Professional Documents

Culture Documents

FP 6321

Uploaded by

Ahmed HussainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FP 6321

Uploaded by

Ahmed HussainCopyright:

Available Formats

1

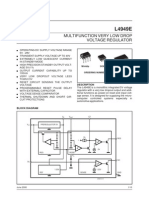

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Synchronous Buck PWM

DC-DC Controller

Pin Assignment

SO Package (SOP-8)

Figure 1. Pin Assignment of FP6321

Ordering Information

Description

The FP6321 is designed to drive two N-channel

MOSFETs in a synchronous rectified buck topology.

It provides the output adjustment, internal soft-start,

frequency compensation networks, monitoring and

protection functions into a single package.

The IC operating at fixed 300KHz frequency provides

simple, single feedback loop, voltage mode control

with fast transient response. The resulting PWM duty

ratio ranges from 0-100%.

The FP6321 features over current protection. The

output current is monitored by sensing the voltage

drop across the R

DS (ON)

of the low side MOSFET

which eliminates the need for a current sensing

resistor.

This device is available in SOP-8 package.

Features

Operates from +5V or +12V

Drives Two Low Cost N-Channel MOSFETs

Fast Transient Response

Simple Single-Loop Control Design

( Voltage-Mode PWM Control)

Internal Soft-Start

Over-Current Fault Monitor

SOP-8 Package

RoHS Compliant

Applications

Motherboard

Graphic Card

Telecomm Equipments

High Power DC-DC Regulators

Servers

P: Pb Free with Commercial

Standard (RoHS Compliant)

TR: Tape / Reel

Blank: Tube

FP6321

Package Type

SO: SOP-8

2

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Typical Application Circuit

Figure 2. Typical Application Circuit of FP6321

Note: It is not recommended to apply FP6321 on V

CC

=12V/ V

IN

=12V condition

Functional Pin Description

Pin Name Pin Function

BOOT

This pin provides bias voltage to the high side MOSFET Driver. A bootstrap circuit may be to create a BOOT

voltage suitable to drive a standard N-Channel MOSFET.

UGATE

Connect UGATE to the high side MOSFET gate. This pin is monitored by the adaptive shoot-through protection

circuitry to determine when the high side MOSFET has turned off.

GND Ground.

LGATE

Connect LGATE to the low side MOSFET gate. This pin is monitored by the adaptive shoot-through protection

circuitry to determine when the high side MOSFET has turned off.

VCC Power Pin.

FB Feedback Pin. The typical reference voltage is 0.8V.

OCSET Shutdown Control and connect a resistance (R

OCSET

) for over current setting.

PHASE Connect the PHASE pin to the high side MOSFET source, and sensing converters input power.

Absolute Maximum Ratings

VCC to GND ------------------------------------------------------------------------------------- - 0.3V to +16V

BOOT, V

BOOT

-V

PHASE

--------------------------------------------------------------------------- - 0.3V to +16V

PHASE -------------------------------------------------------------------------------------------- - 5V to +16V

UGATE -------------------------------------------------------------------------------------------- V

PHASE

- 0.3V to V

BOOT

+0.3V

LGATE --------------------------------------------------------------------------------------------- - 0.3V to V

CC

+0.3V

FB,OCSET to GND ------------------------------------------------------------------------------ - 0.3V to +6V

3

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Absolute Maximum Ratings (Continued)

Continuous Power Dissipation (T

A

=+70C)------------------------------------------------------------ 330mW

Junction Temperature -------------------------------------------------------------------------------------- +150C

Operation Temperature Range -------------------------------------------------------------------------- - 40C to +85C

Storage Temperature Range------------------------------------------------------------------------------ - 65C to +150C

Lead Temperature (Soldering, 10sec.) ----------------------------------------------------------------- +260C

ESD Susceptibility

HBM(Human Body Mode)--------------------------------------------------------------------------------- 2KV

MM(Machine Mode)---------------------------------------------------------------------------------------- 200V

Note Stresses beyond those listed under Absolute Maximum Ratings" may cause permanent damage to the device.

Recommended Operating Conditions

Supply Voltage, VCC ---------------------------------------------------------------------------------- 5V 5%, 12V 10%

Ambient Temperature Range ----------------------------------------------------------------------- 0C to +70C

Junction Temperature Range------------------------------------------------------------------------ 0C to +125C

Block Diagram

Soft-Start

&

Fault Logic

Power on

Reset

Gate Control

Logic

Oscillator

(300KHZ)

GM

Bias Regulators

VCC

FB

OCSET

BOOT

UGATE

PHASE

LGATE

VCC

COMP

UV

0.8VREF

Enable

0.15V

1.5V

0.4V

OC

GND

REFERENCE

Soft- Start

75%VREF

PWM

Inhibit

VIN

Monitor

40A

2.5V

Figure 3. Block Diagram of FP6321

4

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Electrical Characteristics

(V

CC

=5V/12V, T

A

=25C, unless otherwise specified)

Parameter Symbol Conditions Min Typ Max Unit

INPUT

V

CC

Under Voltage Lockout Vrising V

CC

rising 3.7 4.1 4.5 V

Vfalling V

CC

falling 0.25 V

Quiescent Current I

CC

U

GATE

and L

GATE

open 2 6 mA

ERROR AMPLIFIER

Feedback Voltage V

FB

0.784 0.8 0.816 V

FB Input Bias Current I

FB

V

FB

=1V 0.1 uA

Open Loop DC gain A

O

85 dB

OSCILLATOR

Frequency F

OSC

V

CC

=12V 250 300 350 KHz

Ramp Amplitude V

OSC

V

CC

=12V 1.5 Vp-p

GATE DRIVERS

Upper Gate Source I

UGATE

V

BOOT

-V

PHASE

=12V, V

UGATE

-V

PHASE

=6V 300 500 mA

Upper Gate Sink R

UGATE

V

BOOT

-V

PHASE

=12V, V

UGATE

-

VPHASE

=1V 4 8

Lower Gate Source I

LGATE

V

CC

=12V, V

LGATE

=6V 300 500 mA

Lower Gate Sink R

LGATE

V

CC

=12V, V

LGATE

=1V 3 5

Dead Time T

DT

Guaranteed by Design 100 ns

PROTECTION

FB Under-Voltage Trip FB Falling 70 75 80 %

OC Current Source I

OCSET

V

PHASE

=0V 35 40 45 uA

Soft-Start Interval Tss 2 3.5 ms

5

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Typical Performance Curves

-40 -20 0 20 40 60 80

0.75

0.76

0.77

0.78

0.79

0.80

0.81

0.82

0.83

0.84

0.85

R

e

f

e

r

e

n

c

e

V

o

l

t

a

g

e

(

V

)

Junction Temperature (

O

C)

-40 -20 0 20 40 60 80

270

275

280

285

290

295

300

305

310

315

320

F

r

e

q

u

e

n

c

y

(

K

H

z

)

Junction Temperature (

o

C)

Figure 4. Reference Voltage vs. Junction Temperature Figure 5. Frequency vs. Junction Temperature

-40 -20 0 20 40 60 80

36

38

40

42

44

O

C

C

u

r

r

e

n

t

S

o

u

r

c

e

(

u

A

)

Junction Temperature (

o

C)

0 2 4 6 8 10 12 14

60

65

70

75

80

85

90

95

100

E

f

f

i

c

i

e

n

c

y

(

%

)

Output Current (A)

V

CC

=12V

V

IN

=5V

V

OUT

=1.8V

Figure 6. OC Current Source vs. Junction Temperature Figure 7. Efficiency

Figure 8. Power OFF Figure 9. Switching waveform (UGATE rising)

VCC

V

OUT

I

L

Phase

I

OUT

=15A

I

OUT

=0A

V

UGATE

V

PHASE

V

LGATE

6

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Typical Performance Curves (Continued)

Figure 10. Switching waveform (UGATE falling) Figure 11. Switching waveform (UGATE rising)

Figure 12. Switching waveform (UGATE falling) Figure 13. Output Ripple

Figure 14. Load Transient Response Figure 15. Power On

V

UGATE

V

PHASE

V

LGATE

I

OUT

=0A I

OUT

=15A

V

UGATE

V

LGATE

V

PHASE

I

OUT

=15A

V

UGATE

V

PHASE

V

LGATE

I

L

V

OUT

Switching Frequency=1Khz

Slew rate=2.5A/us

V

OUT

I

OUT

VCC

IL

Phase

I

OUT

=15A

V

OUT

7

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Typical Performance Curves (Continued)

Figure 16. OCP using DC loading Figure 17. OCP using Dynamic loading

Functional Description

1. Initialization

The Power-On Reset (POR) function continually

monitors the input supply voltage and the enable

function. The POR monitors the bias voltage at the

VCC pin and the input voltage (VIN) on the phase

pin. After VCC power is ready, turning on the high

side MOS by pulse cycle. After high side MOS turns

on, the phase pin voltage is very close to VIN. The

VIN power is ready by sensing the phase pin voltage

reaches 1.5V four times.

2. Soft-Start

The FP6321 features soft-start to limit inrush current

and control the output voltage rise at start-up. The

soft-start is accomplished by ramping the internal

reference input from 0V to 0.8V. The soft-start

interval is 3.5ms typical.

3. Over-Current Protection

The over-current function protects the converter a

shorted output by using the low side MOSFET

on-resistance r

DS(ON)

to monitor the current. This

method enhances the converters efficiency and

reduces cost by eliminating a current sensing

resistor.

The over-current function cycles the soft-start

function in a hiccup mode to provide fault pro-

tection. After four times are counted, the high side

and low side MOSFET will turn off and the output is

latched off.

A resistor (R

OCSET

), connected from OCSET pin to

the source of high side MOSFET and the drain of

low side MOSFET to set the over-current triple

level. An internal 40uA(typical) current source

develops the voltage across the

ROCSET. The over-current setting equation is

shown as below:

) (

4 . 0 40

ON DS

OCSET

OCSET

r

V R uA

I

=

4. Shutdown

Connecting a small transistor to OCSET pin, and

pulling the OCSET voltage less than 0.15V can

shutdown the FP6321. At this condition, the

FP6321 is shutdown and high side and low side

MOSFETS are turned off. The output is floating.

5. Under-Voltage Protection

The under-voltage function monitors the FB

voltage to protection the converter against the

output short-circuit condition. The under- voltage

threshold is 75%VREF. The UV has 20us

triggered delay. The FP6321 will always trigger

Vin power sensing after 4 times UV. The under-

voltage protection is disable during the soft- start

interval.

VCC

I

L

V

OUT

V

PHASE

VCC

V

OUT

V

PHASE

8

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Application Information

1. Introduction

The FP6321 integrated circuit is a synchronous PWM

controller, it operates over a wide input voltage range.

Being low cost, it is a very popular choice of PWM

controller. This section will describe the FP6321s

application suggestion. The operation and the design

of this application will also be discussed in detail.

2. Design Procedures

This section will describe the steps to design

synchronous buck system, and explains how to

construct basic power conversion circuits including the

design of the control chip functions and the basic loop.

(1) Synchronous buck converter

Since this is a buck output system, the first quantity to

be determined is the duty cycle value. The formula

calculated the PWM duty ratio, apply to the system

which we propose to design:

(2) Inductor Selection

To find the inductor value it is necessary to consider

the inductor ripple current. Choose an inductor which

operated in continuous mode down to 10 percent of the

rated output load:

I

L

= 2 x 10% x I

The inductor L value for this system is connected to

be:

(V

IN

- V

DS(sat)

V

O

) x D

MIN

L

I

L

f

S

If the core loss is a problem, increasing the inductance

of L will be helpful.

(3) Output Capacitor Selection

a. The output capacitor is required to filter the output

noise and provide regulator loop stability. When

selecting an output capacitor, the important

capacitor parameters are; the 100KHz Equivalent

Series Resistance (ESR), the RMS ripples current

rating, the voltage rating, and capacitance value.

For the output capacitor, the ESR value is the most

important parameter.

The ESR can be calculated from the following

formula.

=

L I

VRIPPLE

ESR

An aluminum electrolytic capacitor's ESR value is

related to the capacitance and its voltage rating.

In most case, higher voltage electrolytic

capacitors have lower ESR values. Most of the

time, capacitors with much higher voltage ratings

may be needed to provide the low ESR values

required for low output ripple voltage.

b. The capacitor voltage rating should be at least

1.5 times greater than the output voltage, and

often much higher voltage ratings are needed

to satisfy the low ESR requirements needed for

low output ripple voltage.

(3) Output N-channel MOSFETs Selection

a. The current ability of the output N-channel

MOSFETs must be at least more than the peak

switching current IPK. The voltage rating VDS

of the N-channel MOSFETs should be at least

1.25 times the maximum input voltage. Choose

the low RDSON MOSFETs for reducing the

conduction power loss. Choose the low CISS

MOSFETs for reducing the switching loss. But

most of time, the two factors are trade-off.

Consider the system requirement and define

the MOSFETs rating.

b. The MOSFETs must be fast (switch time) and

must be located close to the FP6321 using

short leads and short printed circuit traces. In

case of a large output current, we must layout

a copper to reduce the temperature of these

two MOSFETs.

(4) Input Capacitor Selection

a. The RMS current rating of the input capacitor

can be calculated from the next page formula

table.

b. This capacitor should be located close to the IC

using short leads and the volt age rating should

be approximately 1.5 times the maximum input

voltage.

9

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Application Information (Continued)

3. Calculating Formula

Calculation Formula

V

OUT

=V

FB

x ((R3/R2) + 1)

[ ]

LOAD(min) LOAD(max)

RIPPPLE

L

ON(max) OUT DS(SAT) IN(min)

I - I = I

I

T V - V - V

L

COUT

OUT Rating - DC

L

RIPPLE

V 1.5 V

]

I

V

[ = ESR

CIN

IN(max) rating - DC

OUT IN(rms)

V 1.5 V

) 1 ( I = I

D D

Calculation Step-down (buck) regulator

T

ON

/(T

ON

+T

OFF

)

D

VOUT/VIN

I

L

2 x 10% x I

I

IN(rms)

) 1 ( I

OUT

D D

Board Layout

Top Layer Bottom Layer

Inner Layer 2 Inner layer 3

10

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Layout Notice

1. Introduction

When designing a high frequency switching

regulated power supply, layout is very important.

Using a good layout can solve many problems

associated with these types of supplies. The

problems due to a bad layout are often seen at high

current levels and are usually more obvious at large

input to output voltage differentials. Some of the main

problems are loss of regulation at high output current

and/or large input to output voltage differentials,

excessive noise on the output and switch waveforms,

and instability. Using the simple guidelines that follow

will help minimize these problems.

2. Inductor

Always try to use a low EMI inductor with a ferrite

type closed core. Open core can be used if they have

low EMI characteristics and are located a bit more

away from the low power traces and components.

3. Feedback

Try to put the feedback trace as far from the inductor

and noisy power traces as possible. You would also

like the feedback trace to be as direct as possible

and somewhat thick. These two sometimes involve a

trade-off, but keeping it away from inductor EMI and

other noise sources is the more critical of the two. It

is often a good idea to run the feedback trace on the

side of the PCB opposite of the inductor with a

ground plane separating the two.

4. Filter Capacitors

When using a low value ceramic input filter capacitor,

it should be located as close to the VIN pin of the IC

as possible. This will eliminate as much trace

inductance effects as possible and give the internal

IC rail a cleaner voltage supply. Sometimes using a

small resistor between VCC and IC VIN pin will more

useful because the RC will be a low-pass filter. Some

designs require the use of a feed-forward capacitor

connected from the output to the feedback pin as

well, usually for stability reasons.

5. Compensation

If external compensation components are needed for

stability, they should also be placed closed to the IC.

Surface mount components are recommended here

as well for the same reasons discussed for the filter

capacitors.

6. Traces and Ground Plane

Make all of the power (high current) traces as

short, direct, and thick as possible. It is a good

practice on a standard PCB board to make the

traces an absolute minimum of 15 mils (0.381

mm) per Ampere. The inductor, output capacitors,

and output diode (In synchronous case, means

the low side switch) should be as close to each

other possible. This will reduce lead inductance

and resistance as well which in turn reduces noise

spikes, ringing, and resistive losses which

produce voltage errors. The grounds of the IC,

input capacitors, output capacitors, and output

diode (or switch, if applicable) should be

connected close together directly to a ground

plane. It would also be a good idea to have a

ground plane on both sides of the PCB. For

multi-layer boards with more than two layers, a

ground plane can be used to separate the power

plane (where the power traces and components

are) and the signal plane (where the feedback

and compensation and components are) for

improved performance. It is good practice to use

one standard via per 200mA of current if the trace

will need to conduct a significant amount of

current from one plane to the other. Due to the

way switching regulators operate, there are power

on and power off states. During each state there

will be a current loop made by the power

components that are currently conducting. Place

the power components so that during each of the

two states the current loop is conducting in the

same direction.

7. Heat Sinking

When using a surface mount power IC or external

power switches, the PCB can often be used as

the heatsink. This is done by simply using the

copper area of the PCB to transfer heat from the

device. Refer to the device datasheet for

information on using the PCB as a heatsink for

that particular device. This can often eliminate the

need for an externally attached heatsink. These

guidelines apply for any inductive switching power

supply. These include Step-down (Buck), Step-up

(Boost), Fly-back, inverting Buck/Boost, and

SEPIC among others. The guidelines are also

useful for linear regulators, which also use a

feedback control scheme, that are used in

conjunction with switching regulators or switched

capacitor converters.

11

FP6321-1.2 -JUL -2007

FP6321 fitipower integrated technology lnc.

Outline Information

SOP- 8 Package (Unit: mm)

DIMENSION IN MILLIMETER

SYMBOLS UNIT

MIN NOM MAX

A 1.35 1.60 1.75

A1 0.10 --- 0.25

A2 --- 1.45 ---

B 0.33 --- 0.51

C 0.19 --- 0.25

D 4.80 --- 5.00

E 3.80 --- 4.00

e --- 1.27 ---

H 5.80 --- 6.20

L 0.40 --- 1.27

y --- --- 0.10

0 --- 8

Note 1 Package Body Sizes Exclude Mold Flash and Gate

Burrs.

Note 2 Dimension L Is Measured in Gage Plane.

Note 3 Tolerance 0.10 mm Unless Otherwise Specified.

Note 4 Controlling Dimension Is Millimeter Converted Inch

Dimensions Are Not necessarily Exact.

Note 5 Followed From JEDEC MO-012.

Life Support Policy

Fitipowers products are not authorized for use as critical components in life support devices or other medical systems.

You might also like

- APW7120Document22 pagesAPW7120nishatiwari82No ratings yet

- Data Sheet Ic fr9886Document14 pagesData Sheet Ic fr9886Setya Budi S100% (1)

- LM2727/LM2737 N-Channel FET Synchronous Buck Regulator Controller For Low Output VoltagesDocument22 pagesLM2727/LM2737 N-Channel FET Synchronous Buck Regulator Controller For Low Output VoltagesselocaNo ratings yet

- LM25005 42V, 2.5A Step-Down Switching Regulator: Literature Number: SNVS411BDocument24 pagesLM25005 42V, 2.5A Step-Down Switching Regulator: Literature Number: SNVS411BPravin MevadaNo ratings yet

- Datasheet AP1513Document7 pagesDatasheet AP1513timigoNo ratings yet

- Single Synchronous Buck PWM DC-DC ControllerDocument16 pagesSingle Synchronous Buck PWM DC-DC Controllerbachet56No ratings yet

- An 6026Document23 pagesAn 6026Иван АлексиевNo ratings yet

- RT9214Document17 pagesRT9214levimolnarNo ratings yet

- Tda 4601Document8 pagesTda 4601Mirko AleksicNo ratings yet

- Application Note AN4121: Design of Power Factor Correction Circuit Using FAN7527BDocument22 pagesApplication Note AN4121: Design of Power Factor Correction Circuit Using FAN7527BRicardo VieiraNo ratings yet

- Fan 7314Document14 pagesFan 7314Kamal NonekNo ratings yet

- Application Note AN-6027: Design of Power Factor Correction Circuit Using FAN7530Document16 pagesApplication Note AN-6027: Design of Power Factor Correction Circuit Using FAN7530Malanie Sriya De SilvaNo ratings yet

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDocument28 pagesLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84No ratings yet

- High Voltage Resonant Controller: DescriptionDocument17 pagesHigh Voltage Resonant Controller: DescriptionJesus SilvaNo ratings yet

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerDocument13 pagesFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadNo ratings yet

- FAN7930BDocument22 pagesFAN7930Bpagy snv100% (1)

- A 2918 SW Data SheetDocument8 pagesA 2918 SW Data SheetGustavo LunaNo ratings yet

- XR-215 PLLDocument32 pagesXR-215 PLLJ Jesús Villanueva GarcíaNo ratings yet

- LSP3131 PWM Control 3A Step-Down ConverterDocument7 pagesLSP3131 PWM Control 3A Step-Down ConverterGerman ContrerasNo ratings yet

- Saa1042v PDFDocument7 pagesSaa1042v PDFVinny TukNo ratings yet

- Dap006 Dap6a DataDocument15 pagesDap006 Dap6a DataluisfeipezzNo ratings yet

- Transition-Mode PFC Controller: 1 FeaturesDocument17 pagesTransition-Mode PFC Controller: 1 Featuresadriancho66No ratings yet

- Obsolete Product(s) - Obsolete Product(s) : Control Circuit For Switch Mode Power Supplies Using Mos TransistorsDocument7 pagesObsolete Product(s) - Obsolete Product(s) : Control Circuit For Switch Mode Power Supplies Using Mos Transistorsbookreader1968No ratings yet

- AOZ1031AIDocument15 pagesAOZ1031AIrachnologistNo ratings yet

- 1.5A Power Switching Regulator: DescriptionDocument16 pages1.5A Power Switching Regulator: DescriptionPravin MevadaNo ratings yet

- MP2307 r1.9Document12 pagesMP2307 r1.9Ray RaiNo ratings yet

- Up7706 DatasheetDocument12 pagesUp7706 DatasheetFernando DupuyNo ratings yet

- PWM ControllerDocument20 pagesPWM ControllerAmrit203No ratings yet

- Thb7128 InstructionsDocument9 pagesThb7128 InstructionsanhxcoNo ratings yet

- 161 20551 0 FS7M0880Document16 pages161 20551 0 FS7M0880Edwin Vitovis TorresNo ratings yet

- FP6321A FitiDocument14 pagesFP6321A FitiJob GarciaNo ratings yet

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocument10 pagesNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNo ratings yet

- En CD00000085Document16 pagesEn CD00000085amijoski6051No ratings yet

- L 6565Document17 pagesL 6565tatatabuchoNo ratings yet

- L4949Document11 pagesL4949Николай КръстевNo ratings yet

- Uc 3854Document12 pagesUc 3854Leandro CoradiNo ratings yet

- Fan 7316Document21 pagesFan 7316sontuyet82No ratings yet

- Fan 6961Document13 pagesFan 6961Ariel NavarreteNo ratings yet

- P1027P65 (SMPS)Document30 pagesP1027P65 (SMPS)Jesus Silva67% (3)

- Ap5002 - PWM Control 2a Step-Down ConverterDocument10 pagesAp5002 - PWM Control 2a Step-Down ConverterAmador Garcia IIINo ratings yet

- FT8260 1x AN Rev0.81Document15 pagesFT8260 1x AN Rev0.81Enéas BaroneNo ratings yet

- Linear Technology LTC3728EG28400Document37 pagesLinear Technology LTC3728EG28400Rickz2k8No ratings yet

- MW Inverter IC RM6203Document7 pagesMW Inverter IC RM6203KybernetikumNo ratings yet

- LB1824 Motor DriverDocument10 pagesLB1824 Motor Driverwhynot05No ratings yet

- FSDM07652R DatasheetDocument16 pagesFSDM07652R Datasheetmarianos67No ratings yet

- Precision Phase-Locked Loop: ... The Analog Plus CompanyDocument21 pagesPrecision Phase-Locked Loop: ... The Analog Plus Companykao08No ratings yet

- Ltc1871ems (LTSX, Frntoluz Welch Allyn)Document36 pagesLtc1871ems (LTSX, Frntoluz Welch Allyn)RICHIHOTS2No ratings yet

- HS8108Document8 pagesHS8108Miloš ZorićNo ratings yet

- AP8012 OFF-LINE SMPS SWITCHERDocument10 pagesAP8012 OFF-LINE SMPS SWITCHERShubham AdkeNo ratings yet

- Mc44608 Fewexternal Components Reliable and Flexible Greenline Very High Voltage PWM ControllerDocument16 pagesMc44608 Fewexternal Components Reliable and Flexible Greenline Very High Voltage PWM ControllerMary ReevesNo ratings yet

- IR5001Document13 pagesIR5001YuvarajaNo ratings yet

- STRW6252Document15 pagesSTRW6252miltoncgNo ratings yet

- 2.5A Power Switching Regulator: DescriptionDocument16 pages2.5A Power Switching Regulator: Descriptionbikram9830No ratings yet

- High-Efficiency, 2A, 16V, 500Khz Synchronous, Step-Down Converter in A 6-Pin Tsot 23 Description FeaturesDocument17 pagesHigh-Efficiency, 2A, 16V, 500Khz Synchronous, Step-Down Converter in A 6-Pin Tsot 23 Description FeaturesAnonymous qpnZNmchFdNo ratings yet

- L6565Document18 pagesL6565Sergio Daniel BarretoNo ratings yet

- LD7750 High-Voltage PWM ControllerDocument20 pagesLD7750 High-Voltage PWM ControllerAndres Alegria100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Isl6266 AhrzDocument30 pagesIsl6266 AhrzAhmed HussainNo ratings yet

- 4 Sony MonitorDocument84 pages4 Sony MonitorAhmed HussainNo ratings yet

- 945GCPE No DisplayDocument2 pages945GCPE No DisplayAhmed HussainNo ratings yet

- Sharp Mxb201d User GuideDocument115 pagesSharp Mxb201d User GuideAhmed HussainNo ratings yet

- How To Repair LCD TV Backlight Shutdown RandomlyDocument5 pagesHow To Repair LCD TV Backlight Shutdown RandomlyAhmed HussainNo ratings yet

- Toner PowderDocument2 pagesToner PowderAhmed HussainNo ratings yet

- BGA ReworkDocument8 pagesBGA ReworkAhmed HussainNo ratings yet

- Ahamed Ullah: ObjectiveDocument4 pagesAhamed Ullah: ObjectiveAhmed HussainNo ratings yet

- Intel D915gavDocument106 pagesIntel D915gavAhmed HussainNo ratings yet

- Samsung SVC VANGOVL40Document34 pagesSamsung SVC VANGOVL40jeanmaikelNo ratings yet

- Li HongDocument4 pagesLi HongJiwen SalimNo ratings yet

- Manual Tud300Document70 pagesManual Tud300DionicioCasanovaNo ratings yet

- Bagi Exercise Listening and StructureDocument16 pagesBagi Exercise Listening and StructureDwiva Muna100% (1)

- Apple Environmental Responsibility Report 2014Document29 pagesApple Environmental Responsibility Report 2014fdgdfgdfgNo ratings yet

- 51-11-15-001-Data Recording of Allowable Damage and Repairs-A320Document6 pages51-11-15-001-Data Recording of Allowable Damage and Repairs-A320FredNo ratings yet

- Meter Moving CoilDocument4 pagesMeter Moving Coilabecdf100% (1)

- Jss Academy Unit 1 BDocument13 pagesJss Academy Unit 1 BbomtozorNo ratings yet

- Instruction Manual: Alfa Laval SB Anti Vacuum ValveDocument30 pagesInstruction Manual: Alfa Laval SB Anti Vacuum ValveMichail KostarevNo ratings yet

- CBSE Class XII Mathematics - Inverse Trigonometric Functions Assignment 2 PDFDocument4 pagesCBSE Class XII Mathematics - Inverse Trigonometric Functions Assignment 2 PDFPooja KathuriaNo ratings yet

- The Enchanted ForestDocument3 pagesThe Enchanted ForestRichealle Vaniel Delicano SeverinoNo ratings yet

- Effect of Accidental EccentricityDocument7 pagesEffect of Accidental EccentricityNani TirumalasettiNo ratings yet

- AstigmatismDocument1 pageAstigmatismAmmellya PutriNo ratings yet

- MCA-12 Web DesigningDocument204 pagesMCA-12 Web DesigningLittaNo ratings yet

- How The World Was Created (Panayan)Document25 pagesHow The World Was Created (Panayan)Mary Kris De AsisNo ratings yet

- New Holland Ec25 Mini ExcavatorDocument153 pagesNew Holland Ec25 Mini ExcavatorJack StinerNo ratings yet

- Theories and philosophies that shaped early childhood educationDocument3 pagesTheories and philosophies that shaped early childhood educationJamille Aira PascuaNo ratings yet

- R/C Soaring Digest - May 2009Document80 pagesR/C Soaring Digest - May 2009Aviation/Space History LibraryNo ratings yet

- The Long Suffering of Frederic ChopinDocument7 pagesThe Long Suffering of Frederic ChopinDaniel CiobanuNo ratings yet

- SEISMIC LOAD ANALYSISDocument9 pagesSEISMIC LOAD ANALYSISAditya RoyNo ratings yet

- Your First ProgramDocument7 pagesYour First ProgramJosephat MugumbaNo ratings yet

- Ihp MicroDocument13 pagesIhp MicroTejas HambirNo ratings yet

- UntreatedDocument29 pagesUntreatedhahahaNo ratings yet

- Manual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Document53 pagesManual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Fer YamashitaNo ratings yet

- Instructional Design HypertensionDocument8 pagesInstructional Design HypertensionGeoffrey OnyanchaNo ratings yet

- COMMUNITY HEALTH NURSING: PREVENTION, FAMILIES, PRIMARY CAREDocument4 pagesCOMMUNITY HEALTH NURSING: PREVENTION, FAMILIES, PRIMARY CAREJohn Vincent VasquezNo ratings yet

- Abinash Master SeminarDocument51 pagesAbinash Master SeminarAGRICULTURE BOYNo ratings yet

- Facemasks Manufacturers DirectoryDocument54 pagesFacemasks Manufacturers DirectoryAlex Kharchuk100% (1)

- Plastics as a Building Material GuideDocument24 pagesPlastics as a Building Material GuideVinod Nair100% (1)

- Cinnamon Streusel Muffin Recipe (Coffee Cake) - DDocument3 pagesCinnamon Streusel Muffin Recipe (Coffee Cake) - DBryce MitchellNo ratings yet

- Corrosion Management and Cathodic Protection GuideDocument52 pagesCorrosion Management and Cathodic Protection GuideErol DAĞNo ratings yet