Professional Documents

Culture Documents

Servo Cut

Uploaded by

Swarupendra Bhattacharyya0 ratings0% found this document useful (0 votes)

26 views1 pageIOC Servo

Original Title

servo cut

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIOC Servo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 pageServo Cut

Uploaded by

Swarupendra BhattacharyyaIOC Servo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

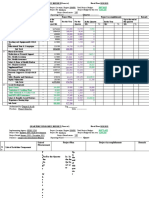

SERVO

PRODUCT DATA SHEET

SERVOCUT S

IndianOil

HEALTH & SAFETY

These oils are unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of industrial and personal hygiene are maintained.

For further information please contact our nearest office OR:

Technical Services Dept., Indian Oil Corporation Ltd., G-9, Ali Yavar Jung Marg, Bandra (East), Mumbai 400 051

E-Mail: tservices@indianoil.co.in OR tech_services@indianoil.co.in

GRADES AVAILABLE SERVOCUT S

CHARACTERISTICS

Kinematic Viscosity, cSt @ 40C (Typical) 20

Flash Point (COC), C Min. 150

Copper strip corrosion @ 100C 1

Cast Iron corrosion test, 0/1-1 Pass

DESCRIPTION

Servocut S is a soluble type high quality cutting

oil which yields rich milky emulsoin with water.

Special emulsifier is incorporated to ensure its

complete dispersion in water. The emulsion

formed is homogeneous and stable in nature, and

does not split during usage or routine machine

shut down periods, under normal conditions.

Servocut S contains rust inhibitors, which impart

anti-rust and anti-corrosive properties to the

emulsion. Carefully selected biocide is

incorporated to prevent bacterial growth in the

emulsion.

PERFORMANCE STANDARDS

Servocut S meets the following specification:

IS : 1115-1986 (Reaffirmed 1996)

APPLICATION

Servocut S is recommended for variety of cutting

operations on ferrous and non-ferrous metals. The

oil is specially suitable for metal working

operations where the cooling property is more

desirable compared to the lubricating

characteristics.

This grade can also be used with advantage in

cold rolling of steel and not rolling of aluminium.

To obtain stable emulsion, oil should be added to

water and not vice versa. A homogeneous

dispersion of oil in water can be obtained by

continuous stirring either manually or

mechanically while preparing the emulsion.

Servocut S is normally used in concentration of

5% for mot machining operations. For grinding

operations more dilute emulsions are preferred.

PERFORMANCE BENEFITS

Has superior cooling and lubricating

properties which contribute towards clean

work, excellent surface finish and minimum

tool wear

When used as a grinding coolant, contribute

towards long grinding wheel life, and

minimised wheel loading

Provides long lasting stable emulsions

Protects work-piece, machine components and

tool materials from rust and corrosion

Enables obtain superior finish and accurate

tolerances to the parts machined

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Liquid Enema ProcedureDocument3 pagesLiquid Enema Procedureapi-209728657No ratings yet

- Bulk-Fill Composite RestorationsDocument9 pagesBulk-Fill Composite RestorationssusethNo ratings yet

- Tool and Manufacturing Engineers Handbook: Design For ManufacturabilityDocument10 pagesTool and Manufacturing Engineers Handbook: Design For ManufacturabilitySwarupendra BhattacharyyaNo ratings yet

- Open Cholecystectomy ReportDocument7 pagesOpen Cholecystectomy ReportjosephcloudNo ratings yet

- Cooling Tower (Genius)Document7 pagesCooling Tower (Genius)JeghiNo ratings yet

- Qualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific ApproachDocument23 pagesQualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific Approachmicrobioasturias100% (4)

- Antrix Devas Scam What Ails Isro Newsroom24x7 1Document42 pagesAntrix Devas Scam What Ails Isro Newsroom24x7 1Swarupendra BhattacharyyaNo ratings yet

- APDL Programmer S Guide PDFDocument91 pagesAPDL Programmer S Guide PDFSwarupendra BhattacharyyaNo ratings yet

- Studovaný Okruh: Physical Therapist Sample Test Questions (G5+)Document8 pagesStudovaný Okruh: Physical Therapist Sample Test Questions (G5+)AndreeaNo ratings yet

- Ammonia Synthesis ConverterDocument26 pagesAmmonia Synthesis ConverterKvspavan Kumar100% (1)

- Effectiveness of Ground Isolation Schemes and Its Demonstration in Heavy Lift LauncherDocument3 pagesEffectiveness of Ground Isolation Schemes and Its Demonstration in Heavy Lift LauncherSwarupendra BhattacharyyaNo ratings yet

- North Sector: MountsDocument2 pagesNorth Sector: MountsSwarupendra BhattacharyyaNo ratings yet

- 22 PWDDocument25 pages22 PWDSwarupendra BhattacharyyaNo ratings yet

- Bangalore To Pune: Sat, 16 Dec 2017 Sat, 16 Dec 2017Document3 pagesBangalore To Pune: Sat, 16 Dec 2017 Sat, 16 Dec 2017Swarupendra BhattacharyyaNo ratings yet

- Pune To Bangalore: Mon, 18 Dec 2017 Mon, 18 Dec 2017Document3 pagesPune To Bangalore: Mon, 18 Dec 2017 Mon, 18 Dec 2017Swarupendra BhattacharyyaNo ratings yet

- Corrosion Protection of Weldable AA2219 AlloyDocument5 pagesCorrosion Protection of Weldable AA2219 AlloySwarupendra BhattacharyyaNo ratings yet

- Bangalore To Pune: Sat, 16 Dec 2017 Sat, 16 Dec 2017Document3 pagesBangalore To Pune: Sat, 16 Dec 2017 Sat, 16 Dec 2017Swarupendra BhattacharyyaNo ratings yet

- Your Monday Ride To Sevashrama: Ride Details Fare DetailsDocument2 pagesYour Monday Ride To Sevashrama: Ride Details Fare DetailsSwarupendra BhattacharyyaNo ratings yet

- Numerical Weld Modeling - A Method For Calculating Weld-Induced Residual StressesDocument12 pagesNumerical Weld Modeling - A Method For Calculating Weld-Induced Residual StressesSwarupendra BhattacharyyaNo ratings yet

- Tuition Fee WaiverDocument2 pagesTuition Fee WaiverSwarupendra BhattacharyyaNo ratings yet

- Indian Institute of Space Science and Technology: AE-311 AerodynamicsDocument9 pagesIndian Institute of Space Science and Technology: AE-311 AerodynamicsSwarupendra BhattacharyyaNo ratings yet

- Manual Gavita Pro 600e SE EU V15-51 HRDocument8 pagesManual Gavita Pro 600e SE EU V15-51 HRwhazzup6367No ratings yet

- S:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Document19 pagesS:/admin/mpi/MP1169 - Amaia Skies Samat/000 - ACTIVE DOCUMENTS/09 - SPECS/2013-07-23 - Design Development/04-Plumbing/15050Lui TCC BariaNo ratings yet

- Quarterly Progress Report FormatDocument7 pagesQuarterly Progress Report FormatDegnesh AssefaNo ratings yet

- Wada Defending Cannabis BanDocument18 pagesWada Defending Cannabis Banada UnknownNo ratings yet

- Waste Sector ProjectsDocument5 pagesWaste Sector ProjectsMrcoke SeieNo ratings yet

- Edgie A. Tenerife BSHM 1108: Page 1 of 4Document4 pagesEdgie A. Tenerife BSHM 1108: Page 1 of 4Edgie TenerifeNo ratings yet

- Roadmap Video: Answer KeyDocument4 pagesRoadmap Video: Answer KeyMaria JuneNo ratings yet

- Microbial Communities From Arid Environments On A Global Scale. A Systematic ReviewDocument12 pagesMicrobial Communities From Arid Environments On A Global Scale. A Systematic ReviewAnnaNo ratings yet

- Birla Institute of Management and Technology (Bimtech) : M.A.C CosmeticsDocument9 pagesBirla Institute of Management and Technology (Bimtech) : M.A.C CosmeticsShubhda SharmaNo ratings yet

- Injection MouldingDocument241 pagesInjection MouldingRAJESH TIWARINo ratings yet

- Generic 5S ChecklistDocument2 pagesGeneric 5S Checklistswamireddy100% (1)

- Brain Slides SEMINAR 1 - 220606 - 142811 - 220606 - 223805Document32 pagesBrain Slides SEMINAR 1 - 220606 - 142811 - 220606 - 223805pang pangNo ratings yet

- Compensation ManagementDocument2 pagesCompensation Managementshreekumar_scdlNo ratings yet

- UM-1D User ManualDocument30 pagesUM-1D User ManualAhmedBalaoutaNo ratings yet

- Crime Free Lease AddendumDocument1 pageCrime Free Lease AddendumjmtmanagementNo ratings yet

- Wa0016Document3 pagesWa0016Vinay DahiyaNo ratings yet

- Project PlanDocument55 pagesProject PlanAlfredo SbNo ratings yet

- Grounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiDocument42 pagesGrounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiSatyam PathakNo ratings yet

- OpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSDocument42 pagesOpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSAngelaNo ratings yet

- LAB ACT 5 Types of Chemical ReactionsDocument12 pagesLAB ACT 5 Types of Chemical ReactionsJerome MosadaNo ratings yet

- Fittings: Fitting Buying GuideDocument2 pagesFittings: Fitting Buying GuideAaron FonsecaNo ratings yet

- Capacity Requirement PlanningDocument17 pagesCapacity Requirement PlanningvamsibuNo ratings yet

- Posi LokDocument24 pagesPosi LokMarcel Baque100% (1)