Professional Documents

Culture Documents

p.32, Special Report

Uploaded by

mostafamounirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p.32, Special Report

Uploaded by

mostafamounirCopyright:

Available Formats

S p e c i a l R e p o r t

Compressed air

systems

Energy assessments

for improved effciency

by Chris Dee and Greg Bordiak

Compressed air is an industrial utility generated on-site by the user,

who is then responsible for its treatment and transmission to the point

of use in process machinery. There is a wide variety of applications

for compressed air, but some of these waste valuable resources be-

cause they are not optimized for maximum efficiency.

It is estimated that more than 10 % of

industrial electrical energy is consumed

in the production of compressed air. As

business and governments around the

world work to conserve limited energy

resources for example through the future

ISO 50001:2011, Energy management

systems Requirements with guidance

for use, the compressed air industry has

developed an assessment standard provid-

ing guidelines for generating and analysing

data with the aim of improving effciency.

The future ISO 11011, Compressed air

systems Energy assessment, considers

the entire system, from energy consumed

to the resulting work performed.

The standard considers compressed air

systems as three functional subsystems :

Supply, including the conversion of

primary energy resources to com-

pressed air energy

Transmission, including movement of

compressed air energy from point of

generation to point of use

Demand, measuring the total of all

compressed air consumers, including

productive end-use applications and

various forms of compressed air waste.

ISO 11011 sets requirements for conduct-

ing compressed air system assessments,

analyzing the data from the assessment, and

reporting and documentation of assessment

fndings. A key element is to identify the

roles and responsibilities of those involved

in the assessment activity.

Shared expertise

The precursor to the current draft, a

work item entitled Reporting on energy

effciency measurements made on-site ,

was initiated in 2004 at the meeting of ISO

technical committee ISO/TC 118, Compres-

sors and pneumatic tools, machines and

equipment and subcommittee SC 6, Air

compressors and compressed air systems,

in Karlsruhe, Germany. The subcommit-

tee began addressing the task through its

working group WG 4 in 2007, conducted

jointly by two industry liaison bodies, the

European Committee of Manufacturers of

Compressors, Vacuum Pumps and Pneumatic

Tools (PNEUROP) and the Compressed

Air and Gas Institute (CAGI).

All parties agreed on the need for an

energy audit standard, but the process was

complicated by a lack of consensus over

how the content should be presented and

indeed what that content should be.

A key element of ISO standardization is

that participants come to the table to share

both their expertise and relevant documents.

A number of ISO member countries have

done work in the energy audit feld, including

with compressed air systems. Some have

produced relatively simple approaches,

while others have pursued more detailed

methodologies for assessment and auditing.

The USA has produced the most com-

prehensive approach under the direction

of the Department of Energy, resulting in

ASME EA-4:2010, Energy assessment for

compressed air systems. To avoid dupli-

cation of effort, the secretariat of WG 4

sought permission to use extracts from

EA-4, winning permission in late 2009 to

use the core principles.

As a result of an extensive rewrite called

for by a 2008 WG 4 meeting in Delft, the

Netherlands, the draft was submitted for

a second CD ballot in 2010, receiving

widespread support.

ISO Focus+ M a y 2 0 1 1 3 2

a

ISO Focus+, www.iso.org/isofocus+

Bringing order to growth

Compressed air systems are designed to

accommodate known uses, but their evolu-

tion over time may conceal problems arising

from add-ons. These systems involve large

pipe runs, and if additions take place without

necessary controls users may experience

problems like the one described by a site

manager who said, Every Thursday, we

run out of compressed air.

System-wide compressed air treatment

strategies are specifed, including remedial

measures to optimize treatment.

End-use applications

The standard considers end-use appli-

cations as part of the assessment process,

including those identifed as critical air

demands , which have the potential to

impact values such as product quality,

production rate, scrap rate, rework cost

and customer satisfaction.

The most relevant effect of improving

the performance of a critical air demand

is on non-energy benefts to production

operations, and may be related less to the

compressed air system itself than to the poor

mechanical state of end-use equipment.

Recognizing the importance of effcient

use, the standard emphasizes that there are

often energy-effciency benefts associated

More than 10 %

of industrial electrical

energy is consumed

in the production

of compressed air.

with improving the performance of these

critical air demands.

Placing yourself on a diet to lose weight

may be a good strategy, but the effort will

be in vain without a regime to maintain

the benefts. Similarly, commissioning an

assessment of a compressed air system

and adopting the recommended actions is

only a frst step ; the benefts must to be

continuously maintained.

ISO 11011 specifes that recommenda-

tions shall consider maintenance programs

to ensure continued results, including

recommendations for specific remedial

measures and estimated reductions in energy

consumption.

ISO 11011 is not intended to replace exist-

ing compressed air assessment activities,

but outlines a framework for the assessment

and audit process that should dovetail with

specifc requirements.

ISO 11011 aims to bring order to this

growth problem by addressing concerns

about present uses, critical production

functions and compressed air system per-

formance. The assessment should identify

and quantify energy waste, balancing com-

pressed air supply and demand, energy use

and total compressed air demand. These

generalizations will guide the selection of

objectives and action items for preliminary

data collection.

Even managers directly responsible for

compressed air systems often cannot specify

a precise level of demand or supply. One

of the key features of the future ISO 11011

standard will be the generation of accurate

statistics through by establishing baseline

performance.

This benchmarking is intended to quantify

the current performance levels and costs of

a compressed air system, and to correlate

the results with the plants present produc-

tion levels. As improvements are made to

the system, it will be possible to estimate

effect by comparing new measurements

with the original baseline.

Like any expensive resource, compressed

air systems should be well managed.

ISO 11011 addresses waste, starting with

leaks that may account for up to 35 % of the

generated compressed air. But the standard

also covers issues such as inappropriate use,

for example compressed air being used for

cooling when a simple fan could do the job

at a lower cost.

ISO 11011 also looks at optimizing air

treatment by assessing the need for and

effciency of installed equipment, looking

to identify opportunities for performance

improvement and reduced energy use.

Chris Dee is

Director-Gene-

ral of the British

Compressed Air

Society (BCAS),

the worlds only

trade association

dedicated solely

to compressed air.

He is also Convenor of ISO technical

committee ISO/TC 118, Compressors and

pneumatic tools, machines and equip-

ment, subcommittee SC 6, Air compres-

sors and compressed air systems and wor-

king group WG 4, Energy management.

About the authors

Greg Bordiak is

Technical Off-

cer of the British

Compressed Air

Society (BCAS).

He is also Secretary

of ISO technical

committee ISO/

TC 118, Com-

pressors and pneumatic tools, machines

and equipment, subcommittee SC 6, Air

compressors and compressed air systems

and working group WG 4, Energy mana-

gement.

ISO Focus+ M a y 2 0 1 1 3 3

a

ISO Focus+, www.iso.org/isofocus+

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DC to AC Conversion with InvertersDocument29 pagesDC to AC Conversion with InvertersTemuNo ratings yet

- Boiler Basics Workshop - FINALDocument87 pagesBoiler Basics Workshop - FINALAhmed GadNo ratings yet

- Multi-fluid installation draftDocument3 pagesMulti-fluid installation draftmostafamounirNo ratings yet

- SCM Checklist Helps Ensure Software QualityDocument5 pagesSCM Checklist Helps Ensure Software QualitymostafamounirNo ratings yet

- SCM Checklist Helps Ensure Software QualityDocument5 pagesSCM Checklist Helps Ensure Software QualitymostafamounirNo ratings yet

- Energy Assessment For Compressed Air Systems: ASME EA-4-2010Document2 pagesEnergy Assessment For Compressed Air Systems: ASME EA-4-2010mostafamounirNo ratings yet

- Egyptian Services & Trade Company ةكرشلا ةيرصملا تامدخلل و ةراجتلاDocument4 pagesEgyptian Services & Trade Company ةكرشلا ةيرصملا تامدخلل و ةراجتلاmostafamounirNo ratings yet

- CocoDocument1 pageCocomostafamounirNo ratings yet

- Software Quality & Systems Engineering Program: Scope, Size and Complexity of A ProjectDocument4 pagesSoftware Quality & Systems Engineering Program: Scope, Size and Complexity of A ProjectmostafamounirNo ratings yet

- IntroductionDocument8 pagesIntroductionmostafamounirNo ratings yet

- Brochure Gen SetDocument15 pagesBrochure Gen SetfitrahjahimNo ratings yet

- Detailed Project Report For Setting Up EV Assembly Facility: Back GroundDocument8 pagesDetailed Project Report For Setting Up EV Assembly Facility: Back GroundSaurav MitraNo ratings yet

- 6-FMX Series: 6-FMX-200 Front Terminal BatteryDocument2 pages6-FMX Series: 6-FMX-200 Front Terminal BatteryMajor Prince100% (1)

- Electricity - Grade 9Document9 pagesElectricity - Grade 9nidda beeNo ratings yet

- MUET Speaking ExerciseDocument1 pageMUET Speaking ExerciseZulaikha ZulkifliNo ratings yet

- Energy Storage Needs in SpainDocument56 pagesEnergy Storage Needs in SpainAhmed WestministerNo ratings yet

- Concept GenerationDocument4 pagesConcept GenerationShahir Afif IslamNo ratings yet

- Work Chapter TestDocument1 pageWork Chapter TestEpay Castañares LascuñaNo ratings yet

- Kiran (B e Ele) CVDocument2 pagesKiran (B e Ele) CVMaunish ThakkarNo ratings yet

- CT SolutionsForCPD EN LRDocument12 pagesCT SolutionsForCPD EN LRWilly Mauricio Garcia PorcelNo ratings yet

- Ads 68 IsDocument61 pagesAds 68 IsThính PhạmNo ratings yet

- North Carolina Testing Program EOC Physics Sample Items Goal 6Document11 pagesNorth Carolina Testing Program EOC Physics Sample Items Goal 6faithinhim7515No ratings yet

- Miniature Industrial Relays: Contact DataDocument10 pagesMiniature Industrial Relays: Contact DataJuan Carlos GòmezNo ratings yet

- Submittal Data Sheet: Ffq18Q2Vju / Rx18QmvjuDocument2 pagesSubmittal Data Sheet: Ffq18Q2Vju / Rx18QmvjuEdNo ratings yet

- GAS X2/MCE - Gas X3/MCE - Gas X4/MCE: Gas Burners Two Stages Progressive or ModulatingDocument4 pagesGAS X2/MCE - Gas X3/MCE - Gas X4/MCE: Gas Burners Two Stages Progressive or ModulatingFernando ValadãoNo ratings yet

- TECHNICAL PROGRAMME Dec 2021Document131 pagesTECHNICAL PROGRAMME Dec 2021123harsh123No ratings yet

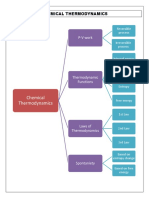

- CHEMICAL THERMODYNAMICS PRINCIPLESDocument12 pagesCHEMICAL THERMODYNAMICS PRINCIPLESKirtan KumarNo ratings yet

- General Notes:: This SiteDocument4 pagesGeneral Notes:: This SiteLouJanisLaudeNo ratings yet

- Ca Vcontact-Vsc (En S2) D 1VCP000532 PDFDocument56 pagesCa Vcontact-Vsc (En S2) D 1VCP000532 PDFGustavo Rodrigo SantanaNo ratings yet

- Optimization of Power Potential in HepDocument14 pagesOptimization of Power Potential in HepSHASHANK JAINNo ratings yet

- Installation Requirements for Grid-Connected Solar PV SystemsDocument11 pagesInstallation Requirements for Grid-Connected Solar PV Systemsashraf-84No ratings yet

- IIT-Madras, Momentum Transfer: July 2005-Dec 2005Document23 pagesIIT-Madras, Momentum Transfer: July 2005-Dec 2005Rehan UmerNo ratings yet

- P. K. Pattanaik Ieema Journal March 2021Document7 pagesP. K. Pattanaik Ieema Journal March 2021kjushnNo ratings yet

- 100 Percent Stator Earth Fault Protection SiemensDocument17 pages100 Percent Stator Earth Fault Protection SiemensImam FirdausNo ratings yet

- Merowe Dam Project: 10 X 140MVADocument16 pagesMerowe Dam Project: 10 X 140MVAibrahimNo ratings yet

- 3AUA0000002420 Acs550 01 012a 4 Acs550 Acs550 01 012a 4 PN 5 5kw I2n 11 9 A Ip21Document3 pages3AUA0000002420 Acs550 01 012a 4 Acs550 Acs550 01 012a 4 PN 5 5kw I2n 11 9 A Ip21Dũng DungNo ratings yet

- Water Intake Panel ListDocument27 pagesWater Intake Panel ListWicakK ChannelNo ratings yet

- New Step-Up and Step-Down 18-Pulse Direct Asymmetric Autotransformer Rectifier UnitsDocument7 pagesNew Step-Up and Step-Down 18-Pulse Direct Asymmetric Autotransformer Rectifier UnitsMaikPortnoyNo ratings yet