Professional Documents

Culture Documents

Equations of Elasticity: Appendix

Uploaded by

Bright MuzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equations of Elasticity: Appendix

Uploaded by

Bright MuzaCopyright:

Available Formats

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

A P P E N D I X B

455

Equations of Elasticity

B.1 STRAIN-DISPLACEMENT RELATIONS

In general, the concept of normal strain is introduced and dened in the context

of a uniaxial tension test. The elongated length L of a portion of the test specimen

having original length L

0

(the gauge length) is measured and the corresponding

normal strain dened as

=

L L

0

L

0

=

L

L

0

(B.1)

which is simply interpreted as change in length per unit original length and is

observed to be a dimensionless quantity. Similarly, the idea of shear strain is often

introduced in terms of a simple torsion test of a bar having a circular cross sec-

tion. In each case, the test geometry and applied loads are designed to produce a

simple, uniform state of strain dominated by one major component.

In real structures subjected to routine operating loads, strain is not generally

uniform nor limited to a single component. Instead, strain varies throughout the

geometry and can be composed of up to six independent components, including

both normal and shearing strains. Therefore, we are led to examine the appropri-

ate denitions of strain at a point. For the general case, we denote u = u(x, y, z),

v = v(x, y, z), and w = w(x, y, z) as the displacements in the x, y, and z coordi-

nate directions, respectively. (The displacements may also vary with time; for

now, we consider only the static case.) Figure B.1(a) depicts an innitesimal el-

ement having undeformed edge lengths dx, dy, dz located at an arbitrary point

(x, y, z) in a solid body. For simplicity, we rst assume that this element is loaded

in tension in the x direction only and examine the resulting deformation as shown

(greatly exaggerated) in Figure B.1(b). Displacement of point P is u while that of

point Q is u + (u/ x) dx such that the deformed length in the x direction is

given by

dx

= dx + u

Q

u

P

= dx + u +

u

x

dx u = dx +

u

x

dx (B.2)

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

456 APPENDI X B Equations of Elasticity

x

x

y

x

z

dy

dx

dz

(a)

y

x

dx

u

dx

P P Q Q

u dx

u

x

(b)

B A

C

(c) (d)

C

B

A

v

x

u

y

Figure B.1

(a) A differential element in uniaxial stress; (b) resulting axial

deformation; (c) differential element subjected to shear;

(d) angular changes used to dene shear strain.

The normal strain in the x direction at the point depicted is then

x

=

dx

dx

dx

=

u

x

(B.3)

Similar consideration of changes of length in the y and z directions yields the

general denitions of the associated normal strain components as

y

=

v

y

and

z

=

w

z

(B.4)

To examine shearing of the innitesimal solid, we next consider the situation

shown in Figure B.1(c), in which applied surface tractions result in shear of the

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

B.1 Strain-Displacement Relations 457

element, as depicted in Figure B.1(d). Unlike normal strain, the effects of shear-

ing are seen to be distortions of the original rectangular shape of the solid. Such

distortion is quantied by angular changes, and we consequently dene shear

strain as a change in the angle of an angle that was originally a right angle. On

rst reading, this may sound redundant but it is not. Consider the denition in the

context of Figure B.1(c) and B.1(d); angle ABC was a right angle in the unde-

formed state but has been distorted to A

BC

by shearing. The change of the

angle is composed of two parts, denoted and , given by the slopes of B A

and

BC

, respectively as v/ x and u/ y. Thus, the shear strain is

xy

=

u

y

+

v

x

(B.5)

where the double subscript is used to indicate the plane in which the angular

change occurs. Similar consideration of distortion in xz and yz planes results in

xz

=

u

z

+

w

x

and

yz

=

v

z

+

w

y

(B.6)

as the shear strain components, respectively.

Equations B.3B.6 provide the basic denitions of the six possible indepen-

dent strain components in three-dimensional deformation. It must be emphasized

that these strain-displacement relations are valid only for small deformations.

Additional terms must be included if large deformations occur as a result of

geometry or material characteristics. As continually is the case as we proceed, it

is convenient to express the strain-displacement relations in matrix form. To

accomplish this task, we dene the displacement vector as

{} =

_

_

_

u(x, y, z)

v(x, y, z)

w(x, y, z)

_

_

_

(B.7)

(noting that this vector describes a continuous displacement eld) and the strain

vector as

{} =

_

xy

xz

yz

_

_

(B.8)

The strain-displacement relations are then expressed in the compact form

{} = [L]{} (B.9)

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

458 APPENDI X B Equations of Elasticity

where [L] is the derivative operator matrix given by

[L] =

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

x

0 0

0

y

0

0 0

x

0

z

0

x

0

y

_

_

(B.10)

B.2 STRESS-STRAIN RELATIONS

The equations between stress and strain applicable to a particular material are

known as the constitutive equations for that material. In the most general type of

material possible, it is shown in advanced work in continuummechanics that the

constitutive equations can contain up to 81 independent material constants. How-

ever, for a homogeneous, isotropic, linearly elastic material, it is readily shown

that only two independent material constants are required to completely specify

the relations. These two constants should be quite familiar from elementary

strength of materials theory as the modulus of elasticity (Youngs modulus) and

Poissons ratio. Again referring to the simple uniaxial tension test, the modulus of

elasticity is dened as the slope of the stress-strain curve in the elastic region or

E =

x

(B.10)

where it is assumed that the axis of loading corresponds to the x axis. As strain is

dimensionless, the modulus of elasticity has the units of stress usually expressed

in lb/in.

2

or megapascal (MPa).

Poissons ratio is a measure of the well-known phenomenon that an elastic

body strained in one direction also experiences strain in mutually perpendicular

directions. In the uniaxial tension test, elongation of the test specimen in the load-

ing direction is accompanied by contraction in the plane perpendicular to the load-

ing direction. If the loading axis is x, this means that the specimen changes dimen-

sions and thus experiences strain in the y and z directions as well, even though no

external loading exists in those directions. Formally, Poissons ratio is dened as

=

unit lateral contraction

unit axial elongation

(B.11)

and we note that Poissons ratio is algebraically positive and the negative sign as-

sures this, since numerator and denominator always have opposite signs. Thus, in

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

B.2 Stress-Strain Relations 459

*The double subscript notation used for shearing stresses is explained as follows: The rst subscript

denes the axial direction perpendicular to the surface on which the shearing stress acts, while the

second subscript denotes the axis parallel to the shearing stress. Thus,

xy

denotes a shearing stress

acting in the direction of the x axis on a surface perpendicular to the y axis. Via moment equilibrium, it

is readily shown that

xy

=

yx

,

xz

=

zx,

and

yz

=

zy.

the tension test, if

x

represents the strain resulting from applied load, the induced

strain components are given by

y

=

z

=

x

.

The general stress-strain relations for a homogeneous, isotropic, linearly elas-

tic material subjected to a general three-dimensional deformation are as follows:

x

=

E

(1 + )(1 2)

[(1 )

x

+ (

y

+

z

)] (B.12a)

y

=

E

(1 + )(1 2)

[(1 )

y

+ (

x

+

z

)] (B.12b)

z

=

E

(1 + )(1 2)

[(1 )

z

+ (

x

+

y

)] (B.12c)

xy

=

E

2(1 + )

xy

= G

xy

(B.12d)

xz

=

E

2(1 + )

xz

= G

xz

(B.12e)

yz

=

E

2(1 + )

yz

= G

yz

(B.12f)

where we introduce the shear modulus or modulus of rigidity, dened by

G =

E

2(1 + )

(B.13)

We may observe from the general relations that the normal components of stress

and strain are interrelated in a rather complicated fashion through the Poisson ef-

fect but are independent of shear strains. Similarly, the shear stress components*

are unaffected by normal strains.

The stress-strain relations can easily be expressed in matrix form by dening

the material property matrix [D] as

[D] =

E

(1 +)(1 2)

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

1 0 0 0

1 0 0 0

1 0 0 0

0 0 0

1 2

2

0 0

0 0 0 0

1 2

2

0

0 0 0 0 0

1 2

2

_

_

(B.14)

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

460 APPENDI X B Equations of Elasticity

x

dy

dx

xz

xy

dz

xy

xy

y

dy

yz

yz

y

dy

xz

xz

x

dx

xy

xy

x

dx

yz

xy

xz

yz

y

y

dy

x

x

dx

xz

xz

z

dz

yz

yz

z

dz

z

z

dz

Figure B.2 A three-dimensional element in a general state of stress.

and writing

{} =

_

xy

xz

yz

_

_

= [D]{} = [D][L]{} (B.15)

Here {} denotes the 6 1 matrix of stress components. We do not use the term

stress vector, since, as we subsequently observe, that term has a generally ac-

cepted meaning quite different from the matrix dened here.

B.3 EQUILIBRIUM EQUATIONS

To obtain the equations of equilibrium for a deformed solid body, we examine

the general state of stress at an arbitrary point in the body via an innitesimal dif-

ferential element, as shown in Figure B.2. All stress components are assumed to

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

B.4 Compatibility Equations 461

vary spatially, and these variations are expressed in terms of rst-order Taylor

series expansions, as indicated. In addition to the stress components shown, it

is assumed that the element is subjected to a body force having axial components

B

x

, B

y

, B

z

. The body force is expressed as force per unit volume and represents

the action of an external inuence that affects the body as a whole. The most

common body force is that of gravitational attraction while magnetic and cen-

trifugal forces are also examples.

Applying the condition of force equilibrium in the direction of the x axis for

the element of Figure B.2 results in

_

x

+

x

x

dx

_

dy dz

x

dy dz +

_

xy

+

xy

y

dy

_

dx dz

xy

dx dz

+

_

xz

+

xz

z

dz

_

dx dy

xz

dx dy + B

x

dx dy dz = 0

(B.16)

Expanding and simplifying Equation B.16 yields

x

x

+

xy

y

+

xz

z

+ B

x

= 0 (B.17)

Similarly, applying the force equilibrium conditions in the y and z coordinate

directions yields

xy

x

+

y

y

+

yz

z

+ B

y

= 0 (B.18)

xz

x

+

yz

y

+

z

z

+ B

z

= 0 (B.19)

respectively.

B.4 COMPATIBILITY EQUATIONS

Equations B.3B.6 dene six strain components in terms of three displacement

components. A fundamental premise of the theory of continuum mechanics is

that a continuous body remains continuous during and after deformation. There-

fore, the displacement and strain functions must be continuous and single valued.

Given a continuous displacement eld u, v, w, it is straightforward to compute

continuous, single-valued strain components via the strain-displacement rela-

tions. However, the inverse case is a bit more complicated. That is, given a eld

of six continuous, single-valued strain components, we have six partial differen-

tial equations to solve to obtain the displacement components. In this case, there

is no assurance that the resulting displacements will meet the requirements of

continuity and single-valuedness. To ensure that displacements are continuous

when computed in this manner, additional relations among the strain components

Hutton: Fundamentals of

Finite Element Analysis

Back Matter Appendix B: Equations of

Elasticity

The McGrawHill

Companies, 2004

462 APPENDI X B Equations of Elasticity

have been derived, and these are known as the compatibility equations. There are

six independent compatibility equations, one of which is

x

y

2

+

y

x

2

=

xy

xy

(B.20)

The other ve equations are similarly second-order relations. While not used

explicitly in this text, the compatibility equations are absolutely essential in

advanced methods in continuum mechanics and the theory of elasticity.

You might also like

- CH 02Document61 pagesCH 02LeonardoMadeira11No ratings yet

- Strain and Material Properties ChapterDocument57 pagesStrain and Material Properties ChapterCristian David BravoNo ratings yet

- Strains:, Respectively, and May Be ADocument15 pagesStrains:, Respectively, and May Be AFiras RocktNo ratings yet

- Stress Strain 2008Document7 pagesStress Strain 2008mdmarufurNo ratings yet

- Chapter 2 MDocument71 pagesChapter 2 MJohnny KozyNo ratings yet

- Analysis of StrainsDocument10 pagesAnalysis of StrainsAditya KoutharapuNo ratings yet

- Matriz de Rigidez GeometricaDocument14 pagesMatriz de Rigidez GeometricaManuel CruzNo ratings yet

- Stress AnalysisDocument16 pagesStress AnalysispemulungNo ratings yet

- TorsionDocument14 pagesTorsionProninaNo ratings yet

- Shear and Torsion: Understanding Drive Shafts and Glue JointsDocument15 pagesShear and Torsion: Understanding Drive Shafts and Glue JointsNadia AzmiNo ratings yet

- DifferentialEquations 02 Strain Disp Eqns 2Document8 pagesDifferentialEquations 02 Strain Disp Eqns 2lipun12ka4No ratings yet

- Mechanics of MachinesDocument79 pagesMechanics of MachinesSyed Waqar Ahmed100% (1)

- Introduction To Elasticity: Stresses and EquiubriumDocument8 pagesIntroduction To Elasticity: Stresses and EquiubriumManander SInghNo ratings yet

- PM288Document29 pagesPM288Phanindra KorleparaNo ratings yet

- A Finite Element Formulation For A Beam With Varying Cross-Section Geometry Along Its Length: Flexibility-Based ApproachDocument10 pagesA Finite Element Formulation For A Beam With Varying Cross-Section Geometry Along Its Length: Flexibility-Based ApproachShemin T JohnNo ratings yet

- Appendix D Review of Mechanics of Materials - 2009 - Elasticity Second Edition PDFDocument14 pagesAppendix D Review of Mechanics of Materials - 2009 - Elasticity Second Edition PDFJaimeNo ratings yet

- As Is Research 2Document13 pagesAs Is Research 2Arj AsisNo ratings yet

- Stress and StrainDocument17 pagesStress and StrainakshatbhargavaNo ratings yet

- Analysis of StrainsDocument8 pagesAnalysis of StrainsMechanical ZombieNo ratings yet

- Stresses and Equilibrium in 3D BodiesDocument26 pagesStresses and Equilibrium in 3D BodiesMD SHAHRIARMAHMUDNo ratings yet

- CH 05Document72 pagesCH 05LeonardoMadeira110% (1)

- Chapter3 180616192627Document55 pagesChapter3 180616192627SALEEM MALIKNo ratings yet

- Introductory Mechanics of Materials ReviewDocument0 pagesIntroductory Mechanics of Materials ReviewDr. Madhukar Vable100% (1)

- Mechanics of Materials: ReferencesDocument15 pagesMechanics of Materials: Referencesعبدالله خيريNo ratings yet

- in This Module Text in "Italic" Indicates Advanced Concepts. 2., Are Used For Shear' in Books and LiteratureDocument35 pagesin This Module Text in "Italic" Indicates Advanced Concepts. 2., Are Used For Shear' in Books and LiteratureKanti SolankiNo ratings yet

- Orthopaedic Biomechanics J. Michael Kabo, PHDDocument12 pagesOrthopaedic Biomechanics J. Michael Kabo, PHDJimNo ratings yet

- Geometric Stiffness and P Delta EffectsDocument14 pagesGeometric Stiffness and P Delta EffectsWahid Omar100% (1)

- Structural Analysis Timoshenko Beam TheoryDocument4 pagesStructural Analysis Timoshenko Beam TheoryDinh Thien NguyenNo ratings yet

- Stress-Strain Relationship and Hooke's LawDocument11 pagesStress-Strain Relationship and Hooke's Lawhamal100% (1)

- Euler Bernoulli BeamsDocument8 pagesEuler Bernoulli BeamsDorin PopaNo ratings yet

- Aircraft Structures Chapter 2Document124 pagesAircraft Structures Chapter 2jose antonio villena medinaNo ratings yet

- Lecture 1 - Stress-Strain RelationshipDocument26 pagesLecture 1 - Stress-Strain RelationshipSri JaiandranNo ratings yet

- ANALYSIS OF STRAINS UNDER PLANE STRAIN CONDITIONDocument6 pagesANALYSIS OF STRAINS UNDER PLANE STRAIN CONDITIONranjith kumarNo ratings yet

- 1D and 2D PlasticityDocument24 pages1D and 2D PlasticityChandra ClarkNo ratings yet

- CH 1Document64 pagesCH 1shaffetiNo ratings yet

- Unit - 1: Stress and StrainDocument34 pagesUnit - 1: Stress and StrainprernaNo ratings yet

- MECHANICS OF DEFORMABLE BODIESDocument3 pagesMECHANICS OF DEFORMABLE BODIESNadlor Gasco OzausNo ratings yet

- 1.objective: What's A Strain Gauge Used For?Document12 pages1.objective: What's A Strain Gauge Used For?Aman kumarNo ratings yet

- LEC9 ProfDocument8 pagesLEC9 ProfDimi ChippsNo ratings yet

- Deformation PDFDocument66 pagesDeformation PDFRicardo ColosimoNo ratings yet

- Elastic ConstantsDocument18 pagesElastic ConstantsÑM balochNo ratings yet

- UntitledDocument9 pagesUntitledEdward NaanmaNo ratings yet

- Vectors and Tensors SummaryDocument13 pagesVectors and Tensors SummaryBittuNo ratings yet

- Understanding stresses in 3D solidsDocument21 pagesUnderstanding stresses in 3D solidsBendis AmmNo ratings yet

- Brannon - Large Deformation KinematicsDocument66 pagesBrannon - Large Deformation KinematicsPatrick SummersNo ratings yet

- Chapter 1Document60 pagesChapter 1Elmar CuellarNo ratings yet

- 09 - Finite Element Formulation of Solid ContinuaDocument106 pages09 - Finite Element Formulation of Solid ContinuadozioNo ratings yet

- AERODocument7 pagesAEROperdezultuNo ratings yet

- In-Plane Boundary Effects on Buckling of Laminated PlatesDocument14 pagesIn-Plane Boundary Effects on Buckling of Laminated PlatesIzzet Ufuk CagdasNo ratings yet

- Geometric Stiffness and P-Delta EffectsDocument14 pagesGeometric Stiffness and P-Delta EffectsMiguel AngelNo ratings yet

- Mos - 2130003 - by H N PatelDocument84 pagesMos - 2130003 - by H N PatelHemantchandra PatelNo ratings yet

- Chapter 4Document9 pagesChapter 4Alexandru PuiuNo ratings yet

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsFrom EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo ratings yet

- Beams and Framed Structures: Structures and Solid Body MechanicsFrom EverandBeams and Framed Structures: Structures and Solid Body MechanicsRating: 3 out of 5 stars3/5 (2)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (4)

- Progress ReportDocument1 pageProgress ReportBright MuzaNo ratings yet

- Buse - Proposed National Sports Academy Phase OneDocument3 pagesBuse - Proposed National Sports Academy Phase OneBright MuzaNo ratings yet

- V62 P6.2-Text 2018-10Document33 pagesV62 P6.2-Text 2018-10Bright MuzaNo ratings yet

- BUQS 7022 - Lecture 2 - Construction Procurement Strategy - 2023 PDFDocument32 pagesBUQS 7022 - Lecture 2 - Construction Procurement Strategy - 2023 PDFBright MuzaNo ratings yet

- Zvishavane Town Council Site VisitDocument4 pagesZvishavane Town Council Site VisitBright MuzaNo ratings yet

- Masvingo Road Widening Project Site Meeting MinutesDocument3 pagesMasvingo Road Widening Project Site Meeting MinutesBright MuzaNo ratings yet

- ERRP2 LOT E MasvingoDocument2 pagesERRP2 LOT E MasvingoBright MuzaNo ratings yet

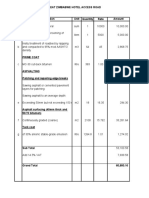

- Great Zimbabwe Hotel Access RoadDocument1 pageGreat Zimbabwe Hotel Access RoadBright MuzaNo ratings yet

- Construction Law by John Uff - 12 EdDocument684 pagesConstruction Law by John Uff - 12 EdBright MuzaNo ratings yet

- Aicd Background Paper 14 Roads Sect Summary enDocument10 pagesAicd Background Paper 14 Roads Sect Summary enBright MuzaNo ratings yet

- Machongwe-Risitu Priming Method StatementDocument9 pagesMachongwe-Risitu Priming Method StatementBright MuzaNo ratings yet

- Bus Stop Shed DrawingDocument1 pageBus Stop Shed DrawingBright MuzaNo ratings yet

- 1 Ha Bean - 11 March 2014 - WebDocument1 page1 Ha Bean - 11 March 2014 - WebBright MuzaNo ratings yet

- UNB Fredericton Tuition & Fees 2017-2018 Course Based Part Time StudentDocument1 pageUNB Fredericton Tuition & Fees 2017-2018 Course Based Part Time StudentBright MuzaNo ratings yet

- ch12 PDFDocument30 pagesch12 PDFRadhika VeeralaNo ratings yet

- Pump B 2nd Lift 1 and 1st Lift 2Document2 pagesPump B 2nd Lift 1 and 1st Lift 2Bright MuzaNo ratings yet

- Late Submission of Lab Results - Soil TechDocument1 pageLate Submission of Lab Results - Soil TechBright MuzaNo ratings yet

- Project Manager Resignation LetterDocument1 pageProject Manager Resignation LetterBright MuzaNo ratings yet

- 231 Regent ST #302, Fredericton, NB E3B 3W8Document5 pages231 Regent ST #302, Fredericton, NB E3B 3W8Bright MuzaNo ratings yet

- Reinforced Concrete Wall Form Design ProgramDocument153 pagesReinforced Concrete Wall Form Design ProgramBright MuzaNo ratings yet

- Tomato Production Guideline 2014Document11 pagesTomato Production Guideline 2014Bright MuzaNo ratings yet

- Concrete Casting - Pump Station ADocument13 pagesConcrete Casting - Pump Station ABright MuzaNo ratings yet

- Article ReviewDocument2 pagesArticle ReviewBright MuzaNo ratings yet

- Guidelines For Participant Consent and Debriefing FormsDocument4 pagesGuidelines For Participant Consent and Debriefing FormsBright MuzaNo ratings yet

- Debriefing FormDocument1 pageDebriefing FormBright MuzaNo ratings yet

- Miracles The Great DebateDocument3 pagesMiracles The Great DebateBright MuzaNo ratings yet

- All Questions: Open Book ExaminationDocument3 pagesAll Questions: Open Book ExaminationBright Muza100% (1)

- Excavation QuantitiesDocument1 pageExcavation QuantitiesBright MuzaNo ratings yet

- TCW5202200605 Foundation Engineering DesignDocument2 pagesTCW5202200605 Foundation Engineering DesignBright MuzaNo ratings yet

- TCW5202200505 Foundation Engineering DesignDocument5 pagesTCW5202200505 Foundation Engineering DesignBright MuzaNo ratings yet

- Purusha: Purusha (Sanskrit Puru ADocument5 pagesPurusha: Purusha (Sanskrit Puru APaola AndreaNo ratings yet

- Understanding Men - PDF' PDFDocument193 pagesUnderstanding Men - PDF' PDFnahum100% (1)

- AvestaDocument537 pagesAvestaAnantha Krishna K SNo ratings yet

- CBCP Monitor Vol. 17 No. 9Document20 pagesCBCP Monitor Vol. 17 No. 9Areopagus Communications, Inc.No ratings yet

- Constructivist Model Literacy 20th CenturyDocument2 pagesConstructivist Model Literacy 20th CenturyMaridol Perico SalamanteNo ratings yet

- Human Bingo Lesson Plan 1Document7 pagesHuman Bingo Lesson Plan 1api-403726607No ratings yet

- Locke and Personal IdentityDocument7 pagesLocke and Personal Identitynumber_tripple7No ratings yet

- Biomechanics InvestigationDocument3 pagesBiomechanics Investigationmcdo0318No ratings yet

- Language Study Material XiDocument8 pagesLanguage Study Material XiPrabhat Singh 11C 13No ratings yet

- Daily Deeds ChecklistDocument2 pagesDaily Deeds Checklistnil8r153100% (2)

- Resilience Building in StudentsDocument15 pagesResilience Building in StudentsRiana dityaNo ratings yet

- Commissioner of Internal Revenue v. Guerrero GR L 20942 22 September 1967 en Banc Fernando JDocument5 pagesCommissioner of Internal Revenue v. Guerrero GR L 20942 22 September 1967 en Banc Fernando JMidzfar OmarNo ratings yet

- Solving PDEs using radial basis functionsDocument10 pagesSolving PDEs using radial basis functionsHamid MojiryNo ratings yet

- Listening Styles and Listening StrategiesDocument4 pagesListening Styles and Listening StrategiesBladyPanopticoNo ratings yet

- Visionary ReportDocument4 pagesVisionary ReportDerek Banas100% (1)

- Detailed Lesson Plan (DLP) Format: Various Models of CommunicationDocument4 pagesDetailed Lesson Plan (DLP) Format: Various Models of CommunicationZeen DeeNo ratings yet

- Aristotle Function ArgumentDocument4 pagesAristotle Function Argumenta967tNo ratings yet

- Research Final Na To TalagaDocument12 pagesResearch Final Na To TalagaAmor VillaNo ratings yet

- Disorders of ThoughtDocument30 pagesDisorders of ThoughtRenault Jia Kai50% (2)

- A.C. No. 7649 Siao Aba Et Al Vs Atty. de GuzmanDocument10 pagesA.C. No. 7649 Siao Aba Et Al Vs Atty. de GuzmanGuy PequeNo ratings yet

- Sound WavesDocument6 pagesSound WavesjenibelNo ratings yet

- 420d Modesto V UrbinaDocument11 pages420d Modesto V Urbinachavit321No ratings yet

- Area and The Definite Integral History EdDocument1 pageArea and The Definite Integral History EdKanishka Ray ChaudhuriNo ratings yet

- Prepare Session PlanDocument10 pagesPrepare Session Planjonellambayan83% (6)

- City Beautiful movements in Chicago, Delhi, Canberra & under dictatorsDocument5 pagesCity Beautiful movements in Chicago, Delhi, Canberra & under dictatorsNirav Lad100% (2)

- Anglistyka JęzykaDocument358 pagesAnglistyka JęzykaMasky officialNo ratings yet

- Physics Interference - Class 12Document17 pagesPhysics Interference - Class 12Abhishek Roy71% (62)

- NA2 Chapter 3Document26 pagesNA2 Chapter 3thugsdei100% (1)

- Holistic Astrology ChironDocument3 pagesHolistic Astrology Chirontratak100% (1)

- The Case of The Crushed Petunias - Tennessee WilliamsDocument13 pagesThe Case of The Crushed Petunias - Tennessee WilliamsVioleta Morada Purpura80% (5)