Professional Documents

Culture Documents

International Service Information Solutions

Uploaded by

Tuấn Neo0 ratings0% found this document useful (0 votes)

128 views7 pagesinternational Service Information Solutions

Original Title

international Service Information Solutions

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentinternational Service Information Solutions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

128 views7 pagesInternational Service Information Solutions

Uploaded by

Tuấn Neointernational Service Information Solutions

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Optimization of kirloskar petrol engine

performance by using open engine control unit

S. J. Adsul

Department of Mechanical Engineering,

Walchand college of engineering, Sangli, Maharashtra, India

P. A. Mane

Department of Mechanical Engineering,

Walchand college of engineering, Sangli, Maharashtra, India

S. S. Mulay

Apex Innovation pvt. Ltd, Kupwad m.i.d.c area, Sangli

Abstract - This paper deals with developing test bench which will give us idea about how to tune engine parameters and

also give the flexibility to change the parameters electronically. To achieve this old carbutretor system is relpaced by

gasoline port injection system. To carry out experimentation modified kirloskar single cylinder water cooled engine is

selected. In optimization process of kirloskar engine air-fuel ratio is try to maintain constant through out the operating

range of engine. Initially in Experimentation work tuning of engine is done as per the same load and rpm condition as

that of carburetor. The rpm range varies in between 1000 to 1800 rpm. And Throttle opening varies in range of 20 to

100%. The graphs of brake power and brake thermal efficiency vs rpm is plotted for each throttle opening and part

throttle efficiency of ecu based system is compared with crburetor system. For tuning of engine we have taken generic

ecu of performnce electronics company from US.

Keywords ecu , engine tuning, part load performance, gasoline port injection system.

I. INTRODUCTION

Today there is no escape from the computer in the modern car. While it is true that carburetors in the old days were

doing the job of supplying an air/fuel mixture to the engine, there were a collection of compromises such as fuel

economy, high emissions etc. When tuning the carburetor you had to decide which you were willing to give up:

power or fuel efficiency. You couldnt get all three. To get all three, computer-controlled fuel injection is required

which is one of the part of engine control unit. Todays automobile manufacturers strive to design automobiles that

provide the best performance balanced against good efficiency. Efficiency has become a central issue in the design

of new engines because of the need to meet tighter environmental regulations and the demand for fuel frugal

automobiles by consumers.

Tuning the engine to achieve maximum efficiency is a huge part of getting the best performance out of the race cars.

Making adjustments to the fuel injection system to change the amount and release time of fuel, changing the size or

flow of fuel injectors, and utilizing the many available engine sensors to make other modifications can all have a

great impact on engine horsepower and efficiency [11]. Modern engines use software loaded in the engines Engine

Control Module (ECM) to optimize performance and efficiency of the engine. The ECM collects all sensor data,

interprets and processes this data, and then sends out control signals necessary for the smooth and efficient operation

of the engine for example: In order to have complete combustion, the air-fuel mixture must be correct. The

Stoichiometric ratio for air-fuel in a petrol engine is 14.7:1. This means that, volumetrically, 14.7 times more air

than fuel is needed for complete combustion. The complete combustion of air yields carbon dioxide (CO2) and

water (H2O). If there is not enough air then the combustion process will be incomplete and produce carbon

monoxide, nitrous oxides and unburnt hydrocarbons as unwanted byproducts. The introduction of the paper should

explain the nature of the problem, previous work, purpose, and the contribution of the paper. The contents of each

section may be provided to understand easily about the paper. In modern automobiles the ECM will have to

calculate the amount of air entering the intake manifold before it can calculate the amount of fuel to deliver to each

cylinder. To do this, the air flow, air temperature and air pressure is measured. For example, if the temperature is

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 292 ISSN: 2319 1058

low, the air density will be high; therefore, more air will enter the intake manifold. However, if the pressure is high,

the air density will also be high, thus more air will enter the intake manifold. Therefore various sensors are used to

measure parameters such as mass air flow, air temp, air pressure then these sensors collect data and feed the

information to the ECM. The ECM computes in real-time the correct amount of fuel to be injected into the cylinders

and the firing times of the spark plugs. As cars became more complex and government regulations related to exhaust

emissions became stricter, however, carburetors have been replaced with electronic fuel injection systems, which

can more precisely control the flow of fuel to the engine. This results in optimum engine performance, better fuel

economy, and lower exhaust emissions.

Now ECU is available in market but how to tune ECU, how mapping of engine is done and idea about how engine

management system works such information is only limited to manufacturer of vehicles. Therefore test bench is

developed in order to give above information through open ecu.

II. EXPERIMENTAL PROCEDURE

Table1- Specification of engine

Engine type Kirloskar

Bore 0.088m

Stroke length 0.11m

No of cylinder 1

No of stroke 4

Type of cooling Water cooled

Rated power 4.5kW @ 1800 rpm

Engine capacity 661cc

Variable compression range 610

Fuel used Petrol

The Schematic diagram of experimental setup is as shown in Fig. 1. The engine used is a conventional single

cylinder, water cooled, vertical four stroke SI engine. The specification of engine is shown in Table 1. The engine is

basically diesel engine with a maximum speed of 1800 rpm. The above engine is modified to petrol mode through

VCR technology by apex organization. The fuel injection system consisting of throttle body, solenoid operated fuel

injector, fuel rail, pressure relief valve, electric operated fuel pump, fuel filter. In the experimental setup, we have

used air temperature sensor, coolant temperature sensor, trigger sensor, throttle position sensor. The air temperature

sensor is mounted at the air intake, coolant temperature sensor is mounted at water outlet of engine and trigger

sensor is mounted at camshaft. The ignition timing, injection timing, air fuel ratio we can adjust it electronically. In

the working of an engine control unit throttle position sensor gives information about how much air is going inside

the combustion chamber and trigger sensor sends pulses to ECU to measure rpm. According to the signal from

throttle position sensor and crank shaft position sensor ECU actuates injector to inject fuel quantity in terms of

injector pulse width and also actuates spark plug to fire.

The engine is coupled to an eddy current dynamometer to measure speed and torque of the engine. The suitable

instruments are connected to engine to measure air flow, fuel flow. Other than above experimental setup we have

used combustion analysis software which will gives us direct measure of engine parameters such as brake thermal

efficiency, brake power, indicated power, brake specific fuel consumption, air fuel ratio etc.

III. RESULT AND DISCUSSION

The aim of present study is to optimize the engine performance of electronically controlled engine over conventional

carburetor engine. In the flow of conducting the experiments and optimizing engine performance, initially we have

compared performance of conventional carburetor engine and electronically controlled engine. In this, the

experiments are conducted at each throttle opening and rpm with same load condition as that of carburetor.

3.1. 40% Throttle opening

At 40% throttle position by keeping same load and rpm as that of carburetor the various parameters of engine are

measured. The graph of brake power and brake thermal Efficiency are plotted against rpm. As reading for ECU

based engine are taken at same load and rpm condition therefore brake power for both carburetor and ECU are

approximately same. The brake power curve for both system is shown in Fig 2. It is observed that bsfc in case ecu

based system is less than that of carburetor system. Therefore I got slightly better brake thermal efficiency in ecu

based engine. The brake thermal efficiency curve is shown in Fig 3. At speed about 1113 rpm brake thermal

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 293 ISSN: 2319 1058

efficiency has maximum value of 20.99%. And after that efficiency goes on decreasing as speed increases and is

minimum at 1744 rpm. Because of error involved in measurement of air and fuel I have got such nature of curve.

Over flow Filter

Atm air

Exhaust Manifold

Ee crank shaft cam shaft

Spark plug

Ignition coil Engine water outlet

12 v ground

Figure1. Schematic diagram of experimental setup

Throttle body

Intake manifold

Dynamometer Kirloskar petrol

engine

Air intake

ATS

Tank

Fuel pump

Fuel rail

ECU

Injector

Pressure

regulator

Water pump

Coolant temp

sensor

Encoder

Trigger

sensor

Battery

Relay

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 294 ISSN: 2319 1058

Fig. 2 variation of brake power vs rpm at 40% throttle opening

Fig. 3 variation of brake thermal efficiency vs rpm at 40% throttle opening

3.2. 60% throttle opening

As similar to that of 40% throttle, brake power for both ecu and carburetor is same. The brake power vs rpm and

brake thermal efficiency vs rpm curve for 60% throttle is shown in Fig.4 and Fig.5. Brake thermal efficiency of ecu

based system is more as compared to brake thermal efficiency of carburetor because bsfc in case of ecu based

system is less as compared to carburetor system. And as compared to carburetor system ecu based system runs to a

very lean mixture. The maximum value of brake thermal efiiciency in carburetor system is 20.56% and is increased

upto 23.58% in ecu based system.

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 295 ISSN: 2319 1058

Fig. 4 rpm vs Brake power at 60% throttle

Fig. 5 rpm vs Brake thermal efficiency at 60% throttle

3.3. 100% throttle opening

The graph of brake power vs rpm and brake thermal efficiency vs rpm at 100% throttle opening is shown in Fig. 6

and Fig.7. In this graph as rpm increases brake power goes on increasing. The brake thermal efficiency of ecu based

engine is 25.39%. and carburetor based engine is 25.13%.

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 296 ISSN: 2319 1058

Figure 6. rpm vs brake power at 100% throttle

Figure 7. rpm vs brake thermal efficiency at 100% throttle

IV. CONCLUSION

From the above experimentation we can conclude that ECU based system works on a very chemically correct

mixture as compared to carburetor system and due to this brake specific fuel consumption is minimum in case of

ECU based system. Therefore brake thermal efficiency is increased in ECU based system.

As compared to that of carburetor system, accurate metering of fuel and air is possible in gasoline port injection

system works.

REFERENCES

[1] D.A. Sen and A.A. Zainul Abidin, An overview of the Engine Control Unit (ECU) and its sensors for the Mitsubishi G93 Engine, Dept.

of Electrical Engineering, University Tenaga Nasional, Malaysia.

[2] Huizong Feng, Fenglin Liu, Yang Xu, Functional Testing System Based on LabVIEW for Gas-fueled Automobile Engine ECU,

Automation College, ChongQing University of Posts and Telecommunications, ChongQing, China (ICACC) 2011, 357-361.

[3] William B. Ribbens, Understanding Automotive Electronics (November 1997), 147-182.

[4] Jochen Schaffnit, Stefan Sinsel and Rolf lsermann, Hardware-in-the-loop simulation for the investigation of truck diesel injection

systems, Institute of automotive control technical university of Darmstadt, American Control Conference Philadelphia, Pennsylvania

(June 1998).

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 297 ISSN: 2319 1058

[5] Luigi Glielmo , Francesco Vasca, Carlo Rossi, Architecture for Electronic Control Unit Tasks in Automotive Engine Control

Dipartimento di Infmatica e Sistemistica, Universitit di Napoli Federico 11,via Claudio 21,80125 Napoli, Italy, September 25-27,2000.

[6] M. L. Mathur and R. P. Sharma, Internal combustion engine, Dhanpat Rao publications.

[7] M. S. Shehate and S.M. Abdel Razek , Engine performance parameters and emissions reduction methods for spark ignition engine

engineering research journal 120, (december 2008) m32 m57.

[8] S. S Mohtasebi, A. keyhani and M. rahami, Simulation, testing and sensitivity analysis of fuel pressure regulator for MPFI paykan 1600 cc

engine, journals of applied sciences 5 (4): 2005, 781-786.

[9] Jacob fraden,Hand book of modern sensor, Advanced Monitors Corporation San Diego,California November 2003.

[10] A.B. Greene, and G.G. Lucas, The testing of internal combustion engines, Department of transport technology, loughborough university

of technology.

[11] George Alexandrov, Kaitlin Bergin, and Rolih Ferdinand, Automotive Engineering: Engine Fuel Map Design.

[12] V Ganesan, Internal combustion engine, professor Emeritus Deptt. Of sMechanical Engineering IIT Madras, Chennai.

[13] www.indrabhagyadighanchi.org/10.html

[14] position/ speed sensor, Toyata motor sales, USA.

[15] Robert Bosch, k- jetronics fuel injection manual,Robert Bosch GmbH, 2000 Postfach 3002 20, D70442 Stuttgart. Automotive Equipment

Business Sector, Department for Automotive Services, Technical Publications (KH/PDI2).

[16] fuel injection system Tbi electronic fuel injection jeep Cherokee 1988.

International Journal of Innovations in Engineering and Technology (IJIET)

Vol. 2 Issue 1 February 2013 298 ISSN: 2319 1058

You might also like

- 1991 Honda Accord Shop ManualDocument903 pages1991 Honda Accord Shop ManualMark DismoreNo ratings yet

- Service Manual Common Rail System Isuzu 4HK1 6HK1Document48 pagesService Manual Common Rail System Isuzu 4HK1 6HK1vagpoul95% (148)

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- 4JH1 Gestión ElectrónicaDocument79 pages4JH1 Gestión ElectrónicaAna Lorca89% (19)

- NavKal UsersGuideDocument9 pagesNavKal UsersGuideJose F Rivera MoralesNo ratings yet

- Codigos Ford Diesel 2011-2015Document157 pagesCodigos Ford Diesel 2011-2015javier67% (3)

- 1967 C150G Owners Manual PDFDocument28 pages1967 C150G Owners Manual PDFalexred89No ratings yet

- Chevrolet Blazer - Engine Performance Theory - OperationDocument30 pagesChevrolet Blazer - Engine Performance Theory - Operationprovajuv100% (1)

- Engine Management MechatronicsDocument18 pagesEngine Management MechatronicsTanuj Kumar67% (3)

- Marvel Schebler Overhaul NewDocument21 pagesMarvel Schebler Overhaul NewRike Fox100% (1)

- DDDL706 ReadmeDocument3 pagesDDDL706 ReadmeTuấn NeoNo ratings yet

- 2016 nmax125 서비스메뉴얼 2DS-F8197-E0 (20권)Document444 pages2016 nmax125 서비스메뉴얼 2DS-F8197-E0 (20권)DonNo ratings yet

- Dictionary of Automotive Terms 2sy65y6y46r6ytDocument527 pagesDictionary of Automotive Terms 2sy65y6y46r6ytTuấn NeoNo ratings yet

- A035C596 - I1 - 201012 E-Controls Manual PDFDocument381 pagesA035C596 - I1 - 201012 E-Controls Manual PDFO mecanico100% (2)

- Design of Intake ManifoldDocument6 pagesDesign of Intake ManifoldShailendra SinghNo ratings yet

- S2000 SOS Supercharger Install ManualDocument43 pagesS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- Eng Fault CodeDocument14 pagesEng Fault CodeNaing Min Htun100% (2)

- BF 175 - 250 Manual (Eng)Document164 pagesBF 175 - 250 Manual (Eng)HuyNo ratings yet

- Trk251 Service ManualDocument508 pagesTrk251 Service ManualDario F HillNo ratings yet

- 250-C20 Illustrated Parts CatalogDocument468 pages250-C20 Illustrated Parts CatalogJose Luis Avendaño95% (21)

- Methods of Improving Engine Performance and EfficiencyDocument34 pagesMethods of Improving Engine Performance and EfficiencyDavid ChikuseNo ratings yet

- Chapter 10Document39 pagesChapter 10ashaNo ratings yet

- Unit - 2 Testing of Ic EngineDocument85 pagesUnit - 2 Testing of Ic EngineVitthal GawhaleNo ratings yet

- SSP 419 The Scirocco 2009Document52 pagesSSP 419 The Scirocco 2009francois.garcia31100% (1)

- Answers To Chapter 6 Activities and QuestionsDocument17 pagesAnswers To Chapter 6 Activities and QuestionsKurt HaanNo ratings yet

- IC Engine FormulaDocument5 pagesIC Engine FormulaKarthikeyan Gnanasekaran0% (1)

- Bosch 35 Pin Early Motronic Pinout (BMW 5,6,7)Document2 pagesBosch 35 Pin Early Motronic Pinout (BMW 5,6,7)Posada Burgueño Carlos67% (3)

- 10M134 AIC Assignment 1 & 2 PDFDocument14 pages10M134 AIC Assignment 1 & 2 PDFChandannnn92No ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- SheronDocument20 pagesSheronSheron ThomasNo ratings yet

- Stepen Kompresije RadDocument10 pagesStepen Kompresije Radcaligula9955No ratings yet

- Modification To Fuel Supply System of Honda CD125 Motorcycle EngineDocument4 pagesModification To Fuel Supply System of Honda CD125 Motorcycle EngineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Energy Conversion and Management: M.A. Ceviz, M. AkınDocument6 pagesEnergy Conversion and Management: M.A. Ceviz, M. AkınMartinito MacraméNo ratings yet

- Me2041 - Advanced Ic Engines: Unit-I Spark Ignition EnginesDocument99 pagesMe2041 - Advanced Ic Engines: Unit-I Spark Ignition EnginesCaleb WilcoxNo ratings yet

- Lect 1-Efi Petrol 3HRSDocument50 pagesLect 1-Efi Petrol 3HRSHodge LorneNo ratings yet

- Modelling of The Exhaust Gas RecirculationDocument15 pagesModelling of The Exhaust Gas RecirculationAdølfo BtzNo ratings yet

- Fuel InjectionDocument4 pagesFuel InjectionWeyih ReganNo ratings yet

- Unit-I Spark Ignition Engines: Introduction About IC EnginesDocument99 pagesUnit-I Spark Ignition Engines: Introduction About IC EnginesRanjith R Engineer PPCNo ratings yet

- Experimental .FullDocument7 pagesExperimental .FullTJPRC PublicationsNo ratings yet

- Mathematical Modelling and Simulation of Spark Ignition Engine For Predicting Engine Performance CharacteristicsDocument5 pagesMathematical Modelling and Simulation of Spark Ignition Engine For Predicting Engine Performance CharacteristicsInnovative Research PublicationsNo ratings yet

- Sesb2 ID106Document8 pagesSesb2 ID106kaesarNo ratings yet

- Novel Configuration For Air Flow Rationalization and Turbo Lag Reduction in CRDI EngineDocument4 pagesNovel Configuration For Air Flow Rationalization and Turbo Lag Reduction in CRDI Engineyash1239No ratings yet

- Fuel Injection NotesDocument37 pagesFuel Injection Notessachin0311No ratings yet

- VGT Control Strategy - SimulinkDocument6 pagesVGT Control Strategy - SimulinkSaurabh ManiNo ratings yet

- A Method of Turbocharger Design Optimization For A Diesel Engine With Exhaust Gas RecirculationDocument13 pagesA Method of Turbocharger Design Optimization For A Diesel Engine With Exhaust Gas RecirculationMuhammad TaimoorNo ratings yet

- Effects of Air Intake Pressure To The Fuel Economy and Exhaust Emissions On A Small Si Engine 1Document15 pagesEffects of Air Intake Pressure To The Fuel Economy and Exhaust Emissions On A Small Si Engine 1divyachandran55No ratings yet

- Experiment No 6 by Arun (1408131017) - 2Document6 pagesExperiment No 6 by Arun (1408131017) - 2arunNo ratings yet

- Albert 2004Document11 pagesAlbert 2004alijannounNo ratings yet

- Development of A Turbojet Engine Lab For Propulsion EducationDocument11 pagesDevelopment of A Turbojet Engine Lab For Propulsion EducationRohit Kumar SinghNo ratings yet

- Electronic Engine ControlDocument40 pagesElectronic Engine Controlvasthav27No ratings yet

- Automotive Vehicles: CarburetionDocument39 pagesAutomotive Vehicles: CarburetionVinodDahiya100% (1)

- Influence of EGR (Exhaust Gas Recirculation) On Engine Components Durability & Lubricating Oil ConditionDocument6 pagesInfluence of EGR (Exhaust Gas Recirculation) On Engine Components Durability & Lubricating Oil ConditionIJERDNo ratings yet

- Advanced Ic Engine Full NotesDocument200 pagesAdvanced Ic Engine Full NotesSundaram100% (2)

- FuelDocument30 pagesFuelrakhikishoreNo ratings yet

- AUTOTRONICADocument3 pagesAUTOTRONICAJhon Arreaga AguilarNo ratings yet

- Panouri SolareDocument12 pagesPanouri SolareDan PetreNo ratings yet

- AE&ES Lab Front Page Merged Pages 2 22Document4 pagesAE&ES Lab Front Page Merged Pages 2 22VIVEK KUMAR DASNo ratings yet

- Modular Engine Management System (Mems) and Air/Fluid ControlDocument2 pagesModular Engine Management System (Mems) and Air/Fluid ControlocernnNo ratings yet

- Imp2 PDFDocument8 pagesImp2 PDFJustin JosephNo ratings yet

- Electronic Carburettors (Automobile) PDFDocument6 pagesElectronic Carburettors (Automobile) PDFManoj100% (3)

- Project Report TE LabDocument7 pagesProject Report TE LabRadhika GurjarNo ratings yet

- Ic Engine Project ReportDocument6 pagesIc Engine Project ReportAtulkumarSutharNo ratings yet

- Effect of Air Fuel Mixer Design On Engine Performance and Exhaust Emission of A CNG Fuelled VehiclesDocument5 pagesEffect of Air Fuel Mixer Design On Engine Performance and Exhaust Emission of A CNG Fuelled VehiclesAshik MahmudNo ratings yet

- Egye205 Marfori Labr3 VRTLDocument5 pagesEgye205 Marfori Labr3 VRTLGritz Kay Labucay MarforiNo ratings yet

- Advanced Ic Engine Full NotesDocument200 pagesAdvanced Ic Engine Full NotesBhagavathi ShankarNo ratings yet

- AMST1Document23 pagesAMST1gursagarvirdi1gmailcomNo ratings yet

- Vtec and Ivtec ComparisionDocument12 pagesVtec and Ivtec ComparisionAjithNo ratings yet

- Electronic Fuel InjectionDocument13 pagesElectronic Fuel InjectionTerrence JimNo ratings yet

- Ic Engine PPT 1Document12 pagesIc Engine PPT 1rajeshNo ratings yet

- CI Engine Lab ReportDocument7 pagesCI Engine Lab ReportMichael Adrian100% (4)

- Chapter 1: Overview of ICE: TR 2019 Internal Combustion EngineDocument62 pagesChapter 1: Overview of ICE: TR 2019 Internal Combustion EngineMinh Hồ BìnhNo ratings yet

- Multi Port Fuel Injection SystemDocument4 pagesMulti Port Fuel Injection SystemVarsha SreekumarNo ratings yet

- Lecture Notes Mech Thermal Engg. II Lecture Notes 4th Semester MechanicalDocument58 pagesLecture Notes Mech Thermal Engg. II Lecture Notes 4th Semester MechanicalSaroj Kumar SahuNo ratings yet

- Parametric Analysis of A Turbojet Engine With Reduced Inlet Pressure To The CompressorDocument9 pagesParametric Analysis of A Turbojet Engine With Reduced Inlet Pressure To The CompressorIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Eti 04 PowerFlowAndEfficiencyDocument129 pagesEti 04 PowerFlowAndEfficiencyshivamminapurNo ratings yet

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDocument8 pagesMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNo ratings yet

- 2008 430 PDFDocument2 pages2008 430 PDFTuấn NeoNo ratings yet

- GRP Unit DescriptionDocument2 pagesGRP Unit DescriptionTuấn NeoNo ratings yet

- Quad High-Side Gate Driver For Automotive Applications: Description Features and BenefitsDocument20 pagesQuad High-Side Gate Driver For Automotive Applications: Description Features and BenefitsTuấn NeoNo ratings yet

- Additions, Revisions, or Updates: Subject DateDocument3 pagesAdditions, Revisions, or Updates: Subject DateTuấn NeoNo ratings yet

- 1001 12 PDFDocument26 pages1001 12 PDFTuấn NeoNo ratings yet

- IdcplgDocument40 pagesIdcplgFernando SanzNo ratings yet

- 74HCT14D Datasheet en 20160524 PDFDocument8 pages74HCT14D Datasheet en 20160524 PDFTuấn NeoNo ratings yet

- 01 New 0001-1Document2 pages01 New 0001-1Tuấn NeoNo ratings yet

- Geben Sie Hier Den Titel Der Datei EinDocument8 pagesGeben Sie Hier Den Titel Der Datei EindanrcgNo ratings yet

- 74HCT14D Datasheet en 20160524 PDFDocument8 pages74HCT14D Datasheet en 20160524 PDFTuấn NeoNo ratings yet

- Tempfet BTS 113A: FeaturesDocument10 pagesTempfet BTS 113A: FeaturesTuấn NeoNo ratings yet

- IdcplgDocument40 pagesIdcplgFernando SanzNo ratings yet

- Mack DP F OperationDocument13 pagesMack DP F OperationTuấn NeoNo ratings yet

- March 2009 Mercedes Benz Reset Service Indicator GuideDocument12 pagesMarch 2009 Mercedes Benz Reset Service Indicator Guiderolandslade100% (3)

- 1990 Porsche 928 S4 Auto B2 Piston Failure March 2005mDocument29 pages1990 Porsche 928 S4 Auto B2 Piston Failure March 2005mTuấn NeoNo ratings yet

- System Wiring Diagrams Air Conditioning CircuitsDocument1 pageSystem Wiring Diagrams Air Conditioning CircuitsTuấn NeoNo ratings yet

- 5e7656b1b3bf2b52b34c1db33adb21e7Document3 pages5e7656b1b3bf2b52b34c1db33adb21e7Tuấn NeoNo ratings yet

- XHTH ThapDocument5 pagesXHTH ThapTuấn NeoNo ratings yet

- 147Document6 pages147Engr Nayyer Nayyab MalikNo ratings yet

- Acc Nissan VeraDocument4 pagesAcc Nissan VeraTuấn NeoNo ratings yet

- Fgtech Driver List Truck TractorDocument6 pagesFgtech Driver List Truck TractorTuấn NeoNo ratings yet

- Sensors AmericaDocument105 pagesSensors AmericaMarcelo SchmidtNo ratings yet

- 1 MB Professional MemoryDocument9 pages1 MB Professional MemoryTuấn NeoNo ratings yet

- 316 HO AAM, Key Replacement 98-99Document2 pages316 HO AAM, Key Replacement 98-99arkhom1No ratings yet

- Xprog MDocument1 pageXprog MTuấn NeoNo ratings yet

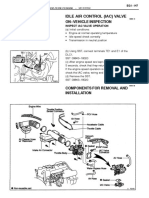

- Idle Air Control Iac ValveDocument2 pagesIdle Air Control Iac ValveHugo Armando Garcia Lepe0% (1)

- Check Valve and Throttle/Check Valve With SAE Flanged Ports: RE 64 548/06.03 1/6 Replaces: 03.94Document6 pagesCheck Valve and Throttle/Check Valve With SAE Flanged Ports: RE 64 548/06.03 1/6 Replaces: 03.94Enayat IzadiNo ratings yet

- Yamaha Golf Car G8 - AK PDFDocument47 pagesYamaha Golf Car G8 - AK PDFAhmed WissamNo ratings yet

- Briggs and Stratton For Snapper Parts Manual 128T020112B1Document25 pagesBriggs and Stratton For Snapper Parts Manual 128T020112B1Mike KrisanitsNo ratings yet

- I2ecs-1kd 2017-2018Document23 pagesI2ecs-1kd 2017-2018Alfredo MedinaNo ratings yet

- Governing of Steam TurbinesDocument4 pagesGoverning of Steam Turbinesmahanta331100% (1)

- Vag - ComDocument26 pagesVag - ComwujkoNo ratings yet

- Ej18 DetailsDocument6 pagesEj18 Detailsdaniel FerreiraNo ratings yet

- Cross-Reference Information For Diagnostic CodesDocument9 pagesCross-Reference Information For Diagnostic CodesEdwin Alfonso Hernandez MontesNo ratings yet

- Fault Code Identification - 齐海行 Unit KE215Document7 pagesFault Code Identification - 齐海行 Unit KE215Angga 99No ratings yet

- AUTOMOTIVE MECHATRONICsDocument9 pagesAUTOMOTIVE MECHATRONICsshubham goleNo ratings yet

- Stanadyne Pump Diagnostic Troubleshooting PDFDocument3 pagesStanadyne Pump Diagnostic Troubleshooting PDFOctavio RamosNo ratings yet

- Engine Throttle ControlDocument14 pagesEngine Throttle Controltiago100% (1)

- P and H Chapter 6Document129 pagesP and H Chapter 6oliver kimNo ratings yet

- C1358Document6 pagesC1358Lucas CamposNo ratings yet