Professional Documents

Culture Documents

Lecture - 19 Applied Rheology 3

Uploaded by

dev11739Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture - 19 Applied Rheology 3

Uploaded by

dev11739Copyright:

Available Formats

Applied Rheology in Polymer

Processing

Rheological systems

Purely Elastic Behaviour

Purely elastic response of materials is characterized by their stress

strain curves

Different materials give different stress-strain curves, for example

brittle materials and metals and alloys are characterized by high

stress and low strain but brittle plastic suffer the brittle failure

whereas the metals undergo yield i.e. the ductile failure.

The rubber and rubber like materials show low stress and very

high elongation and their stress strain curves pass through a number

of stages.

The cross linking or vulcanization increase the stress valves but

reduces the elongation where as the fillers give the similar effect but

to the lesser extent.

Rheological systems...

Purely Viscous Behaviour

Purely viscous behavior is characterized

by the dependence of shear stress on the

rate of shear (also sometimes written as

the rate of deformation or the shear rate).

The liquids are capable of sustaining

infinite deformation and the linear

relationship between shear stress, and

the rate of shear is the well known

Newtons law of viscosity representing the

Newtonian flow behaviour.

The behavior of such fluids can

be best demonstrated by shearing

a fluid between two parallel plates

Viscous deformation

Purely Viscous Behaviour...

If the distance between the plates is y and a force F is

applied to the top of surface area A so that it moves

with a velocity of Vx with the lower plate being

fixed, the shear stress and the rate of shear can be

calculated and the relationship between them can be

written

Most of the low molecular weight liquids organic

solvents and dilute solution of polymers follow this

equation. The viscosity for these liquids is constant

over the entire range of rate of shear at a particular

temperature.

A plot of shear stress and rate of shear gives a

straight line passing through the origin and the slope

of the line is the viscosity of the fluid.

Time independent non-Newtonian fluids

A large no of liquids like polymer and rubber

melts, concentrated polymer solutions, solid

suspensions and slurries invariably do not follow

the Newtons law but show the viscosity to be a

function of rate of shear, only. Such fluids are

known as the time independent non Newtonian

fluids.

For these fluids the viscosity is either found to decrease

with rate of shear as in the case of pseudoplastic fluids or to

increase in the case of dilatent fluids.

The Bingham plastic fluids on the other hand demonstrate

the existence of yield stress , i.e. to say that these fluids

require a definite amount of energy before they start flowing

and then flow as Newtonian fluids.

Some polymer melts may flow as pseudoplastic liquids after

yielding, these are known as plastoviscous or viscoplastic

fluid.

Pseudoplastic fluids

The viscosity of these fluids reduces with the shear

rate and the curve of shear stress versus rate of

shear is concave downwards.

A log log plot of shear stress and rate of shear

clearing show three different regions. These are

A low shear region of a small range with the

slope of the line =1, known as the first

Newtonian region

An intermediate shear region with line of slope

<1 known as pseudoplastic or shear thinning

region and

A high shear region with slope of the line again

=1 known as second Newtonian region

Plot of ln versus ln for

Pseudoplastic fluids

Pseudoplastic fluids...

Depending on the type of polymer the slope of

the line in the intermediate region many vary

form just <1 to very close to zero.

The extent of pseudoplasticing or the shear

thinning behavior increases with the decrease in

the value of slope below 1.

The viscosity and shear stress or rate of shear

plot for such fluids shows a general nature with

the viscosity being constant at low shear region,

continuously falling in the intermediate region

and the again constant in the high shear region

particularly for the polymer solutions and low

molecular weight polymer melts.

Variation of viscosity with rate of

shear

Pseudoplastic fluids...

Such a behavior can be explained by

assuming that in the polymer melts and

solutions, which show shear thinning

nature the macromolecules or the

particles are completely random in the

spatial orientation when at rest Fig a) and

are bound by weak intermolecular forces.

When the applied stress is relatively low

the molecules maintain their randomness

and the molecular forces do not allow

them to be oriented in the direction of

force resulting in constant viscosity in this

region.

Pseudoplastic fluids under shear

deformation

As the shear rate increases the polymer molecules

start orienting in the direction of flow. As the

polymer system contains a molecular weight

distribution the small molecules, which require less

energy to change the direction start orienting,

initiating the reduction in the viscosity. The high

molecular weight molecules have very long coiled

chains, which are entangled with each other. these

molecules require higher energy for

disentanglement, uncoiling and then orientation.

Pseudoplastic fluids...

As the shear stress and shear rate

increases further the system is subjected to

increasingly higher energy for deformation

resulting in more and more molecules

being oriented.

The resistance to the flow of the oriented

molecules is reduced due to the fact that

the oriented molecules can slip past each

other with relative ease. This gives a

continuous decrease in the viscosity till all

the molecules are oriented at some higher

value of rate of shear.

Beyond this value of rate of shear there is no

further increase in the extent of orientation of

molecules and the systems show a constant

viscosity or the second Newtonian region.

The greatest man of our times.

- Einstein called Gandhiji

The real hero of Mine.

- Obama called Gandhiji

Mohandas Karamchand Gandhi was the

preeminent leader of Indian independence

movement in British-ruled India.

Born: October 2, 1869, Porbandar

Assassinated: January 30, 1948, New Delhi

Spouse: Kasturba Gandhi (m. 18831944)

Parents: Karamchand Gandhi, Putlibai Gandhi

You might also like

- Orifice Plate Flow Calculator Pressure DropDocument6 pagesOrifice Plate Flow Calculator Pressure Droplutfi awnNo ratings yet

- Procees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetDocument17 pagesProcees Design of Centrifugal Pumps - Sizing and Specification SpreadsheetMagesh leoNo ratings yet

- Hydaulics Engineering Sample ProblemDocument5 pagesHydaulics Engineering Sample ProblemTabbyNo ratings yet

- RHEOLOGYDocument39 pagesRHEOLOGYraju niraulaNo ratings yet

- Sanitary Survey of Drinking WaterDocument19 pagesSanitary Survey of Drinking Waterahmad shodiqNo ratings yet

- Rheology of Pharmaceutical FormulationsDocument95 pagesRheology of Pharmaceutical FormulationsHuma Hameed Dogar40% (5)

- Vicosity of FluidsDocument31 pagesVicosity of Fluidsusman_uet08100% (2)

- Viscosity MeasurementDocument20 pagesViscosity MeasurementMohit Awasthi100% (1)

- RheologyDocument67 pagesRheologyLaiq Khan100% (4)

- Viscosity Concepts and Fluid Flow ModelsDocument31 pagesViscosity Concepts and Fluid Flow Modelsanjaneya mishraNo ratings yet

- Chapter 4. Analysis of DamsDocument2 pagesChapter 4. Analysis of DamsJames Fontanilla Cudal Jr.100% (1)

- Rab Igm Dan Hydrant Rsud Kolaka Timurr 2023Document8 pagesRab Igm Dan Hydrant Rsud Kolaka Timurr 2023Asriawan darangaNo ratings yet

- Viscosity of Fluids-Newtonian and Non Newtonian Analysis As Applied To PlasticsDocument20 pagesViscosity of Fluids-Newtonian and Non Newtonian Analysis As Applied To PlasticsSushmaNo ratings yet

- Unit 2 Part 1 PhysicalDocument33 pagesUnit 2 Part 1 PhysicalRenuNo ratings yet

- RheologyDocument57 pagesRheologyAli AL-aqzam100% (1)

- Rhe OlogyDocument54 pagesRhe OlogyUkash sukarmanNo ratings yet

- Lecture 3Document28 pagesLecture 3EyasuNo ratings yet

- Rheology: The Study of Flow and DeformationDocument10 pagesRheology: The Study of Flow and DeformationKeith OmwoyoNo ratings yet

- Fluid MechanicsDocument25 pagesFluid MechanicsDominic GograNo ratings yet

- 07 - RheologyDocument58 pages07 - RheologyPuspa DasNo ratings yet

- Rheology I & IIDocument39 pagesRheology I & IIROSHAN P GOWDANo ratings yet

- Rheology: Essential Elements ..How Materials Flow 4 Essential Elements of Rheology AreDocument17 pagesRheology: Essential Elements ..How Materials Flow 4 Essential Elements of Rheology Arefakemoney makeNo ratings yet

- Rheology: Roselyn Aperocho-Naranjo Faculty, College of Pharmacy UspfDocument20 pagesRheology: Roselyn Aperocho-Naranjo Faculty, College of Pharmacy Uspfasit_mNo ratings yet

- RheologyDocument36 pagesRheologyAbdulAhadNo ratings yet

- MOMENTUM TRANSFER AND VISCOSITYDocument98 pagesMOMENTUM TRANSFER AND VISCOSITYMelita FernandesNo ratings yet

- CE2021 - Lecture 1Document41 pagesCE2021 - Lecture 1Akilan JenarththanNo ratings yet

- Understanding The Properties of Fluid and Rheology of Fluid FoodDocument19 pagesUnderstanding The Properties of Fluid and Rheology of Fluid FoodTanvir BhagatNo ratings yet

- Advanced Fluid and Heat Transfer (AE 6411) Lecture 1-1Document49 pagesAdvanced Fluid and Heat Transfer (AE 6411) Lecture 1-1Just DearNo ratings yet

- Fluid Mechanics: C.Suresh M140539MEDocument30 pagesFluid Mechanics: C.Suresh M140539MESureshSuryaNo ratings yet

- What Is Fluid?: Deforms Shear Stress Phases of Matter Liquids Gases Newtonian Fluids Non-Newtonian FluidsDocument13 pagesWhat Is Fluid?: Deforms Shear Stress Phases of Matter Liquids Gases Newtonian Fluids Non-Newtonian FluidsTan Wei TingNo ratings yet

- FALLSEM2022-23 BCHE205L TH VL2022230100718 Reference Material I 25-07-2022 Module 1-Basic Concepts of Momentum Transfer Part IIDocument40 pagesFALLSEM2022-23 BCHE205L TH VL2022230100718 Reference Material I 25-07-2022 Module 1-Basic Concepts of Momentum Transfer Part IILuha Fathima BasheerNo ratings yet

- 4th and 5th WeeksDocument57 pages4th and 5th WeeksnaverfallNo ratings yet

- Viscoelasticity and Viscoelastic Models in PolymersDocument52 pagesViscoelasticity and Viscoelastic Models in PolymerssoumyajyotideyNo ratings yet

- Fluid Properties ExplainedDocument41 pagesFluid Properties ExplainedP0130 ChandanaNo ratings yet

- CHEM 210 IR SpectrosDocument50 pagesCHEM 210 IR SpectrosHafiz Shoaib SarwarNo ratings yet

- Fluid Mechanics: Presented By: Engr. Franz D. SantosDocument68 pagesFluid Mechanics: Presented By: Engr. Franz D. Santoserick oracionNo ratings yet

- BFBM Unit - 2Document27 pagesBFBM Unit - 2Kripa NNo ratings yet

- Unit 1: Properties of FluidDocument37 pagesUnit 1: Properties of Fluidintustan leeNo ratings yet

- Fluid Mechanics - Physical Properties of FluidsDocument35 pagesFluid Mechanics - Physical Properties of FluidsAnustup MaityNo ratings yet

- Fluid 2 Project 1Document11 pagesFluid 2 Project 1Sanjay RagupathyNo ratings yet

- Factors Affecting Fluid ViscosityDocument12 pagesFactors Affecting Fluid ViscosityBF3nobelNo ratings yet

- Rheological Behavior of Polymers and ViscoelasticityDocument34 pagesRheological Behavior of Polymers and ViscoelasticityaymaNo ratings yet

- Rhe OlogyDocument48 pagesRhe OlogyAhmed ImranNo ratings yet

- Biofluid Mechanics Chapter 1Document72 pagesBiofluid Mechanics Chapter 1AbcdNo ratings yet

- ViscosityDocument20 pagesViscositymbakhshi2No ratings yet

- Fluid Flow, Mixing, and Bioreactor DesignDocument51 pagesFluid Flow, Mixing, and Bioreactor DesignAnimaNo ratings yet

- Project FluidDocument12 pagesProject FluidisyraffitriNo ratings yet

- Handout - Introduction To Fluid MechanicsDocument2 pagesHandout - Introduction To Fluid Mechanicskristine amerNo ratings yet

- Some Factors Affecting Viscosity in Newtonian FluidsDocument4 pagesSome Factors Affecting Viscosity in Newtonian Fluidsalexandre_motta_3No ratings yet

- M-2 Fluid Mechanics BasicsDocument56 pagesM-2 Fluid Mechanics BasicsPraveen KumarNo ratings yet

- RheologyDocument53 pagesRheologynurul jannahNo ratings yet

- Viscosity WikipediaDocument5 pagesViscosity WikipediaAlex GHNo ratings yet

- Module 1Document153 pagesModule 1Raj KashyapNo ratings yet

- Lecture - 16 Applied Rheology in Polymer ProcessingDocument12 pagesLecture - 16 Applied Rheology in Polymer Processingdev11739No ratings yet

- Me 361/3061 Fluid Mechanics: Chapter 1: Introduction and Basic ConceptsDocument21 pagesMe 361/3061 Fluid Mechanics: Chapter 1: Introduction and Basic ConceptsAhmet Yüksel ToprakNo ratings yet

- Fluids and Solids: FundamentalsDocument14 pagesFluids and Solids: Fundamentalsbiswajit_baruah6487No ratings yet

- Dr. Abitha Note 1Document36 pagesDr. Abitha Note 1Alkesh KNo ratings yet

- Unit 2 RheologyDocument25 pagesUnit 2 RheologyMutale InongeNo ratings yet

- Chapter 1Document47 pagesChapter 1Charbel KhouryNo ratings yet

- 11 - Rheology 2Document51 pages11 - Rheology 2amirNo ratings yet

- ICH 361 Polymer RheologyDocument9 pagesICH 361 Polymer RheologyOkolo GloryNo ratings yet

- Sifat Fisik FluidaDocument37 pagesSifat Fisik FluidaTheodorus SiboroNo ratings yet

- Fluid Mechanics 1 ME 321: Dr. M. Ehtisham SiddiquiDocument23 pagesFluid Mechanics 1 ME 321: Dr. M. Ehtisham SiddiquiMahtab IlyasNo ratings yet

- Liquid Glass Transition: A Unified Theory From the Two Band ModelFrom EverandLiquid Glass Transition: A Unified Theory From the Two Band ModelNo ratings yet

- Ministry of Culture: Required: District Youth CoordinatorsDocument1 pageMinistry of Culture: Required: District Youth Coordinatorsdev11739No ratings yet

- 6Document48 pages6dev11739No ratings yet

- 2nd SCH 2013-14 PDFDocument67 pages2nd SCH 2013-14 PDFdev11739No ratings yet

- 4th - QTR - Result2013-14 PDFDocument39 pages4th - QTR - Result2013-14 PDFdev11739No ratings yet

- 4th - QTR - Result2013-14 PDFDocument39 pages4th - QTR - Result2013-14 PDFdev11739No ratings yet

- 2nd SCH 2013-14 PDFDocument67 pages2nd SCH 2013-14 PDFdev11739No ratings yet

- Notification SAIL Management Trainee PostsDocument9 pagesNotification SAIL Management Trainee PostsAnusha PalakurthyNo ratings yet

- 4th - QTR - Result2013-14 PDFDocument39 pages4th - QTR - Result2013-14 PDFdev11739No ratings yet

- 4 PDFDocument12 pages4 PDFdev11739No ratings yet

- 3.1.1polymers in Everyday Things - Contact LensesDocument5 pages3.1.1polymers in Everyday Things - Contact LensesDhif MohamedNo ratings yet

- 4th - QTR - Result2013-14 PDFDocument39 pages4th - QTR - Result2013-14 PDFdev11739No ratings yet

- 5 2014 PDFDocument11 pages5 2014 PDFRajesh Kumar ChauhanNo ratings yet

- Block Diagram ReductionDocument7 pagesBlock Diagram ReductionMahendra Sutar100% (1)

- Chemical Treatment of Waste Water: Presented By:-Vinai Agarwal (Bt10Che084)Document10 pagesChemical Treatment of Waste Water: Presented By:-Vinai Agarwal (Bt10Che084)dev11739No ratings yet

- GATE 2016 Certificate From PrincipalDocument1 pageGATE 2016 Certificate From PrincipalPraveen KumarNo ratings yet

- Flow Chart Heat Equation (BT10CHE051) Prashant MeenaDocument1 pageFlow Chart Heat Equation (BT10CHE051) Prashant Meenadev11739No ratings yet

- Cen 03 - 2014Document12 pagesCen 03 - 2014dev11739No ratings yet

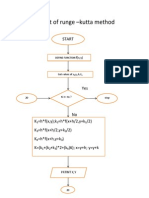

- Flow Chart of Runge - Kutta Method: StartDocument1 pageFlow Chart of Runge - Kutta Method: Startdev11739No ratings yet

- Sewage Sludge Incineration Processes and Emissions RegulationsDocument53 pagesSewage Sludge Incineration Processes and Emissions RegulationsTaufik Abdillah Natsir100% (1)

- Advantage Plus Consent LetterDocument1 pageAdvantage Plus Consent Letterdev11739No ratings yet

- Lecture - 20 Applied Rheology 4Document9 pagesLecture - 20 Applied Rheology 4dev11739No ratings yet

- Ozone DisinfectionDocument7 pagesOzone DisinfectionKwang Je LeeNo ratings yet

- Lecture - 17 B - Identification - of - PlasticsDocument22 pagesLecture - 17 B - Identification - of - Plasticsdev11739No ratings yet

- 02 5Document18 pages02 5dev11739No ratings yet

- Lecture - 18 Applied Rheology 2Document7 pagesLecture - 18 Applied Rheology 2dev11739No ratings yet

- Lecture - 15 Decorating PlasticsDocument24 pagesLecture - 15 Decorating Plasticsdev11739No ratings yet

- Applied Rheology in Polymer ProcessingDocument11 pagesApplied Rheology in Polymer Processingdev11739No ratings yet

- Lecture - 17 A - Identification of PlasticsDocument3 pagesLecture - 17 A - Identification of Plasticsdev11739No ratings yet

- Lecture - 16 Applied Rheology in Polymer ProcessingDocument12 pagesLecture - 16 Applied Rheology in Polymer Processingdev11739No ratings yet

- Exp F4 - System and Pump CharacteristicsDocument6 pagesExp F4 - System and Pump CharacteristicsMohamad IkhwanNo ratings yet

- Calculate Mixing Time With CFD ApproachDocument20 pagesCalculate Mixing Time With CFD ApproachNi'amNisbatulFathonahNo ratings yet

- Fuel Oil Pump House Data SheetsDocument9 pagesFuel Oil Pump House Data SheetsarulNo ratings yet

- Aerodynamics Analysis of Formula One Vehicles: 2.2. The Entire Flow Around The VehicleDocument11 pagesAerodynamics Analysis of Formula One Vehicles: 2.2. The Entire Flow Around The VehicleGourav DasNo ratings yet

- More Information: Cambridge University Press 978-0-521-10587-3 - Distillation Tray Fundamentals M. J. Lockett FrontmatterDocument22 pagesMore Information: Cambridge University Press 978-0-521-10587-3 - Distillation Tray Fundamentals M. J. Lockett FrontmatterrajeshNo ratings yet

- Performance of One Unit Inlet Shell Side Outlet Inlet Tube Side OutletDocument4 pagesPerformance of One Unit Inlet Shell Side Outlet Inlet Tube Side OutletMohammad Mehdi JafariNo ratings yet

- 520A - Control Valve - 1Document3 pages520A - Control Valve - 1Nikhil KarkeraNo ratings yet

- Assembly Fluid 1 TDSDocument1 pageAssembly Fluid 1 TDSpokleNo ratings yet

- ME-51016, Fluid Mechanics II (First Semester) : Ministry of Science and Technology Technological University (Thanlyin)Document19 pagesME-51016, Fluid Mechanics II (First Semester) : Ministry of Science and Technology Technological University (Thanlyin)rob inNo ratings yet

- Mecánica de Fluidos. Taller N 2 (2019-1)Document4 pagesMecánica de Fluidos. Taller N 2 (2019-1)Juan ClavijoNo ratings yet

- LIFESAVER Jerrycan Quick User GuideDocument2 pagesLIFESAVER Jerrycan Quick User GuideIdan AwaludinNo ratings yet

- Role of Sparger Design in Mechanically Agitated Gas-Liquid ReacDocument8 pagesRole of Sparger Design in Mechanically Agitated Gas-Liquid ReacAriel AnnaNo ratings yet

- Taitel and Duckler ModelDocument36 pagesTaitel and Duckler ModelAngga RizkyNo ratings yet

- Nodal Analysis - TAMUDocument53 pagesNodal Analysis - TAMUAhmad FaizilNo ratings yet

- US600A B ManualDocument8 pagesUS600A B ManualebevmNo ratings yet

- Lab 6Document19 pagesLab 6IzzatiHazwaniNo ratings yet

- AGA3 1990 AlgorithmDocument3 pagesAGA3 1990 Algorithmyan2huaNo ratings yet

- Pentosynth 5W-50: Product Data SheetDocument1 pagePentosynth 5W-50: Product Data SheetRafael Canizares ChiarandiNo ratings yet

- Hydraulics Lab Manual - PandemicDocument12 pagesHydraulics Lab Manual - PandemichghvtfNo ratings yet

- PWS Chief Operator Course Manual OverviewDocument423 pagesPWS Chief Operator Course Manual OverviewsksghNo ratings yet

- 30 44 TribologyDocument15 pages30 44 TribologyahmadmosadeghNo ratings yet

- MANUAL de PARTES SIST - Lubrication Oil StationDocument1 pageMANUAL de PARTES SIST - Lubrication Oil StationKasjdkasd AksdjasdjNo ratings yet

- PVT Concepts Reservoir ConceptDocument23 pagesPVT Concepts Reservoir ConceptherikugisNo ratings yet