Professional Documents

Culture Documents

6 Simple Vapor Compression RS

Uploaded by

captainhassCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Simple Vapor Compression RS

Uploaded by

captainhassCopyright:

Available Formats

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M .

Mallikarjuna

6.5 Simple Vapor Compression Refrigeration System:

A simple vapor compression refrigeration system consists of the following equipments:

i) Compressor ii) Condenser iii) Expansion valve iv) Evaporator.

B COMPRESOR

C

∆Q1

200C

FLUID TO

BE COOLED EVAPORATOR

w CONDENSER

COOLING

WATER

(-300C) (350C)

00C

∆Q2 EXPANSION VALVE

A D

Fig.6.5. Simple vapour compression system

The schematic diagram of the arrangement is as shown in Fig.6.5. The low

temperature, low pressure vapor at state B is compressed by a compressor to high

temperature and pressure vapor at state C. This vapor is condensed into high pressure

vapor at state D in the condenser and then passes through the expansion valve. Here,

the vapor is throttled down to a low pressure liquid and passed on to an evaporator,

where it absorbs heat from the surroundings from the circulating fluid (being

refrigerated) and vaporizes into low pressure vapor at state B. The cycle then repeats.

The exchange of energy is as follows:

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

a) Compressor requires work, δw. The work is supplied to the system from the

surroundings.

b) During condensation, heat δQ1 the equivalent of latent heat of condensation

etc, is lost from the refrigerator.

c) During evaporation, heat δQ2 equivalent to latent heat of vaporization is

absorbed by the refrigerant.

d) There is no exchange of heat during throttling process through the expansion

valve as this process occurs at constant enthalpy.

6.5.1 Simple Vapor Compression Cycle:

C"

T C

350c D C'

T1

-300C B"

T2

T A B' B

P Q R' R S

Fig.6.5.1. T-s diagram of refrigeration cycle

Figure 6.5.1 shows a simple vapor compression refrigeration cycle on T-s diagram for

different compression processes. The cycle works between temperatures T1 and T2

representing the condenser and evaporator temperatures respectively. The various

process of the cycle A-B-C-D (A-B’-C’-D and A-B”-C”-D) are as given below:

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

i) Process B-C (B’-C’ or B”-C”): Isentropic compression of the vapor from state

B to C. If vapor state is saturated (B), or superheated (B”), the compression is

called dry compression. If initial state is wet (B’), the compression is called

wet compression as represented by B’-C’.

ii) Process C-D (C’-D or C”-D): Heat rejection in condenser at constant

pressure.

iii) Process D-A: An irreversible adiabatic expansion of vapor through the

expansion value. The pressure and temperature of the liquid are reduced.

The process is accompanied by partial evaporation of some liquid. The

process is shown by dotted line.

iv) Process A-B (A-B’ or A-B”) : Heat absorption in evaporator at constant

pressure. The final state depends on the quantity of heat absorbed and same

may be wet (B’) dry (B) or superheated (B”).

6.5.2 COP of Vapor Compression Cycle:

Heat extracted at low tempreature

COP =

Work sup plied

Heat extracted at low temperature = Heat transfer during the process A-B =

refrigerating effect.

q 2 = (h B - h A )

Work of compression = w = (hc-hB) (adiabatic compression).

⎧ h - hA ⎫

So, COP = ⎨ B ⎬

⎩ hc - hB ⎭

Now, heat rejected to the condenser, = q1 = w + q 2

= (h C - h B ) + (h B - h A )

= (h C - h A ) = (h C - h D )

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

6.5.3 Comparison of Simple Vapor Compression Cycle with Carnot

Cycle:

350c D C'

T1 S

-300C

T2

E T A B' B

O L P Q R' R

S

Fig.6.5.3. Comparison of simple vapor compression cycle with Carnot cycle

a. In vapor compression cycle, de-superheating between C and C’ is at constant

pressure rather than constant temperature. Therefore, more work has to be

supplied to the compressor. There is an equivalent amount of increase in the

magnitude of heat rejected.

b. In vapor compression cycle, no work is done by the system during the throttling

process. Hence, the network supplied to the cycle increases further by area EDT

as compared to the reversed Carnot cycle. Because,

{(Area RSDO – Area RBEO) – Area EDT } = Area BSDT

c. In vapor compression cycle, there is a loss of refrigeration effect equivalent to

area PQAT due to increase in entropy during the irreversible throttling expansion.

d. The effect of all these deviations is to increase the compression work required or

to decrease the refrigeration effect and therefore the COP of the vapor

compression cycle will be less than that of reversed Carnot cycle.

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

6.5.4 Factors Affecting the Performance of Vapor Compression

Refrigeration System:

(a) Sub-cooling of Liquids:

In the Fig.6.5.4(a) of simple vapor compression cycle, condensation process CD

resulted in the liquid at saturated state D. If it was possible to further cool down the

liquid to some lower value say upto D’, then the net refrigeration effect will be increased

as (hB – h’A) > (hB - hA). Hence, the sub cooling of the liquid increases the refrigerating

effect without increasing the work requirement. Thus COP is improved. The sub cooling

may be achieved by any of the following methods:

8.46 D' D 350C C' C C''

P

(bar)

1.00 -300C

A' A B''

B

59.05 175.81 192.60 212.70 235.60

h(kj/kg)

Fig.6.5.4(a). Subcooling and superheating of refrigerant

(i) By passing the liquid refrigerant from condenser through a heat exchanger

through which the cold vapor at suction from the evaporator is allowed to flow

in the reversed direction. This process subcools the liquid but superheats the

vapor. Thus, COP is not improved though refrigeration effect is increased.

(ii) By making use of enough quantity of cooling water so that the liquid

refrigerant is further cooled below the temperature of saturation. In some

cases, a separate subcooler is also made use of for this purpose. In this case,

COP is improved.

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

(b) Superheating of Vapor:

If the vapor at the compressor entry is in the superheated state B”, which is produced

due to higher heat absorption in the evaporator, then the refrigerating effect is increased

as (h”B - hA) > (hB – hA). However, COP may increase, decrease or remain unchanged

depending upon the range of pressure of the cycle.

(c) Change in suction pressure (PS):

p'd D' 500C C"

12.10

pd D 350C L C C'

8.46

P

(bar)

M

ps A A" -50C B

2.60

p's A' -300c B'

1.00

69.63 85.37 187.91 209.25 219.59

h(kj/kg)

Fig.6.5.4(c). Effect of change in evaporator and condenser pressure

Let the suction pressure or the evaporating pressure in a simple refrigeration cycle be

reduced from PS to P’S. It will be clear from the figure that:

The refrigerating effect is reduced to: (h ′B - h ′A ) < (h B - h A )

The work of compression is increased to: (h C′′ - h ′′B ) > (h C - h B )

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

Hence, the decrease in suction pressure decreases the refrigeration effect and at the

same time increases the work of compression. But, both the effects tend to decrease

the COP.

(d) Change in discharge pressure (Pd):

In Fig.6.5.4(c), let us assume that the pressure at the discharge or the condensing

pressure is increased from Pd to P’d. It will have effects as follows:

′′ - h B ) > (h C - h B )

The compressor work requirement is increased to: (h C

The refrigerating effect is reduced to: (h B - h ′′A ) < (h B - h A )

Therefore, the increase in discharge pressure results in lower COP. Hence, the

discharge pressure should be kept as low as possible depending upon the temperature

of the cooling medium available.

(e) Effect of Volumetric Efficiency of Compressor:

C' DISCHARGE C

pd

SUCTION

PS B

B" B'

VC V2 V V1

Fig.6.5.4(e). Effect of volumetric efficiency

Indian Institute of Technology Madras

Refrigeration Cycles Prof. U.S.P. Shet , Prof. T. Sundararajan and Prof. J.M . Mallikarjuna

The factors like clearance volume, pressure drop through discharge and suction values,

leakage of vapor along the piston and superheating of cold vapor due to contact with

hot cylinder walls, affects the volume of the vapor actually pumped by the compressor.

The volumetric efficiency of a compressor is defined as;

Actual mass of vapor drawn at suction conditions

ηvol =

Theoritical mass that can be filled in the displacement volume

Figure 6.5.4(e) represents the p-v diagram of a compressor. Now, during suction stroke

B”–B, the vapor filled in clearance space at pressure Pd expands along C’-B’ and the

suction valve opens only when the pressure has dropped down to pS. Therefore, the

actual amount of vapor sucked during the suction stroke is (v1 - v2) while the stroke

volume is (v1 - vc). Volumetric efficiency decreases the refrigeration effect.

Indian Institute of Technology Madras

You might also like

- 100 Items Elements in Power and Industrial Plant Engineering PipeDocument7 pages100 Items Elements in Power and Industrial Plant Engineering PipeMark Andrew CabaleNo ratings yet

- Ciclos RefrigeracionDocument64 pagesCiclos RefrigeracionSergyNo ratings yet

- Classifying Pumps by Design and ApplicationDocument6 pagesClassifying Pumps by Design and ApplicationAriel GamboaNo ratings yet

- ME3122E - Tutorial Solution 5Document21 pagesME3122E - Tutorial Solution 5LinShaodun64% (11)

- Ideal Gas Refrigeration Cycle & R-134a Vapor Compression Refrigerator PerformanceDocument3 pagesIdeal Gas Refrigeration Cycle & R-134a Vapor Compression Refrigerator Performanceanask15No ratings yet

- Performance Analysis of Ice Plant Using Ecofriendly RefrigerantsDocument9 pagesPerformance Analysis of Ice Plant Using Ecofriendly RefrigerantsAungThawNyeinChanNo ratings yet

- Solution Machine DesignDocument9 pagesSolution Machine DesignRheymar MercadoNo ratings yet

- Lab Exercise #4Document12 pagesLab Exercise #4John Glenn Lausin MaticNo ratings yet

- ME463 - Lab Exercise 1: Design of Flat BeltDocument4 pagesME463 - Lab Exercise 1: Design of Flat BeltJoshua OliverNo ratings yet

- Aim: Capacitive RectificationDocument9 pagesAim: Capacitive RectificationPriNo ratings yet

- Rac Problems Set 1Document6 pagesRac Problems Set 1Mohammad Umair100% (1)

- Experiment No. 1Document4 pagesExperiment No. 1subhamgupta7495100% (1)

- Tutorial 9v18sol PDFDocument4 pagesTutorial 9v18sol PDFSohayb GattousNo ratings yet

- Mech1442851738363 PDFDocument57 pagesMech1442851738363 PDFMonevNo ratings yet

- A Propeller Shaft As Shown Is To Receive 300 HP at 315 RPM From The Right Through A Flexible CouplingDocument5 pagesA Propeller Shaft As Shown Is To Receive 300 HP at 315 RPM From The Right Through A Flexible CouplingMark AgusNo ratings yet

- Lesson 3 Exercises Problem 7Document3 pagesLesson 3 Exercises Problem 7Ariel GamboaNo ratings yet

- Refrigeration cycle analysis and performance parametersDocument18 pagesRefrigeration cycle analysis and performance parametersSaurabh JainNo ratings yet

- Tables Stoecker and JonesDocument11 pagesTables Stoecker and JonesGenard RantaelNo ratings yet

- Santillan LBYME3B Laboratory Report 05Document21 pagesSantillan LBYME3B Laboratory Report 05Nygel Gian SantillanNo ratings yet

- CO Assign#2 BSEE-2ADocument3 pagesCO Assign#2 BSEE-2AEisen JaylordNo ratings yet

- Ref Systems Lecture Notes 1Document9 pagesRef Systems Lecture Notes 1Retro GamerNo ratings yet

- ACE Engineering Academy Mock Test 1 Mechanical Engineering Paper 1Document15 pagesACE Engineering Academy Mock Test 1 Mechanical Engineering Paper 1vidya chakitwarNo ratings yet

- Blue Book Terms p1 1 100Document101 pagesBlue Book Terms p1 1 100Listless ListlessNo ratings yet

- LBYME4A - EE3 - Expt. 1 - Group 2Document15 pagesLBYME4A - EE3 - Expt. 1 - Group 2catalan153709No ratings yet

- Questions For Period 1: TRG-TRC001-ENDocument9 pagesQuestions For Period 1: TRG-TRC001-ENRenato OrosaNo ratings yet

- PUMPS Part 2Document11 pagesPUMPS Part 2Kaiser CarloNo ratings yet

- Chapter 2 - Gas Vapor MixtureDocument47 pagesChapter 2 - Gas Vapor MixturenunuNo ratings yet

- Refrigeration-Systems Part 1Document11 pagesRefrigeration-Systems Part 1Sean GuanzonNo ratings yet

- Experiment 1 Lab ReportDocument25 pagesExperiment 1 Lab ReportJasper Laurence SyNo ratings yet

- Ventilation Lesson Guide Natural Forced CoolingDocument13 pagesVentilation Lesson Guide Natural Forced CoolingMohammed SiddiqueNo ratings yet

- Questions and solutions for engineering problemsDocument82 pagesQuestions and solutions for engineering problemsRyan Llona FernandezNo ratings yet

- Bearing Selection - Bearing Sample 2A V2Document3 pagesBearing Selection - Bearing Sample 2A V2Suchi Suchi SuchiNo ratings yet

- Module 7 Exercises Problem No. 1Document3 pagesModule 7 Exercises Problem No. 1Ariel Gamboa100% (1)

- Exercises Problem 4 Heat TransferDocument3 pagesExercises Problem 4 Heat TransferMeeko TanNo ratings yet

- Band Brake: Front View Isometric ViewDocument3 pagesBand Brake: Front View Isometric ViewDave Vendivil SambranoNo ratings yet

- Buok Chapter 3Document44 pagesBuok Chapter 3Edmil Jhon AriquezNo ratings yet

- Termodinâmica - 8 Ed - Soluções em Inglês Cap 7Document201 pagesTermodinâmica - 8 Ed - Soluções em Inglês Cap 7phxcostaNo ratings yet

- Cooling TowerDocument6 pagesCooling TowerLucas FurlanNo ratings yet

- DZL Series Chain Grate Boiler OkDocument10 pagesDZL Series Chain Grate Boiler OkCarlos LehmanNo ratings yet

- Piping Problems With SolutionDocument5 pagesPiping Problems With Solutionganapathi_54No ratings yet

- 3rd CheckingDocument21 pages3rd CheckingKing Cyruz PabloNo ratings yet

- Hvac Rpoblems NewDocument20 pagesHvac Rpoblems NewGrace Joy CariNo ratings yet

- Vapor Compression CycleDocument23 pagesVapor Compression CycleNiaz KilamNo ratings yet

- ConstantDocument8 pagesConstantDhayane RedoquerioNo ratings yet

- Noel Godinez Original PPT Ice RefrigerationDocument30 pagesNoel Godinez Original PPT Ice RefrigerationCharlton InaoNo ratings yet

- Sheet 3Document1 pageSheet 3Mohamed MaherNo ratings yet

- Tutorial 3Document4 pagesTutorial 3Ngudo Ewart NephaweNo ratings yet

- A-1 PIPE Terms Coaching Part 1Document351 pagesA-1 PIPE Terms Coaching Part 1Ralph Adrian MielNo ratings yet

- Design A Bell Crank'95Document27 pagesDesign A Bell Crank'95Al DrinNo ratings yet

- Educspace - Pumps - Problems SetDocument3 pagesEducspace - Pumps - Problems SetMatthew John SyNo ratings yet

- Ideal Gas Law Simulation: PV NRTDocument3 pagesIdeal Gas Law Simulation: PV NRTElla GreenNo ratings yet

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocument13 pagesLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloNo ratings yet

- Actual VCR CycleDocument4 pagesActual VCR Cyclepramod kumar yadavNo ratings yet

- Analysis of Vapour Compression Refrigeration CycleDocument10 pagesAnalysis of Vapour Compression Refrigeration CycleSyed Shahryar HussainNo ratings yet

- RAC Experiments FinalDocument31 pagesRAC Experiments FinalEr Nikhil KakadeNo ratings yet

- COP VCCDocument8 pagesCOP VCCHussein SalahNo ratings yet

- Refrigeration COP and Capacity CalculationDocument12 pagesRefrigeration COP and Capacity CalculationxofigoNo ratings yet

- Boiler Energy Analysis ReportDocument7 pagesBoiler Energy Analysis ReportImran Sajid ShahidNo ratings yet

- 16 Research PaperDocument7 pages16 Research Paperkhaja ziauddinNo ratings yet

- MsdsDocument9 pagesMsdsJay ShuklaNo ratings yet

- Tata Aggreto BrochureDocument3 pagesTata Aggreto BrochureJay ShuklaNo ratings yet

- TDC - BF Slag - Rev 01 19 11 2015Document1 pageTDC - BF Slag - Rev 01 19 11 2015Jay ShuklaNo ratings yet

- BF SLAG: Optimized Slag Granulation for Quality Cement ProductionDocument2 pagesBF SLAG: Optimized Slag Granulation for Quality Cement ProductionJay ShuklaNo ratings yet

- Adversity to opportunity: How Tata Nirman utilizes LD slagDocument33 pagesAdversity to opportunity: How Tata Nirman utilizes LD slagJay ShuklaNo ratings yet

- Important RaitosDocument1 pageImportant RaitosJay ShuklaNo ratings yet

- Brochure IFAPADocument5 pagesBrochure IFAPAJay ShuklaNo ratings yet

- Adversity to opportunity: How Tata Nirman utilizes LD slagDocument33 pagesAdversity to opportunity: How Tata Nirman utilizes LD slagJay ShuklaNo ratings yet

- Important RaitosDocument1 pageImportant RaitosJay ShuklaNo ratings yet

- Catalog Cables (RPG) (1Document32 pagesCatalog Cables (RPG) (1Jay ShuklaNo ratings yet

- Scan Doc0017Document2 pagesScan Doc0017Jay ShuklaNo ratings yet

- DR - Lal Path Labs: Invoice Cum Cash Receipt (Please Bring This Receipt For Report Collection)Document1 pageDR - Lal Path Labs: Invoice Cum Cash Receipt (Please Bring This Receipt For Report Collection)Jay Shukla0% (2)

- Stay InsulatorDocument1 pageStay InsulatorJay ShuklaNo ratings yet

- FatigueDocument50 pagesFatigueJay Shukla100% (1)

- Colour Guide - Ici Dulux LRDocument19 pagesColour Guide - Ici Dulux LRswifthuntNo ratings yet

- Edexcel French Vocabulary Work BookDocument155 pagesEdexcel French Vocabulary Work BookJoseph Nguyen100% (1)

- Pegasus-Umfolozi Soils ReportDocument47 pagesPegasus-Umfolozi Soils ReportJay ShuklaNo ratings yet

- Student CV With Summer and Winter Trainings-1Document4 pagesStudent CV With Summer and Winter Trainings-1Jay ShuklaNo ratings yet

- National AIDS Control Program: Dr. Kanupriya ChaturvediDocument42 pagesNational AIDS Control Program: Dr. Kanupriya ChaturvedifahimalikNo ratings yet

- Automobile Workshop Planning and LayoutDocument3 pagesAutomobile Workshop Planning and LayoutautocarewinNo ratings yet

- BoilerDocument109 pagesBoilerArijit Debroy100% (6)

- AIDS / HIV Awareness: 7 Grade 2009-2010Document25 pagesAIDS / HIV Awareness: 7 Grade 2009-2010Jay ShuklaNo ratings yet

- PABX Telecommunication 10Document1 pagePABX Telecommunication 10Jay ShuklaNo ratings yet

- A8 s8Document107 pagesA8 s8Jay ShuklaNo ratings yet

- EmeDocument20 pagesEmeJay ShuklaNo ratings yet

- AIDS / HIV Awareness: 7 Grade 2009-2010Document25 pagesAIDS / HIV Awareness: 7 Grade 2009-2010Jay ShuklaNo ratings yet

- Resume: Kul BhushanDocument2 pagesResume: Kul BhushanJay ShuklaNo ratings yet

- Nokia Secret Codes 1Document2 pagesNokia Secret Codes 1Jay ShuklaNo ratings yet

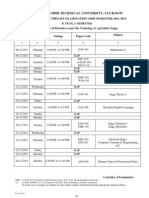

- S Revise Odd 2011 12 2Document64 pagesS Revise Odd 2011 12 2Gagan GwalaniNo ratings yet