Professional Documents

Culture Documents

Plastic Injection Mold Calculations

Uploaded by

fieramina0 ratings0% found this document useful (0 votes)

773 views10 pagesmold calculation

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmold calculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

773 views10 pagesPlastic Injection Mold Calculations

Uploaded by

fieraminamold calculation

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 10

S.

No Name of Material Abbrevation

Relative

Density

Ease of

Ignition

Whether self

extinguishing

Character of

Flame

1 Polystyrene PS 1.05 Readily burns No

Yellow Dense

Black Smoke

sooty

2 Acrylic

S.No Name of Material

Density

g/cm

3

Bulk

Factor

Heat

Distortion

Temperature

Moulding

Temperature

Specific Heat

Capacity

J/Kg

o

K

1 Polystyrene 1.05 1.9 - 2.15 90 200 1344

2 Acrylic 1.2 1.8-2 85 225 1470

Properties of Material

Identification of Thermoplastics

Odour of

burning

Behaviour

of material

Oppressive

Flowery

Melts and

bubbles

Total Heat

Content

KJ/Kg

239.4

302.4.

Properties of Material

Identification of Thermoplastics

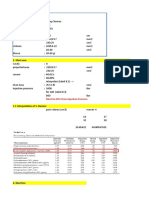

S.No Category Description Size Unit

Screw Diameter 22 mm

Shot Weight 29 gm

Shot Size 32

cm

3

Injection Pressure 3008

kg/cm

2

Injection Rate 37

cm

3

/sec

Screw Stroke 85 mm

Plasticising Capacity 31 kg/hr

Screw Speed 0-440 rpm

Clamping Force 245.52 KN

Height 395 mm

Width 365 mm

General Dry Cycle 1.73 Sec

Cycle Time 17 Sec

2

1

Metal Industry Development Institute

Product Design and Development

Machine Specification

Platen Size

Injection

Unit

Clamping

Unit

S.No Description Unit

1 Material Type Acrylic

2 Density of mould

3

Mass of the component

(m)

5.05 gm

4

Projected area of the

component

2166.52

mm

2

5 Volume of the mold 3556.58

6 Surface Area

7 Elastic Modulus

8 Poisson's Ratio

9 Shear Modulus

10 Tensile Strength

11 Compressive Strength

12 Yield Strength

13 Thermal Expansion

14 Specifice Heat

15 Damping Ratio

Material Properties

Shot Capacity of the machine 98 gm

1 Shot Weight Capacity with material B

Material A Polystyrene

Density of Material A

Bulk factor of A

Shot Weight Capacity of material A

Material B

Density of Material B

Bulk factor of B

Shot Weight Capacity of Material B

Shot Weight capacity with material B #DIV/0!

2 Shot Capacity Gram

Swept Volume 32

cm

3

Density of Plastic r 1.2

gm/cm

3

C for amorphous plastics 0.93

C for crystalline plastic 0.35

Shot Capacity of the machine with the

given material

35.712 gm

Shot Capacity

Material B

Material A

Plasticising Capacity Unit

Plasticising Capacity of the machine 31 Kg/h

Plasticising Rate of material A (Polystyrene) Kg/h

Specific Heat Capacity of Polystyrene

J/Kg

o

K

Specific Heat capacity of material

J/Kg

o

K

Moulding Temperature of Polystyrene

Moulding Temperature of material

Total Heat Content Polystyrene 239.4 J/Kg

Total Heat Content Material 302.4 J/Kg

Plasticising Capacity of the machine with

the given material

24.54167

Plasticising Rate of material

Plasticising Rate

Mass of moulding (m) Kg

Number of mouldings per hour

Plasticising Rate 0

For maximum efficiency athe machine operated at 80 to 85% of

the shot weight or plasticising capacity

Clamping Force

Projecting area of moulding 2166.52

mm

2

Injection Pressure 63

MN/m

2

Clamping Force 136.49076 KN

Cycle Time

Mass of Shot (m) 5.05 gm

Plasticising Capacity of the machine (P) 24.541667 Kg/h

Minimum cycle time attinable (t

c

) 0.740781 Sec

S.No Description UNIT

Determination By Shot Capacity

Based on 85% of rated shot capacity

Rated Shot capacity of the mateial (W) 35.712 gms

Mass of the component per cavity (M) 5.05 gms

Number of cavity based on shot capacity 6.010930693

Determination By Plasticising Capacity

Based on 85% of rated Plasticising capacity

Overall cycle time (T

C

) 17

Rated Plasticising Capacity (P) 24.54166667 Kg/hr

Mass of molding per cavity (m) 5.05 gm

Number of cavity based on Plasicising

capacity

19.50644023

Determination By Clamping Capacity

Based on 85% of rated Plasticising capacity

Rated clamping capacity C 245.52 KN

Cavity Pressure (Pc) 63 Mpa

Projected area (Am) 2166.52

mm

2

Number of cavity based on clamping capacity 1.798803084

Number Of Cavities

2

1

3

Mass of components

(g)

Factor

0.3 to 0.5 1.5

0.5 to 1 1.4

1 to 3 1.3

3 to 5 1.25

5 to 10 1.15

10 to 20 1.1

above 20 1.05

You might also like

- How To Select Plastic Injection Moulding MachineDocument48 pagesHow To Select Plastic Injection Moulding MachineDiego Sáchica60% (5)

- Mold CalculationDocument2 pagesMold CalculationMohammed Khatib100% (1)

- Runners and GatesDocument35 pagesRunners and Gatesbjdavies2010100% (2)

- Mold Design Fundamental Calculation BATTERY COVERDocument10 pagesMold Design Fundamental Calculation BATTERY COVERBoby SaputraNo ratings yet

- Advanced Injection Mould Split Design TechniquesDocument175 pagesAdvanced Injection Mould Split Design TechniquesŠetkić SemirNo ratings yet

- Mold Design FeasabilityDocument16 pagesMold Design FeasabilitySreedhar PugalendhiNo ratings yet

- Mold DesignDocument68 pagesMold DesignBagus Bramantya bagusbramantya.2019No ratings yet

- Scientific Approach To Injection MoldingDocument52 pagesScientific Approach To Injection MoldingSamik MukherjeeNo ratings yet

- PIM 101 Ebook-1Document33 pagesPIM 101 Ebook-1agniflameNo ratings yet

- Shot Area: Must Be 50% From Injection PressureDocument7 pagesShot Area: Must Be 50% From Injection PressureAri Wibowo NugrohoNo ratings yet

- Plastic InjectionDocument39 pagesPlastic InjectionRishav KumarNo ratings yet

- Protomold - Design For Mold AbilityDocument16 pagesProtomold - Design For Mold Abilitylanning15No ratings yet

- Injection Molding CycleDocument3 pagesInjection Molding CyclepavankumarsrsNo ratings yet

- Injection Molding Mold DesignDocument26 pagesInjection Molding Mold DesignDiligence100% (1)

- Molding CavityDocument7 pagesMolding CavitySudarno BaraNo ratings yet

- Formulas Tool & DieDocument62 pagesFormulas Tool & Dievinayak100% (1)

- Injection Mold Design Engineering Complete Self-Assessment GuideFrom EverandInjection Mold Design Engineering Complete Self-Assessment GuideNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- GE Design GuideDocument53 pagesGE Design GuideGuido Kats100% (1)

- Mold Buyers Tip Guide CompleteDocument24 pagesMold Buyers Tip Guide CompleteAshraf_Elzieny100% (3)

- Design MoldDocument48 pagesDesign Moldjohnquest75% (4)

- Injection Molding Troubleshooting Flash BurnmarksDocument60 pagesInjection Molding Troubleshooting Flash Burnmarkswawawa1100% (1)

- Moulding ProblemDocument52 pagesMoulding ProblemSree RajNo ratings yet

- Useful Data On Plastic Injection MouldingDocument71 pagesUseful Data On Plastic Injection MouldingMahesh Deivasiga Mani D100% (2)

- Theory of Moulds - ContentsDocument9 pagesTheory of Moulds - Contentsnagesh_sprao19275% (4)

- Hot Runner SystemsDocument17 pagesHot Runner SystemsAkash Shettannavar50% (2)

- Troubleshooting Injection Moulding Process ProblemsDocument24 pagesTroubleshooting Injection Moulding Process ProblemsKaixin Go50% (2)

- Mold and Die - PPTDocument110 pagesMold and Die - PPTThaloengsak Kucharoenpaisan100% (2)

- Chapter 2 Injection MoldsDocument83 pagesChapter 2 Injection MoldsRadia ElkhaniNo ratings yet

- Plastic Injection Molding Write UpDocument16 pagesPlastic Injection Molding Write UpVishal MahajanNo ratings yet

- Mold Flow AnalysisDocument30 pagesMold Flow AnalysisArun PrasadNo ratings yet

- Weld Line Defect Analysis and TroubleshootingDocument4 pagesWeld Line Defect Analysis and TroubleshootingJackie LeeNo ratings yet

- Classification of Polymers: 02 - Plastic Materials Mould Design ProjectDocument8 pagesClassification of Polymers: 02 - Plastic Materials Mould Design ProjectDaniAmdaniNo ratings yet

- Injection MouldinDocument32 pagesInjection MouldinKarthick KarthickNo ratings yet

- MPI Fill Analysis of 3D CAD ModelDocument21 pagesMPI Fill Analysis of 3D CAD ModelArmando JimNo ratings yet

- CAE DS – Mould Design Standard PartsDocument13 pagesCAE DS – Mould Design Standard PartsMohd Nazri SalimNo ratings yet

- BDD 40903 Injection Mold Design Chapter 5Document35 pagesBDD 40903 Injection Mold Design Chapter 5Churreya Chai LomNo ratings yet

- Injection Moulding - Quality Molded PartsDocument28 pagesInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Tips For Defect Free Injection MoldingDocument33 pagesTips For Defect Free Injection MoldingjaonnNo ratings yet

- Injection MouldDocument256 pagesInjection Mouldsandokan_mc1100% (1)

- Design of The Injection MouldDocument19 pagesDesign of The Injection MouldSiddhant Prakash GoyalNo ratings yet

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocument6 pagesThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarNo ratings yet

- Injection Moulding Defects GuideDocument10 pagesInjection Moulding Defects GuideAmith S KaratkarNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- A Practical Guide to the Selection of High-Temperature Engineering ThermoplasticsFrom EverandA Practical Guide to the Selection of High-Temperature Engineering ThermoplasticsNo ratings yet

- Computer Modeling for Injection Molding: Simulation, Optimization, and ControlFrom EverandComputer Modeling for Injection Molding: Simulation, Optimization, and ControlHuamin ZhouNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Mold Design of Lan BoxDocument85 pagesMold Design of Lan BoxGaurav AkotkarNo ratings yet

- Aluminium Composite Panel: Physical PropertiesDocument2 pagesAluminium Composite Panel: Physical PropertiesTabish IzharNo ratings yet

- Academic Project PresentationDocument20 pagesAcademic Project Presentationkishore pm100% (1)

- Compac Shot F49S-6: General InformationDocument1 pageCompac Shot F49S-6: General Informationmahreza189No ratings yet

- DESIGN AND FABRICATION OF MOULD FORDocument20 pagesDESIGN AND FABRICATION OF MOULD FORajaysurya9245No ratings yet

- Ball Mill OptimizationDocument82 pagesBall Mill OptimizationRashek_119588% (16)

- Melt Flow Index Deluxe: Presto Stantest Private LimitedDocument1 pageMelt Flow Index Deluxe: Presto Stantest Private LimitedAkhilesh KumarNo ratings yet

- Ajm V2.0Document3 pagesAjm V2.0Raja KarNo ratings yet

- Lecture 2Document93 pagesLecture 2fieraminaNo ratings yet

- DC Motor and Magnetism GuideDocument18 pagesDC Motor and Magnetism GuidefieraminaNo ratings yet

- Lecture 6Document72 pagesLecture 6fieraminaNo ratings yet

- Lecture 5Document80 pagesLecture 5fieraminaNo ratings yet

- Synchronous Machine Fundamentals and Static Stability AnalysisDocument32 pagesSynchronous Machine Fundamentals and Static Stability AnalysisfieraminaNo ratings yet

- 8 JoiningDocument7 pages8 Joiningdawoodabdullah56No ratings yet

- Book Review On Linsu Kim's Imitation To InnovationDocument3 pagesBook Review On Linsu Kim's Imitation To InnovationdonghaoliNo ratings yet

- Lecture 1Document56 pagesLecture 1fieramina100% (1)

- Action Plan For The Project2Document1 pageAction Plan For The Project2fieraminaNo ratings yet

- Design Guidelines for Turned Parts and Rapid Prototyping MethodsDocument19 pagesDesign Guidelines for Turned Parts and Rapid Prototyping MethodsfieraminaNo ratings yet

- LectureDocument3 pagesLecturefieraminaNo ratings yet

- Three Phase TransformerDocument27 pagesThree Phase Transformerfieramina100% (1)

- Dongshin PRO-WD Series High Precision Intelligent Injection Molding Machines GuideDocument60 pagesDongshin PRO-WD Series High Precision Intelligent Injection Molding Machines Guidefieramina100% (1)

- 3 Phase Induction Machines 1 (Construction)Document75 pages3 Phase Induction Machines 1 (Construction)fieraminaNo ratings yet

- Single PhaseDocument23 pagesSingle PhasefieraminaNo ratings yet

- Example of Different DC MotorsDocument22 pagesExample of Different DC MotorsfieraminaNo ratings yet

- Engineering Drawing Handbook PDFDocument120 pagesEngineering Drawing Handbook PDFRobert Nixon100% (1)

- Starter MotorDocument15 pagesStarter MotorfieraminaNo ratings yet

- Rotational Dynamics and Motor ModelsDocument22 pagesRotational Dynamics and Motor ModelsfieraminaNo ratings yet

- 23 Shaft and Its Design Based On StrengthDocument9 pages23 Shaft and Its Design Based On StrengthPRASAD326No ratings yet

- DCDocument25 pagesDCfieraminaNo ratings yet

- Metals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkDocument4 pagesMetals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkfieraminaNo ratings yet

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- Absolute MotionDocument1 pageAbsolute MotionfieraminaNo ratings yet

- Cabo de Mão GoproDocument1 pageCabo de Mão GoproTiago BorinNo ratings yet

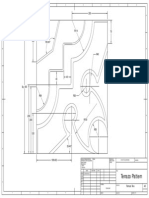

- Terazzo Two - Sheet1 PDFDocument1 pageTerazzo Two - Sheet1 PDFfieraminaNo ratings yet

- Bags, Boxes, Bowls, and Beyond: Portable Collections ProgramDocument20 pagesBags, Boxes, Bowls, and Beyond: Portable Collections ProgramfieraminaNo ratings yet

- Briefcases and Bags4 PDFDocument22 pagesBriefcases and Bags4 PDFfieraminaNo ratings yet

- Cane Sugar PDFDocument633 pagesCane Sugar PDFbernie_bph50% (2)

- Material Balance On A 2 Unit DistillationsDocument6 pagesMaterial Balance On A 2 Unit Distillationsnhalieza1067No ratings yet

- The role of root canal fillings in endodontic successDocument9 pagesThe role of root canal fillings in endodontic successYassir MudharNo ratings yet

- Measuring Instruments Practice QuestionsDocument6 pagesMeasuring Instruments Practice QuestionsAsif Ayaz100% (2)

- Experiment #2: Continuous-Time Signal Representation I. ObjectivesDocument14 pagesExperiment #2: Continuous-Time Signal Representation I. ObjectivesMarvin AtienzaNo ratings yet

- Schlumberger Log Interpretation ChatsDocument287 pagesSchlumberger Log Interpretation ChatsSabrianto AswadNo ratings yet

- Conduction, Convection, & RadiationDocument14 pagesConduction, Convection, & Radiationyuvionfire100% (1)

- Mec 424 - Laboratory Report: Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingDocument24 pagesMec 424 - Laboratory Report: Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingWan AimanNo ratings yet

- Molecular Partition Function ExplainedDocument18 pagesMolecular Partition Function ExplainedAnimasahun Olamide HammedNo ratings yet

- Pelton TurbineDocument18 pagesPelton Turbinetiwarishbhm0% (1)

- Pseudocode for determining minimum launch angle to clear an obstacleDocument8 pagesPseudocode for determining minimum launch angle to clear an obstacleChristian BatayenNo ratings yet

- Turbocharger Test GuidelinesDocument13 pagesTurbocharger Test Guidelinespardomu0% (1)

- Dynamics Lab Sheet 1 - Free Vibration Experiment - PKPDocument3 pagesDynamics Lab Sheet 1 - Free Vibration Experiment - PKPfaqhrulNo ratings yet

- Venturi and Orifice Volumetric Flow Measure-MentDocument4 pagesVenturi and Orifice Volumetric Flow Measure-Mentmuiz_jojoNo ratings yet

- Adaptive Followup Mastering PhysicsDocument8 pagesAdaptive Followup Mastering PhysicsElloani Ross Arcenal PitogoNo ratings yet

- 4 Rough Draft2 Impact of A Water JetDocument14 pages4 Rough Draft2 Impact of A Water JetBrennan GenusaNo ratings yet

- Probe PH Meter Ultraglass For Orion STARA2115Document33 pagesProbe PH Meter Ultraglass For Orion STARA2115chaerul.anwar554No ratings yet

- Berco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inDocument1 pageBerco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inrameshNo ratings yet

- Latent Heat of Fusion VaporizationDocument18 pagesLatent Heat of Fusion Vaporizationapi-449002661No ratings yet

- Mock C4 Paper Key ConceptsDocument4 pagesMock C4 Paper Key ConceptsWojtek BażantNo ratings yet

- Atomic TheoryDocument2 pagesAtomic TheorybabeNo ratings yet

- PhoneticsDocument5 pagesPhoneticsKarensita Totty' HerreraNo ratings yet

- POLYMERIZATION PROCESSESDocument0 pagesPOLYMERIZATION PROCESSESmajesticdharma1985No ratings yet

- Calcul Evaltn-Embankments Reinforced With geocells-FEM-2015Document14 pagesCalcul Evaltn-Embankments Reinforced With geocells-FEM-2015Rakesh KapoorNo ratings yet

- Archimedes Heat RayDocument5 pagesArchimedes Heat RayElliah Jen BiluganNo ratings yet

- Alloy ZN Ni PDFDocument8 pagesAlloy ZN Ni PDFElenaNo ratings yet

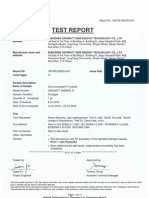

- High-Efficiency Solar Inverter Test Report SummaryDocument17 pagesHigh-Efficiency Solar Inverter Test Report Summarybharath prabhuNo ratings yet

- Liquid Liquid SeparatorsDocument26 pagesLiquid Liquid SeparatorsAjay Pratap SinghNo ratings yet

- 3 RPM and 6 RPMDocument4 pages3 RPM and 6 RPMAnonymous T32l1RNo ratings yet

- MCAT Formula SheetDocument3 pagesMCAT Formula SheetYank AzharNo ratings yet