time as a phase for

operational or managerial reasons, or use a phase to ensure a certain period of time for

parameters to be changed.

Control Step

A control step is the lowest-level processing used to state operating actions or events in a

phase with which the operator is especially concerned.

A control step contains instructions that directly act upon the manipulation of a final control

element. Normally, this manipulation is stated using a control instruction.

For example, just as the user uses a batch-oriented language to state charge of compo-

nent A in charge sequence, the user can use control instructions to state the desired

control step, as shown below:

Phase Control Step

Charge of component A Open charge valve A

Wait until amount of charge reaches B kg

Close charge valve A

G010305E.EPS

Figure An Example of Phases and Corresponding Control Steps

In the actual description of control instructions using SEBOL, a sequence table, or a logic

chart, one control instruction may be represented by a single statement or it may require

multiple statements.

These instructions for the control steps are given in such a manner that they directly asso-

ciate with the specific actions or manipulations of equipment modules or units.

10th Edition : Dec.18,2003-00

G1-12 <G1.4 Application Capacity>

IM 33S01B30-01E

G1.4 Application Capacity

This section describes application capacities for different types of batch manage-

ment function.

Application Capacities for Recipe Management

Maximum Number of Master Recipes

The table below shows application capacities for the recipe management function:

Table Application Capacities for Recipe Management Function

Item Max.

Number of recipe group/project 16

Number of master recipes/recipe group 1000

Number of unit recipes/master recipe 32

Number of Path menu/master recipe 64

G010401E.EPS

Number of defining a formula/master recipe 30000

Application Capacities for Process Management

Maximum Number of Control Recipes

The table below shows application capacities for the process management function:

Table Application Capacities for Process Management Function

Item Max.

Number of server stations/recipe group 2

Number of client stations/recipe group 14

Number of trains/recipe group 16

Number of Path/train 64

Number of control recipes/recipe group 999

Number of control recipes/project 999

Number of control unit recipes/project 4000

Number of common blocks/project 1000

Number of common blocks/master recipe 256

Number of common data items/common block 256 (*1)

Data check pattern/common block 255

G010402E.EPS

Number of unit recipes Number of control recipes x 8

*1: This figure assumes the entire array as 1. The data area size is less than 32 Kbytes. The array is up to two dimensions

(999, 999) and the total sum of array elements is 10000 or less.

14th Edition : Dec.26,2006-00

<G1.4 Application Capacity> G1-13

IM 33S01B30-01E

Number of ACTIVE Control Recipes by Type

There are three types of the process management function with different capacities, i.e.

they support different number of ACTIVE control recipes, to match the scale and complexity

of different plants. The number of ACTIVE control recipes refers to a total sum of the control

recipes whose recipe status is other than RESERVED or COMPLETE. The table below

shows the number of ACTIVE control recipes for each type:

Table Number of ACTIVE Control Recipes by Type

Type classification Number of ACTIVE control recipes

Type A 4 or less

Type B 10 or less

Type C 999 or less

G010403E.EPS

SEE ALSO

For the recipe status, see the following:

Control Recipe Statuses in G3.1, Batch Execution Management

Number of ACTIVE Control Recipes by Type

There are three types of the process management function with different capacities, i.e.

they support different number of ACTIVE control recipes, to match the scale and complexity

of different plants. The number of ACTIVE control recipes refers to a total sum of the control

recipes whose recipe status is other than RESERVED or COMPLETE. The table below

shows the number of ACTIVE control recipes for each type:

Table Number of ACTIVE Control Recipes by Type

Type classification Number of ACTIVE control recipes

Type A 10 or less

Type B 50 or less

Type C 999 or less

G010404E.EPS

Table Number of ACTIVE Control Recipes by Type (For Entry Class)

Type classification Number of ACTIVE control recipes

Type A 4 or less

Type B 10 or less

Type C 999 or less

G010405E.EPS

SEE ALSO

For the recipe status, see the following:

Control Recipe Statuses in G3.1, Batch Execution Management

11th Edition : Oct.28,2004-00

Blank Page

<G2. Recipe Management> G2-1

IM 33S01B30-01E

G2. Recipe Management

This chapter explains the master recipes created by Recipe Management.

What is Recipe Management?

Recipe management is positioned at the same level as the production planning and sched-

uling and the production information management in the system hierarchy, and it interfaces

with the process management. The recipe management categorizes recipes and allows the

user to create and modify master recipes.

G020001E.EPS

Production planning

and scheduling

Production information

management

Recipe management

Process management

Unit supervision

Process Control

(Function block)

Scope of this chapter

Figure Positioning of Recipe Management

10th Edition : Dec.18,2003-00

G2-2 <G2.1 Master Recipes>

IM 33S01B30-01E

G2.1 Master Recipes

Master recipes can be created using the Recipe Builder and the Recipe Procedure

Builder. This section explains the structure and components of a master recipe.

Structure of Master Recipe

A master recipe is composed of the following components.

G020101E.EPS

Header Equipment requirements Formula Procedure

Master recipe

Figure Structure of Master Recipe

Header

Defines the management information of the recipe such as the name and version of the

recipe, and the date when the recipe was created.

Procedure

Defines the procedure for manufacturing the specified product in the processes; coded as

a sequential function chart (SFC).

The procedures may be created via master recipe are recipe unit procedure and recipe

procedure.

Formula

Defines the parameters used in the procedure for manufacturing the specified product. The

parameters include process values and the type and quantity of the component.

Equipment Requirements

Define the equipment units required for manufacturing the product by specifying the unit

names. Equipment Requirements can be defined with train names-Path names or unit

names.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-3

IM 33S01B30-01E

G2.1.1 Header

The header contains the basic information required for managing the recipe, such as

the recipe name, version, and date of creation. Data values set in the header are

displayed in the Recipe Header dialog box opened from the Product Overview

window or Product Control window.

Unit Recipe Formula Equipment Requirement (Train-Path) Equipment Requirement (Unit)

Recipe Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpHead.edf]

Recipe Comment

File Edit View Tools Window Help

Recipe Comment

Recipe Header

Recipe RECIPE01

Create Date 1998/08/05 17:01

Comment PRODUCT-A RECIPE.

Description This recipe is for Product-A

This recipe has two parts for two units

The recipe for unit 2 is started by the recipe for unit 1.

The reaction process requires manual charge of the additive,

prepare the additive before the process starts.

Product Name Product-A

Version No. 1

Version Date 1998/08/05 17:01

Creator Name CENTUM

G020102E.EPS

Ready

Message

Figure Recipe Header Tab

SEE ALSO

For the Recipe Header dialog box, see the following:

Recipe Header Dialog Box in G7.2.2, Dialog Boxes Extended from Product Overview Window

Create New Recipe Group

When creating a recipe header, if the recipe group for the recipe has not been created, a

warning dialog box appears.

Recipe Builder

G020115E .EPS

The Reference Project Directory is unspecified or incorrect

OK

Figure Warning Message Box

To create a new recipe group, select BATCH folder on System View, then choose [File] -

[Create New] - [Recipe group].

The newly created recipe group needs to be configured on Process Management Builders.

10th Edition : Dec.18,2003-00

G2-4 <G2.1 Master Recipes>

IM 33S01B30-01E

Header Definitions

Defining Recipe Header

After a recipe is created on Recipe View, the data values of the recipe header can be set.

The data values in the header are set in the Recipe Header tab on the Recipe Builder

window. The table below lists the data items in the Recipe Header tab.

Table Header Data

Data Item Description Data Type

Recipe Name The name of the recipe CHR16

Recipe Creation Date The date when the recipe was created U32

Recipe Comment The comment for the recipe CHR64

Recipe Description The description for the recipe CHR805

Product Name The name of the product manufactured by the recipe CHR32

Version Number The version number of the recipe CHR16

Version Date The date when the Version Number setting was modified last U32

Author The person who modified the recipe last CHR32

Approved by The person who approved the recipe last CHR32

Approval Date The date when the recipe was approved last U32

Master Recipe Status The master recipe status CHR16

Engineering Unit The engineering unit of the recipe CHR8

Recipe Standard Size The unit requirement of the recipe F64

Maximum Production Quantity The maximum production quantity of the recipe F64

Minimum Size of Recipe The minimum production quantity of the recipe F64

Security Level The security level of the recipe U8

Recipe Download Mode The download mode of the recipe

Recipe Start Mode The start mode of the recipe

CHR8

CHR8

G020103E.EPS

F64: 64-bit double-precision floating point real number

U32: 32-bit integer without a sign

U8: 8-bit integer without a sign

CHRn: Text string data with n characters

CHRnm: Text string data with n characters on row m

Recipe Name

The name set for a recipe newly created in the recipe view window is displayed. To change

the recipe name, enter up to 16 alphanumeric characters or eight double-byte characters.

Recipe Creation Date

The date when the recipe was created in the recipe view window is set.

Recipe Comment

The comment set for a recipe newly created in the recipe view window is displayed. To

change the recipe comment, enter up to 64 alphanumeric characters or 32 double-byte

characters.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-5

IM 33S01B30-01E

Recipe Description

Enter a description for a recipe such as operation methods on up to five lines. Each of

these lines can contain up to 80 alphanumeric characters or 40 double-byte characters.

Product Name

Enter up to 32 alphanumeric characters or 16 double-byte characters for the name of a

product manufactured according to a recipe.

Version Number

Version Number is used to control the modification of recipe. When a recipe is modified, a

version number will be added automatically.

If the recipe revision number is not under automatic management, the revision number

needs to be manually entered when the recipe is revised. If the revision number is under

the automatic management, users do not set the revision number.

When the recipe revision number is under the automatic management, the recipe revision

number is increased by one whenever recipe build is performed even though the recipe

build fails. The upper limit of the revision number is 100,000,000, when reaches the limit,

the revision number restarts from 1.

When copying a recipe on Recipe View, or when importing a recipe from the recipe builder,

the copied or the imported recipe has the same revision number of the original recipe.

IMPORTANT

If the revision number is under the automatic management, when run download/build the

recipe on Recipe View or on Procedure Builder, the recipe builder should be closed. When

download/build a recipe on Recipe View or on Procedure Builder without closing the recipe

builder, a build error will occur. However, download/build on Recipe Builder has no such

problem.

When set a recipes revision number under the automatic management, if the existing

revision number was set with the R3.02 or earlier software release, the revision number

under the automatic management is processed as follows.

If the revision number is a natural number of alphanumeric character string, this

number will be based for increment.

If the revision number is an alphanumeric character string but not a natural number,

the existing revision number will be cleared and the increment of new revision number

will be started from 1.

SEE ALSO

For more information about recipe revision number automatic management, see the following:

Create New -Project in File Menu of Recipe View in G2.5, Recipe View

14th Edition : Dec.26,2006-00

G2-6 <G2.1 Master Recipes>

IM 33S01B30-01E

Version Date

The date when the Version Number setting was modified last is set. The date cannot be set

by user.

Author

The name of the user who logged on is set by default. The name may be modified accord-

ingly.

Approved by

Setting is enabled when Master Recipe Status is changed to Approved. The name of the

user who logged on is set by default. The name may be modified accordingly.

When status of the master recipe is changed to [Not Approved], the approver name in

[Approved by] item is reset.

Approval Date

The date when Master Recipe Status is changed to Approved is set.

When status of the master recipe is changed to [Not Approved], the date in [Approval Date]

item is reset.

Master Recipe Status

The setting is Approved or Not Approved. Modification is allowed also on a recipe whose

Master Recipe Status is Approved.

When status of the master recipe is changed from [Approved] to [Not Approved], the

approver name in [Approved by] item and the date in [Approval Date] item are reset.

G020104E.EPS

Creation of new recipe

(Approved by and Approval Date=blanks;

Version Number=1)

Not

Approved

Approved

Cancellation of approval

(Approved by and

Approval Date

settings are reset.)

Approval

(Approved by and

Approval Date are set)

Modification of approved recipe

(Approved by Approval Date,

and Version Number settings are kept)

Figure Master Recipe Status

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-7

IM 33S01B30-01E

Engineering Unit Symbol

Set an engineering unit symbol for use in manufacture.

Recipe Standard Size

Set a standard size for a recipe. The CS Batch 1000/CS Batch 3000 does not have the

scaling function supporting the recipe standard size.

Maximum Production Quantity

Set a maximum quantity of products to be manufactured according to a recipe. The CS

Batch 1000/CS Batch 3000 does not have the scaling function supporting the maximum

production quantity.

Minimum Production Quantity

Set a minimum quantity of products to be manufactured according to a recipe. The CS

Batch 1000/CS Batch 3000 does not have the scaling function supporting the minimum

production quantity.

Security Level

Define the security level from 1 to 8 for the recipe. Downloading a control recipe or starting

a command is restricted by the security level. The default setting is security level 4.

SEE ALSO

For more information about security levels of recipe, see the following:

G3.7, Security Settings of Process Management

Recipe Download Mode

Select from the three modes: MAN, AUT, and TIME.

MAN: The recipe is downloaded to FCSs manually.

AUT: The recipe is downloaded to FCSs automatically upon completion of its

setup.

TIME: The recipe is downloaded to FCSs automatically at a time specified by the

production planning and scheduling function.

Recipe Start Mode

Select from the three modes: MAN, AUT, and TIME.

MAN: The recipe is started manually.

AUT: The recipe is started automatically upon completion of its downloading to

FCSs.

TIME: The recipe is started automatically at a time specified by the production

planning and scheduling function.

10th Edition : Dec.18,2003-00

G2-8 <G2.1 Master Recipes>

IM 33S01B30-01E

Data Items in Common Block

The following data items exist in a system-fixed common block, SYSRCM, and hence their

values can be displayed in a graphic window by referring to them using a SEBOL program

or using the batch ID as the key:

Recipe Name (RECIPE)

Engineering Unit (RCP_UNIT)

Recipe Standard Size (RCP_SIZE)

Maximum Size of Recipe (RCP_MAX)

Minimum Size of Recipe (RCP_MIN)

Recipe Download Mode (LOADMODE)

Recipe Start Mode (STRTMODE)

SEE ALSO

For details of system-fixed common blocks, see the following:

System-Fixed Common Block in G2.3, Common Block

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-9

IM 33S01B30-01E

G2.1.2 Procedure

The procedure is coded as an SFC and defines the procedure for manufacturing a product.

In the recipe management, the procedures are divided into Recipe Procedures and Recipe

Unit Procedures.

Recipe Procedure

Recipe procedure determines the order and relationships of recipe unit procedures. Each

step of a recipe procedure can be assigned with a recipe unit procedure.

A recipe unit procedure can not be executed from the step of the recipe procedure, so that

assigning a recipe unit procedure to a recipe procedure step can be omitted.

A recipe unit procedure can be executed by a SEBOL command in an operation, it can also

started from an operation and monitoring window.

G020105E.EPS

Unit

#1

#2

#3 #4

#5

Reaction B

Initialize

Charge

Reaction A

Mixture

1

2

3 4

5

Unit Procedure for Unit #1

Figure A Recipe Procedure

Recipe Procedure SFC

The differences of a recipe procedure and a unit procedure in unit instrument are as fol-

lows:

The first step can be a wait step

A step number of a recipe procedure can be different from the number of the recipe

unit procedure assigned to the step.

The transition condition, if scripted, is ignored during transition.

10th Edition : Dec.18,2003-00

G2-10 <G2.1 Master Recipes>

IM 33S01B30-01E

Defining a Recipe Procedure

When implementing a recipe procedure, the recipe procedure should be created first in

Recipe View. After creating the recipe, the recipe procedure can be edited on Procedure

builder.

Describing a recipe procedure is much similar to describing a unit procedure. However,

each step of the recipe procedure shall be defined with a unit recipe.

When defining the recipe is completed, the comment for the unit recipes defined to the

steps will be automatically set.

G020106E.EPS

Ready X=03,Y=01

Procedure Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpPT01.edf]

No.

ATTR OUT

01 Initialize

02 Charge

03 Reaction A

Mixture

04 Reaction B

05

File Edit View Draw Tool Window Help

Figure Procedure Builder

SEE ALSO

For more information about creating recipe procedures, see the following:

G2.5, Recipe View

For more information about editing recipe procedures, see the following:

F6, Editing SFC

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-11

IM 33S01B30-01E

Recipe Unit Procedure

A recipe contains a unit procedure for each equipment entity (a unit). A recipe unit proce-

dure defines the sequence of operations to be completed in each unit. Up to 32 unit proce-

dures can be defined in each recipe.

Each step of a recipe unit procedure can be assigned with an operation.

The operations and the function blocks called by the operations can be generated on the

Control Drawing Builder or the Function Block Overview Builder.

The figure below shows an example of recipe unit procedure.

G020107E.EPS

Unit

#1

#2

#3 #4

#5

Supply additive Agitate

Initialize

Charge

Heat-up

Discharge

Cleaning

End

1

2

3 4 5

6

7

8

Unit Procedure for Unit #1

Figure A Recipe Unit Procedure

10th Edition : Dec.18,2003-00

G2-12 <G2.1 Master Recipes>

IM 33S01B30-01E

Defining a Recipe Unit Procedure

A recipe unit procedure can be defined on Procedure Builder.

Describing a recipe unit procedure is much similar to describing a unit procedure.

Each step of the recipe unit procedure shall be defined with an operation in the same FCS

for the procedure.

Procedure Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpPT01.edf]

No.

ATTR OUT

01 Initialize

02 Charge

03 Heat-up 04 Supply additive

06 Discharge

07 Cleaning

05 Agitate

08 End

File Edit View Draw Tool Window Help

G020108E.EPS

Ready X=03,Y=01

Message

Figure Recipe Unit Procedure Builder

SEE ALSO

For more information about editing recipe unit procedures, see the following:

F6, Editing SFC

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-13

IM 33S01B30-01E

Defining Unit Recipes

Unit Recipe Comment, Unit Recipe Download Mode, Unit Recipe Start Mode

Define the actions of a unit procedure in the unit recipe.

The unit recipe can be set in the Unit Recipe tab of the Recipe Builder window. The follow-

ing items need to be set:

UnitRcpNo. Unit Recipe Comment Unit Recipe Download Mode Unit Recipe

1 UNIT1 Manual Manual

2 UNIT2 Manual Manual

3 Manual Manual

4 Manual Manual

5 Manual Manual

6 Manual Manual

7 Manual Manual

8 Manual Manual

Unit Recipe Formula Equipment Requirement (Train-Path) Equipment Requirement (Unit)

Recipe Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpHead.edf]

Unit Recipe

Comment

File Edit View Tool Window Help

Unit Recipe

Comment

Recipe Header

G020109E.EPS

Ready

Message

Figure Unit Recipe Tab

Unit Recipe Comment

In this box, type the comment of up to 24 alphanumeric characters or twelve double-byte

characters for the unit recipe.

Unit Recipe Download Mode

Select from the three modes: MAN, AUT, and TIME.

MAN: The unit recipe is downloaded to FCSs manually.

AUT: The unit recipe is downloaded to FCSs automatically upon

completion of its setup.

TIME: The unit recipe is downloaded to FCSs automatically at a time

specified by the production planning and scheduling function.

10th Edition : Dec.18,2003-00

G2-14 <G2.1 Master Recipes>

IM 33S01B30-01E

Unit Recipe Start Mode

Select from the three modes: MAN, AUT, and TIME.

MAN: The unit recipe is started manually.

AUT: The unit recipe is started automatically upon completion of its

downloading to FCSs.

TIME: The unit recipe is started automatically at a time specified by the

production planning and scheduling function.

Download Destination of Recipe Unit Procedure

Each unit procedure in a unit recipe can be downloaded to a unit instrument (non-resident),

which then carries out the actions defined in the downloaded unit procedure.

The unit instrument where the recipe is downloaded may be created on the Control Draw-

ing Builder or on the Function Block Overview Builder.

Operation3

Operation2

G020110E.EPS

HIS

Download

Recipe unit procedure

FCS

Unit instrument (non-resident)

Recipe unit procedure

Operation1

Figure Download Destination of Recipe Unit Procedure

TIP

There are two types of unit instruments, resident type and non-resident type. A resident type unit instru-

ment may have a fixed procedure while a non-resident unit instrument does not. Thus, a recipe unit

procedure may only be downloaded to a non-resident type unit instrument in which no procedure is

resided.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-15

IM 33S01B30-01E

G2.1.3 Formula

A formula, as defined in ISA S88.01, is a category of recipe information including the

process parameters. When setting up a recipe, the formula is downloaded and

stored in the common block in the FCS.

Formula and Common Block

There are two types of common blocks : user-defined common blocks and system-fixed

common blocks. The user-defined common blocks can be further deviled into three catego-

ries in accordance with their usage.

For the whole recipe (common to all units).

For a group of units (unit common block).

For a group of operations (operation common block).

The common blocks to be specified in the formula are user-defined common blocks. When

a recipe is set up, the user-defined common blocks specified in the formula and the sys-

tem-fixed common blocks are copied to the control recipe as part of the master recipe.

A common block can be accessed from an operation, SEBOL program, or operation and

monitoring window by using the batch ID as the key.

Common blocks can share a data area for all the unit recipes within the same recipe.

Hence, a common block is useful for sharing the same data among multiple sequences

and exchanging data between unit recipes.

The formula can be set so as to modify the default values of data in common blocks. Also,

the data values in common blocks can be modified when setting up a recipe by opening the

Formula dialog box. The data changes made when setting up the recipe are effective only

for the current production.

G020111E.EPS

HIS

Recipe

Formula

FCS

Unit instrument

Recipe unit procedure

Setting Referencing

Operation

Common blocks Common blocks

Download data to the

specified common blocks

via formula.

specifies

common

blocks

Figure Download of Formula

SEE ALSO

For details on batch ID, see the following:

Batch ID (Batch Identifier) in G3.2, Recipe Setup

For details on common blocks, see the following:

G2.3, Common Block

10th Edition : Dec.18,2003-00

G2-16 <G2.1 Master Recipes>

IM 33S01B30-01E

Unit Common Block and Operation Common Block

It will be more convenient for engineering or for operating and monitoring if designating a

common block and its array data to a specific unit or operation block. With unit common

block, the following features become available.

The formula data can be displayed in hierarchies on HIS, i.e., only the formula data

specific to the designated unit or operation can be displayed.

A common block can be treated as a parameter in unit recipe, and it is easier when

defining a formula or handling a block name.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-17

IM 33S01B30-01E

Defining a Formula

Defining Formula

Set the formula in the Formula tab of the Recipe Builder. To configure unit common block or

to configure operation common block, the editing mode switching button on Recipe View

can be used. Before setting the formula, the common blocks to be specified must be

created in System View. If any one of the common blocks specified in the formula does not

exist in the HIS, an error occurs when the recipe is set up. The following items need to be

set for the formula.

SEE ALSO

For more information about unit common block and operation common block, see the following in the

later part of this chapter:

Editing Unit Common Block

No. Common Block Data Item Array1 Array2 Value Display

1 CHARGE SC1SV 0 0 20 Display at Recipe Setup and in

3 REACT1 R11SV 0 0 100 Display at Recipe Setup and in

4 R120SV 0 0 20 Display at Recipe Setup and in

5 R130SV 0 0 50 Display at Recipe Setup and in

Unit Recipe Formula Equipment Requirement (Train-Path) Equipment Requirement (Unit)

Recipe Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpHead.edf]

Common Block

File Edit View Tools Window Help

CHARGE: CHAR

REACT1: REAC

REACT2: REAC

REACT3: REAC

REACT4: REAC

SYSPCM01: #01

SYSPCM02: #02

SYSPCM03: #03

SYSPCM04: #04

SYSPCM05: #05

SYSPCM06: #06

SYSPCM07: #07

SYSPCM08: #08

SYSPCM09: #09

Recipe Header

G020112E.EPS

Ready

Message

Position: Line 1 Column 2

2 SCMAIN1 0 0 80 Display at Recipe Setup and in Common block name

is CHARGE.

Common block name

is REACT1.

Unit Common Block Edit Mode switching button

Figure Formula Tab

10th Edition : Dec.18,2003-00

G2-18 <G2.1 Master Recipes>

IM 33S01B30-01E

Common Block

Specify the name of a user-defined common block or system-fixed common block. If this

specification is omitted, the common block name on the previous row will be used.

When designating a common block without designating the data items, all the data items of

the common block will be taken by the formula. The default values specified on Common

Block Builder will be used as initial values.

Moreover, when a reference project is specified in the property sheet of the project in

Recipe View, the contents of the common blocks defined in Common Block Builder for the

project can be used. The details are shown as follows.

1. Choose [Get Common Blocks..] from [Tool] menu on Recipe Builder. A dialog box for

selecting a common block will appear.

2. Choose a common block name on the dialog box, the block will be used for holding

data in the formula. From the contents defined for common blocks, the data items that

the existing formula does not have, will be set to the formula.

Data Item

Specify the data item name, which must be defined in the common block using the Com-

mon Block Builder.

When a reference project is specified in the property sheet of the project in Recipe View,

the data items defined in Common Block Builder for the project can be used. The details

are shown as follows.

1. Specify a common block name for the formula on Recipe Builder.

2. Select the line the common block name is defined.

3. Choose [Get Items] from [Tool] menu on Recipe Builder. Then all data items defined in

Common Block Builder for the project will be set into the formula.

TIP

Multiple common block data items can be set to formula all together. In the above procedure step 3,

select multiple lines of data items, then choose [Get Items] from [Tools] menu on Recipe Builder, thus all

the data items will be set to the formula except the data items that the formula already have.

Array 1 and Array 2

If the data item specified is not an array, the default settings can be use. By default, Array 1

and Array 2 are set to zeros. If the data item specified is an array, the number of array

elements need to be specified.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-19

IM 33S01B30-01E

Value

When initial value is different from the default setting in the common block, the value can be

set here. The data values can also be modified when setting up the recipe.

When entering a value of a datum, the data type is irrelevant to the [Data Type] specified on

the common block builder. However, entering a value to the datum with the type of [Result

Data], restriction may be applied to prevent from erroneous entry.

Do the following settings may apply the restriction on entering value to the datum with the

type of [Result Data].

1. On recipe builder, choose [Formula Settings] from [Tools] menu. A Formula Settings

dialog box displays.

Cancel To Default OK

G020118E.EPS

Protected data items when acquiring

Unit Common Block Information

Editing Result Data

Allowed

Not Allowed

Value

Display

Comment

Title

Formula Settings

Figure Formula Settings Dialog Box

2. On the Formula Settings dialog box, choose the option [Not Allowed] for the field of

[Editing Result Data].

10th Edition : Dec.18,2003-00

G2-20 <G2.1 Master Recipes>

IM 33S01B30-01E

Display

Specify whether to display the data items when setting up the recipe and in the Formula

dialog box. Select from NO, DATA, and AUTO. AUTO can be set for up to 512 data items

per recipe.

NO: The data item is not displayed when setting up the recipe or in the

Formula dialog box.

DATA: The data item is not displayed when setting up the recipe, but is

displayed in the Formula dialog box.

AUTO: The data item is displayed when setting up the recipe and in the

Formula dialog box.

The display status for data items in the Formula dialog box can also be specified in the

Common Block Builder. If data items are set not to be displayed using the Common Block

Builder, they will not be displayed in the Formula dialog box.

Note that if AUTO is specified for data items using the Recipe Builder, they will be displayed

in the Formula dialog box regardless of the settings in the Common Block Builder.

Comment

Type a comment of up to 16 alphanumeric characters or double-byte eight characters.

When a reference project is specified in the property sheet of the project in Recipe View,

the comment defined in Common Block Builder for the project can be used.

Select the data items for reflecting the comment. Then choose [Get Comments of Items]

from [Tool] menu on Recipe Builder. The comments defined in Common Block Builder will

be set into the formula.

Title

The title name can be defined for the formula dialog box when setting up a recipe. Up to 16

alphanumeric or 8 double-byte characters can be used.

When displaying the formula dialog with a title, the common block name and the data item

name should not be specified. If the common block name or data item name is specified,

the common block name or data item name will be displayed instead of displaying the title.

And the setting for Display should be AUTO.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-21

IM 33S01B30-01E

Editing Unit Common Block

When editing the Formula tab, to configure a unit common block or to configure an opera-

tion common block can be switched.

Switching the editing mode can be performed by choosing [Unit Common Block Edit Mode]

on [Edit] menu of Recipe View or by clicking the Unit Common Block Edit Mode button on

Recipe View.

G020116E.EPS

Recipe Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpHead.edf]

Ready

UnitRcpNo.

UnitRcpNo.

No. UnitRcpNo. Operation Name Tag/Generic Operation ID Common Block Data Item Array 1 Array2

Message

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

0

0

0

0

0

1

1

1

1

1

1

1

1

2

2

2

2

0

0

0

0

0

0

0

1

1

2

2

3

3

0

0

1

1

CHARGE

REACT1

COMB01

COMB11

COMB12

COMB13

COMB01

COMB11

OP1011

OP1012

UGEN01

OP2011

1

2

3

1

Tag

Tag

Generic

Tag

SC1SV

SCMAIN1

R11SV

R120SV

R130SV

PICSV

TICSV

SETV1

ACTV1

SETV2

ACTV2

MV1

MV2

PICSV

TICSV

SETV1

ACTV1

File Edit View Tools Window Help

Unit Recipe Formula Equipment Requirement (Train-Path) Equipment Requirement (Unit) Recipe Header

Position: Line 1 Column 2

Unit Common Block Edit Mode switching button

Figure Switching Editing Mode of Formula Tab

Switching the editing mode of formula tab, the columns for defining unit recipe number,

operation name, tag and generic names and operation ID will be added.

By defining these items, a common block can be used as unit common block or an opera-

tion common block. By designating the unit common block, the part of the formula only for

the unit recipe running in the formula dialog box can be extracted and displayed.

10th Edition : Dec.18,2003-00

G2-22 <G2.1 Master Recipes>

IM 33S01B30-01E

Configuration Items of Formula in Unit Common Block Edit Mode

The configuration items of Formula in Unit Common Block Edit Mode are shown in the

following figure.

G020117E.EPS

Formula

No. UnitRcpNo. Operation Name Tag/Generic Operation ID Common Block Data Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

CHARGE

REACT1

COMB01

COMB02

COMB03

COMB04

COMB01

COMB02

OP1011

OP1012

UGEN01

OP2011

1

2

3

1

Tag

Tag

Generic

Tag

SC1SV

SCMAIN1

R11SV

R120SV

R130SV

PICSV

TICSV

SETV1

ACTV1

SETV2

ACTV2

MV1

MV2

PICSV

TICSV

SETV1

ACTV1

Common block configuration

for whole recipe

Common block configuration

for a designated unit

Common block configuration

for a designated unit

Common block configuration

for a designated operation

Common block configuration

for a designated operation

Unit recipe 1

Unit recipe 2

Unit recipe n

Common

Figure Configuration Items of Formula in Unit Common Block Edit Mode

The formula of a common block in Unit Common Block Edit Mode is scripted in the follow-

ing order.

Common block configuration for whole recipe (Common)

The configuration is the same as not in Unit Common Block Edit Mode.

Configuration for unit recipe 1

Configuration for unit recipe 2

:

:

Configuration for unit recipe n

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-23

IM 33S01B30-01E

Get Unit Common Blocks

The common blocks used by a unit (unit common blocks) or the common blocks used by an

operation (operation common blocks) can be collected all together, and automatically

entered to the configuration area of Formula.

To get the unit common blocks, choose [Get Unit Common Blocks] task on [Tools] menu of

the recipe builder.

When getting the unit common blocks by this way, all the information in the configuration

area of the formula will be erased before the collected blocks are entered. However, the

configuration of the formula for common part will be intact. Moreover, it is necessary to

define the unit common blocks and operation common blocks on unit common block

builder and to define unit recipe procedure on recipe procedure builder before performing

Get Unit Common Blocks.

SEE ALSO

For more information about unit common block builder, see the following:

Configuring Unit Common Block and Operation Common Block in G2.3, Common Block

For more information about how to define recipe unit procedure, see the following:

Defining a Recipe Unit Procedure in Recipe Unit Procedure in G2.1.2, Procedure

Protected Data Items when Acquiring Unit Common Block Information

When acquiring the unit common block information for the first time, the items of Value,

Display, Comment and Title are all set with the data obtained from the common block.

When acquiring the unit common block information for the second time, the data of the

above items are overwritten by the data obtained from the unit common block (by default

action).

However, with the following settings, the data of the above data items can be protected

from overwritten by the obtained unit common block information.

1. On recipe builder, choose [Formula Settings] from [Tools] menu. A Formula Settings

dialog box displays.

Cancel To Default OK

G020119E.EPS

Protected data items when acquiring

Unit Common Block Information

Editing Result Data

Allowed

Not Allowed

Value

Display

Comment

Title

Formula Settings

Figure Formula Settings Dialog Box

2. On the Formula Settings dialog box, check the items to be protected from the obtained

unit common block information.

10th Edition : Dec.18,2003-00

G2-24 <G2.1 Master Recipes>

IM 33S01B30-01E

G2.1.4 Equipment Requirements

Equipment requirements constrain the choice of the equipment that will eventually be used

to implement the procedure for manufacturing the products. There two types configura-

tions, Train-Path and Unit for defining the Equipment Requirements.

Defining Equipment Requirements Train

Train Name, Path Name

When using train or path for equipment requirements configuration, the train or the path

needs to be configured first on the Train Builder. When a train or a path is defined here for

equipment requirements, the unit and the unit recipe previously assigned to the train or the

path will be set for equipment requirements.

A wildcard (*) can be used for specifying a train or a path. When the wildcard (*) is used, all

the trains and all the paths defined in the recipe group can be used. However, a wildcard

character can be used at the end of the string of a Train Name or a Path Name.

SEE ALSO

For details of Train and Path, see the following:

G2.2, Recipe Group and Train

Unit Recipe Formula Equipment Requirement (Train-Path) Equipment Requirement (Unit)

Recipe Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpHead.edf]

Train Name

File Edit View Tool Window Help

LINE1: Train1

LINE2: Train2

Recipe Header

G020113E.EPS

Ready

Message

Position: Line 1 Column 2

No. Train Name Path Name

1 LINE1 PASS1

2 PASS2

3 PASS3

4 LINE2 *

5

6

7

8

9

Figure Equipment Requirements (Train-Path) Tab

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-25

IM 33S01B30-01E

Defining Equipment Requirements Unit

Unit

The equipment requirements indicate equipment units to be used for manufacturing the

product. Unit name can be specified if the train and path are not used. In the equipment

requirements, the names of the units, i.e., the tag names of the non-resident unit instru-

ment blocks created on the Control Drawing Builder or on the Function Block List Builder

may be specified as the unit names for the unit recipe. Up to 16 units can be set for each

unit procedure and each recipe may contain up to 32 unit recipes.

When setting up a recipe, the unit name for equipment requirements needs to be selected

from the menu. If hyphen (-) is set as the unit name, it stands for a dynamic assignment.

Dynamic assignment allows operator to specify the unit name before the unit recipe starts.

A dynamic assignment can be specified for the second and subsequent unit recipes.

If the unit names are left blank (all units 1 to 16), the direct unit name specification for the

during the recipe setup.

SEE ALSO

For details of dynamic unit assignment, see the following:

Dynamic Unit Assignment in G3.2, Recipe Setup

Unit Recipe Formula (Train-Path)

G020114E.EPS

Recipe Builder [Pjt:MYPJT Gr:RG01 Rcp:RCP0001 File:RcpHead.edf]

Unit1

UT0101

UT0102

UT0103

UT0201

UT0202

Recipe Header

UnitRcpNo. Unit Recipe Comment Unit1 Unit2 Unit3

1 UNIT RECIPE1 UT0101 UT0102

2 UNIT RECIPE2 - UT0201 UT0202

3 UNIT RECIPE3

4

5

6

7

8

File Edit View Tool Window Help

Equipment Requirement (Unit)

Ready

Message

Position: Line 1 Column 2

Direct specification

Select from unit menu

Figure Equipment Requirements (Unit) Tab

10th Edition : Dec.18,2003-00

G2-26 <G2.1 Master Recipes>

IM 33S01B30-01E

G2.1.5 Handling Master Recipe File

The File menu in the Recipe Builder window and Recipe Procedure Builder window

contains the following commands for handling a master recipe file:

Saving a File

Save

Saves the new master recipe or saves the changes you made in an existing master recipe,

without checking the contents.

Save As...

Use this command to save a currently opened master recipe file as a different master

recipe file (*.sva). The file is saved under the specified name and in the specified location

without checking the contents.

Build

Build

Saves the new master recipe or saves the changes you made in an existing master recipe,

and checks the contents. If no error is found, the master recipe file to be downloaded to the

master server is created. The master recipe is saved regardless of whether there is an

error.

Download

Download

Use this command after the master recipe file is created correctly by the Build command.

Selecting Download opens a dialog box for downloading the master recipe file to the

master server.

TIP

The master server is defined for each recipe group using the Process Management Configuration Builder

and Recipe Builder.

10th Edition : Dec.18,2003-00

<G2.1 Master Recipes> G2-27

IM 33S01B30-01E

External File Recipe Builder

In Recipe Builder, files can be handled as follows.

Default

Using [Create Default File] on [Tool] menu may create a default file. Otherwise, the system

default file will be used when opening a default file.

Import

The builder file (*.edf) and the file saved in a different name (*.sva) can be imported.

In Recipe Builder, the data for Recipe Header, Unit Recipe, Formula, Equipment Require-

ments (Train-Path) and Equipment Requirements (Unit) can all be imported.

Import CS Source File

The master recipe source file (*.s) created in CS Batch can be imported.

Import Formula

An eternal file can be imported for the contents configured on Formula tab. Only the CSV

format file (*.csv) can be imported.

Export Formula

The contents configured on Formula tab can exported into an external file in CSV format

(*.csv). Only the configured contents can be exported.

External File Recipe Procedure Builder

In Recipe Procedure Builder, files can be handled as follows.

Default

Using [Create Default File] on [Tool] menu may create a default file. Otherwise, the system

default file will be used when opening a default file.

Import

The builder file (*.edf), the file saved in a different name (*.sva) and the text file (*.txt) can

be imported.

Export

The contents can exported to an external file in text format (*.txt).

Import CS Source File

The master recipe source file (*.s) created in CS Batch can be imported.

10th Edition : Dec.18,2003-00

G2-28 <G2.2 Recipe Group and Train>

IM 33S01B30-01E

G2.2 Recipe Group and Train

Recipe group and train are implemented for controlling the control recipes.

Recipe Group

Recipe Group Number, Recipe Group Comment, Recipe Comment

Recipes are managed in units called recipe groups. Up to 16 recipe groups can be used.

Recipe groups are divided into equipment units and product line units when used. Dividing

recipes into groups makes it easier to manage the recipes and prevents wrong recipes

unrelated to the production from being downloaded by mistake.

Since master recipes and control recipes are managed in recipe groups, there are no

recipes that belong to more than one recipe group. The diagram below shows how recipes

are positioned in recipe groups:

G020201E.EPS

Project

Master recipe Control recipe

Recipe group 1

Master recipe Control recipe

Recipe group 16

Figure Structure of Recipe Groups

Creating Recipe Groups

The recipe of the group 1 exists by default. A new recipe group can be created via the

System View.

When creating a recipe group, the dialog box to set the group number and comment

appears.

Recipe group number

Set the group number in the range of 1 to 16.

Recipe group comment

Define the recipe comment with up to 32 single-byte or 16 double-byte characters.

IMPORTANT

You must enter a recipe group comment to create a recipe group.

10th Edition : Dec.18,2003-00

<G2.2 Recipe Group and Train> G2-29

IM 33S01B30-01E

Train

A train stands for a bunch of physical devices and equipment entities applied in the recipe

group.

Based on the train, the units can be grouped. When defining a train, the control recipes are

managed in recipe group and train.

When using train to manage the equipment requirements, the combinations of units in a

train (path) may be set beforehand and then assigned.

When omitting the train configuration, the equipment requirements will use the unit name

specified for each unit recipe.

The relationship of recipe group and train is shown as follows.

G020202E.EPS

Recipe Group1

UNIT-A1

UNIT-A2

UNIT-A3

Train A

UNIT-B1

UNIT-B2

UNIT-B3

Train B

UNIT-C1

UNIT-C2

UNIT-C3

Train C

Recipe Group

1 to 16

Figure Recipe Group and Train

10th Edition : Dec.18,2003-00

G2-30 <G2.2 Recipe Group and Train>

IM 33S01B30-01E

Defining a Train

Train, Train Comment

Up to 16 trains can be defined in a recipe group.

Path

G020203E.EPS

Train Builder [Pjt:MYPJT Gr:RG01 File:TrainName.edf]

Ready

Train

Train

No. Train1 Train Comment

01 TRAIN1 TRAIN1

02 TRAIN2 TRAIN2

03

04

05

06

07

08

09

Message

File Edit View Tool Window Help

Position: Line 1 Column 2

Figure Train Builder (Train Tab)

Train

Up to 16 alphanumeric capital characters can be used to define a train name. Hyphen

[-] can also be used, however, the train name must be started by an alphabet. The

train names in the recipe group should not be identical.

Train Comment

Up to 24 alphanumeric or 12 double-byte characters can be used for defining the train

comment.

17th Edition : Jul.14,2008-00

<G2.2 Recipe Group and Train> G2-31

IM 33S01B30-01E

Path

Similar as a train stands for a bunch of physical devices, a path stands for a group of units

assigned for the implemented unit recipe.

A path structure is a group of units connected in sequence or in parallel for implementing

the recipe. In a path, each unit recipe is assigned with a unit name.

When setting up a recipe, by selecting train or path, the pre-set unit recipe and unit can be

assigned.

The units used for the path can be defined on Train Builder. By setting the train name and

path name on the Equipment Requirements tab of Recipe Builder, the train or the path can

be selected during the recipe setup.

The relationship of train and path is shown as follows.

G020204E.EPS

UNIT-A1

UNIT-A2

UNIT-A3 UNIT-B3

UNIT-A4 UNIT-B4

Unit Recipe#1

Unit Recipe#2

Unit Recipe#3

Unit Recipe#4

Path A Path B

Train

Figure Relationship of Train and Path

10th Edition : Dec.18,2003-00

G2-32 <G2.2 Recipe Group and Train>

IM 33S01B30-01E

Defining Paths

Train, Path, Path Comment, Unit Recipe1 to 32

Up to 64 paths can be defined for one train.

Path

G020205E.EPS

Train Builder [Pjt:MYPJT Gr:RG01 File:TrainName.edf]

Ready

Train

Train

No. Train Path Path Comment Unit Recipe1 Unit Recipe

01 TRAIN1 PATH1-1 Path1-1 UT0101 UT0201

02 PATH1-2 Path1-2 UT0101 UT0202

03 PATH1-3 Path1-3 UT0101 UT0203

04 TRAIN2 PATH2-1 Path2-1 UT0102 UT0201

05

06

07

08

09

Message

File Edit View Tool Window Help

Position: Line 1 Column 2

Figure Train Builder (Path Tab)

Train

A train name can be selected on Train tab. When train name is omitted, the train used

in the previous row will be used.

Path

Path name can be defined with up to 16 capital case alphanumeric characters and a

hyphen (-). However, the path name must be started with an alphabet letter. The path

names in a train can not be identical.

Path Comment

Up to 24 alphanumeric or 12 double-byte characters can be used for defining the path

comment.

Unit Recipe 1 - 32

The name of units assigned for each unit recipe can be defined.

A tag list of the non-resident unit instruments defined in the project will display. If the

unit name consists a hyphen (-) then perform dynamic unit assignment. The dynamic

unit assignment may designate a unit before the execution of the unit recipe. Dynamic

unit assignment may be applied to the unit recipes from the second.

SEE ALSO

For more information about dynamic unit assignment, see the following:

Dynamic Unit Assignment in G3.2, Recipe Setup

10th Edition : Dec.18,2003-00

<G2.3 Common Block> G2-33

IM 33S01B30-01E

G2.3 Common Block

Common block is used to hold the processing data of recipes, unit recipes as well