Professional Documents

Culture Documents

Yanmar 4tne88 TNE Series PDF

Uploaded by

luna281068Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yanmar 4tne88 TNE Series PDF

Uploaded by

luna281068Copyright:

Available Formats

10-1

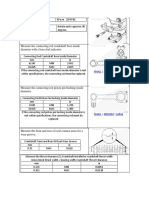

l1em Threaddia. x piteh Tightening torque RemarXs

M6x 1 1.0-1.2 1) When bolting the aluminum parts, tighten

Hexagon headed boIt

M8){ 125 2.3-2.9

Ihe bolts with 80% 01the tightening torque

specified in !he Table.

(7T)!lOO nut

M10 J I ; 1.5 4.5-5.5

2}4T bolt and lock nut should be lightened

M12x 1.75 8.0-10.0

wilh 60% 01the torque shown in the table.

1/8 1.0

1/4 2.0

PT plug

318 3.0

1 1 2 6.0

MB 1.3-1.7

Pipejoint bolt

M12 2.5-3.5

M14 4.0-5.0

M16 5.0-5.5

(Unit: kgt-m)

*:Lubricating011 notapplied

10-2 Standard bolt and nut

~

3TNE7BA

314TNE82,

No ltem 2I3TNE66 3TNE74

3TNE82A

314TNE84(T).

oe

314TNEBa

1 Cylinder head bolt

IJ .A>ricaling olapplied 3.8-4.2 6.0-6.5 6.8-7.2 8.7-9.3

(Threadda. xpik:h) (M8x 1.25) (M9 x 1.25) (M9x 1.25) (MIO x 1.25)

2 Connecting red bolt

Wlricaling oilapplled 2.3-2.8 2.3-2.8 3.8-4.2 4.5-5.5

(ThreadIia.x piten) (M7 x 1.0) (M7 x 1.0) (M8 x 1.0) (M9 x 1.0)

3

Flywheel clamping L.ubricafugoil appied 8.2-8.8 8.0-9.0 8.5-9.0 8.5-9.0

boft (Threadda. )(pl1ch) (Ml0x 1.25) (Ml0 x 1.25) (M10 x 1.25) {MI O x 1.25}

4

Metal cap clamplng LubrcatingolIapplied 5.3-5.7 8.0-8.5 7.6-8.2 9.8-10.2

bolt (Ttvead da.x pitch) (M9x 1.25) (Ml0 x 1.25) (Ml0xl.5) (M12)( 1.5)

._

Crankshaft V-pulley Lubri<;atirlg01appll8(j

S48C: 11.5-12.5 S48C:".5-12.5 11.5-12.5 11.5-12.5

5 FC25: 8.5-9.5 FC25: 6.5-9.5 (M14x1.5) (M14 x 1.5)

clamping bol! (Threaddia. )( pilch)

(M12x 1.5) (M12 x 1.5)

6

Fuel injection W:>ricating oiI not applied 5.0-5.4 5.0-5.4 0.7-0.9 0.7-0.9

nozzle nut (Threaddia. x pilch) (M20 x 1.5) (M20x 1.5) (M6 x 1.0) (M6 x 1.0)

7 Timar clamping nut

~g oi not appI ied

- -

6.0-7.0 6.0-7.0

(Thread dia. xpitch) {M12 x 1.75) (M12xl.75)

8 Glowplug

Lubricating oiI not applled 1.5-2.0 1.5-2.0

{Threa{j dia. >< pitchI (Ml0 x 1.25) (Ml0 x 1.25)

- -

9 Stub shaft boI t

LubricangoiI not applied 5.5-6.5 5.S-6.5

(Threaddia x p~ch) (Ml0 x 1.S) (Ml0 x 1.5)

- -

10

Govemor weight Lubricating oiI no! applied 7.0-7.5 7.0-7.5 4.5-5.0 4.5-5.0

supportnut (Thread dia. x pitch) (M12 x 1.25) (M12x 1.25) (M12 "X 1.25) (M12 x 1.25)

11

High pressure pipe Lubricating oil not appried 3.0-3.5 3.0-3.5 3.0-3.5 3.0-3.5

sleeve clamping nut (Threadda.)C pitch) (M12 x 1.5) (M12 x 1.5) (M12 " 1.5) (M12 x 1.5)

(Unit: kgf-m)

10. Tightening Torque

10-1 Main boltlnut

10. TlgIltBnIIlf TtlflllIf

8-9

(11) .Afler having reassembled 1hecylinder

heads, carryout conflrmation running

to see Hthey are free from leakage of

water and 011.

<:

3TNE78A

314TNE82

213TNE68 3TNE74

3TNE82A

314TNE84(T)

3/4TNE88

Tightening

3.8 ~4.2 6.0-6.5 6.8-7.2 8.7-9.3

torque

(kgf-m)

FO puma side

1

cr:

(4cyIlnder )

~

.

(3cyfinder)

~

.;

el>

-+---t- -;---.--- ~

g

O

FOpumpsidc

Camshaft side

(j)

<D

@

-8

@

.

@ ~

<ID

@

~

FO pump sde

Camshalt side

<ID

@

Camshaft sida

~

41

"O

v;

Q)

W

4i

<1)

( 2cylinder)

.,

~

ni

l

1.)

lij

:

@

<!I

O

Tighten cylinder heads in numerical arder shown below to the specified torque.

(10) Order of tightenlng cyUnder heads

and tightenlng torque

8. DIsassembIy IntI RI88IItHfIbJy

Alignment mar!<

14---Embossedmark

(Fiywheel side)

8-8

Rywheel siete

Cy~nder

size mar\(

1.0. mark

<1)

'O

.;

!2

N

N

o

Z

Cylnder

size ma/f( Flywheel 6ide

1.0. mar k

3TNE78A,3TNE82A,~4TNE82

3/4lNE84(T), 3f4TNE88

213TNE68, 3TNE74

(9) Assembly directlon of plston and connecUngrod

Apply lubficating oil

Appty J ubrca11ngoil to thehatched portiOn

of Ihe push rodas shown inthe figure, before

reassembly.

(8) Coatlng the lubrlcatlng oil to

pushrod adJ ustlngscrew eontact

,. Dfsassem tJfy andReassembly

8-5

Step RemovaJ Parts Remarks

Apply adial gauge 10the endof crankshaft @ . force

Ihe crankshaft on both sides in the axial direclion 10

measure thethrust gap. AJ ternatillely, nsenathlckness

gauga directly between the base Ihrust metal and the

thrust suriace of {he crankshaft lo measure the gap.

Ifthe limitsize is exceeded, (aplace Ihethrust metatwith

a newone.

(mm)

--

Al! models

-_

Thrusl gap 0.090 - 0.271

2. Notice on the removal of thrust metal @.

{1) When removing thrust metal @ , ascertatn the

position anddirection wnere thrust metal is installed

in relation to the cap.

(2) Make surethat tne thrust metal groove ts outward in

relalion lo the cap.

24 1. Removepiston @ andconnecling 1. To selectillely remolle a desired pistan and connecting

rod @ asserroiy. rod assembly without extracling crankshafl @ , take

the steps itamizad below:

(t) Hemove carbn deposits fromlhe upper wall of the

cylinder using fine sandpaper, taking care not to

damage the inner surtace of the cylinder.

(2}While turning the crankshaft, with the crankpin side

cap ~ removed, raisethe pisten up10ths lop dead

center (TDe).

(3) Extract the pistorVconnecting rod assembly while

tapping the connecting rod at the largeendwilh

the handle of a plastic hammer or the like.

25 1. Bernove lappet @J .

8. O l s a s s e m 1 J 1 y a m i R n s s e m t J / y

8 2

2. Remove cylindef head assen1J ly

@.

3. Remove cylinder headgasket @.

Camshah siete

~

@

a>

"O

.;

'" @

@

'i

~

- - -

III

oC

@

@ @ (j)

o

.t

ii

u.

@ ~

Fuel injection pump side

Camshalt side

~ e

@ @

a>

@

"O

.;;

<D

@ @

.

1

Q)

.

-

-

~ ..c

@ @ @

@

< ID

~ ~

ir

@ @

Q >

o

Fuer inecliOn pump side

t. Lay a cardbOard or the like on the floor and place

cylinder head assernbly @ on it so as net to damage

the combuslion surtace.

2. Order 01 loosening the cyllncler head tighlening bcns

1. Remove cylinder head tightening

boll .

10

9 1. D isconnect cooling water pipe @

from the oool;ng water purT'p.

2. Removethermostat assembly @.

3. Remove coollng water pump @.

2. Remove fuel filter @.

8 1. D isconnect fuel retum pipeS @ to

@.

7 1. Remove lubricating oil filter assem-

bly @l.

2. EXlractdlpstick @ fromtheoildip-

stick hole.

1. Never tum down alternator @ vigorously toward Ihe

cyllnder block. Otherwise, your finger may be nipped

and alternator @ broken.

6 1. Remove tan mounting balt @ I

andthenremovefan ~.

2. Loosenadjuslingboll @ torlheV-

belt adjuster, and lhen remove V-

beh 4]).

3. Remove allernator @.

4. Remove the spacer for cooIing fan

@ and V-pulle)' @.

Step Removal Parts

Remarks

Camshalt side

~

o

:2

.;

@) @ '"

Q ~

Q )

- -

t1I

s:

@

< D

Q

~

t;

,

ro

111

C)

Fuer injeeticn pump side

8. Dlsassembly Ind Reassemflly

7-26

Direction 01rolation

*PTO (oplion)

Camshaft gear

Fue! injection pump drive gear

(V1ewthe gear case)

4. Geartran

After ins1alling each gear, make sure that

aligning marks @,@ano 01the diegear

are aligned with those of the fuel injection

pump gear, cam gear and crank gear .'

7. Mnsating Procedure. Servlce Data 1M COrree/TveAclion

7-25

(DirectInjecllon systsm)

(rndJ rectInjectlon systern)

(2) Make sure that the ol hale of the idlegear

shaft ano bushing is a through hale.

r.

3TNE 78A182A.

213TNE 68, 3/4TNE 02.

3TNE 74 3i4TNE 84(T).

3t4TNE 88

Wear Wear

Slandard r . Standard r '1

umt um

Shaft outside 19.959

19.93

45.950

45.93

dia. -19.980 -45.975

Idle Bushing 20.000 46.000

46.0B

inside da. -20.021

-

-46.025 gear

Ol clearance

0.020

0.15

0.025

0.15

-0.062 -0.075

3. Checking and measuring the idllng

gear shaft and idling gear

(1) Measure the bushing nsdediameter ano

the idle gear shaft autside diameter, and

replace the bushing 01" idling gear snan it

the ail clearance exceeds the wear limit.

(mm)

-------......_

3TNE 78A182A.

2/3TNE68. 314TNE 82

........----.., 3TNE7"

314TNE 84!T),

314TNE 88

Crrishaft gear,

Camshaft gear.

0.04-0.12 0.07-0.15

8ack-

!dieggar and

lash

Fue! injection

pumpdrivegear

L.O. pumpgear 0.11-0.19

(mm)

2. Mes8urlng too backrash

Apply adial gauge ontothepitch cuele ofthe

gear, and measure Ihe backlash.

1. Checking gears

Inspectthegears andreplace if theteethare

damaged, wom. or chipped.

7. Measurfau Procedure, Serv/ce Dsls Bnd Cart8ctlve A&lion

7-8. Gears

(Measuring the crankshaft bend)

V-block V-bleck

Dial gauge

Dellectien

----. . . . . . . . . _

Al! models

"~. . . . . . . . . . '"

- . . . . . . . .

Standard

<. . ,

Bene! 0. 02or J ess

(mm)

4. Bend 01the crankshaft

Support the crankshatt with V- blocks at

botnendsofthe journals; measuretherunout

at the center journal with a dial gauge while

rotating tne crankshaft to check the extent

of crankshaft bend.

3. Ctlecking the metal

Checkthametal forflaking, melting, saizure.

and the state of the contact face. Replace

the metal i1found defective.

(Color check lnspectlon)

7-22

2. Color check of crankshaft

Clean the crankshaft and check it using a

color check kit or a magnaflux inspector,

Replace the crankshaft if cracked or badly

damaged. I f the cranksnart is slightly dam-

aged. correet it by re- grinding.

Craokahaf t

Thrust gap

AII models

- - - - - - - 0. 090-0. 271

(mm)

1. Side gap around the crankshaft

Before extracting the crankshaft and when

reassembling it, bring -a dial gauge Into

contact to the end of the crankshaft Force

the crankshaft to both sides in me axial

direction to rneasure the thrust gap. A1ter-

natively, insert a thickness gauge directly

into athrust gapbstween the thrust metal in

thestandard part anderankshaftto measure

the side gap.

If the limit is exceeded, replace the thrust

metal with a new ona.

7-7. Crankshaft

7. MUsurlng PrDC4r1ure,Serrla Data aooCorrecfive Aman

7-19

(Measuringtheconnecting rod slde gap)

0.2-0.4 Side gap

AII modsls

(mm)

7. Sldegap01the connecting rod

After attaching the connecting rod lo the

crankshaft, tighten the rod bolt tothe speci-

fiedtorqua (see this seetion3). Measurethe

side gapby insertngathekness gauge into

the side gap. lf the standard 15excesded,

replaee the crankpn metal or connecting

rod.

1.0. mark

Combustion

chamber recess

(Indirect InjecUonsystemplston)

Camshalt sicle

,

(Dlrect Injectlon systemplston)

6. ASsembling,heplstonandconnectlng

rod

Assemble the piston with the connectng

rod, with tne mark at the big end of the

connectingrodfacingthefuel injectionpump.

Reassemble the pistonso thatthe recess of

thecombustion chamber is onthesideofthe

fuel injection pump as seen fromthe topo

Crankpin metal

Assemblsso

!hatIhlit PlJ ndled

mark01larga

end faces !he

fuel~cction

pump.

7. MJasuring Proctdure, Serv ce Data and Corre&UVBA&/ion

7-17

I~

3/4TNE82,

2I3TNE68 3TNE7BA 314lNE84(T1,

STNE74 3TNE82A 3/4TNE88

SpeclfiBd torque

Aod bolt ligllten-

ingtorqU9

2.3-2.8 3.8~4.2 4,5-5,5

(AppIy lube oil

to the roo batt)

(kgf-m)

(

Measuringthe inside diameter of )

the crankpln metal

3. Measuring the crankpln and bushlng

clearance

To measure th oi!clearance 01the crank-

pin and bushing, measure the lnslde diam-

eter 01 the crankpin metal and outside di-

ameter of the crankpin, and obtainthe difter-

ence between them.

If the measured oH clearance exceeds or

near the wear limit, replace the

crankpin metal. If the crankpin is exoes-

sively or unevenly wom, grind the crankpin,

and use an oversized crankpin metal.

* romeasure tne insidediameterofthe cfank-

pin metal, resssemote tne crankpin metal

ro tne connecttnq rod and tighten tne roo

bolt to tbe speciea torque, making sure

each metal is tittea on the corree! postuon.

(

Measutingthetwist with)

connecting red aligner

(Measurlngthe twfst and paranensrn)

~"-i

Al! rnodals

Standard

Wear

limil

Twis1and paraUelism

0.03 or lass

0.08

per 100 mm

(mm)

2_ .Measuring the twlst and parallellsm

Measure the twist and parallelism by use of

the connecting red a1igner.

1. Visual Inspection

Inspect the portion nearthe boundary ofthe

chamferedportion and I-beamsectionofthe

bigand small ends of the connecting roo as

well as the portion near the oi! hale of the

bushlng at the small end for cracks, detor-

mation. and discoloration.

7. Measuring Procedure, Service Dais ami COlrect;veAtlion

7-5. Connecting rod

1-11

*1. Designation of engine dimension and dryweight in numerals.

CUCH applica1ion: engina with flywheel housing

VMNH application: angine with back plate/with flywheel hausing

-

Modal

4TNE88

118m Unt

Application - Cl VM

Type - Vertical. 4-cycle water-cooled diesel em:lne

Combus1ionsyslem

- Oirect ~ction s~

No. of cylinders - Bore x Stroke mm 4-8ax90

Dlsplacement e 2..189

Fring order

-

1- 3- 4- 2- 1

RevQlutionspeed rpm 1500 1600 2000 2200 2400 2.000 2800 3000

-

Continuous

kW(HP)

16.4 19.6

- - -

- - -

Output*

rating ( 22. 0) (26.3)

-

18.0 21.6 24.1 26.5 28.S 31.3 33.7 36.0

Max. rating kW(HP)

(24. t) (29.0) (32.3) (35.5) (38.6) (42.0) (45.2) (48.3)

Max. rsvoufion speed al

1575~ 1870sg 2180o s : ; 2400+s g

2590"~ 2810s g 2995"~

3210+5g

no load

Min. revolution speed at

rpm

no load

~1200 ~800

Direction 01rotation - Counterclockwise (viewed from flywt1eel)

Power take off - Flywheel

e n

Compression ratio - 18.0

z

O

Fue! injection timng

~

(FID, b.T.O.C.)

deg 101 121 14t 161

o

Compression pressure MPa

e

3.43O.1(351). al 250 rpm

(3 (kg Vcni)

Ul

Fuel nJ ecHonpressure MPa

19.6+1.~(200+'~) 19.6+l.g (200+1~)

o .

sn

I(kgf/cm2)

Recommended diesel gas oil

-

ISO ~17 DMA. BS 2869Al or A2 (Cetane No. 45 mio.

lubrlcation svstem - Forced lubrication with trochoid pump

lubrcating oil capacity

e 5.8/2.3 7.912.5

MaxJ Effective

Recommended lubric81ing oi! - API grade CC csassor hig_her

Cooling system - Liquid cooling/Radiator

Cooling water capacity 2.7 (for ertgine onJ y)

._

e

Coolingfan

mm Pusher type. 6 x ~370

No. of blade x dla.

Crank V-pulley dia.!

mm ~120/~ 911019110

Fan V-pulley dia.

Governor

- Machanical centrif~al~vemor (AII SQ_ged tvDe)

Starting system

- Electrica'

*1Dimensions L x W x H

mm 683x498.5)( 618 632 x498.5 x618(658 x498.5 x618

! f e1Ory weight k g 184 160 /170

Transient speed

% :;;10 ~8 ~12

dfference

LU Governing

S1eadystate

1

o

perform- % ss s 4 s s ~ !J

z speed band

~

anCQ

a:

(tull speed

Recoll8ry tlme sec s s s s

~

ranga)

-

a:

Fluctuatian of

rpm ~15 525

Ul

revolut;on

CL

Rated opereton

MPa

0.29: : 0.05 0.34O.O5

L O; pres s . (3.0o.S) J .3.5O.~

Idling

(kgl/cm2)

~0.06(~.6)

*Output conditions: Intakeback pressurs ::;250 mmAq,Exhausl back pressure $550 mmAq, .

otherconditionsoomlllyingwith J ISDl00s....:19B6. Afterminimum30hour'srun;n.

1-11. 4TNE88

1. Spe &lication ssn d p.n "n n an ce

6-3

Abnormal

2. Make sure that the valve cap 15nested en

the head 01intakelexhaust valves.

*: 1. J I tne va/ve cap is wom or etherwise

damaged on me head, replaes I t wlth a

new one.

0.15- 0.25

Intake/exhaust valve

head cfeaarance

AII models

(AdJ ustlng the valve head clearance)

(mm)

Lock nut

Ac:fJ Uslingscrew

(4) Insert a thickness gauge in between the

rccker armand vave cap. Tighten the

adjusting screw until the clearance listad

below 15attalned.

(3) Loosen the J ocknut and adjusting screw.

Maka surs that the valve cap is free from

inclination or trapped dirt.

Norm91

(2) Raiga the piston in the cylinder lo be

measured lo the top dead center (TOe)

of compresson.

(1) Inspect and adjusta vavehead cJ earance

while the angine is in cold state.

6-2. Adjusting the valve head

clearance

6. Measurement. I nspectlon and A dJ ustment

6 9

(4) If the measured injeerion timing differs

fromthe specified timing, adjust the njec-

tion timing byturning down the fuel injec-

tion pump toward the engine or to

the opposte sida after loosening the lock

nut of the fuel injection pump.

1 1 injection timing ts late, turn down the

fuel In~tion pumpawayfrom theengine.

11the injection timing too ear1y,turn the

injection pump down toward the englne.

Timing mark

Acoesshale

(2) When thecrankshaft is turnedintoo speci-

fieddreccn, the olllevel risesat the tip of

the delivery valve spring holder. Al tnat

time, stop the crankshaft.

(3) Identify the timing mark stamped on the

flywheel through the access hola ct tila

flywhBel housing.

*: ForfuelinjectiontimingforeachenginemodeJ,

reter to cnepter 1 , Specifications and

Performance.

2. Olrect In,ecdan system

(1) Using the crankShaft pUlley. turn the en-

gine In the specified direction. Check ttte

inj9Ctiontiming at the dellvery valve of the

fuellnjection pump for cyUnderNO.1.(Cyl-

inders are numbered se-quentially frorn

cylinder No. 1fromthe flywheel soe).

6. Measurement, InspectlDII BRdAdjuSlmeDl

You might also like

- LeeBoy Hatz Engine Service Electrical Sytem ManualDocument309 pagesLeeBoy Hatz Engine Service Electrical Sytem ManualJonathan Canton Avendaño100% (9)

- Engine Valve Lash ADJUST C27 C32Document5 pagesEngine Valve Lash ADJUST C27 C32manu luvunga100% (1)

- Perkins 1100 SeriesDocument48 pagesPerkins 1100 Seriesjrodríguez_658168100% (4)

- John Deere Service Manual JD S ctm3 PDFDocument25 pagesJohn Deere Service Manual JD S ctm3 PDFDavid Ramirez0% (1)

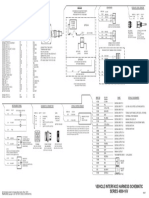

- SERIES 4000-16V Vehicle Interface Harness SchematicDocument1 pageSERIES 4000-16V Vehicle Interface Harness Schematicluna281068No ratings yet

- Perkins 1104DDocument158 pagesPerkins 1104Dsj1202100% (17)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Cat 3204 Specifications Manual AbbyDocument43 pagesCat 3204 Specifications Manual AbbyMarcos100% (3)

- 1104 Troubleshooting PERKINS PDFDocument220 pages1104 Troubleshooting PERKINS PDFAhmed Gad100% (2)

- Perkins 900 Series CR 3 Cylinder Diesel Engine Service Repair ManualDocument35 pagesPerkins 900 Series CR 3 Cylinder Diesel Engine Service Repair ManualBobCav57% (7)

- Kubota 1505 Workshop ManualDocument124 pagesKubota 1505 Workshop Manualsolserengsa85% (13)

- O MM 8060 Series Iveco MotorsDocument79 pagesO MM 8060 Series Iveco Motorsfishhunter18100% (3)

- Perkins Seria 400 C Typ H... MANUALDocument108 pagesPerkins Seria 400 C Typ H... MANUALjwdNo ratings yet

- Technical Repair Manual N45 N67 ENU 426Document426 pagesTechnical Repair Manual N45 N67 ENU 426Вячелав Егоров100% (1)

- Perkins Engine Number & Location Guide.Document5 pagesPerkins Engine Number & Location Guide.scribdadiddly100% (1)

- Detroit ManualDocument435 pagesDetroit Manualvictorhernandezrega50% (2)

- Parts Catalogue: 4TNV98T-GGEDocument35 pagesParts Catalogue: 4TNV98T-GGEVitorMello80% (5)

- Iveco F4ge PDFDocument142 pagesIveco F4ge PDFHandy Lee67% (3)

- 400d Cat c2.2 Shibaura Perkins PDFDocument108 pages400d Cat c2.2 Shibaura Perkins PDFIV FV100% (9)

- Alpha Series Workshop Manual: Lpa, LPW, LPWT, Lpws and LPWGDocument109 pagesAlpha Series Workshop Manual: Lpa, LPW, LPWT, Lpws and LPWGAndres Huertas100% (1)

- Perkins Series 400 Injection AnglesDocument40 pagesPerkins Series 400 Injection Anglesbudimir231083% (6)

- Lighting Tower 3TNV76Document288 pagesLighting Tower 3TNV76rezandriansyahNo ratings yet

- Yanmar Manual Motori PDFDocument136 pagesYanmar Manual Motori PDFAhmer Camdzic50% (2)

- Perkins 1103 &1104 Series: Workshop Manual SpecificationsDocument42 pagesPerkins 1103 &1104 Series: Workshop Manual SpecificationsTASHKEEL100% (6)

- LOVOL Workshop ManualDocument293 pagesLOVOL Workshop ManualWernerw100% (6)

- 3054E and 3056E Industrial Engines-Engine SafetyDocument12 pages3054E and 3056E Industrial Engines-Engine SafetySantiago Capiato33% (3)

- Bosch Diesel Catalogo 15-02-07 PDFDocument126 pagesBosch Diesel Catalogo 15-02-07 PDFluna281068100% (3)

- Nissan BD30 Valve Adjustment Procedure, Valve Lash Clearance Specifications, Nissan BD30 Engine Parts ContactDocument1 pageNissan BD30 Valve Adjustment Procedure, Valve Lash Clearance Specifications, Nissan BD30 Engine Parts ContactLuis BastardesNo ratings yet

- Kubota Engine SpecsDocument84 pagesKubota Engine Specsjmbcp96100% (1)

- Resumen Cummins b3.3Document6 pagesResumen Cummins b3.3rectificamosNo ratings yet

- Mitsubishi s4s CatalogDocument142 pagesMitsubishi s4s Catalogbga187535100% (9)

- Perkins 1104D Repair Manual PDFDocument43 pagesPerkins 1104D Repair Manual PDFSergey100% (5)

- B/FL/FM 2011: Operation ManualDocument60 pagesB/FL/FM 2011: Operation Manualstephen prosser75% (4)

- Asme B18.12-2020Document113 pagesAsme B18.12-2020윤규섭0% (1)

- Engine: Engine Model: 4Tnv88-XybDocument216 pagesEngine: Engine Model: 4Tnv88-Xybjulianmata100% (3)

- Single Core Compacted Aluminium - HT Cables - Stainless Steel WiresDocument7 pagesSingle Core Compacted Aluminium - HT Cables - Stainless Steel WiresWires CableNo ratings yet

- 4LE2 Parts CatalogDocument45 pages4LE2 Parts CatalogKevin LiuNo ratings yet

- Kubota V3300Document45 pagesKubota V3300moises75% (4)

- Kubota v3300 SMDocument140 pagesKubota v3300 SMjosephvanbac100% (3)

- Parts Catalogue: 3TNV76-GGEDocument31 pagesParts Catalogue: 3TNV76-GGEmessaoudiNo ratings yet

- Codigos de Fallas Mtu Mdec 2 PDFDocument32 pagesCodigos de Fallas Mtu Mdec 2 PDFluna281068100% (1)

- Avr R449 LeroyDocument24 pagesAvr R449 Leroyluna281068No ratings yet

- Workshop Manual 2G e Motores HatzDocument161 pagesWorkshop Manual 2G e Motores HatzLuis Enrique Peña100% (3)

- Td122 Engine Tighteting RorquesDocument2 pagesTd122 Engine Tighteting RorquesFilipposNo ratings yet

- 03-03MM Series Torque SpecsDocument4 pages03-03MM Series Torque SpecsJuan Pablo urria schwarzenbergNo ratings yet

- Huafengdongli 495 4100 Series OperationmanualDocument126 pagesHuafengdongli 495 4100 Series OperationmanualEngr Osama Khan100% (5)

- Kubota Manual 9Y011-02153 PDFDocument124 pagesKubota Manual 9Y011-02153 PDFMiguel Chacon100% (2)

- Perkins HP 403 Parts ManualDocument123 pagesPerkins HP 403 Parts ManualynadeemNo ratings yet

- MS150025 02eDocument187 pagesMS150025 02eDhanraj Patil0% (1)

- Operation Manual K-Series 4 LanguagesDocument182 pagesOperation Manual K-Series 4 Languagesratooren100% (4)

- Injector Installation 107 EngineDocument5 pagesInjector Installation 107 EnginevalterripNo ratings yet

- Deutz Operation Manual 2011Document69 pagesDeutz Operation Manual 2011andrei20041100% (3)

- Keil Undercut AnchorsDocument16 pagesKeil Undercut AnchorsTracyval CadaNo ratings yet

- MOS Main Truss Bridge Rev 01Document35 pagesMOS Main Truss Bridge Rev 01Ami ShafiNo ratings yet

- 3TNV76 HgeDocument33 pages3TNV76 HgeJoan Gene100% (3)

- MWM 616V16Document107 pagesMWM 616V16Dhudhik Arief Hadiyanto100% (2)

- Casting Fundamentals and Basics ConceptsDocument68 pagesCasting Fundamentals and Basics Conceptsquiron2010No ratings yet

- EMD, Special ToolsDocument116 pagesEMD, Special ToolsMaurice Connor81% (16)

- IVECO 8031I06.05 y 8031I40.05 Especificaciones PDFDocument6 pagesIVECO 8031I06.05 y 8031I40.05 Especificaciones PDFJorge Luis BahamondeAzcarate50% (2)

- Mitsubishi Engine k4c k4d K4e k4f Mm201422Document151 pagesMitsubishi Engine k4c k4d K4e k4f Mm201422Bojan BorkoNo ratings yet

- en WHB Hatz W35 PDFDocument76 pagesen WHB Hatz W35 PDFpricopdaniel100% (3)

- Motor Yanmar 4tne88 (Komatsu 4d88e)Document28 pagesMotor Yanmar 4tne88 (Komatsu 4d88e)FILO7433% (3)

- John Deere 4039 TDocument63 pagesJohn Deere 4039 Tluna28106833% (3)

- 6bt Valve Lash PDFDocument7 pages6bt Valve Lash PDFmilNo ratings yet

- 19.cylinder Head AssemblyDocument7 pages19.cylinder Head AssemblyMohamad ZuhailiNo ratings yet

- MT PDFDocument66 pagesMT PDFRolfs Almonte DiazNo ratings yet

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pages2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozNo ratings yet

- Crankshaft - InstallDocument5 pagesCrankshaft - InstallalonsoNo ratings yet

- Ec10d 1Document9 pagesEc10d 1Guido Leonardo EnriqueNo ratings yet

- Torque Converter, Transmission and Bevel Pinion: Bottom Removal (Preferred Method)Document12 pagesTorque Converter, Transmission and Bevel Pinion: Bottom Removal (Preferred Method)ait mimouneNo ratings yet

- Installation Procedure: NoticeDocument3 pagesInstallation Procedure: NoticeGlaidsonNo ratings yet

- CAT C27 - C32 Ajuste La Luz de ValvulasDocument5 pagesCAT C27 - C32 Ajuste La Luz de ValvulasGdar KbzaNo ratings yet

- E Mopi TS005 eDocument8 pagesE Mopi TS005 emikestifflerNo ratings yet

- Engine Completion Information: To: All Deutz Parts Managers / Engine Sales ManagersDocument2 pagesEngine Completion Information: To: All Deutz Parts Managers / Engine Sales Managersluna281068No ratings yet

- Section 9 - Parts: (Mexico)Document11 pagesSection 9 - Parts: (Mexico)luna281068No ratings yet

- Parts Policy Information: Attention: Purchasing / Parts ManagersDocument1 pageParts Policy Information: Attention: Purchasing / Parts Managersluna281068No ratings yet

- Section 9 - Parts: (North America)Document11 pagesSection 9 - Parts: (North America)luna281068No ratings yet

- Parts Policy Information: To: All Deutz Parts Managers Re: Addition To Parts Rebate PolicyDocument1 pageParts Policy Information: To: All Deutz Parts Managers Re: Addition To Parts Rebate Policyluna281068No ratings yet

- Parts Policy Information: To: All Deutz Distributors Re: 2001 Parts Policy ChangeDocument1 pageParts Policy Information: To: All Deutz Distributors Re: 2001 Parts Policy Changeluna281068No ratings yet

- ETL Yanmar Schneefraese YSR 3120 - 3420Document73 pagesETL Yanmar Schneefraese YSR 3120 - 3420luna281068No ratings yet

- 2506C E15tag2Document2 pages2506C E15tag2luna281068No ratings yet

- Section 11 - Engine Completion: Stock OrderDocument2 pagesSection 11 - Engine Completion: Stock Orderluna281068No ratings yet

- Parts Policy Information: "Dealer Compensation Policy Change"Document1 pageParts Policy Information: "Dealer Compensation Policy Change"luna281068No ratings yet

- Avr Ea05afDocument1 pageAvr Ea05afluna281068No ratings yet

- Ford CrossRef PDFDocument4 pagesFord CrossRef PDFLuisYFer1No ratings yet

- Valores Limites ShutdownDocument1 pageValores Limites Shutdownluna281068No ratings yet

- Canbus Wiring For DSE Controllers Issue6 20110719 PDFDocument87 pagesCanbus Wiring For DSE Controllers Issue6 20110719 PDFmanuelbeasNo ratings yet

- Operator's Manual: Power Systems, IncDocument28 pagesOperator's Manual: Power Systems, Incluna281068No ratings yet

- 3tne84mt Ek PDFDocument29 pages3tne84mt Ek PDFluna281068100% (1)

- Countryman Manual (Eng) (13204)Document30 pagesCountryman Manual (Eng) (13204)Moz NazNo ratings yet

- Bukti 5.3a - Manual Sheet Bagi Rekabentuk Awam5Document1 pageBukti 5.3a - Manual Sheet Bagi Rekabentuk Awam5Azizi RazakNo ratings yet

- Blurred Transparencies in Contemporary Glass Archi... - (PG 76 - 127)Document52 pagesBlurred Transparencies in Contemporary Glass Archi... - (PG 76 - 127)sherinshaji2002No ratings yet

- Casing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogDocument3 pagesCasing Centralizer Series - 1 - Types of Centralizers - Pegasus Vertex, Inc. - BlogNihad PaşazadəNo ratings yet

- Marshal Stability TestDocument1 pageMarshal Stability TestAenan BashirNo ratings yet

- Quick SeriesDocument46 pagesQuick SeriesIrfan PoeNo ratings yet

- Astm B566 93 2002Document2 pagesAstm B566 93 2002rahittNo ratings yet

- Training Manual: EASA Part-66 38 Level 3Document24 pagesTraining Manual: EASA Part-66 38 Level 3Luis Enrique La Font FrancoNo ratings yet

- 2011 UK Waste WoodDocument31 pages2011 UK Waste WoodStuart JonesNo ratings yet

- Calculation Rail Beam (Hoist Capacity 3 Ton)Document4 pagesCalculation Rail Beam (Hoist Capacity 3 Ton)Edo Faizal2No ratings yet

- A Performances Study On GGBS With Alccofine - Based High Strength Self-Compacting ConcreteDocument5 pagesA Performances Study On GGBS With Alccofine - Based High Strength Self-Compacting ConcreteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Slab With ReportsDocument36 pagesSlab With ReportsER Manish MakhijaNo ratings yet

- Chemdur - 42 RHDocument3 pagesChemdur - 42 RHICPL-RWPNo ratings yet

- GVAR210 Exploded ViewDocument4 pagesGVAR210 Exploded ViewUEENo ratings yet

- Quantity Surveying and Contract Management NotesDocument83 pagesQuantity Surveying and Contract Management NotesMohammad AliNo ratings yet

- Manningham Appendices GlossaryDocument24 pagesManningham Appendices GlossaryHarshit RathoreNo ratings yet

- Yangpu Riverfront South Section Phase IIDocument49 pagesYangpu Riverfront South Section Phase IIJitenra KhatriNo ratings yet

- Bridge Types: CIL (COWI India Pvt. Limited) - Bridge DepartmentDocument29 pagesBridge Types: CIL (COWI India Pvt. Limited) - Bridge DepartmentvikramannNo ratings yet

- Feasibility OutlineDocument20 pagesFeasibility OutlineAlyyssa Julfa ArcenoNo ratings yet

- AD AUSAT Reviewer - Dimensions: Study Online atDocument2 pagesAD AUSAT Reviewer - Dimensions: Study Online atGrace ComiaNo ratings yet

- FM9 Rev 1 ManualDocument30 pagesFM9 Rev 1 ManualTomaszNo ratings yet

- QA&QC D2020.15060-Pipes & Pipe Fittings EDITEDDocument4 pagesQA&QC D2020.15060-Pipes & Pipe Fittings EDITEDbryesanggalangNo ratings yet

- Anclajes Al Terreno DELFTDocument46 pagesAnclajes Al Terreno DELFTRankineNo ratings yet

- Hardware Catalogue 2020Document24 pagesHardware Catalogue 2020reynaldo widiantoNo ratings yet

- HML Estimate Ambakanti ThandaDocument22 pagesHML Estimate Ambakanti ThandanayaninikshilreddyNo ratings yet