Professional Documents

Culture Documents

Team Works 2012 Green Process

Uploaded by

Praks Saxena0 ratings0% found this document useful (0 votes)

18 views24 pagest

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views24 pagesTeam Works 2012 Green Process

Uploaded by

Praks Saxenat

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 24

A Green Process

for Innovative

Cosmetic

Ingredients

TeamWorks

March 21

st

, 2012

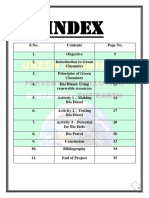

Agenda

Defining Green

What is Biocatalysis?

Developing Anti-Aging Actives

Emollient Esters

GEM

TM

(Green Enzymatic Manufacturing)

Environmental Footprint

Formulating

Industry Trends

So what is Green?

Natural: having or constituting a classification

based on features existing in nature; that has

undergone minimal processing and contains no

preservatives or artificial additives

Organic: produced with the use of feed or fertilizer

of plant or animal origin without employment of

chemically formulated fertilizers, growth stimulants,

antibiotics, or pesticides

Green: concerned with or supporting

environmentalism

Defining Green

EPA: Twelve Principles of Green

Chemistry*

1.

Prevent waste, rather than clean it up

2.

Maximize atom economy

3.

Design less hazardous chemical syntheses, for workers & the environment

4.

Design safer chemicals and products, for end use applications

5.

Use safer solvents, or eliminate them entirely

6.

Increase energy efficiency

7.

Use renewable feedstocks, whenever feasible

8.

Avoid chemical derivatization, in the reaction process

9.

Use catalysts, not stoichiometric reagents, more selective & efficient

10.

Design products to biodegrade after use

11.

Analyze reactions in real time, to prevent by-products

12.

Minimize the potential for accidents, such as fire

*Originally published by Paul Anastas and John Warner in Green Chemistry: Theory and Practice

(Oxford University Press: New York, 1998).

Defining Green

How to Apply these Principles?

Biocatalysis

the use of whole microbial cells or isolated

enzymes to catalyze a chemical transformation.

Biocatalysis is one of the oldest chemical

transformations, but has been employed for

man-made compounds in the past 30 years.

What is Biocatalysis?

Cover Story

May 21, 2001

BIOCATALYSIS: Chemical and pharmaceutical

makers seek more efficient and often cleaner routes

to making old and new products

Benefits

Chemoselectivity

Lower Energy Required

Mild Conditions

Challenges; Robust Catalyst to manufacture high

Volumes and high Yield @Low Cost

Volume 79, Number 2; CENEAR 79 21 pp. 27-34; SSN 0009-2347

No Side Reactions

Biodegradable

Minimal Waste

What is Biocatalysis?

Enzymatic Biocatalysis

The covalent attachment of an

enzyme to a solid matrix so

that it cannot move but still act

on its substrate

Enzyme selection and

functionality

Substrate functionality

What is Biocatalysis?

Anti-aging ingredients:

retinyl esters

Chemical synthesis of retinyl esters can be harsh to the delicate

functionality of the reactants and products.

Enzymatic esterification is a mild method, but requires the very

unstable retinol.

Enzymatic inter-esterification is a preferred method.

O

O

+ RCOOH

enzyme

solvent

O R

O

+ CH

3

COOH

Actives

Process comparison: retinyl esters

Twelve Principles of Green Chemistry were applied to the process

Actives

Process comparison: Idebenone esters

Biocatalytic

Process 1

Biocatalytic

Process 2

Biocatalytic

Process 3

Product quality

Yield 98% 98% 99%

Assay 98.4% 98.3% 98.3%

Residual idebenone 0.2% 0.4% 0.6%

Residual acid 0.2% 0.3% 0.3%

Reaction Solvent

(Liters /kg product)

2.87 0 0

Isolation Solvent

(Liters /kg product)

7.47 3.37 0

Total solvent

(Liters/kg product)

10.34 3.37 0.00

10

Limited

By Volume

Actives

Cosmetic ingredients: Esters

Category

Actives

Sunscreens

Preservatives

Emollients

Thickeners

Surfactants

Polymers

<1%

>10%

Esters are a class of cosmetic

ingredients represented across

functional categories.

Actives are low volume ingredients

Additional functional ingredients

can benefit from greener and

sustainable manufacture

Emollient Esters

Estimate for actives is ~1 kMT

Regional demand for cosmetic esters:

Worldwide market for all cosmetic esters

~500 kMT

Cosmetic esters market

Sources: 2008 Global Industry Analysis; SRI Consulting Cosmetic Report 2007

Surfactant

Esters

Volume

(kMT)

North America 31

Europe 39

Total 70

Emollient

Esters

Volume

(kMT)

North America 19

Europe 32

Total 51

Emollient Esters

Estimated greenhouse gas potential savings* based

on product volume

*Difference between conventional and enzymatic processes.

13

Emollient Esters

Alcohol Reactant Acid Reactant

Reaction product is substantially pure, no further processing is required.

Boaz & Clendennen, Cosmetics & Toiletries Magazine, 2009.

Solvent-free biocatalysis

GEM

Conventional GEM

Process comparison: Emollient esters

100-150

o

C

>150

o

C

<100

o

C

catalyst

by-products

liquid

volatiles

water

oxidant

filter aid

solid

reaction

drying

filtration

packaging

bleaching

washing

raw materials

catalyst

(re-used)

inputs

raw materials

packaging

reaction

outputs

liquid

Batch Batch or Continuous

outputs

liquid

solid

filtration filtration

water

GEM

What can be Manufactured?

+ OH +

Eastman

CalB-3

N

2

HO

O

O

O

palmitic acid

- H

2

O

2-ethylhexanol 2-ethylhexyl palmitate

enzyme

GEM

Greenhouse Gas Reduction

52%

Reduction

Environmental Footprint

Energy Reduction

59%

Reduction

Environmental Footprint

Waste Comparison

93%

Reduction

Environmental Footprint

Batch Processing Water Usage

100%

Reduction

Environmental Footprint

52% GHG emission

reduction

59% energy reduction

93% waste reduction

100% process water

reduction

GEM

TM

Summary

Batch Process Summary

Continuous Production would further reduce environmental footprint

Environmental Footprint

Can this impact a formulation?

Cosmetic Emollient & Emulsifier Esters

Glyceryl Stearate

Isopropyl Palmitate

2-Ethylhexyl Palmitate

Isopropyl Myristate

Myristyl Myristate

Glyceryl Oleate

Isononyl Isononanoate

Isostearyl Linoleate

Hexyl Laurate

Cetyl Ricinoleate

Cetyl Palmitate

Isopropyl Isostearate

Water (70%)

Emollients(18%)

Emulsifiers(7%)

Frag/Pres/Thickener (5%)

Skin Care Product

Green your product by 7%

These ingredients are also used in color cosmetics and AP DEO Products

Formulating

October 2011 release a report titled Biotechnology and

its Role in Sustainable Design

Industry Trends

The beauty is in the process

Thank You

You might also like

- Green ChemistryDocument9 pagesGreen ChemistrymidhunNo ratings yet

- Green Chemistry Application For Sustainable DevelopmentDocument53 pagesGreen Chemistry Application For Sustainable DevelopmentAlinaCrinaCiubotariuMuresanNo ratings yet

- c15 Kirchhoff p1Document45 pagesc15 Kirchhoff p1tiago.trad6924No ratings yet

- Benzoin Condensation: - 1 - DE JonesDocument9 pagesBenzoin Condensation: - 1 - DE JonesLiz HackettNo ratings yet

- Recycle@Source: To End of The Pipe TreatmentDocument31 pagesRecycle@Source: To End of The Pipe TreatmentIndustrial Green Chemistry WorldNo ratings yet

- Biotechnology in Textiles 240305Document78 pagesBiotechnology in Textiles 240305Edward MenezesNo ratings yet

- Unit V - Green Chemistry CompositiesDocument16 pagesUnit V - Green Chemistry Compositiesaraq3501No ratings yet

- Green ChemistryDocument28 pagesGreen ChemistryH Janardan PrabhuNo ratings yet

- Chemistry ProjectDocument26 pagesChemistry ProjectMohammad HassanNo ratings yet

- Biocatalysis-An Effective Tool For A Cost Efficient, Sustainable & Green ManufacturingDocument14 pagesBiocatalysis-An Effective Tool For A Cost Efficient, Sustainable & Green Manufacturingnurul9535No ratings yet

- Abstract:: Keywords: Drug Design, Drug Discovery, Green ChemistryDocument5 pagesAbstract:: Keywords: Drug Design, Drug Discovery, Green ChemistryRajendra SinhaNo ratings yet

- Chemistryinvestigatoryproject-170126130926 (3) - RemovedDocument30 pagesChemistryinvestigatoryproject-170126130926 (3) - RemovedRaghav SharmaNo ratings yet

- Green ChemistryDocument40 pagesGreen Chemistryjara6896No ratings yet

- Acetaldehyde EconomicsDocument26 pagesAcetaldehyde EconomicsKudouNo ratings yet

- 441 Green Chemistry - Ramesh - Gec CLTDocument58 pages441 Green Chemistry - Ramesh - Gec CLTJerry JNo ratings yet

- Q&A Green ChemistryDocument3 pagesQ&A Green ChemistryArturIonescuNo ratings yet

- Green ChemistryDocument6 pagesGreen ChemistryRay RenoldNo ratings yet

- 24.8.18 GctiDocument112 pages24.8.18 GctiReena SinghalNo ratings yet

- Physico-Chemical Characterization of A Biosurfactant Produced byDocument23 pagesPhysico-Chemical Characterization of A Biosurfactant Produced byKV DeepikaNo ratings yet

- Green Chemistry: Editor: Prof. Dr. Phan Thanh Sơn NamDocument39 pagesGreen Chemistry: Editor: Prof. Dr. Phan Thanh Sơn NamTrung LeNo ratings yet

- The Principles of Green ChemistryDocument4 pagesThe Principles of Green Chemistryrk_gummaluri5334No ratings yet

- Principles of Green ChemistryDocument5 pagesPrinciples of Green ChemistryTanveer Irshad SiddiqiNo ratings yet

- How Green Can Reduce Environmental PollutionDocument6 pagesHow Green Can Reduce Environmental PollutionMUHAMAD HAMMAD AHMEDNo ratings yet

- Environment CBCS APIDocument28 pagesEnvironment CBCS APIPratik DasNo ratings yet

- ChemDocument13 pagesChemShivam SidhuNo ratings yet

- Final Project ReportDocument24 pagesFinal Project ReportPaulina AragónNo ratings yet

- Unit 3 ChemistryDocument112 pagesUnit 3 ChemistryAjawin EmmanuelNo ratings yet

- Application of Green ChemistryDocument19 pagesApplication of Green ChemistryKumaran RNo ratings yet

- Green ChemistryDocument32 pagesGreen Chemistry2222swayamNo ratings yet

- Ilamathi.V M.Tech Environmental Engineering and Management Center For Pollution ControlDocument15 pagesIlamathi.V M.Tech Environmental Engineering and Management Center For Pollution ControlIlamathi VelayudhamNo ratings yet

- 12 Principle of Green ChemDocument42 pages12 Principle of Green ChemTyagi MonikaNo ratings yet

- Class 3Document45 pagesClass 3avk50261No ratings yet

- Green Chemistry.......Document57 pagesGreen Chemistry.......Santosh Kumar pandeyNo ratings yet

- Sakshi Green ChemistryDocument20 pagesSakshi Green ChemistryAyushi JainNo ratings yet

- Additional Information For Organic Certified Chemically Processed Agro IngredientDocument2 pagesAdditional Information For Organic Certified Chemically Processed Agro IngredientSyed Mohamed YusufNo ratings yet

- Green Chemistry - 7Document39 pagesGreen Chemistry - 7MD Samin IslamNo ratings yet

- Pharmaceutical Waste-Water: Parth Naik ICT, MumbaiDocument48 pagesPharmaceutical Waste-Water: Parth Naik ICT, MumbaiShraddha MalveNo ratings yet

- Green TechnologyDocument23 pagesGreen Technologyaggarwalsaksham245No ratings yet

- Green ChemistryDocument13 pagesGreen ChemistryShireen AqeelNo ratings yet

- Catalysis and Sustainable Green Chemistry PDFDocument12 pagesCatalysis and Sustainable Green Chemistry PDFMaiaG17No ratings yet

- IUPAC Abstract Cromatografi LiquidDocument2 pagesIUPAC Abstract Cromatografi LiquidKamella GustinaNo ratings yet

- Chemistry Chapter 5 Form 5 KSSMDocument81 pagesChemistry Chapter 5 Form 5 KSSMnoorsuriatiNo ratings yet

- Enzyme Application in The Textile IndustryDocument14 pagesEnzyme Application in The Textile IndustryFie100% (1)

- Application Pesticides Olive Oil Captiva Emr Lipid 5994 0405en AgilentDocument10 pagesApplication Pesticides Olive Oil Captiva Emr Lipid 5994 0405en AgilentbesserianiNo ratings yet

- Green Chemistry ModuleDocument17 pagesGreen Chemistry ModuleAniruddhNo ratings yet

- Biodiesel From Waste Cooking OilDocument6 pagesBiodiesel From Waste Cooking OilJam imtiazNo ratings yet

- Green Chemistry Application For Sustainable DevelopmentDocument35 pagesGreen Chemistry Application For Sustainable DevelopmentAlinaCrinaCiubotariuMuresanNo ratings yet

- Principle 5: Safer Solvents and AuxiliariesDocument12 pagesPrinciple 5: Safer Solvents and AuxiliariesdeepakangadiNo ratings yet

- Principle V Safer Solvent and Auxilaries: Mithrun Lingesh Thinagaran LogendiranDocument10 pagesPrinciple V Safer Solvent and Auxilaries: Mithrun Lingesh Thinagaran LogendiranRathish RagooNo ratings yet

- Role of Chemistry in Environmental Protection and Economic DevelopmentDocument6 pagesRole of Chemistry in Environmental Protection and Economic Developmentrimo1567% (6)

- Green ChemistryDocument7 pagesGreen Chemistrysyakirin mnNo ratings yet

- Green ChemistryDocument31 pagesGreen ChemistrySiddharth ManiyarNo ratings yet

- Green ChemistryDocument28 pagesGreen Chemistrydatascientist100% (1)

- Ekb 4293 Green & Sustainable Chemical Process: 12 Principles of Green Chemistry Principle 1: PreventionDocument15 pagesEkb 4293 Green & Sustainable Chemical Process: 12 Principles of Green Chemistry Principle 1: PreventionMark Antony LevineNo ratings yet

- Industrial Chemicals Technology Hand BookDocument8 pagesIndustrial Chemicals Technology Hand BookGulfam ShahzadNo ratings yet

- Project On Green ChemistryDocument39 pagesProject On Green ChemistryHardik Shukla80% (5)

- Biotechnology of Microbial Enzymes: Production, Biocatalysis and Industrial ApplicationsFrom EverandBiotechnology of Microbial Enzymes: Production, Biocatalysis and Industrial ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- Biosurfactants: A Boon to Healthcare, Agriculture & Environmental SustainabilityFrom EverandBiosurfactants: A Boon to Healthcare, Agriculture & Environmental SustainabilityNo ratings yet

- Glad Energy Poetry BookDocument13 pagesGlad Energy Poetry BookPraks SaxenaNo ratings yet

- Update On Food and Nonfood Uses of Oils and Fats: InformDocument2 pagesUpdate On Food and Nonfood Uses of Oils and Fats: InformPraks SaxenaNo ratings yet

- Proverbs Basic YeahDocument1 pageProverbs Basic YeahPraks SaxenaNo ratings yet

- Is Failing Less A Better Safety GoalDocument2 pagesIs Failing Less A Better Safety GoalPraks SaxenaNo ratings yet

- Safety Ambassador SpeechDocument9 pagesSafety Ambassador SpeechPraks SaxenaNo ratings yet

- Castor OilDocument19 pagesCastor OilPraks SaxenaNo ratings yet

- Lessons Learned From The Red Bead Experiment: SS Prevette 509-373-9371 1Document6 pagesLessons Learned From The Red Bead Experiment: SS Prevette 509-373-9371 1Praks SaxenaNo ratings yet

- Demings 14 PtsDocument20 pagesDemings 14 PtsPraks SaxenaNo ratings yet

- Fiitjee Take PrintDocument17 pagesFiitjee Take PrintPraks SaxenaNo ratings yet

- English PresentationDocument6 pagesEnglish Presentationberatmete26No ratings yet

- Training and DevelopmentDocument46 pagesTraining and DevelopmentRavi JoshiNo ratings yet

- Jayanti Sengupta Oxford History & Civics Solution Class 8 Chapter 1 The Beginning of The Modern WorldDocument8 pagesJayanti Sengupta Oxford History & Civics Solution Class 8 Chapter 1 The Beginning of The Modern WorldSarah HopeNo ratings yet

- Glo 20is 2017 PDFDocument317 pagesGlo 20is 2017 PDFKristine LlamasNo ratings yet

- CounterfeitingDocument21 pagesCounterfeitingnujahm1639No ratings yet

- Lesson Guide 2.2 Beware of Banking FeesDocument4 pagesLesson Guide 2.2 Beware of Banking FeesKent TiclavilcaNo ratings yet

- The Best in YouDocument33 pagesThe Best in YouEgwim Ifeanyi100% (4)

- E-Learning PCE Question Bank ENG - Oct.2014Document125 pagesE-Learning PCE Question Bank ENG - Oct.2014Saya FarezNo ratings yet

- Just KidsDocument8 pagesJust KidsSean MichaelNo ratings yet

- K.E.E.I. Notes - Fall 2010Document8 pagesK.E.E.I. Notes - Fall 2010Kijana Educational Empowerment InitiativeNo ratings yet

- Marketing Term Paper Guidelines T4 2022 1Document2 pagesMarketing Term Paper Guidelines T4 2022 1Chad OngNo ratings yet

- Micro Econ Topic Tracker 2023Document5 pagesMicro Econ Topic Tracker 2023ryan sharmaNo ratings yet

- Majestic Writings of Promised Messiah (As) in View of Some Renowned Muslim Scholars by Hazrat Mirza Tahir Ahmad (Ra)Document56 pagesMajestic Writings of Promised Messiah (As) in View of Some Renowned Muslim Scholars by Hazrat Mirza Tahir Ahmad (Ra)Haseeb AhmadNo ratings yet

- DDI - Company Profile 2024Document9 pagesDDI - Company Profile 2024NAUFAL RUZAINNo ratings yet

- Affidavit of Probable Cause: ArresteeDocument3 pagesAffidavit of Probable Cause: ArresteeMcKenzie StaufferNo ratings yet

- Sacred Scrolls - 29-32Document9 pagesSacred Scrolls - 29-32Wal EldamaNo ratings yet

- NEW Handbook On Debt RecoveryDocument173 pagesNEW Handbook On Debt RecoveryRAJALAKSHMI HARIHARAN100% (5)

- Annexes G - Attendance SheetDocument2 pagesAnnexes G - Attendance SheetrajavierNo ratings yet

- RemarksDocument1 pageRemarksRey Alcera AlejoNo ratings yet

- MBG-PO-33281 Amd 1Document13 pagesMBG-PO-33281 Amd 1Santanu MuduliNo ratings yet

- Classification of CreditsDocument4 pagesClassification of CreditsMatthew WittNo ratings yet

- Law of Contract: TerminationDocument32 pagesLaw of Contract: TerminationemilyNo ratings yet

- Shaykh Rabee Advises Before He RefutesDocument7 pagesShaykh Rabee Advises Before He Refuteshttp://AbdurRahman.orgNo ratings yet

- Kincaid Ravine Report 12 12 2018Document22 pagesKincaid Ravine Report 12 12 2018api-301815693No ratings yet

- 175 PMP Sample QuestionsDocument78 pages175 PMP Sample QuestionsJuan Luis FerretNo ratings yet

- Problems On Financial AssetsDocument1 pageProblems On Financial AssetsNhajNo ratings yet

- CondrenDocument303 pagesCondrenbebelizaNo ratings yet

- Ncert BookDocument14 pagesNcert Bookviswanathan periyasamyNo ratings yet

- Class 9 Marketing and Sales PDFDocument1 pageClass 9 Marketing and Sales PDFAyushNo ratings yet

- Building Brand Architecture by Prachi VermaDocument3 pagesBuilding Brand Architecture by Prachi VermaSangeeta RoyNo ratings yet