Professional Documents

Culture Documents

Permeable PDF

Uploaded by

Hồ Thắng0 ratings0% found this document useful (0 votes)

67 views12 pagesThis article aims to provide an overview of the upcoming technology of permeable reactive barriers for groundwater remediation. A comprehensive list of references and web-links are also provided for further in-depth understanding.

Original Description:

Original Title

permeable.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis article aims to provide an overview of the upcoming technology of permeable reactive barriers for groundwater remediation. A comprehensive list of references and web-links are also provided for further in-depth understanding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views12 pagesPermeable PDF

Uploaded by

Hồ ThắngThis article aims to provide an overview of the upcoming technology of permeable reactive barriers for groundwater remediation. A comprehensive list of references and web-links are also provided for further in-depth understanding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Review

Permeable reactive barrier for groundwater remediation

R. Thiruvenkatachari

a

, S. Vigneswaran

a,

*

, R. Naidu

b

a

Faculty of Engineering, University of Technology, Sydney, P.O. Box 123, Broadway, NSW 2007, Australia

b

CRC CARE, University of South Australia, Australia

Received 14 December 2006; accepted 26 October 2007

Abstract

This article aims to provide an overview of the upcoming technology of permeable reactive barriers for groundwater remediation. A

comprehensive list of references and web-links are also provided for further in-depth understanding. A brief discussion on the Australian

perspective on this emerging technology is also included.

# 2008 Published by Elsevier B.V. on behalf of The Korean Society of Industrial and Engineering Chemistry.

Keywords: Permeable reactive barriers; Groundwater; Remediation; Pollution

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

2. Sources and types of groundwater contamination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

3. Permeable reactive barrier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4. Conguration of PRBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.1. Conventional systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

4.2. Advanced methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5. Mechanism of interaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

6. Treatment of inorganic and organic pollutants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7. Zero-valent iron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8. Activated carbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

9. Zeolites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10. Alkaline materials-complexing agents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

11. Bioremediation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

11.1. Organic carbon for denitrication and sulphate reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

12. Sequential reactive media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

13. In situ chemical oxidation (ISCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

13.1. Use of oxidants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

14. PRB studies in Australia and New Zealand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Acknowledgement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

1. Introduction

Groundwater is a limited ecological resource representing a

small percentage of the total water distribution [1,2,3]. The

contribution from groundwater is vital; perhaps as many as two

billion people depend directly upon aquifers for drinking water,

and 40%of the worlds food is produced by irrigated agriculture

www.elsevier.com/locate/jiec

Available online at www.sciencedirect.com

Journal of Industrial and Engineering Chemistry 14 (2008) 145156

* Corresponding author. Tel.: +61 2 9514 2641; fax: +61 2 9514 2633.

E-mail address: s.vigneswaran@uts.edu.au (S. Vigneswaran).

1226-086X/$ see front matter # 2008 Published by Elsevier B.V. on behalf of The Korean Society of Industrial and Engineering Chemistry.

doi:10.1016/j.jiec.2007.10.001

that relies largely on groundwater. Australia has 25,780 GL of

groundwater suitable for potable, stock and domestic use, and

irrigated agriculture that can be extracted sustainably each year.

It is extensively used for urban water supplies, agriculture,

irrigation, industry and mining. In Australia, some of the

regions like arid zones of South Australia, the Northern

Territory, and the Pilbara are entirely dependent on ground-

water. Most of the countrys premium wine districts rely on

groundwater. Due to the cap on surface water extractions in the

MurrayDarling Basin and the scarcity of surface water

resources in other areas, groundwater use across Australia has

increased signicantly in the last 10 years [4]. South Australia,

New South Wales and Victoria use more than 60% of

groundwater for irrigation, while Western Australia uses

72% for urban and industrial purposes [5,6].

Studies by [4,7] identied increased demand for water in

Australia and called for proper management of groundwater.

The report also revealed that groundwater resource in Australia

has been highly committed in some places, or of poor quality in

others, and poorly investigated in others [8]. If not managed

properly, groundwater resources are highly vulnerable to

widespread contamination. There are many reports of serious

incidents of groundwater contamination due to accidental

spills, or unsatisfactory disposal of industrial chemicals,

agricultural practices, mining activities, etc.

Attempts at large-scale groundwater cleanup began in

earnest in the 1980s and the results of early remediation efforts

seldom produced the expected reduction in contamination

levels. Studies by the U.S. Environmental Protection Agency

(EPA) [9,10] found that the commonly used pump-and-treat

(P&T) technologies (pump the water and treat it at the surface)

rarely restored sites that had contaminated groundwater to

background conditions. This was conrmed in a much more

extensive 1994 National Research Council (NRC) study that

explicitly reviewed 77 sites across the United States where full-

scale pump-and-treat was being used [11,12]. One of the most

promising remediation technologies is the use of permeable

reactive barriers (PRBs) lled with reactive material(s) to

intercept and decontaminate plumes in the subsurface. In the

last decade, there has been an explosion of activities directed at

the development and implementation of PRBs. This study

presents a comprehensive review on PRBs technology.

2. Sources and types of groundwater contamination

Broadly, groundwater contaminants come from two cate-

gories of sources:

(a) Point Sources and

(b) Distributed, or Non-Point Sources.

Localised sources are known as point sources of contam-

ination. The contaminant interacts with the moving ground-

water and the soil and spreads out to form a plume moving in

the same direction as the groundwater. The resulting ground-

water contamination plume may extend several hundred metres

or even further away from the source of pollution.

Groundwater can also be contaminated by diffuse sources

over a wide area, for instance widespread use of fertilisers on

gardens and elds. Diffuse contamination may have greater

environmental impacts than contamination from point sources

because a much larger volume of water is affected. Pollutants

from point sources are generally related to urban development,

while diffuse sources are generally rural in nature. Some of the

examples of point and diffuse pollutions are given in Table 1.

Analysts estimate that there are between 300,000 and

400,000 sites in the USA contaminated with a wide variety of

toxic chemicals, representing clean up cost in the range of $500

billion to $1 trillion [11]. Many of these sites experience

groundwater contamination by complex mixtures of chlori-

nated solvents, fuels, metals, and/or radioactive materials.

Europes groundwater is polluted in several ways: nitrates,

pesticides, hydrocarbons, chlorinated hydrocarbons, sulphate,

phosphate and bacteria. Some of the most serious problems are

pollution by nitrates and pesticides. The key ndings of

Australia: State of the Environment Report [13] highlighted that

Australias inland waters are under increasing pressure from

over-extraction, algal blooms, catchment modication, habitat

destruction and pollution. Also, the experiences from Europe

and North America suggest that groundwater pollution in

Australia will become a more serious issue in the future. There

are many well-documented cases of groundwater pollution in

Australia. The most signicant diffuse contaminant of ground-

water throughout each state and territory in Australia is nitrates,

due to their adverse affects on people, animals and the

environment [14,15]. The main source of nitrate contamination

is through the application of fertilizers for cropping and pasture

[15]. Direct discharges of nitrogen compounds from on-site

sanitation and from sewer efuent also exacerbate the problem.

In many areas, the concentration is greater than the Australian

Drinking Water Guidelines [16] level of 50 mg/L nitrate (as

nitrate), resulting in groundwater that is unt for drinking. In

some of the more contaminated areas, the concentration is in

excess of 100 mg/L [15].

Recent incidences of reported pesticide contamination of

groundwater in this country are listed in the [5] report. In most

affected areas, pesticides were detected in at least 20% of

samples, indicating signicant contamination. However, sys-

tematic monitoring of pesticide contamination of groundwater in

Australia is limited indicating inadequate data on the quantities,

locations and types of pesticides used, as well as knowledge gaps

in the fate of pesticides in local environments [17].

Table 1

Examples of point and diffuse pollutions

Point source Non-point or diffuse pollution

Municipal landlls, industrial waste

disposal sites, leaking gasoline storage

tanks, leaking septic tanks, and accidental

spills and leaks of petroleum products and

of dense industrial organics

Atmospheric deposition,

contaminated sediments,

and many land activities

that generate polluted runoff,

such as agriculture

(pesticides and fertilisers),

logging, and onsite sewage

disposal

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 146

3. Permeable reactive barrier

This technology termed as Permeable Reactive Barriers is

dened [9] as:

An emplacement of reactive media in the subsurface

designed to intercept a contaminated plume, provide a ow

path through the reactive media, and transform the

contaminant(s) into environmentally acceptable forms to

attain remediation concentration goals down-gradient of the

barrier

The concept of PRBs is relatively simple. A permeable

reactive barrier material consisting of permanent, semi

permanent or replaceable reactive media is placed in the

subsurface across the ow of path of a plume of contaminated

groundwater, which must move through it as it ows, typically

under its natural gradient, thereby creating a passive treatment

system. As the contaminant moves through the material,

reaction occur that transform the contaminants into less

harmful (non-toxic) or immobile species. The PRB is not a

barrier to the groundwater, but it is a barrier to the

contaminants. PRBs are designed to be more permeable than

the surrounding aquifer materials so that contaminants are

treated as groundwater readily ows through without sig-

nicantly altering groundwater hydrogeology.

PRBs potentially have several advantages over conventional

pump-and-treat methods for groundwater remediation.

PRBs can degrade or immobilize contaminants in situ

without any need to bring them up to the surface. Hence no

need for expensive above ground facilities for storage,

treatment, transport, or disposal other than monitoring wells.

After the installation the above ground can be re-used for

other purposes. Also, as the contaminants are not brought to

the surface; there is no potential cross media contamination.

They also do not require continuous input of energy, because

a natural gradient of groundwater ow is used to carry

contaminants through the reactive zone. Only periodic

replacement or rejuvenation of the reaction medium might

be required after its reactive capacity is exhausted or it is

clogged by precipitants and/or microorganisms. However, the

drastically reduced operating costs offsets the higher

construction cost that are typical for PRBs, which results

in an overall reduction in the life cycle cost of this technology.

Degradation of most of the contaminants is achieved rather

than mere change of phase of contaminants. The barrier

provides effective contaminant remediation, much more than

simple migration control of the pollutants.

Technical and regulatory problems related to ultimate

discharge requirements of efuent from pump-and-treat

systems are avoided with the PRB technology.

However, so far, limited data are available on the

performances of reactive barriers with different materials

and their comparative performances. Limited long-term eld

testing data are available and eld monitoring is in its infancy

[18].

4. Conguration of PRBs

4.1. Conventional systems

Two installation schemes are more frequently used in eld

applications [19,20]; Continuous and Funnel-and-Gate PRB.

The continuous PRB conguration consists of a single

reactive zone installed across the contaminant plume, while the

funnel-and-grate system consist of a permeable gate (reactive

zone) placed between two impermeable walls that direct the

contaminated plume towards the reactive zone.

The choice between the two congurations depends on

both the hydrogeological characteristics of the site and the

reactive material cost [19]. When a high cost reactive material

is used, funnel-and gate conguration is preferred since the

reactive zone requires less material. However, construction

cost of continuous type barrier is much cheaper than funnel-

and-gate system. Hence a balance must be struck between the

cost of reactive material and the construction cost of the

barrier, in accordance with the target pollutant and level of

removal to be achieved. Multiple reactive medium in

succession or in series can be installed in the funnel-and

gate setup [20]. Alternatively, a relatively less expensive

method using multiple caisson gates can also be installed [20].

A caisson is a hallow, load-bearing (usually cylindrical)

enclosure generally used as an alternative method for

excavation. For the purpose of emplacing a reactive cell, a

prefabricated, steel caisson (normally 8-ft-dia or smaller) is

pushed or vibrated down into the subsurface. Once the caisson

has reached the intended depth, the soil within the caisson can

be augered out and replaced with the reactive medium. Upon

emplacement of the reactive cell/medium, the caisson can be

pulled straight out. The caisson can be installed from the

ground surface and completed without requiring personnel to

enter the excavation.

Usually, the conventional PRB installation techniques

require some degree of excavation, which limits the PRB to

fairly shallow depths of 20 m [21]. However, use of new

construction techniques, such as slurry injection and hydro-

fracturing are able to overcome this depth limitation.

4.2. Advanced methods

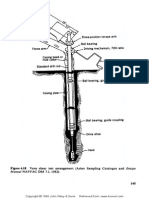

(i) Injection system: Injection system involves creating a

treatment zone within the contaminant boundary by

drilling series of bore holes or injection wells and injecting

the reactive material (chemical/particulate mixture) into

the treatment zone. Potential advantages of this approach

are that there is no need to construct a trench and possible

aquifer access at greater depths. Ususally, two or three

rows of overlapping, interlocking columns can offer

effective barrier [22]. Nevertheless, it has to be made sure

that the contaminant plume is efciently taken care of and

no by-passing or ngering occurs, which may impair the

remediation effect.

(ii) Hydraulic/pneumatic fracturing: Hydraulic/pneumatic

fracturing is intentional fracturing (cracking) of a subsur-

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 147

face using pumped water and/or air under high pressure.

As the conning pressures are exerted in the borehole,

fractures will open and propagate out laterally from an

initiation point. A fracture ll slurry composed of the

reactive medium, can then be injected into the fracture to

form a reactive treatment zone. More than one fracture

may be required within the treatment zones. Fractures have

a preferred direction of propagation, they are therefore

asymmetric with respect to the borehole and they climb in

the preferred direction of propagation. Fractures can be

controlled to happen either horizontally or vertically

[24,25]. Some advantage to this technique includes the

ability to emplace a barrier to a depth greater than 80 ft.

Also, fracturing causes minimal disturbance, does not

generate contaminated soils, and is inexpensive. Fractured

zones may also be applied to direct groundwater ow

towards the gates in funnel-and-gate system [26]. Some

drawbacks of emplacement by hydraulic fracturing include

difculty in controlling the fracture direction and the

limited soil conditions in which it can be used effectively.

(iii) Passive groundwater capture and treatment by reactor

cells: This technique involves emplacement of reactor

cell(s) in the subsurface consisting of reactive medium and

capturing the contaminated plume into the reactor for

treatment [27]. This system does not involve any pumping

equipment and the plume is directed into the reactor by

siphoning or by natural gradient. Because of the passive-

mode of operation, the operating and maintenance

requirements are relatively minor.

The selection of the construction technique to be used

depends upon the site characteristics [25] such as depth of PRB,

geotechnical consideration, soil excavation: space for handling

and disposal of soil (contaminated), health and safety of

personnel. Common contaminants being treated using PRB

technologies are given in Table 2.

5. Mechanism of interaction

Proper understanding of the underlying process by which the

reactive material interact with the pollutants and the mechan-

ism of removal is very important. In general, the contaminant

removal mechanisms can be classied broadly into three

categories [18]:

- Degradation: Through chemical or biological reactions that

lead to decomposition or degradation of contaminants into

harmless compounds.

- Precipitation: Immobilization of contaminants within the

reaction zone by formation of insoluble compounds. Here, the

chemical state of the contaminant is not altered.

- Sorption: Immobilization of contaminants within the reaction

zone by adsorption or complex formation. Here, the chemical

state of the contaminant is not altered.

More specically, the principal processes are [29]:

Reductive degradation of organic pollutants.

Oxidative degradation of organic pollutants.

Retardation and biodegradation of organic pollutants.

Sorption of organic or inorganic pollutants.

Reduction and/or precipitation of heavy metal compounds.

In general, the types of reactive materials used for the

construction of permeable reactive barriers, are [30]:

Those changing pH or redox potential,

Those causing precipitation,

Materials with high sorption capacity, and

Those releasing nutrients/oxygen to enhance biological

degradation.

A study by USEPA [31], classied the reactive barrier

materials according to the target pollutant and the mechanism

of removal (Table 3).

Zero-valent iron (Fe

0

) is the most common reactive material

in the current eld of application [19]. A comprehensive review

on iron in the use of PRBs has been carried out recently by [32].

Apart from iron based materials, other types of materials

[25,30,33] such as organic based (activated carbon, leaf, peat,

sewage sludge, sawdust, etc.) [34,35], alkaline- complexing

agents (hydrated lime, ferrous sulphate) [30,36], phosphate

minerals like hydroxyapatite and biogenic apatite (e.g. sh

bone) [37], zeolites [3840], clay [41], metal oxides [38,42],

Table 2

Some of the common contaminants in groundwater for remediation

Groups Pollutants

Organic compounds

Methane Tetrachloromethane, trichloromethane, dichloromethane

Ethanes Hexachloroethane, 1,1,1-trichloroethane, 1,1,2-trichloroethane 1,1-dichloroethane

Ethenes Tetrachloroethene, trichloroethene, cis-1,2-dichloroethene

Propanes 1,2,3-Trichloropropane, 1,2-dichloropropane

Aromatics Benzene, toluene, ethylbenzene

Others Hexaxhlorobutadiene, 1,2-dibromoethane, Freon 113, N-nitrosodimethylamine

Inorganic compounds

Trace metals/heavy metals Chromium, nickel, lead, uranium, iron, manganese, technetium, selenium, copper, cobalt, cadmium, zinc

Anion contaminants Sulphate, nitrate, phosphate, arsenic

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 148

microorganisms [4346], polymers [47,48], innovative poly-

mer membrane (as liner) containing iron [49] are also being

evaluated.

Ref. [50] evaluated 124 PRB projects in the USA and

reported that in majority of projects (45%), zero-valent iron was

the material used as reactive barrier material. Another study

conducted by [51], on around 50 PRB sites across US, Canada

and Europe revealed that zero-valent iron is used in more

number of occasions. Refs. [52,53] reported that the primary

determinant of degradation rate in different in the case of iron is

the available reactive surface area. The parameter generally

used to discriminate between different irons is the specic

surface area, or the surface area per unit mass (m

2

/g) of iron. In

most cases, a linear relationship has been observed between

reduction rates and iron metal surface area concentration

[54,55]. Therefore commercial irons with higher surface area

are preferred [20]. Finer iron particles can also be mixed with

sand in order to increase the hydraulic conductivity. Iron with

several amendments has been tested to improve the perfor-

mance.

During the reaction, oxidation of Fe

0

to Fe

2+

results in an

increase in pH, which eventually leads to the formation of

precipitation of number of minerals. In order to overcome

this, pyrite or iron sulde are added (oxidation of pyrite

produces acid) which lowers the pH and increases the organic

removal efciency [56,57]. One negative effect of addint pH-

controlling amendments could be the increased possibility of

higher levels of dissolved iron in water downstream after the

reactive cell.

Instead of using granular sized iron medium, use of colloidal-

size iron (13 mm) or of nanosize (1100 nm = 0.001

0.1 mm) would signicantly increase the surface area and a

lower total iron mass may be required in the treatment zone

[20,5860]. Nanosized [61,62] or as emulsion state [63] have

also been studied. Colloidal or nono-state iron allows the

formulation of slurries that can be injected in PRB by

boreholes or fractured media.

Bimetallic systems where several metals are plated onto zero-

valent iron (ZVI) (e.g. FeCu, FePd, FeNI) have shown to

produce greater performance compared to having ZVI alone

[6466]. Some bimetals enhance the degradation by acting as

catalysts and as galvanic couples (increase electron activity).

However it has been cited that reactivity of bimetallic system

may be high initially but may decline gradually [20].

Acid pre-treatment of ZVI was also found to increase the

degradation efciency; probably due to removal of oxide

coating layer on the iron surface or due to increase in surface

area by etching or pitting corrosion [52,67].

6. Treatment of inorganic and organic pollutants

Fundamental difference exists between organic and inor-

ganic contaminant remediation. Organic contaminants can be

broken down into innocuous elements and compounds, such as

carbon dioxide and water because they are molecules consisting

of carbon, hydrogen, halogens, oxygen, and sometimes sulphur,

phosphorous, and nitrogen. Conversely, most inorganic

contaminants are themselves elements. They cannot be

destroyed but can only change speciation [68]. Therefore

remediation strategies must focus on transforming inorganics

into forms that are non-toxic, not bioavailable, immobile, or

capable of being removed from the subsurface [68]. The

characteristics of these elements have in common is that they

can undergo redox reactions and can form solid precipitates

with carbonates, sulphide and hydroxide [68].

7. Zero-valent iron

ZVI tend to be oxidised, passing its electron to contaminants

(organic-halogenated hydrocarbons, inorganic- some metal;

U(VI), Cr(VI), etc., which undergo reductive mechanism

resulting in precipitation or degradation. The mechanism for

metal precipitation and degradation of halogenated hydro-

carbon by ZVI is given elsewhere [19,25,68]. In the case of

reductive precipitation, there is also a potential risk of

remobilization due to dissociation [33].

Interferences with reactions can occur while treating

groundwater with ZVI [20,68].

Oxygen oxidises ZVI and causes FeO(OH) or Fe(OH)

3

solids

to form. Besides making the ZVI no longer available to

interact with contaminants, the solid formation can clog the

reactive media, thus reducing the hydraulic permeability/

conductivity. In order to overcome this limitation, a pre-

treatment buffer zone of sand and pae gravel mixed with

about 1015% ZVI by weight can be placed before the actual

treatment reactive barrier with 100% ZVI reactive cell. The

pre-treatment cell containing small amounts of ZVI will

remove the dissolved oxygen from the contaminated plume

Table 3

Reactive materials classied based on the target pollutant and the mechanism of removal

Target and mechanism of removal Reactive materials

Inorganics-sorption or substitution

barriers

Activated carbon, activated alumina, bauxite, exchange resin, ferric oxides and oxyhydroxides, magnetite,

peat, humate, lignite, coal, phosphates, titanium dioxide, zeolite

Inorganics-precipitation barriers Biota, dithionite, ferrous hydroxides, ferrous carbonates, ferrous sulde, hydrogen sulde gas, lime, yash,

limestone, miscellaneous (Mg(OH)

2

, MgCO

3

, CaCl

2

, CaSO

4

, BaCl

2

, zero-valent metals

Inorganics-degradation barriers Biota, zero-valent metals

Organics-degradation barriers Ferrous minerals, oxygen release, ultramicrobacteria, zero-valent metals

Organics-sorption barriers Zeolite, activated carbon, clays

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 149

before it reaches the actual reactive cell. Also, most of the

precipitates formed in the pre-treatment stage will be retained

and as the permeability is higher, it will not affect the

groundwater ow to the main barrier [20].

ZVI interaction with the contaminant plume would also result

in the increase in pH, which results in the formation of

precipitates. The carbonate and hydroxide precipitates with

species like Fe, Ca, and Mg could impede the groundwater

ow through the barrier. Solid precipitation can be favored

when it results in the removal of toxic metals from the

groundwater. However, it is detrimental if it decreases the

hydraulic conductivity through the barrier or if it interferes

with the dominant contaminant removal mechanism. To

overcome this limitation, buffering amendments to prevent

the increase in pH is applied, as also reported earlier in this

report [20]. Alternative methods like ultrasound technology

to deal with permeability problem are also being evaluated

[33,69].

Under anaerobic conditions, hydrogen gas is formed as a

product of iron corrosion which may also temporarily

passivate the iron surface [70]. Venting of H

2

bubbles may be

required to maintain water ow and iron reactivity.

Alternatively, microorganism that can utilize hydrogen as

an energy source in anaerobic environment can also be

introduced [70,71].

Nitrate has been shown to negatively impact reaction rates by

progressively passivating iron surface [72].

Early indications suggest that high concentration of dissolved

silica also may have similar inhibitory effect on iron like

nitrates [73].

Certain types of dissolved organic carbon (DOC) have been

shown to coat reactive sites on the iron, rendering it

unreactive [27].

Recent studies indicate that microorganisms with Fe

0

increase the contaminant removal efciency [74]. Application

of bio-augmentation in conjunction with the ZVI technology

and found that these two technologies can have a symbiotic

effect on each other [7577]. Till et al. [75] identied that Fe

0

can stoichiometrically reduce nitrate to ammonium and that

hydrogen produced (during anaerobic Fe

0

corrosion by water)

can sustain microbial denitrication to reduce nitrate to more

innocuous products (i.e., N

2

O and N

2

).

Experiments with mixtures of contaminants have also shown

that bioaugmentation of PRBs with bacteria offers promise

when more than one contaminant is present. More complete

dechlorination occurred when the Fe

0

was bioaugmented.

Batch experiments with mixtures of carbontetrachloride, Cr

6+

,

and nitrate showed that bioaugmentation reduced competition

by these pollutants for active sites on the Fe

0

surface [74].

Permeable reactive barriers designed to enhance bacterial

sulfate reduction (sulfate reducing bacteria-SRB) and metal

sulde precipitation have the potential to prevent acid mine

drainage and the associated release of dissolved metals. In this

situation, the conditions typically found within a reactive

barrier environment are well suited to SRB. Permeable reactive

barriers provide dissolved C, N, and P, and the plume water

entering the barrier provides high concentrations of iron and

other metals, provides the necessary condition and promotes

growth and reproduction of microorganisms [78]. A synergistic

interaction between microbial activity and ZVI obtained an

enhanced degradation efciency of hydrocarbon pollutants,

according to the study by [79].

8. Activated carbon

Activated carbons are chemically stable materials and are

widely considered as suitable adsorbent for on-site or off-site

treatment of polluted groundwater [40]. This material presents

a high adsorption capacity for many organic and inorganic

contaminants largely due to its high surface area (about

1000 m

2

/g) and the presence of different types of surface

functional groups (hydroxyl, carbonyl, lactone, carboxylic

acid, etc.) [80]. In granular form, activated carbon appears to

be highly suitable for use in permeable barriers [34].

Signicant removal of hexavalent chromium from contami-

nated groundwater using granular activated carbon (GAC) was

achieved by [34]. Regeneration of carbon by phosphate

extraction and acid washing also appeared to be successful

[34], allowing the possibility for repeated use of the material.

Microbial regeneration of activated carbon (used in organic

sorption) in PRB is a promising area, which needs to be

explored. A recent study by [81] with PRB using activated

carbon and microorganism for polyaromatic hydrocarbon

removal, showed that the degradation efciency of organic

material was found to increase when the organic material was

adsorbed on the carbon. Few more studies on the organic

removal using activated carbon in PRBs have shown

promising outcomes [82]. Its effect on inorganic species is

yet to be evaluated in detail.

9. Zeolites

Zeolites are tectosilicates with three-dimensional alumino-

silicates structure containing water molecules, alkali and

alkaline earth metals in their structural framework [83]. These

minerals have very high ion-exchange, adsorbing, catalytic,

molecular sieving capacities and make them potentially useful

as treatment mineral for use in the PRBs [18,27]. As the mineral

is anionic (negatively charged), it can be used to remove cations

from aqueous solutions. Several hundred zeolitic materials

exists; Clinoptilolite, a natural zeolite, is a potential material for

remediation of aqueous solutions since it demonstrates strong

afnity for several toxic heavy metals [84] and can selectively

adsorb some radionuclides [85]. A new surfactant modied

zeolite has been tested to simultaneously remove organic and

inorganic species [19].

10. Alkaline materials-complexing agents

Hydrated lime (Ca(OH)

2

) is a cheap reagent which can be

used in PRBs for groundwater remediation. Previously, it has

been used for remediation of acid mine drainage [18,27].

Lime barriers cause pH to increase to 1212.5 in order to

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 150

facilitate the formation of metal hydroxides, which reduce the

solubility of certain metals. They have proved to be

successful in remediation of anionic and cationic pollutant

species [27].

11. Bioremediation

Remediation of pollutants using microorganisms (bioreme-

diation) is one of the promising and viable technologies, which

Table 4

Advantages and limitations of various reactive barriers used in PRB technology

Material Advantages Limitations

Zero valent iron (ZVI) Most commonly used reactive barrier material.

Vast amount of background data available

Not effective on all types of organic compounds especially

certain dense non-aqueous phase liquid compounds like

1,2-dichloroethane and dichloromethane [54]

Ability to be used in different states: as a

pile [24,90], powder/granular [62],

ling [91], colloidal [58,59], nanosized [61,62],

emulsion that can be injected [63]

Lifetime of the material could be reduced due to the

formation of surface coating due to geological condition

of the site [93]

High reactivity with organic and inorganic

contaminants [92]

Increase in pH during reaction induces corrosion and

subsequent precipitation of minerals would lead to

decreased permeability of reactive material [94]

Ability to combine with other treatment

methods, e.g. bioremediation

H

2

gas produced and the microorganism (biofouling)

could reduce the porosity of reactive material

Less or no major problems associated with

occupational health and safety (OHS) in

handling this material

Limited information available on long term performance

of the system especially on the build-up of surface

precipitates and biofouling.

Compounds like silica or natural organic matter (NOM)

have passivating effect; reducing the iron reactivity [18,93]

Competitive reaction inhibits the reactivity in the presence of

certain compounds. In the presence of nitrate the

dehalogenation of chlorinated compounds is decreased

[95,96]

Activated carbon Different types (with different reactivities) of

activated carbon can be obtained from low cost

natural products, e.g. coconut shell based

Vast data on ex situ water and wastewater treatment.

But very limited data on in situ treatment under eld

conditions

Effective in the treatment of organic and heavy

metal contaminants [97]

Rapid breakthrough and thus frequent carbon change-outs

or regeneration. Requires optimization studies

Excellent material to combine with biotreatment Performance highly dependent on temperature and other

extrinsic parameters

Chemically stable material Surface coatings may decrease sorption capacity

Competitive adsorption

Lime (calcium carbonate

or hydroxide)

Low cost reactive PRB material Slow reaction time

Effective in neutralization; reducing the solubility of

certain metals or conditioning hydrochemical

system to assist with other treatment processes,

e.g. bioremediation

Loss in efciency of the system because of coating of

the limestone particles with iron precipitates

Used extensively for acid mine drainage remediation or

acidic agricultural soils

Difculty in treating acid mine drainage with a high

ferrousferric ratio, and ineffectiveness in removing

manganese

Limestone treatment is generally not effective for acidities

exceeding 50 mg/L

Voluminous sludge is produced with hydrated lime

(calcium hydroxide)

Microbial bioremediation Less expensive and easy to install A perceived lack of knowledge about biodegradation

mechanism

Natural processes to treat contaminants Specic contaminants may not be amenable to

biodegradation [98]

Capability to degrade organic contaminants into relatively

less toxic end products

In the case of mixed wastes, some are amenable only under

aerobic condition and some only under aerobic condition

Reduced risk of human exposure to contaminated media Site characterization and optimization studies are required for

each contaminated site. Chemical characteristics of the

contaminants dictate the extent of biodegradability

Remediation is not restricted to the treatment zone alone

Works well for dissolved contaminants and contamination

adsorbed onto higher permeability sediments

(sands and gravels)

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 151

utilizes naturally occurring microorganisms and biological

reactions for the degradation of toxic contaminants (mostly

organic and in some instances inorganic compounds) in the

subsurface groundwater. In situ bioremediation creates subsur-

face environmental conditions (without withdrawing the

contaminated water from under the ground), typically through

the principle of oxidationreduction manipulation, which

induce the degradation of chemicals via microbial catalyzed

biochemical reactions [45].

Many environmental pollutants such as petroleum hydro-

carbons are highly reduced, which allows oxidation of these

pollutants to innocuous nal compounds like carbon dioxide

and water. On the other hand some pollutants like chlorinated

solvents and nitrates are highly oxidized and are prone to

undergo reduction. Microorganisms mediate such redox

reactions (anaerobically or aerobically) and thrive on the

contaminant degradation process to obtain it energy and food

for its growth [33].

11.1. Organic carbon for denitrication and sulphate

reduction

Organic carbon for denitrication and sulfate reduction has

been well recognized. Robertson and Cherry [86] adapted the

use of permeable organic carbon material to stimulate

biologically mediated denitrication and sulfate reduction in

contaminated groundwater in PRB system. Denitritrifying and

sulfate reducing bacteria are ubiquitous in the environment. In

the presence of organic source, these heterotrophic bacteria

reduce nitrate to nitrogen gas and sulphate to sulphide, in the

absence of oxygen [35,8789]. Generation of sulphide during

sulphate reduction, precipitate the soluble metals or metalloids

as low-solubility sulphide minerals. In combination, the

sulphate reduction and sulphide precipitation reaction have

the potential effect of decreasing concentrations of sulphate,

iron, and other metals and metalloids and increasing alkalinity

and pH. Table 4 shows the advantages and limitations of various

reactive barriers used in PRB technology.

12. Sequential reactive media

Two of the most common classes of organic contaminants in

groundwater are chlorinated solvents and petroleum derived

aromatics. These chemicals are known to contaminate vast

quantities of water and are difcult to remediate. Chlorinated

solvents including chlorinated ethenes and chloromethanes

have densities grater than water, allowing them to penetrate far

below the water table. In addition, they have very low

solubilities in water and are resistant to degradation. Even if

they do degrade, it is often along pathways that can lead to

products of greater concern than the original contaminants.

These characteristics have led to the phrase dense nonaqueous

phase liquids (DNAPL) to describe such chemicals [99].

The chlorinated solvents contain carbon in a relatively

oxidized form, while, in contrast, the petroleum derived

organics contain carbon in a relatively reduced form. Hence the

geochemical conditions required for degradation of these

classes of chemical in an aquifer are quite different. Often

mixtures of such contaminants are encountered and in many

occasions PRBs with single media would be unable to deal with

such situations. This has led to the development of new

strategies for the cleanup of contaminated aquifer.

The PRB with sequential treatment with duel or more kinds

of reactive barriers have recently been given more attention

(Fiorenza et al., 2000). Some of the sequential PRBs adopted

are given in Table 5 [27,100,101].

13. In situ chemical oxidation (ISCO)

ISCO can be applied to a variety of soil types and sizes and

can treat volatile organic chemicals (VOCs) including

dichloroethene (DCE), trichloroethene (TCE), tetrachlor-

oethene (PCE), and benzene, toluene, ethylbenzene, and

xylene (BTEX) as well as semi-volatile organic chemicals

(SVOCs) including pesticides, polycyclic aromatic hydrocar-

bons (PAHs), and polychlorinated biphenyls (PCBs). The

oxidants such as hydrogen peroxide (H

2

O

2

), potassium

permanganete (KMnO

4

), ozone (O

3

) are applied [102,103].

The mechanism of degradation is the production of hydroxyl

radicals, which are capable of oxidizing complex organic

compounds. For most in situ reactive zone targets, hydroxyl

radical oxidation is a much faster treatment method [104].

Some of the advantages and limitations in adopting ISCO is

given in Table 6.

13.1. Use of oxidants

(i) Potassium or sodium permanganate (KMnO

4

/NaMnO

4

):

Permanaganate is an oxidizing agent and has an afnity

towards organic compounds containing carbon-carbon

bonds, aldehyde groups, or hydroxyl groups [105107]. As

the permanganate dose increases, organic degradation also

increases and the permanganate consumption also

increases [27]. In some instances where permanganate is

used for the degradation of DNAPL, production of MnO

2

(s) may signicantly lower the permeability of the soil

matrix and form a coating on DNAPL [27,108]. Phase

transfer catalyst (like quaternary amines), which has both

polar and non-polar segments, are also used along with

permanganate, to assist in the removal hydrophobic

Table 5

Examples of sequential PRBs

Granular zero-valent iron to treat chlorinated hydrocarbons followed by

aerobic bioremediation (using oxygen release compounds) to treat aromatic

hydrocarbons

Granular zero-valent iron to treat chlorinated hydrocarbons followed by

nutrient addition or solid carbon source addition to promote anaerobic

biodegradation of volatile organic carbons (VOCs) that cannot be degraded by

granular iron

Sequential anaerobic biodegradation of chlorinated solvents followed by

aerobic biodegradation for toluene degradation

Solid carbon sources to treat nitrate followed by granular iron to treat VOCs

A four component PRB consisting of four reactive media in series for treating

(immobilizing or destroying) multiple contaminants

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 152

organic contaminants [104]. Permanganate reaction rate is

much slower than those of hydroxyl radical reactions,

which gives it s signicant advantage in achieving greater

contact with contaminats, especially with NADPL

compounds [104].

(ii) Hydrogen peroxide (H

2

O

2

)/fenton (H

2

O

2

Fe) oxidation:

Concentration of peroxide injection generally varies

between 3% and 35% (w/w) at a pH range of 3.56, with

or without a metal catalyst (usually iron). The process

involves the production of hydroxyl radicals (OH.), which

act as a powerful oxidizing agent for the degradation of

organic contaminants. The initial amount of H

2

O

2

and Fe

catalyst also depends on the contaminant level in the soil,

and the volume of groundwater remediated [27].

Hydrogen peroxide and fenton oxidation has been

applied for the remediation of several contaminants

including petroleum hydrocarbons [109,110], hexadecane

[111], atrazine [112,113], aromatic compounds [114,115],

dioxins [116] and chlorinated solvents [117]. The

usefulness of fenton oxidation may be limited by low

soil permeability, subsurface heterogeneities, and highly

alkaline soil (where carbonate ions are free radical

scavengers) [105].

(iii) Persulfate: Sodium persulfate (Na

2

S

2

O

8

) is recently being

used in ISCO. The conversion of the persulfate results in

the production of sulfate radicals or a single electron

radical. Free radicals act as strong oxidizing agents and are

known to oxidize many VOCs. Many sites have sufcient

background conditions which allow the persulfate to

oxidize the targeted VOCs present in the soils and

groundwater without the addition of a catalyst. In some

instances, chelated iron compounds have been used as

activators [27,118].

(iv) Ozone (O

3

): Ozone is a very powerful oxidant and is

commonly used for the remediation of hydrocarbon and

chlorinated solvent contaminants [27,119,120]. Ozone

solubility and the concentration of ozone in the injected

gas stream are the key variables affecting the rate of

treatment. Ozone degrades to oxygen and promotes

biodegradation in combination to ozone oxidation process

[27,121]. Treatment with ozone in combination of

hydrogen peroxide (termed as peroxone process) [104]

and fenton reagents [122] has also been attempted.

The characteristics of various oxidants used in the ISCO

technology are given in Table 7.

14. PRB studies in Australia and New Zealand

Several sightings on petroleum hydrocarbon contamination

have been reported.

- BTEX (benzene, toluene, ethylbenzene and xylene)

contamination in metropolitan Perth, Western Australia.

Biodegradation has been adopted as the remedial method.

Preferential intrinsic biodegradation of selected organic

compounds within the BTEX plume was shown to be

occurring [98].

- BTEX and other dissolved organic contamination from

gasoline spills at Kwinana eld on the Swan Coastal Plain

in Western Australia. Aerobic bioremediation was adopted.

Volatalization found to be a dominant mechanism of

removal of the VOCs contaminant present. Evidence of

Table 6

Advantages and limitations in using ISCO method in PRB technology

Advantages Limitations

Rapid treatment Limited information is available on the operational history

Capability of contaminants to be degraded into nal

innocuous compounds like carbon dioxide, water and chloride

Proper oxidant selection must be made depending on site

characteristics and nature of contaminants

Oxidants can be injected and can be applied to greater depths

compared to method which require excavation

Problems such as gas evolution (also explosive vapors), toxic by-products,

resolubilization of metals and reduction of biomass

Also suitable for complex organics (recalcitrant compounds)

and mixed waste streams

Precise control of pH, temperature, and contact time is important

Certain materials like natural organic matter (NOM), reduced inorganics such

as iron and manganese can exert a demand for oxidant

Occupational health and safety concerns

Table 7

Characteristics of common oxidants

Technology features Fentons reagent Permanganate Persulfate Ozone

Physical state as injected Liquid Liquid Liquid Gas

Key oxidant OH

MnO

4

SO

4

2

O

3

and OH

Oxidation potential 2.8 V 1.7 V 2.5 V 2.07 V/2.8 V

By-products Fe(III), O

2

, H

2

O Mn(VI) Sulfate Oxygen

Reagent costs Moderate Moderate for KMnO

4

; high for NaMnO

4

Moderate Moderate

Subsurface fouling Possible Yes, due to MnO

2

formation No No

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 153

biodegradation of dissolved organics was also identied

from the oxygen utilization rates [123].

- Trace concentrations of petroleum hydrocarbonnonaro-

matic hydrocarbons (BTEX) and chlorinated solvents-

halogenated aliphatic hydrocarbon (tetrachloroethene-

PCE) at the Swan Coastal Plain area, Western Australia

was treated by biodegradation method. The results from the

column studies indicated that indigenous microorganisms

were capable of degrading trace amounts of toluene and

ethylbenzene under denitrifying conditions and toluene

under sulfate-reducing conditions. Benzene was persistent

under anoxic conditions, but degraded readily under

oxygenated condition. PCE failed to degrade under either

oxic or anoxic conditions.

- A funnel and gate PRB was adopted with saturated peat

(70% biogreen humic reed sedge, 20% sphagnum peat and

10% cocoa bre) reactive material was tested for the

remediation of toluene, ethylbenzene, xylene and n-alkane

contaminants (spirit petroleum hydrocarbon spill at the

underground storage site in South Eastern Australia). This

study [124] reported high sorptive efciencies compared to

previous study which shows a decrease in removal

performance with time [125]. This reinforces the impor-

tance of testing local peat types prior to full-scale

application.

Leachate contamination: Coal washery alkaline slag lea-

chate, Kemblawarra, Port Kembla, NSW, Australia [68]. The

wastes include air-cooled blast furnace slag, steel making

slag and coal washery discard. A PRB wall with coal washery

discard was chosen. The geochemical calculations indicate

that the reactive walls ability to control alkalinity and S

2

should outlast the slags ability to produce toxic leachate

[68,126].

DNAPL contamination: Apilot scale zero valent iron reactive

barrier was tested for the remediation of DNAPL, including

trichloroethene (TCE), tetrachloroethene (PCE), carbon

tetrachloride (CTC), 1,1,2,2-tetrachloroetane (PCA), 1,1,1-

trichloroethane, 1,2-dichloroethane, chloroform, chloroben-

zene, hexachlorobutadiene and hexachloroethane, at South of

City of Sydney, Australia [127]. Very high removal

efciencies of VOC was observed. However, very low

removal performance was noted for compounds such as 1,2-

dichloroethane and dichloromethane [54].

Ammonium contaminated groundwater: Pilot scale, sequen-

tial use of polymer mat reactive barrier for the remediation of

ammonium-contaminated groundwater [128]. Two polymer

mats were placed in series along the ow of the contaminant

plume. The upgradient mat delivered oxygen to induce

bacterial nitrication of the ammonium to nitrite/nitrate and

the downgradient mat delivered ethanol to induce bacterial

denitrication of the nitrite/nitrate to produce nitrogen gas.

Signicant reduction (>90%) in total N was achieved.

Denitrication (Bardowie farm, Cambridge, North Island,

New Zealand): Pilot scale denitrication wall was con-

structed by mixing a carbon source, such as sawdust (Pinus

radiata) (40 m

3

), in the subsurface aquifer. The added carbon

source stimulates nitrate reduction to nitrogen gas by

denitrication. However, it was found that carbon availability

was not limiting the size of the microbial population [129].

Acid rock drainage (AMD) treatment: Remediation of acid

mine drainage was attempted at Mt Carrington silver and gold

mine, in northern New South Wales, Australia. Bauxsol

TM

, a

product made from seawater-neutralized red mud (a by-

product of alumina rening) was used as the reactive barrier

material. This material has very low hydraulic conductivity

(as it is very ne-grained (<10 mm)), it was mixed with sand.

Over 45,000 L of ARD was treated above ground with

Bauxsol/sand PRB material. It was found that Bauxsol/sand

PRB was able to avoid clogging (which is a major problem

when using carbonates and hydroxides for acid neutraliza-

tion) and achieve reductions satisfactory with Australian

Water quality Standards. Metal removal efciency was also

very high. Analysis of the spent Bauxsol also indicated that

the bound metals are not readily leachable, allowing the spent

material to be disposed safely in landlls.

Biodegradation of pesticides: Contamination of groundwater

by atrazine (2-chloro-4-ethylamino-6-isopropylamino-1,3,5-

triazine), terbutryn (2-tert-butylamino-4-ethylamino-6-

methylthio-1,3,5-triazine) and fenamiphos (1-(methy-

lethyl)-ethyl-3-methyl-4-(methylthio) phenylphosphorami-

date) from inltration of pesticide-laden washwater from

Dianella, Perth, Western Australia, was treated using a lab-

scale column experiments by biodegradation [130]. Polymer

mats were used to deliver oxygen into the groundwater to

induce biodegradation. Degradation rates of atrizine were

relatively high, however, no signicant degradation of

terbutryn or fenamiphos was observed.

Acknowledgement

This study was funded by the CRC Care (Land and Water),

Australia. At the time of the study the rst author was with the

University of Technology Sydney.

References

[1] UK Environmental Agency, http://www.environment-agency.gov.uk/,

2005.

[2] S.S.D. Foster, in: O. Sililo (Ed.), Groundwater-Past Achievements and

Future Challenges, Balkema, Rotterdam, The Netherlands, 2000, p. 27.

[3] UNEP, Groundwater and its susceptibility to degradation: a global

assessment of the problem and options for management, early warning

and assessment report series, UNEP/DEWA/RS. 03-3, joint publication

from United Nations Environment Programme, Department for Interna-

tional Development and the Natural Environment Research Council

(NERC), 2003.

[4] Land and Water Australia, Australian Water Resource Assessment 2000

Surface Water and Groundwater Availability and Quality, Land and

Water Resource Audit, Commonwealth of Australia, 2001.

[5] Australia State of Environment Report, Inland Waters, Commonwealth

of Australia, 2001.

[6] Water and Rivers Commission, Water Facts, Department of Western

Australia, 1998.

[7] Ministry of Land and Water Conservation, The NSW State Government

Policy Framework Document, NSW Government, Australia, 1997.

[8] P.B. Bedient, H.S. Rifai, C.J. Newell, Groundwater Contamination:

Transport and Remediation, PTR Prentice Hall, Inc., USA, 1994.

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 154

[9] USEPA, Evaluation of Groundwater Extraction Remedies, vols. 1 and 2,

EPA Ofce of Emergency and Remedial Responses, Washington, DC,

1989.

[10] USEPA, Evaluation of Groundwater Extraction Remedies: Phase II, vol.

1, Summary Report, Publication 9355.4-05, EPA Ofce of Emergency

and Remedial Responses, Washington, DC, 1992.

[11] National Research Council (NRC), Alternatives for Groundwater

Cleanup, National Academy Press, Washington, DC, 1994.

[12] NRC, Contaminants in the Subsurface: Source Zone Assessment and

Remediation, National Academy Press, Washington, DC, USA, 2005.

[13] J. Ball, Inland Waters-Theme Report, Australia State of the Environment

Report 2001 (Theme Report), CSIRO Publishing on behalf of the

Department of the Environment and Heritage, Commonwealth of Aus-

tralia, Website: http://www.deh.gov.au/soe/2001/inland/, 2001.

[14] SKM, Impact of Logging Practices on Water Yield and Quality in the

Otway Forests, Department of Natural Resources and Environment,

Australia, 2000.

[15] LWRRDC, Contamination of Australian Groundwater Systems with

Nitrate, Occasional Paper No. 03/99, Land and Water Resources

Research and Development Corporation, Canberra, 1999.

[16] NHMRC/ARMCANZ, Australian Drinking Water Guidelines, National

Health and Medical Research Council & Agricultural and Resource

Management, Council of Australia and New Zealand, Canberra, 1996.

[17] N.J. Schoeld, B.W. Simpson, Aust. J. Water Resour. 1 (2) (1996) 91.

[18] K.E. Roehl, T. Meggyes, F.G. Simon, D.I. Stewart, Long-term Perfor-

mance of Permeable Reactive Barriers, Elsevier Publishers, 2005.

[19] A. Xenidis, A. Moirou, I. Paspaliaris, J. Miner. Wealth 123 (2002) 35.

[20] A.R. Gavaskar, N. Gupta, B.M. Sass, R.J. Janosy, D. OSullivan, Perme-

able Barriers for Groundwater Remediation: Design, Construction, and

Monitoring, Battelle Press, Columbus, Ohio, 1998.

[21] R.D. Vidic, Permeable Reactive Barriers: Case Study Review, Technol-

ogy Evaluation Report TE01-01, Groundwater Remediation Technolo-

gies Analysis Center, 2001.

[22] R.D. Vidic, F.G. Pohland, Treatment wells, Technology Evaluation

Report TE 96-01. GWRTAC, Pittsburg, USA, 1996.

[24] A.R. Gavaskar, J. Hazard. Mater. 68 (1999) 41.

[25] T. Meggyes, F.-G. Simon, J. Land Contam. Remediat. 8 (3) (2000) 1.

[26] Golder Associates Ltd., Active Containment: Combined Treatment and

Contaminant Systems, Department of Environment, Transport and the

Regions, ISBN 1851121145, London, 1998.

[27] ITRC, Permeable Reactive Barriers: Lessons Learned/New Directions.

Technical/Regulatory Guidelines, ITRC, Washington, DC, 2005.

[29] F.-G. Simon, T. Tunnermeier, T. Meggyes, in: G. Prokop (Ed.), Proceed-

ings 1st IMAGE-TRAIN Cluster Meeting, Karlsruhe, November 79,

2001, (2002), p. 145, Vienna (Umweltbundesamt).

[30] PEREBAR, 5th Framework Programme Research and Technology

Development Project on Long-term Performance of Permeable Reactive

Barriers Used for the Remediation of Contaminated Groundwater.

PEREBAR EVK1-CT-1999-00035, National Technical University of

Athens, Greece, 2002.

[31] USEPA, Permeable reactive barrier technologies for contaminant reme-

diation, Report number EPA/600/R-98/125, Washington, DC, 1998.

[32] P.G. Tratnyek, M.M. Scherer, T.L. Johnson, L.J. Matheson, in: M.A. Tarr

(Ed.), Chemical Degradation Methods for Wastes and Pollutants: Envir-

onmental and Industrial Application, Marcel Dekker, New York, 2003, p.

371.

[33] M.M. Scherer, S. Richter, R.L. Valentine, P.J.J. Alvarez, Environ. Sci.

Technol. 30 (3) (2000) 363.

[34] I. Han, M.A. Schlautman, B. Batchelor, Water Environ. Res. 72 (1)

(2000) 29.

[35] S.G. Benner, D.W. Blowes, W.D. Gould, R.B. Herbert, C.J. Ptacek,

Environ. Sci. Technol. 33 (1999) 2793.

[36] R.S. Hedin, G.R. Watlaf, in: Proceedings, International Land Reclama-

tion and Mine Drainage Conference and Third International Conference

on the Abatement of Acid Drainage, 1, Pittsburg, Pensylvania, (1994), p.

184.

[37] W. Admassu, T. Breese, J. Hazard. Mater. B 69 (1999) 187.

[38] M. Fuhrman, D. Aloysius, H. Zhou, J. Waste Manage. 15 (7) (1995) 485.

[39] P. Misaelides, A. Godelitsas, D. Filippidis, D. Charistos, I. Anousis, Sci.

Total Environ. 173/174 (1995) 237.

[40] P. Huttenlock, K.E. Roehl, K. Czurda, Environ. Sci. Technol. 35 (2001)

4260.

[41] C.L. Ake, K. Mayura, H. Huebner, G.R. Bratton, T.D. Phillips, J. Toxicol.

Environ. Health, Part A 63 (2001) 459.

[42] M.J. Baker, D.W. Blowes, C.J. Ptacek, Environ. Sci. Technol. 32 (1998)

2308.

[43] R. Wilson, D.M. Mackay, K.M. Scow, Environ. Sci. Technol. 36 (2)

(2002) 190.

[44] A. Abdelouas, W. Lutze, W. Gong, E.H. Nuttall, B.A. Strietelmeier, B.J.

Travis, Sci. Total Envrion. 250 (13) (2000) 21.

[45] ITRC, ASystematic Approach to In situ Bioremediation in Groundwater,

Including Decision Tree on In situ Bioremediation for Nitrates, Carbon

Tetrachloride, and Perchlorate, ITRC, USA, 2002.

[46] USEPA, Engineered Approaches to In Situ Bioremediation of Chlori-

nated Solvents: Fundamentals and Field Applications. EPA 542-R-00-

008, Ofce of Solid Waste and Emergency Response, Technology

Innovation Ofce, USEPA, Washington, DC, 2000.

[47] F. Caruso, D. Trau, H. Mohwald, R. Renneberg, Langmuir 16 (2000)

1485.

[48] PEREBAR, 5th Framework Programme Research and Technology Pro-

ject on Long-term Performance of Permeable Reactive Barriers Used for

the Remediation of Contaminated Groundwater, University of Leeds,

UK, 2003.

[49] T. Shimotori, E. Nuxoll, E. Cussler, W.A. Arnold, Environ. Sci. Technol.

38 (2004) 2264.

[50] J.A. Sacre, Treatment Walls: A Status Update, Groundwater Remedia-

tion Technologies Analysis Center, TP-97-02, Pitsburg, PA, Homepage:

http://www.gwrtac.org, 1997.

[51] USEPA, Fiels Applications of In situ Remediation Technologies: Perme-

able Reactive Barriers, Ofce of Solid Waste and Emergency Response

Technology Innovation Ofce, Washington, DC, 2002.

[52] A. Agarwal, P.G. Tratnyek, Environ. Sci. Technol. 30 (1) (1996) 153.

[53] L.J. Matheson, P.G. Tratnyek, Environ. Sci. Technol. 28 (1994) 2045.

[54] R.W. Gillham, S.F. OHannesin, Ground Water 32 (6) (1994) 958.

[55] T.L. Johnson, M.M. Scherer, P.G. Tratnyek, Environ. Sci. Technol. 30 (8)

(1996) 2634.

[56] D.R. Burris, T.J. Campbell, V.S. Manoranjan, Environ. Sci. Technol. 29

(11) (1995) 2850.

[57] R.A. Holser, S.C. McCutcheon, N.L. Wolfe, in: Mass Transfer Effect on

the Dehalogenation of Trichloroethene by Iron/pyrite Mixtures.

Extended Abstracts from the 209th ACS National Meeting, Anaheim,

CA 35(1) p. 788, Division of Environmental Chemistry, American

Chemical Society, Washington, DC, 1995.

[58] K.J. Cantrell, D.I. Kaplan, T.J. Gilmore, J. Environ. Eng. 123 (8) (1997)

786.

[59] D.I. Kaplan, K.J. Cantrell, T.W. Wietsma, M.A. Potter, J. Environ. Qual.

25 (1996) 1086.

[60] H.-L. Lien, W.-X. Zhang, J. Environ. Eng. 125 (11) (1999) 1042.

[61] S.H. Joo, et al. Environ. Sci. Technol. 38 (2004) 2242.

[62] C.-B. Wang, W.-X. Zhang, Environ. Sci. Technol. 31 (7) (1997) 2154.

[63] J. Quinn, et al. Environ. Sci. Technol. 39 (2005) 1309.

[64] R. Muftikian, Q. Fernando, N. Korte, Water Res. 29 (1995) 2434.

[65] N.E. Korte, L. Liang, J. Clausen, Emerging Technologies in Hazardous

Waste Management VII, Extended Abstract for the Special Symposium,

Atlanta, GA, (1995), p. 45.

[66] E.L. Appleton, Environ. Sci. Technol. 30 (12) (1996) 536A.

[67] T.M. Sivavec, D.P. Horney, in: Reductive Dechlorination of Chlorinated

Ethenes by Iron Metal. Presented at the 209th ACS National Meeting,

Anaheim, CA, April 26, 1995.

[68] N. Ott, Permeable Reactive Barriers for Inorganics, USEPA, Washington,

DC, Report obtained from website http://www.clu-in.org, 2000.

[69] C.L. Geiger, C.A. Clausen, D.R. Reinhart, N. Ruiz, K. Farrell, A.S.

Sonawane, Using Ultrasound for Restoring Iron Activity in Permeable

Treatment Walls. 221st National Meeting, American Chemical Society.

San Diego, CA, 2001, p. 1167 (Preprint Extended Abstracts, Division of

Environmental Chemistry 41, No. 1).

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 155

[70] R.T. Wilkin, R.W. Puls, G.W. Sewell, Long-term Performance of Perme-

able Reactive Barriers Using Zero-valent Iron: An evaluation at Two

Sites, Environmental Research Brief, EPA/600/S-02/001, 2002.

[71] R.M. Atlas, R. Bartha, Microbial Ecology, third ed., Benjamin Cum-

mings, New York, 1993.

[72] K. Ritter, M.S. Odziemkowski, R.W. Gillham, J. Contam. Hydrol. 55

(2002) 87.

[73] T. Kohn, S.R. Kane, D.H. Fairbrother, A.L. Roberts, Environ. Sci.

Technol. 37 (24) (2003) 5806.

[74] G.F. Parkin, P.J. Alvarez, M.M. Scherer, J.L. Schnoor, Role of Microbes

in Remediation with Fe

0

Reactive Barriers, Ground Water Currents

USEPA 542-N-00-002 issue no. 35, p. 2, website http://www.clu-in.

org/products/newsltrs/gwc/gwc0300.htm, 2000.

[75] B.A. Till, L.J. Weathers, P.J.J. Alvarez, Environ. Sci. Technol. 32 (5)

(1998) 634.

[76] ARS Technologies Inc., http://www.arstechnologies.com/, Website vis-

ited January 2005, 2005.

[77] B.-T. Oh, C.L. Just, P.J. Alvarez, Environ. Sci. Technol. 35 (2001) 4341.

[78] K.R. Waybrant, C.J. Ptacek, D.W. Blowes, Environ. Sci. Technol. 36

(2002) 1349.

[79] B. Wrenn, Enhanced Reductive Dechlorination through Biological Inter-

action with Zero-valent Iron, Federal Remediation Technologies Round-

table Meeting, Arlington, Virginia, USA, Website: http://www.frtr.gov/

pdf/meetings/summary_09jun04.pdf, 2004.

[80] M.O. Corapcioglu, C.P. Huang, Carbons 25 (1987) 569.

[81] P. Leglize, Bacteria-phenanthrene-activated Carbon Interactions Studies

for PRB Process Evaluation, Dissertaion, Faculty of Sciences and

Technology of Nancy, France, ADEME, Research Programme Planning,

Cedex, France, Website: http://www.ademe.fr/anglais/thesis/thesis04/

vath201204.htm, 2004.

[82] H. Schad, P. Gratwohl, in: H. Burmier (Ed.), Treatment Walls and

Permeable Reactive Barriers, vol. 229, pp. 56065, NATOCCMS, Vienna,

1998.

[83] G. Gottardi, E. Galli, Natural Zeolites, Springer, Berlin, 1985, p. 409.

[84] M. Loizidou, R.P. Townsend, Zeolites 7 (2) (1987) 153.

[85] D. Lepperd, J. Mining Eng. (1990) 604 (June Issue).

[86] W.D. Robertson, J.A. Cherry, Ground Water 33 (1995) 99.

[87] W.J. Hunter, R.F. Follett, J.W. Cary, Am. Soc. Agric. Eng. 40 (1997) 345.

[88] S.G. Benner, D.W. Blowes, C.J. Ptacek, Groundwater Monit. Remediat.

17 (4) (1997) 99.

[89] W.D. Robertson, D.W. Blowes, C.J. Ptacek, J.A. Cherry, Ground Water

38 (5) (2000) 99.

[90] R.D. Vidic, F.G. Pohland, Treatment Wells, Technology Evaluation

Report TE 96-01, GWRTAC, Pittsburg, USA, 1996.

[91] A.M. Moore, C.H. De Leon, T.M. Young, Environ. Sci. Technol. 37 (14)

(2003) 3189.

[92] D.W. Blowes, C.J. Ptacek, S.G. Benner, C.W.T. McRae, T.A. Bennett,

R.W. Puls, J. Contam. Hydrol. 45 (2000) 123.

[93] J. Klausen, P.J. Vikesland, T. Kohn, D.R. Burris, W.P. Ball, A.L. Roberts,

Environ. Sci. Technol. 37 (2003) 1208.

[94] D.H. Phillips, B. Gu, D.B. Watson, Y. Roh, L. Liang, S.Y. Lee, Environ.

Sci. Technol. 34 (2000) 4169.

[95] J. Farrell, M. Kason, N. Melitas, T. Li, Environ. Sci. Technol. 34 (2000)

514.

[96] O. Schlicker, M. Ebert, M. Fruth, M. Weidner, W. Wust, A. Dahmke,

Ground Water 38 (3) (2000) 403.

[97] I. Snape, C.E. Morris, C.M. Cole, Cold Reg. Sci. Technol. 32 (23)

(2001) 157.

[98] G.B. Davis, C. Barber, T.R. Power, J. Thierrin, B.M. Patterson, J.L.

Rayner, Q. Wu, J. Contam. Hydrol. 36 (1999) 265.

[99] ITRC, Dense Non-aqueous Phase Liquids (DNAPLs): Review of Emer-

ging Characterization and Remedial Technologies. Technology Over-

view, ITRC Work Group DNAPLs/Chemical Oxidation Work Team,

USA, 2000.

[100] S. Fiorenza, C.L. Oubre, C.H. Ward, Sequenced Reactive Barriers for

Groundwater Remediation, Lewis Publishers, New York, NY, 2000.

[101] J.P. Kaszuba, P. Longmire, B.A. Strietelmeier, T.P. Taylor, D. Counce,

P.S. den Baars, T. Cota, J. Myers, R.S. Johnson, Demonstration of a

Multi-Layered Permeable Reactive Barrier in Mortandad Canyon at Los

Alamos National Laboratory. LA-UR-03-7320. Los Alamos, N.M., Los

Alamos National Laboratory, 2003.

[102] Environmental Security Technology Certication Program (ESTCP),

Technology Status Review In situ Oxidation, USA, 1999.

[103] USEPA, A Citizens Guide to Chemical Oxidation, EPA 542-F-01-013,

April 2001, Washington, DC, 2001.

[104] S.S. Suthersan, F.C. Payne, In situ Remediation Engineering, CRCPress,

USA, 2005.

[105] ITRC, Technical and Regulatory In situ Chemical Oxidation of Con-

taminated Soil and Groundwater, Technical/Regulatory Guidelines,

ITRC Work Group and In situ Chemical Oxidation Work Team, USA,

2001.

[106] B.S. Tunnicliffe, N.R. Thomson, J. Contam. Hydrol. 75 (2004) 91.

[107] L.K. Mackinnon, N.R. Thomson, J. Contam. Hydrol. 56 (2002) 49.

[108] M.H. Schroth, M. Oostrom, T.W. Wietsma, J.D. Istok, J. Contam. Hydrol.

50 (2001) 79.

[109] B.V. Moran, P. Babaian, C.P. Young, Annual Conference on Contami-

nated Soils, University of Massachusetts, 1998.

[110] R.J. Watts, D.R. Haller, A.P. Jones, A.L. Teel, J. Hazard. Mater. 76 (1)

(2000) 73.

[111] R.J. Watts, P.C. Stanton, Water Res. 33 (6) (1999) 1405.

[112] S.M. Arnold, W.J. Hickey, R.F. Harris, Environ. Sci. Technol. 29 (8)

(1995) 2083.

[113] R. Mecozzi, L.D. Palma, C. Merli, Chemosphere 62 (9) (2006)

1481.

[114] I. Casero, D. Sicilia, S. Rubio, D. Perez-Bendito, Water Res. 31 (8)

(1997) 1985.

[115] L. Lunar, D. Sicilia, S. Rubio, D. Perez-Bendito, U. Nickel, Water Res.

34 (6) (2000) 1791.

[116] C.M. Kao, M.J. Wu, J. Hazard. Mater. 74 (3) (2000) 197.

[117] C.K.J. Yeh, Y.A. Kao, C.P. Cheng, Chemosphere 46 (1) (2002) 67.

[118] C. Liang, C.J. Bruell, M.C. Marley, K.L. Sperry, Chemosphere 55 (2004)

1213.

[119] USEPA, NATO/CCMS Pilot Study, Evaluation of Demonstrated and

Emerging Technologies for the Treatment of Contaminated Land and

Groundwater (Phase III), 1998 Special Session, Treatment Walls

and Permeable Reactive Barriers, Number 229, EPA 542-R-98-003,

North Atlantic Treaty Organization, Vienna, Austria, 1998.

[120] H.-N. Lim, H. Choi, T.-M. Hwang, J.-W. Kwang, Water Res. 36 (2002)

219.

[121] Y. Zeng, P.K.A. Hong, D.A. Wavrek, Environ. Sci. Technol. 34 (2000)

854.

[122] A. Goi, N. Kulik, M. Trapido, Chemosphere 63 (10) (2006) 1754.

[123] C.D. Johnston, J.L. Rayner, B.M. Patterson, G.B. Davis, J. Contam.

Hydrol. 33 (1998) 377.

[124] T.F. Guerin, S. Horner, T. McGovern, B. Davey, Water Res. 36 (2002) 15.

[125] A.D. Cohen, M.S. Rollings, W.M. Zunic, J.D. Durig, Water Resour. Res.

25 (9) (1991) 1047.

[126] R. Naidu, R.S. Kookana, D.P. Oliver, S. Rogers, M.J. Mclaughlin,

Contaminants and the soil environment in the Australian-Pacic

Regions. Proceedings of the Australasia-Pacic conference on contami-

nants and soil environment in the Australasia-Pacic regions, held in

Adelaide, Kluwer Academic Publishers, Australia, 1823, 1996.

[127] J.M. Duran, J. Vogan, J.R. Stening, Reactive Barrier Performance in a

Complex Contaminated and Geochemical Environment. II International

Conference on Remediation of Recalcitrant Compounds, Montery, CA,

Columbus, May 2225, 2000.

[128] B.M. Patterson, M.E. Grassi, B.S. Robertson, G.B. Davis, A.J. Smith,

A.J. Mckinley, Environ. Sci. Technol. 38 (2004) 6846.

[129] L.A. Schipper, M. Vojvodic-Vukovic, Water Res. 35 (14) (2001)

3473.

[130] B.M. Patterson, P.D. Franzmann, G.B. Davis, J. Elbers, L.R. Zappia, J.

Contam. Hydrol. 54 (2002) 195.

R. Thiruvenkatachari et al. / Journal of Industrial and Engineering Chemistry 14 (2008) 145156 156

You might also like

- Fitness WalkingDocument192 pagesFitness Walkingjha.sofcon5941100% (1)