Professional Documents

Culture Documents

TFP1580 11 2007 PDF

Uploaded by

ambition1340cn0 ratings0% found this document useful (0 votes)

117 views16 pagesTyco (r) 2 thru 8 inch (DN50 thru DN200) Model PRV-1 pressure Reducing Valves are factory assembled and fully trimmed valve arrangements for pressure control. The PRV-1 is intended to automatically maintain the outlet "set pressure" (static and residual) within a close range.

Original Description:

Original Title

TFP1580_11_2007.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTyco (r) 2 thru 8 inch (DN50 thru DN200) Model PRV-1 pressure Reducing Valves are factory assembled and fully trimmed valve arrangements for pressure control. The PRV-1 is intended to automatically maintain the outlet "set pressure" (static and residual) within a close range.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

117 views16 pagesTFP1580 11 2007 PDF

Uploaded by

ambition1340cnTyco (r) 2 thru 8 inch (DN50 thru DN200) Model PRV-1 pressure Reducing Valves are factory assembled and fully trimmed valve arrangements for pressure control. The PRV-1 is intended to automatically maintain the outlet "set pressure" (static and residual) within a close range.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

General

Desc ription

The Tyco

2 thru 8 inch (DN50 thru

DN200) Model PRV-1 Pressure Re-

ducing Valves are factory assembled

and fully trimmed valve arrangements

for pressure control. They are used on

water filled pipe where it is necessary

to reduce a higher inlet pressure to

a lower delivery pressure under static

and/or residual flowing conditions. The

PRV-1 is intended to automatically

maintain the outlet set pressure

(static and residual) within a close

range, regardless of fluctuations in the

higher pressure inlet line or varying

flow rates.

The PRV-1 is provided with a factory

outlet set pressure of 125 psi (8,6

bar); however it may be field set to a

nominal outlet set pressure of 80 to

225 psi (5,5 to 15,5 bar) per its FM

Approval or 80 to 150 psi (5,5 to 10,3

bar) per its UL Listing.

Typical applications are as follows:

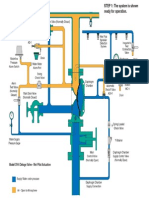

Within the main header (Ref. Figure

1) supplying wet pipe, dry pipe, del-

uge, or preaction system risers,

and/or a standpipe system supply-

ing hose connections.

As part of a sectional floor control

assembly (Ref. Figure 2) supplying

sprinkler systems, and/or hose sta-

tions.

Features are as follows:

Can be installed in any orientation.

Eliminates any required bleeding of

trapped ai r from the di aphragm

chamber during installation.

Globe or angle pattern.

Accurate pressure control.

Standard nylon coated internal and

external.

(continued)

Model PRV-1 Pressure Reduc ing Valve

2 thru 8 Inc h (DN50 thru DN200), 250 psi (17,2 bar)

Pilot Operated, Globe and Angle Body Styles

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

Page 1 of 16 TFP1580 NOVEMBER, 2007

End Connection

2 Inch

(DN50)

3 Inch

(DN80)

4 Inch

(DN100)

6 Inch

(DN150)

8 Inch

(DN200)

Nominal Valve Size

Thread x Thread

Groove x Groove Globe

Flange x Flange

Available Body Styles, End Connections & Sizes

N/A N/A N/A

N/A

N/A

N/A

N/A N/A Thread x Thread

Groove x Groove

Flange x Flange

Angle

Body

Style

= Available

N/A

N/A

N/A = Not Available

SOUTH AMERICA, CENTRAL AMERICA & EASTERN HEMISPHERE

End Connection

2 Inch

(DN50)

3 Inch

(DN80)

4 Inch

(DN100)

6 Inch

(DN150)

8 Inch

(DN200)

Nominal Valve Size

Available Body Styles, End Connections & Sizes

Body

Style

NORTH AMERICA

Thread x Thread

Groove x Groove Globe

Flange x Flange

N/A N/A N/A

N/A

= Available N/A = Not Available

N/A

N/A

N/A

N/A

One piece, one moving part dia-

phragm.

In-line service.

One pilot valve sub-assembly pro-

vides for any outlet set pressure,

i.e., 80 to 225 psi (5,5 to 15,5 bar).

WARNING

The Model PRV-1 Pressure Reducing

Valves described herein must be in-

stalled and maintained in compliance

with this document, as well as with the

applicable standards of the National

Fire Protection Association, in addition

to the standards of any other authori-

ties having jurisdiction. Failure to do

so may impair the performance of

these devices.

The owner is responsible for maintain-

ing their fire protection system and de-

vices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted

with any questions.

Due to the flow regulating charac-

teristic of this device, its impact on

system hydraulics should be carefully

considered, especially when retrofit-

ted into existing systems.

Downstream pressure adjustment

is only to be performed by experi-

enced personnel who understand

the impact of adjusting the down-

stream pressure and who take full

responsibility of the readjustment

from the factory setting. The Pilot

Valve is provided with a Tamper Cap,

which upon removal for purposes of

downstream adjustment will provide

an indication that the PRV-1 may have

been altered from its factory setting.

Page 2 of 16

TFP1580

FIGURE 1

TYPICAL MAIN HEADER APPLICATION

FIGURE 2

TYPICAL SECTIONAL FLOOR CONTROL APPLICATION

MAIN

HEADER

PRV-1

HOSE

STATIONS

MAIN

DRAIN

DRY PIPE

SPRINKLER

RISER

WET PIPE

SPRINKLER

RISER

MAIN

CONTROL

VALVE

MAIN

DRAIN

PRV-1

MAIN

CONTROL

VALVE

RELIEF

VALVE

HOSE

VALVE

PRV-1

SECTIONAL

CONTROL

VALVE

SECTIONAL

FLOOR

CONTROL

SECTIONAL

FLOOR

CONTROL

SPRINKLERS

HOSE

VALVE

PRV-1

RELIEF VALVE

RELIEF VALVE

Z

RISER

MANIFOLD

OR

ZONE

CHECK

SPRINKLERS

CHECK

VALVE

SECTIONAL

CONTROL

VALVE

CHECK

VALVE

Page 3 of 16

TFP1580

FIGURE 3

MODEL PRV-1 PRESSURE REDUCING VALVE

ASSEMBLY

Refer to Kit DESCRIPTION

Diaphragm

Hex Bolt,

6 Inch Valve, M16 x 45

3 & 4 Inch Valves,

6 & 8 Inch Valves, M16

8 Inch Valve, M16 x 55

M16 x 55

2 Inch Valve, M12 x 35

Handhole Cover

Flat Washer,

2 Inch Valve, M12

3 & 4 Inch Valves, M16

Valve Body

Hex Nut, M16,

4 Inch Valve Only

6

3

4

5

NO.

2

1

. .

. . . . . . . 4 CH

. . 8

8

CH

CH

VALVE PARTS

. . . . . . .

. . . . . . . . . . .

. . . . . . . . . . .

1 NR

. . . . . .

. .

. .

4

8

4

CH

CH

CH

QTY.

1

1

(a)

NR

. . 4 CH

. . . . . . . . . . . . . 4 CH

Diaphragm,

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

REPLACEMENT PARTS

. . . . . . . . . . . . .

. . . . . . . . . . . . .

(a)

2 Inch Valves

3 Inch Valves

4 Inch Valves

8 Inch Valves

6 Inch Valves

DESCRIPTION NO.

92-570-2-011

92-570-2-012

92-570-2-013

92-570-2-015

92-570-2-014

P/N

CHAMBER

DIAPHRAGM

INLET

CAVITY

4, 5, 6

2

3

7

Pilot Valve . . . . . . . . . . . . 1

(c)

7

(b) Pilot Valve . . . . . . . . . . . . . . . 92-570-2-200

INLET

PRESSURE

GAUGE

PRESSURE

GAUGE

OUTLET

11

. . Water Pressure Gauge 8 2

(d)

Water Pressure Gauge (c) 92-570-2-201 . . . . .

1

ANGLE BODY STYLE

GLOBE BODY STYLE

3 PRESSURE

GAUGE

INLET

GAUGE

PRESSURE

2

4, 5, 6

OUTLET

DIAPHRAGM

CHAMBER

7

11

Strainer 9 . . . . . . . . . . . . . . 1

(e)

Strainer: (d)

92-570-2-202

8

8

OUTLET CAVITY

8

8

(SEE DETAIL)

STRAINER

STRAINER

(SEE DETAIL)

Tubing and Fitting Kit, (f)

Pressure Sensor Insert 10 . . 1

(f)

STRAINER

Excludes Items 7, 8, 9, and 10

Globe Style Valve:

2 Inch Valve . . . . . . . . . . . . . . 92-570-3-001

92-570-3-004

92-570-3-005

92-570-3-003

92-570-3-002

8 Inch Valve

6 Inch Valve

4 Inch Valve

3 Inch Valve . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

2 Inch Valve

6 Inch Valve

4 Inch Valve

3 Inch Valve

Angle Style Valve:

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

Fits Either Body Style,

Includes Item 2 only:

GLOBE ANGLE

OUTLET FLOW OUTLET FLOW

TAB IS ORIENTED

DIAPHRAGM

PERPENDICULAR TO

OUTLET FLOW

Tubing and Fittings 11 . . . . . 1

(e) Pressure Sensor Insert:

92-571-3-004

92-571-3-003

92-571-3-002

92-571-3-001

PRESSURE SENSOR

DETAIL INSERT DETAIL 92-570-2-204

92-570-2-205

92-570-2-207

92-570-2-206

92-570-2-203

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

3 Inch Valve

4 Inch Valve

6 Inch Valve

8 Inch Valve

2 Inch Valve

(SEE DETAIL)

SENSOR INSERT

PRESSURE

(SEE DETAIL)

SENSOR INSERT

PRESSURE

1

2, 3, & 4 Inch Valves

6 & 8 Inch Valves

. . . . . . .

. . . . . . . . . . 92-570-2-209

(b)

NOTES:

NR - Not Replaceable

CH - Common Hardware

1.

2.

DOWNSTREAM

UPSTREAM

DOWNSTREAM

VALVE

BODY

TO

TRIM

CAVITY

INTERIOR

OF OUTLET

10

SENSOR

INLET FACES

INTERIOR

VALVE

BODY

TO

TRIM

OF INLET

9

CAVITY

DOWNSTREAM

OUTLET CAVITY

INLET CAVITY

UPSTREAM

DOWNSTREAM DOWNSTREAM

Tec hnic al

Data

Approvals:

UL Listed. FM Approved.

The UL Listing is based on

Installation requirements refer-

enced in the Standard for Installa-

tion of Sprinkler Systems, NFPA

13, or the Standard for Installation

of Standpipe and Hose Valves,

NFPA 14, as applicable.

Inspection, testing, and mainte-

nance requirements referenced in

the Standard for Inspection, Test-

ing, and Maintenance of Water-

Based Fire Protection Systems,

NFPA 25.

The Model PRV-1 being field set to

provide the required outlet pres-

sures and flows for the given appli-

cation.

The Model PRV-1 being tested af-

ter installation in accordance with

NFPA 13 and/or NFPA 14 as appli-

cable.

The Model PRV-1 being tested pe-

riodically thereafter in accordance

with NFPA 25.

Maximum Inlet Pressure:

250 psi (17,2 bar)

Factory Outlet Set Pressure:

125 psi (8,6 bar)

Field Outlet Set Pressure Range:

80 to 225 psi (5,5 to 15,5 bar) per its

FM Approval, or 80 to 150 psi (5,5 to

10,3 bar) per its UL Listing

Pressure Loss With Inlet Pressure

Above "Set Pressure"

The inlet pressure minus the outlet

"set pressure" equals pressure loss.

For example: assumimg that the inlet

flowing pressure is 225 psi (15,5 bar)

and the field outlet "set pressure" is

130 psi (9,0 bar), the pressure loss

is 95 psi (6,5 bar).

Pressure Loss with Inlet Pressure

Below Set Pressure

Refer to Graphs A thru E. (These

graphs are a requirement of UL and

should be used as reference only.)

Rated Flowing Range:

2 inch (DN50): 0 to 250 GPM

(0 to 946 LPM)

3 inch (DN80): 0 to 550 GPM

(0 to 2080 LPM)

4 inch (DN100): 0 to 1000 GPM

(0 to 3785 LPM)

6 inch (DN150): 0 to 2200 GPM

(0 to 8325 LPM)

8 inch (DN200): 0 to 4000 GPM

(0 to 15140 LPM)

End Connections:

Threaded end connections are avail-

able NPT threaded or threaded per

ISO 7/1. Flanged end connections

are available drilled per Table A.

Grooved end connections are per in-

dustry standard groove specifica-

tions.

Construction (Ref. Figure 3):

Body. Rilsan* blue coated ductile

iron per ASTM A536-77, Grade 65-

45-12.

Handhole Cover. Ri l san* bl ue

coated ductile iron per ASTM A536-

77, Grade 65-45-12.

Diaphragm. Nylon fabric reinforced,

natural rubber per ASTM D2000.

Diaphragm Cover Fasteners. Gal-

vanized carbon steel.

Pilot Valve. Brass and stainless

steel with nylon fabric reinforced,

natural rubber per ASTM D2000 dia-

phragm.

Strainer. Brass and stainless steel.

Pressure Gauges. 2-1/2 inch (65

mm) diameter, stainless steel case,

0 to 350 psi (25 bar).

Tube, Fittings, and Needle Valve.

Copper, brass, and stainless steel.

*Rilsan is a registered trademark of

ATOFINA Chemicals, Inc. (The Ril-

san coating is a polyamide (Nylon

11) coating.)

Page 4 of 16

TFP1580

TABLE A

DIMENSIONAL SPECIFICATION FOR SELECTION OF FLANGE DRILLING

Same drilling as for BS 4504 Section 3.2 (PN16) and DIN 2532 (PN16).

ANSI B16.1 AS 2129 ISO 7005-2 JIS B 2210

(Class 125) (Table E) (PN10) (10K)

2

A

7.50

9.50

(190,5)

(241,3)

B

0.75

0.88

(19,0)

(22,2)

7.00

9.25

(178,0)

(235,0)

0.71

0.87

(18,0)

(22,0)

6.89

(175,0)

Flange Drilling Specification

Nominal Dimensions in Inches and (mm)

9.45

(240,0)

11.75

(298,5)

0.88

(22,2)

11.50

(292,0)

0.87

(22,0)

11.61

(295,0)

0.75

(19,0)

0.91

(23,0)

Valve

4 Inch

6 Inch

(DN100)

(DN150)

8 Inch

(DN200)

3 Inch

(DN80)

N

4

8

8

8

A B N

8

ISO 7005-2

(PN16)

7.09

9.45

(180,0)

(240,0)

11.61

(295,0)

A B N

8

8

8

12

ISO 7005-2

(PN16)

USE

A B N

8

8

A B N

8

8

8

Dim. Dim.

Nominal

Qty. Dim. Dim. Qty. Dim. Dim. Qty. Dim. Dim. Qty. Dim. Dim. Qty.

Same drilling as for BS 4504 Section 3.2 (PN10) and DIN 2532 (PN10).

Dim. A

Bolt Circle

Diameter

Dim. B

Bolt Hole

Diameter

Qty. N

Number of

Bolt Holes

3

2

3

6.00

(152,4)

6.30

(160,0)

Size

Same drilling as for ANSI B16.5 (Class 150) and ANSI B16.42 (Class 150).

1

1

0.75

(19,0)

0.75

(19,0)

0.91

(23,0)

0.91

(23,0)

0.59

(15,0)

8 4

0.71

(18,0)

5.75

(146,0)

5.90

(150,0)

0.75

(19,0)

11.42

(290,0)

12

0.75

(19,0)

0.59

(15,0)

Operation

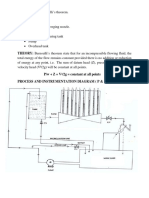

With reference to Figure 4, the system

water supply pressure from the inlet

cavity of the PRV-1 enters the Dia-

phragm Chamber through a Strainer

and Needle Valve. The factory set

Needle Valve provides the required

orifice size for the supply line to the

Diaphragm Chamber to optimize per-

formance.

Exit flowfromthe DiaphragmChamber

through the Pilot Valve is controlled by

a regulating spring that is factory set,

and subsequently field adjustable, to

the desired downstreamset pressure

that is to be maintained. A sensing line

connects the outlet of the Pilot Valve

to the system piping downstream of

the PRV-1 via the Pressure Sensor

Insert in the outlet cavity.

When the downstream pressure rises

above the set pressure of the spring,

exit flow from the Diaphragm Chamber

through the Pilot Valve to the PRV-1

outlet cavity is stopped and pressure

increases in the Diaphragm Chamber.

When downstream pressure falls be-

low the set pressure of the spring,

exit flow from the Diaphragm Chamber

through the Pilot Valve to the PRV-1

outlet cavity resumes and pressure in

the Diaphragm Chamber decreases.

The regulated flow through the Pilot

Valve decreases and increases the

pressure in the diaphragm chamber to

sufficiently open and close the PRV-1,

as required, to regulate the down-

stream set pressure.

The operation sequence is as follows:

When there i s no fl ow demand

downstream of the PRV-1, the

PRV-1 Seat is closed and the Pilot

Valve Seat is closed. With the Pilot

Val ve Seat cl osed, pressure i s

trapped in the Diaphragm Chamber

to seat the Diaphragm and the

PRV-1 remains closed.

When there is a flow demand down-

stream of the PRV-1 and the PRV-1

outlet pressure drops below the set

pressure, the Pilot Valve Seat opens

to relieve pressure from the Dia-

phragm Chamber allowing the

PRV-1 to open.

As the flowdemand continues down-

stream of the PRV-1 and the set

pressure is met, the Pilot Valve

Seat closes. As the Pilot Valve Seat

closes to reduce the opening, pres-

sure is trapped in the Diaphragm

Chamber at a point that allows the

Diaphragm to remain lifted from the

PRV-1 Seat to retain the down-

stream set pressure.

Should the downstream pressure

start to fall below the set pressure,

the Pilot Valve Seat re-opens to al-

low for a decrease in pressure in the

Diaphragm Chamber to allow the

PRV-1 to open further and then once

again establish the downstream set

pressure.

When the downstream pressure is at

or above the set pressure and as-

sumi ng there is a flow demand

downstream of the PRV-1, the Pilot

Valve Seat is closed to trap a suffi-

cient pressure in the Diaphragm

Chamber to allow the PRV-1 to re-

main open to provide the set pres-

sure.

Page 5 of 16

TFP1580

BODY

VALVE

OF INLET

CAVITY

INTERIOR

STRAINER

SUPPLY

LINE

SPRING

REGULATING

VALVE

PILOT

EXIT FLOW

SYSTEM

SUPPLY

WATER

PRESSURE

INLET CAVITY OUTLET CAVITY

PRV-1

DIAPHRAGM SEAT

PRV-1

SENSING

LINE

PILOT

SEAT

VALVE

PRESSURE

SENSOR INSERT

DIAPHRAGM

CHAMBER

LOCKNUT

ADJUSTING

SCREW

(FACTORY SET,

DO NOT READJUST)

NEEDLE VALVE

CAP

TAMPER

BODY

VALVE

INLET FACES

OF OUTLET

INTERIOR

UPSTREAM

SENSOR

CAVITY

TRIM

TO

TRIM

TO

PRESSURE

GAUGE

INLET

GAUGE

PRESSURE

OUTLET

FIGURE 4

MODEL PRV-1 PRESSURE REDUCING VALVE

OPERATION

Design

Considerations

The following items must be consid-

ered and applied accordingly for an

installation that will be using the Model

PRV-1 Pressure Reducing Valve:

The PRV-1 may be installed verti-

cally or horizontally and in any orien-

tation without affecting its operating

efficiency. When planning the posi-

tioning of the PRV-1, it is recom-

mended that consideration be given

to the vi ewi ng of the pressure

gauges. Consideration should also

be given to positioning the PRV-1 so

that the diaphragm cover is facing

up. With the cover facing up, internal

access is more easily achieved.

The PRV-1 must be in an area that

is easily accessible for maintenance

purposes, not subject to freezing

temperatures, and not subject to

physical damage.

The valve is designed for fresh water

service. When corrosive atmos-

pheres and/or contaminated water

suppl i es are present, i t i s the

owners responsibility to verify com-

patibility with the pressure reducing

valve, pilot valve, and trim.

The difference between the water

supply pressure and the desired out-

let (downstream) pressure must be

25 psi (1,7 bar) or greater per its FM

Approval or 50 psi (3,4 bar) or

greater per its UL Listing. The differ-

ential maintains accuracy control of

the discharging pressure over the

full rated flowing range.

Cavitation may occur when the inlet

pressure is greater than twice the

set pressure. For this case, the

pressure should be reduced in two

steps by using two PRV-1s in se-

ries.

When reducing pressure for a sprin-

kler system, a relief valve of not less

than 1/2 inch (DN15) in size shall be

located downstream of the PRV-1.

The relief valve shall be set at a

pressure equal to the lowest pres-

sure rated component downstream

of the PRV-1. NOTE: FM Approval is

based on the use of the 1/2 inch,

Watts Regulator, Series 530C Pres-

sure Relief Valve.

When reducing pressure for a sprin-

kler system, a listed indicating valve

shall be provided on the inlet side of

the PRV-1.

When reducing pressure for a sprin-

kler system, means shall be pro-

vided downstream of the PRV-1 to

facilitate a flow test at the sprinkler

system demand.

Installation

The Tyco

Model PRV-1 Pressure Re-

ducing Valve must be installed with the

flow arrow located on the Diaphragm

Cover pointing in the intended direc-

tion of flow. Installation dimensions are

provided in Figures 5 and 6.

Before the PRV-1 is installed, pipe

lines should be flushed of all chips,

scale and foreign matter. Care must be

exercised to assure that the trim is not

damaged during installation. Do Not

Lift The Valve By Its Trim.

NOTES

The inlet and outlet connections must

be made based on the direction of flow

arrow provided on the handhole cover.

The valve cannot operate if connected

backwards.

Do not alter the trim. Altering the trim

may render the valve ineffective and

impair the system operation.

Plac ing The

Valve In Servic e

Steps 1 through 12 are to be per-

formed when placing the Model PRV-1

Pressure Reducing Valve in service.

WARNING

Downstream pressure adjustment

is only to be performed by experi-

enced personnel who understand

the impact of adjusting the down-

stream pressure and who take full

responsibility of the readjustment

from the factory setting. The Pilot

Valve is provided with a Tamper Cap,

which upon removal for purposes of

downstream adjustment will provide

an indication that the PRV-1 may have

been altered from the factory setting.

Adjustment of the Needle Valve is

factory set and must not be altered.

The Needle Valve is provided with a

tamper indication, which upon removal

for purposes of any adjustment will

provide an indication that the PRV-1

may have been altered from the fac-

tory setting.

NOTES

Per the requirements of NFPA 13, a

means shall be provided downstream

of the PRV-1 to simulate the sprinkler

system demand. In the case of hose

stations, the opening of a hose valve

or multiple hose valves, as required,

will be necessary to simulate hose

stream demand.

For the purposes of the following in-

struction, the opening of a flow test

valve simulates either the sprinkler

demand or hose stream demand, as

applicable. The sprinkler demand or

hose stream demand must be at least

50 GPM (190 LPM) for 2 to 6 inch

(DN50 to DN150) valves and at least

100 GPM (380 LPM) for 8 i nch

(DN200) valves.

There is no need to vent any trapped

air from the Diaphragm Chamber.

Filling The System:

Step 1. Verify that downstream drain

valves are closed and that there are no

leaks.

Step 2. Partially open a valve or valves

at the end of the system (e.g., an in-

spectors test connection on a wet pipe

system) to allow trapped air to escape

when filling the system.

Step 3. Slowly and partially open the

water supply control valve feeding the

PRV-1.

Step 4. After the system fills with

water, close the valve or valves that

had been partially opened in Step 2.

Step 5. Completely open the main

water supply control valve feeding the

PRV-1.

Downstream Pressure Adjustment:

Step 6. Remove the Tamper Cap from

the Pilot Valve by first loosening its set

screw and then unscrewing the Tam-

per Cap.

Step 7. Open the flow test valve to

simulate either the desired sprinkler

demand or hose stream demand.

NOTE

If surging flow occurs, attempt to bleed

trapped air from the system via the

inspectors test valve and any other

valve that can vent trapped air.

Step 8. Loosen the locknut on the ad-

justing screw of the Pilot Valve.

Step 9. Turn the adjusting screw

clockwise to increase outlet pressure

or counterclockwise to decrease outlet

pressure.

Step 10. After achieving the desired

performance, tighten the locknut on

the adjusting screw.

Step 11. Close the flow test valve.

Observe the outlet pressure gauge

and compare to the required set

pressure. If the required set pres-

sure is not achieved, repeat Step 8

and proceed accordingly.

Page 6 of 16

TFP1580

Step 12. Replace the Tamper Cap and

tighten its set screw.

The pressure reducing valve is now

set for service.

NOTES

Due to the spring tolerance within the

Pilot Valve, it may be necessary to

alternate back and forth between re-

sidual and static conditions to achieve

the desired set pressure for both re-

sidual and static conditions.

After any downstream pressure ad-

justment, the following items are to be

recorded on a tag attached to the

valve:

- Valve installation location

- Inlet static pressure

- Outlet static pressure

- Inlet residual pressure

- Outlet residual pressure

- Intended outlet flow

The tag is not to be removed until after

the system has been accepted by the

Authority Having Jurisdiction. It is rec-

ommended that the tag not be re-

moved even after acceptance by the

Authority Having Jurisdiction unless

another means of record keeping is

maintained.

Care and

Maintenanc e

Inspection, testing, and maintenance

must be performed in accordance with

the requirements of the NFPA, and any

impairment must be immediately cor-

rected.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of any authorities having ju-

risdiction. The installing contractor or

product manufacturer should be con-

tacted relative to any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualified Inspection Service in accord-

ance with local requirements and/or

national codes.

NOTE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection systems must

fi rst be obtained from the proper

authorities and all personnel who may

be affected by this decision must be

notified.

The Model PRV-1 Pressure Reducing

Valve requires no lubrication, packing

or preventative maintenance; how-

ever, replacement of the diaphragm

every five years is recommended.

Flow Tests. Flow tests per NFPA are

required every five years, at which

point the outlet pressure is compared

to previous tests. If necessary the

PRV-1 can be readjusted following the

Placing The Valve In Service section.

If the desired pressure cannot be

achieved, the Diaphragm and/or Pilot

Valve should be replaced.

Diaphragm Replacement. Prior to re-

placing the Diaphragm, the PRV-1

must be taken out of service and com-

pletely drained. With reference to Fig-

ure 3, the Diaphragm Tab is oriented

perpendicular to the outlet flow. When

reinstalling the Diaphragm Cover, the

Diaphragm Cover Fasteners must be

uniformly and securely tightened

using a cross-draw sequence. After

tightening, double check to make cer-

tain that all of the Diaphragm Cover

fasteners are securely tightened.

Pilot Valve Replacement. Prior to re-

moving the Pilot Valve, the PRV-1

must be taken out of service and com-

pletely drained. When installing the re-

placement Pilot Valve, the trim compo-

nents must be replaced exactly as they

were. After reinstalling the Pilot Valve

and before returning the PRV-1 into

service, completely unscrew the Ad-

justing Stem of the replacement Pilot

Valve so as to obtain a minimum outlet

set pressure. Then proceed to use

the instructions under Placing The

Valve In Service section to place the

PRV-1 in service.

NOTES

The Pilot Valve is not field repairable.

Attempting to repair the Pilot Valve

may render the valve ineffective and

impair the system operation.

Completely unscrewing the Adjusting

Stem of the replacement Pilot Valve

will help to avoid an accidental over

pressurization of the system piping

prior to achieving the desired set

pressure.

Limited

Warranty

Products manufactured by Tyco Fire &

Building Products (TFBP) are war-

ranted solely to the original Buyer for

ten (10) years against defects in mate-

rial and workmanship when paid for

and properly installed and maintained

under normal use and service. This

warranty will expire ten (10) years

from date of shipment by TFBP. No

warranty is given for products or com-

ponents manufactured by companies

not affiliated by ownership with TFBP

or for products and components which

have been subject to misuse, improper

installation, corrosion, or which have

not been installed, maintained, modi-

fied or repaired in accordance with ap-

plicable Standards of the National Fire

Protection Association, and/or the

standards of any other Authorities

Having Jurisdiction. Materials found

by TFBP to be defective shall be either

repaired or replaced, at TFBPs sole

option. TFBP neither assumes, nor

authorizes any person to assume for it,

any other obligation in connection with

the sale of products or parts of prod-

ucts. TFBP shall not be responsible for

sprinkler system design errors or inac-

curate or incomplete information sup-

pl i ed by Buyer or Buyer s repre-

sentatives.

In no event shall TFBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential dam-

ages, including but not limited to labor

charges, regardless of whether TFBP

was informed about the possibility of

such damages, and in no event shall

TFBPs liability exceed an amount

equal to the sales price.

The foregoing warranty is made in lieu

of any and all other warranties, ex-

press or implied, including warranties

of merchantability and fitness for a par-

ticular purpose.

This limited warranty sets forth the ex-

clusive remedy for claims based on

failure of or defect in products, materi-

als or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full ex-

tent permitted by law. The invalidity, in

whole or part, of any portion of this

warranty will not affect the remainder.

Page 7 of 16

TFP1580

Page 8 of 16

TFP1580

FIGURE 5

MODEL PRV-1 PRESSURE REDUCING VALVE

GLOBE STYLE INSTALLATION DIMENSIONS

A

B

D

F

E

(DN100)

4"

(DN150)

6"

(DN80)

3"

(DN200)

8"

A

Flange x Flange End Connections

Valve

Nominal

Sizes

(305)

12.00

(406)

15.98

(283)

11.14

(470)

18.50

B

(57)

2.24

(142)

5.59

(100)

3.93

(170)

6.69

C D

(201)

7.91

(171)

6.73

(190)

7.48

(182)

7.16

E

(246)

9.68

(292)

11.49

(235)

9.25

(319)

12.55

F

(115)

4.52

(150)

5.90

(177)

6.96

(DN50)

2"

A

Thread x Thread End Connections

Valve

Nominal

Sizes B C D E F

(60)

2.36

(DN100)

4"

(DN150)

6"

(DN80)

3"

(DN50)

2"

A

Groove x Groove End Connections

Valve

Nominal

Sizes

(346)

13.62

(452)

17.79

(283)

11.14

(191)

7.51

B

(111)

4.37

(84)

3.30

(45)

1.77

(38)

1.49

C D

(201)

7.91

(171)

6.73

(190)

7.48

(163)

6.41

E

(246)

9.68

(292)

11.49

(235)

9.25

(208)

8.18

F

(115)

4.52

(150)

5.90

(60)

2.36

(191)

7.51

(38)

1.49

(163)

6.41

(208)

8.18

(DN80)

3"

(283)

11.14

(45)

1.77

(190)

7.48

(235)

9.25

(100)

3.93

(186)

7.32

(221)

8.70

(251)

9.88

(208)

8.19

(186)

7.32

(208)

8.19

C

(283)

11.14

(221)

8.70

(251)

9.88

(208)

8.19

(100)

3.93

(100)

3.93

Nominal Installation Dimensions in Inches and (mm) Weight

Nominal Installation Dimensions in Inches and (mm) Weight

Nominal Installation Dimensions in Inches and (mm) Weight

(6,9)

15.2

(13,9)

30.6

(kg)

lbs.

(kg)

lbs.

(kg)

lbs.

(20,5)

45.2

(53,5)

118.0

(21,0)

46.3

(29,5)

65.0

(53,5)

118.0

(75,5)

166.5

(6,9)

15.2

(13,9)

30.6

FIGURE 6

MODEL PRV-1 PRESSURE REDUCING VALVE

ANGLE STYLE INSTALLATION DIMENSIONS

(DN100)

4"

(DN150)

6"

(DN80)

3"

A

Nominal Installation Dimensions in Inches and (mm)

Flange x Flange End Connections

Valve

Nominal

Sizes B C D E F

(DN50)

2"

A

Nominal Installation Dimensions in Inches and (mm)

Thread x Thread End Connections

Valve

Nominal

Sizes B C

(186)

7.32

D

(163)

6.41

E

(208)

8.18

F

(61)

2.40

(DN100)

4"

(DN150)

6"

(DN80)

3"

(DN50)

2"

A

Nominal Installation Dimensions in Inches and (mm)

Groove x Groove End Connections

Valve

Nominal

Sizes

(161)

6.33

(226)

8.89

(154)

6.06

B

(116)

4.56

(170)

6.69

(115)

4.52

C

(221)

8.70

(251)

9.88

D

(201)

7.91

(171)

6.73

(190)

7.48

E

(246)

9.68

(292)

11.49

(235)

9.25

F

(115)

4.52

(150)

5.90

(100)

3.93

(90)

3.54

(81)

3.18

B

C

A

G D

F

E

(7,2)

15.9

(19,9)

44.0

(40,5)

89.3

(163)

6.41

(208)

8.18

(61)

2.40

(90)

3.54

(81)

3.18

(161)

6.33

(226)

8.89

(154)

6.06

(116)

4.56

(170)

6.69

(115)

4.52

(201)

7.91

(171)

6.73

(190)

7.48

(246)

9.68

(292)

11.49

(235)

9.25

(115)

4.52

(150)

5.90

(100)

3.93

(30,5)

67.3

(52,7)

116.2

(15,9)

35.1

(DN80)

3"

(154)

6.06

(115)

4.52

(208)

8.19

(190)

7.48

(235)

9.25

(100)

3.93

(15,5)

34.1

(186)

7.32

(208)

8.19

(208)

8.19

(221)

8.70

(251)

9.88

Weight

(kg)

lbs.

G

G

(61)

2.40

G

(115)

4.52

(150)

5.90

(100)

3.93

(61)

2.40

(115)

4.52

(150)

5.90

(100)

3.93

(100)

3.93

Weight

(kg)

lbs.

Weight

(kg)

lbs.

(7,2)

15.9

(15,5)

34.1

Page 9 of 16

TFP1580

Page 10 of 16

TFP1580

GRAPH A-1

2 INCH (DN50) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 80 PSI

(This graph is a requirement of UL and should be used as reference only.)

1 GPM = 3,785 LPM

FLOW RATE IN GALLONS PER MINUTE (GPM)

0

1 PSI = 0,06895 BAR

250 25 50 75 100 125 150 175 200 225

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

40

20

0

10

30

130

110

120

90

70

80

100

60

50

140

B = 50 PSI INLET PRESSURE

A = 70 PSI INLET PRESSURE

A

B

GRAPH A-2

2 INCH (DN50) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 150 PSI

(This graph is a requirement of UL and should be used as reference only.)

225 200 175 150 125 100 75 50 25 250 0

1 GPM = 3,785 LPM 1 PSI = 0,06895 BAR

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 100 PSI INLET PRESSURE

A = 140 PSI INLET PRESSURE

C = 50 PSI INLET PRESSURE

FLOW RATE IN GALLONS PER MINUTE (GPM)

A

B

C

GRAPH B-1

3 INCH (DN80) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 80 PSI

(This graph is a requirement of UL and should be used as reference only.)

GRAPH B-2

3 INCH (DN80) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 150 PSI

(This graph is a requirement of UL and should be used as reference only.)

Page 11 of 16

TFP1580

1 GPM = 3,785 LPM

0

1 PSI = 0,06895 BAR

550 50 100 150 200 250 300 350 400 450 500

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 50 PSI INLET PRESSURE

A = 70 PSI INLET PRESSURE

A

B

FLOW RATE IN GALLONS PER MINUTE (GPM)

550 500 450 400 350 300 250 200 150 100 50 0

1 GPM = 3,785 LPM 1 PSI = 0,06895 BAR

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 100 PSI INLET PRESSURE

A = 140 PSI INLET PRESSURE

C = 50 PSI INLET PRESSURE

B

A

C

FLOW RATE IN GALLONS PER MINUTE (GPM)

GRAPH C-1

4 INCH (DN100) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 80 PSI

(This graph is a requirement of UL and should be used as reference only.)

GRAPH C-2

4 INCH (DN100) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 150 PSI

(This graph is a requirement of UL and should be used as reference only.)

Page 12 of 16

TFP1580

0 1000

1 GPM = 3,785 LPM 1 PSI = 0,06895 BAR

100 200 300 400 500 600 700 800 900

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 50 PSI INLET PRESSURE

A = 70 PSI INLET PRESSURE

B

A

FLOW RATE IN GALLONS PER MINUTE (GPM)

1 PSI = 0,06895 BAR

400 300 200 100 0 900 800 700 600 500 1000

1 GPM = 3,785 LPM

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

A = 140 PSI INLET PRESSURE

B = 100 PSI INLET PRESSURE

C = 50 PSI INLET PRESSURE

C

B

A

FLOW RATE IN GALLONS PER MINUTE (GPM)

GRAPH D-1

6 INCH (DN150) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 80 PSI

(This graph is a requirement of UL and should be used as reference only.)

GRAPH D-2

6 INCH (DN150) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 150 PSI

(This graph is a requirement of UL and should be used as reference only.)

Page 13 of 16

TFP1580

2250 2000 1750 1500 1250 1000 750 500 250 2500 0

1 GPM = 3,785 LPM 1 PSI = 0,06895 BAR

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 50 PSI INLET PRESSURE

A = 70 PSI INLET PRESSURE

A

B

FLOW RATE IN GALLONS PER MINUTE (GPM)

2500 2250 2000 1750 1500 1250 1000 750 500 250 0

1 GPM = 3,785 LPM 1 PSI = 0,06895 BAR

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 100 PSI INLET PRESSURE

A = 140 PSI INLET PRESSURE

C = 50 PSI INLET PRESSURE

C

B

A

FLOW RATE IN GALLONS PER MINUTE (GPM)

GRAPH E-1

8 INCH (DN200) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 80 PSI

(This graph is a requirement of UL and should be used as reference only.)

GRAPH E-2

8 INCH (DN200) PRESSURE REDUCING VALVE

OUTLET PRESSURE VERSES FLOW

SHOULD INLET PRESSURE FALL BELOW A SET PRESSURE OF 150 PSI

(This graph is a requirement of UL and should be used as reference only.)

Page 14 of 16

TFP1580

1000 500 0 1500 2000 2500 3000 3500 4000

1 GPM = 3,785 LPM 1 PSI = 0,06895 BAR

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 50 PSI INLET PRESSURE

A = 70 PSI INLET PRESSURE

B

A

FLOW RATE IN GALLONS PER MINUTE (GPM)

1 GPM = 3,785 LPM

0

1 PSI = 0,06895 BAR

4000 500 1000 1500 2000 2500 3000 3500

40

O

U

T

L

E

T

P

R

E

S

S

U

R

E

I

N

P

O

U

N

D

S

P

E

R

S

Q

U

A

R

E

I

N

C

H

(

P

S

I

)

0

10

20

30

50

60

70

80

90

100

110

120

130

140

B = 100 PSI INLET PRESSURE

A = 140 PSI INLET PRESSURE

C = 50 PSI INLET PRESSURE

B

A

C

FLOW RATE IN GALLONS PER MINUTE (GPM)

Ordering

Proc edure

North Americ a

Pressure Reducing Valve:

Specify: Globe Type, (specify size),

125 psi Outlet Set Pressure with (T

x T, G x G, or F x F) Connection, P/N

(specify from below).

P/Ns for GLOBE BODY STYLE

AVAILABLE IN AMERICAS

2 Inch T x T

NPT . . . . . . . . . . . . . . . . P/N 52-570-8-060

2 Inch G x G

2.37 inch (60,3 mm)

Groove O.D.. . . . . . . . . . P/N 52-570-8-920

3 Inch G x G

3.50 inch (88,9 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-922

4 Inch G x G

4.50 inch (114,3 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-923

4 Inch F x F

ANSI Flange . . . . . . . . . P/N 52-570-8-023

6 Inch G x G

6.62 inch (168,3 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-925

6 Inch F x F

ANSI Flange. . . . . . . . . P/N 52-570-8-025

8 Inch F x F

ANSI Flange . . . . . . . . . P/N 52-570-8-026

Pressure Relief Valve:

Specify: 1/2 inch (DN15) Watts Regu-

lator, Series 530C Pressure Relief

Valve for use downstream of a PRV-1

being used for reducing pressure in

sprinkler system, P/N 92-570-2-208.

Replacement Valve Parts:

Specify: (description) for use with

(specify) size Model PRV-1 Pressure

Reducing Valve, P/N (see Figure 3).

Ordering

Proc edure

South Americ a,

Central Americ a &

Eastern Hemisphere

Pressure Reducing Valve:

Specify: (Globe or Angle) Type, (spec-

ify size), 125 psi Outlet Set Pressure

with (specify) Connection (and for

flanged valves specify flange drilling),

P/N (specify from complete listing on

Page 16).

Valve Type & Size

(Globe, 2, 3, 4, 6, or 8 Inch)

(Angle, 2, 3, 4, or 6 Inch

125 psi Outlet Set Pressure

Pressure

Connection Type

(Threaded, Grooved, Flanged)

For threaded, specify NPT or ISO

For grooved, specify O.D. Pipe Size

- 2 inch (DN50):

2.88 inch (60,3 mm) O.D.

- 3 inch (DN80):

3.50 inch (88,9 mm) O.D.

- 4 inch (DN100):

4.50 inch (114,3 mm) O.D.

- 6 inch (DN150):

6.62 inch (168,3 mm) O.D. or

6.50 inch (165,1 mm) O.D.

- 8 inch (DN200):

8.62 inch (219,1 mm) O.D.

For flanged, specify flange drilling

per

- ANSI B16-1 (Class 125)

- ISO 7005-2 (PN16)

- ISO 7005-2 (PN10),

8 inch valve only

- JIS B2210 (10K)

- AS 2129 (Table E)

NOTES

Refer to Table A for flange drilling di-

mensional specifications.

Pressure Relief Valve:

Specify: 1/2 inch (DN15) Watts Regu-

lator, Series 530C Pressure Relief

Valve for use downstream of a PRV-1

being used for reducing pressure in

sprinkler system, P/N 92-570-2-208.

Replacement Valve Parts:

Specify: (description) for use with

(specify) size Model PRV-1 Pressure

Reducing Valve, P/N (see Figure 3).

Page 15 of 16

TFP1580

P/Ns for GLOBE BODY STYLE

2 Inch T x T

NPT . . . . . . . . . . . . . . . . P/N 52-570-8-060

2 Inch T x T

ISO . . . . . . . . . . . . . . . . P/N 52-570-8-160

2 Inch G x G

2.37 inch (60,3 mm)

Groove O.D.. . . . . . . . . . P/N 52-570-8-920

3 Inch T x T

NPT . . . . . . . . . . . . . . . . P/N 52-570-8-062

3 Inch T x T

ISO . . . . . . . . . . . . . . . . P/N 52-570-8-162

3 Inch G x G

3.50 inch (88,9 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-922

3 Inch F x F

ANSI Flange . . . . . . . . . P/N 52-570-8-022

3 Inch F x F

ISO (PN16) Flange. . . . P/N 52-570-8-112

3 Inch F x F

JIS Flange. . . . . . . . . . . P/N 52-570-8-722

3 Inch F x F

AS Flange . . . . . . . . . . . P/N 52-570-8-522

4 Inch G x G

4.50 inch (114,3 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-923

4 Inch F x F

ANSI Flange . . . . . . . . . P/N 52-570-8-023

4 Inch F x F

ISO (PN16) Flange. . . . P/N 52-570-8-113

4 Inch F x F

JIS Flange. . . . . . . . . . . P/N 52-570-8-723

4 Inch F x F

AS Flange . . . . . . . . . . . P/N 52-570-8-523

6 Inch G x G

6.62 inch (168,3 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-925

6 Inch G x G

6.50 inch (165,1 mm)

Groove O.D. . . . . . . . . . P/N 52-570-8-945

6 Inch F x F

ANSI Flange . . . . . . . . . P/N 52-570-8-025

6 Inch F x F

ISO (PN16) Flange. . . . P/N 52-570-8-115

6 Inch F x F

JIS Flange. . . . . . . . . . . P/N 52-570-8-725

6 Inch F x F

AS Flange . . . . . . . . . . . P/N 52-570-8-525

8 Inch F x F

ANSI Flange . . . . . . . . . P/N 52-570-8-026

8 Inch F x F

ISO (PN10) Flange. . . . P/N 52-570-8-116

8 Inch F x F

ISO (PN16) Flange. . . . P/N 52-570-8-126

8 Inch F x F

JIS Flange. . . . . . . . . . . P/N 52-570-8-726

8 Inch F x F

AS Flange . . . . . . . . . . . P/N 52-570-8-526

P/Ns for ANGLE BODY STYLE

2 Inch T x T

NPT. . . . . . . . . . . . . . . . P/N 52-571-8-060

2 Inch T x T

ISO . . . . . . . . . . . . . . . . P/N 52-571-8-160

2 Inch G x G

2.37 inch (60,3 mm)

Groove O.D.. . . . . . . . . P/N 52-571-8-920

3 Inch T x T

NPT. . . . . . . . . . . . . . . . P/N 52-571-8-062

3 Inch T x T

ISO . . . . . . . . . . . . . . . . P/N 52-571-8-162

3 Inch G x G

3.50 inch (88,9 mm)

Groove O.D. . . . . . . . . . P/N 52-571-8-922

3 Inch F x F

ANSI Flange. . . . . . . . . P/N 52-571-8-022

3 Inch F x F

ISO (PN16) Flange . . . P/N 52-571-8-112

3 Inch F x F

JIS Flange . . . . . . . . . . P/N 52-571-8-722

3 Inch F x F

AS Flange. . . . . . . . . . . P/N 52-571-8-522

4 Inch G x G

4.50 inch (114,3 mm)

Groove O.D. . . . . . . . . P/N 52-571-8-923

4 Inch F x F

ANSI Flange . . . . . . . . P/N 52-571-8-023

4 Inch F x F

ISO (PN16) Flange . . . P/N 52-571-8-113

4 Inch F x F

JIS Flange . . . . . . . . . . P/N 52-571-8-723

4 Inch F x F

AS Flange. . . . . . . . . . . P/N 52-571-8-523

6 Inch G x G

6.62 inch (168,3 mm)

Groove O.D. . . . . . . . . P/N 52-571-8-925

6 Inch G x G

6.50 inch (165,1 mm)

Groove O.D. . . . . . . . . P/N 52-571-8-945

6 Inch F x F

ANSI Flange . . . . . . . . P/N 52-571-8-025

6 Inch F x F

ISO (PN16) Flange . . . P/N 52-571-8-115

6 Inch F x F

JIS Flange . . . . . . . . . . P/N 52-571-8-725

6 Inch F x F

AS Flange. . . . . . . . . . . P/N 52-571-8-525

Page 16 of 16

TFP1580

2007 TYCO FIRE & BUILDING PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Coca-Cola Company Struggles With Ethical CrisesDocument16 pagesThe Coca-Cola Company Struggles With Ethical Crisesambition1340cnNo ratings yet

- Hodgson - Is Socialism Feasible (2019) - Pages-1,5,36-46Document13 pagesHodgson - Is Socialism Feasible (2019) - Pages-1,5,36-46ambition1340cnNo ratings yet

- Inventory Management System: Arina Ramlee, Bruce Chhay, David HenryDocument9 pagesInventory Management System: Arina Ramlee, Bruce Chhay, David Henryambition1340cnNo ratings yet

- Fomtec Foam Equipment BrochureDocument7 pagesFomtec Foam Equipment Brochureambition1340cnNo ratings yet

- DV-5 Wet Step by Step PDFDocument15 pagesDV-5 Wet Step by Step PDFambition1340cnNo ratings yet

- Fire Alarm Tal 1734 Electrical SpecificationDocument11 pagesFire Alarm Tal 1734 Electrical Specificationambition1340cnNo ratings yet

- Waterflow Indicator PDFDocument8 pagesWaterflow Indicator PDFambition1340cnNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Aerodynamic Design, Characterization and Flight Performance of RLV-TDDocument16 pagesAerodynamic Design, Characterization and Flight Performance of RLV-TDbalasubramanian.sNo ratings yet

- Iso 8010 - 1988Document61 pagesIso 8010 - 1988Rizki A-f100% (1)

- RA 9A23303 Fluid Flow in Bio ProcessesDocument1 pageRA 9A23303 Fluid Flow in Bio ProcessessivabharathamurthyNo ratings yet

- BN DS C43Document4 pagesBN DS C43yulianus_srNo ratings yet

- Aerodynamics 2 Exam #4Document8 pagesAerodynamics 2 Exam #4Kisna Bhurtel100% (1)

- Topic 1: Introduction To Fluid MechanicsDocument19 pagesTopic 1: Introduction To Fluid MechanicsAeroNo ratings yet

- Naval Arch - OutlineDocument19 pagesNaval Arch - OutlinezaamanishNo ratings yet

- Centrifugal Blowers and Industrial BlowersDocument5 pagesCentrifugal Blowers and Industrial BlowersAhmed AbdulnaimNo ratings yet

- Nano Fluids-Project ReportDocument35 pagesNano Fluids-Project ReportRavi vital100% (1)

- Effect of Integral Finned Tube On Heat Transfer CHDocument7 pagesEffect of Integral Finned Tube On Heat Transfer CHgiangfvuNo ratings yet

- Rodi 2017Document20 pagesRodi 2017Anonymous a7EsJT592No ratings yet

- Problem 1 PDFDocument67 pagesProblem 1 PDFStanley ChenNo ratings yet

- FMM Solved Unit 1 Previous Years ProblemsDocument14 pagesFMM Solved Unit 1 Previous Years ProblemsAjith KumarNo ratings yet

- Clariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MDocument6 pagesClariflocculator: Description Unit Input Calculated Range Value Value 54000 Mim M 492 M MAnonymous EKxXjqyVHNo ratings yet

- Measurement of Airflow in A Simulated Underground Mine Environment Using An Ultrasonic Anemometer C. D. Taylor, R. J. Timko, M. J. Senk, and A. LusinDocument8 pagesMeasurement of Airflow in A Simulated Underground Mine Environment Using An Ultrasonic Anemometer C. D. Taylor, R. J. Timko, M. J. Senk, and A. LusinVanco AdziskiNo ratings yet

- SI Heat 4e Chap08 Lecture-1Document80 pagesSI Heat 4e Chap08 Lecture-1Aiena AzlanNo ratings yet

- BERNOULLIS THEOREM PracticalDocument4 pagesBERNOULLIS THEOREM PracticalMandeep PathakNo ratings yet

- Mike 11 Reference ManualDocument536 pagesMike 11 Reference Manualkubow100% (2)

- Pipe Laying For Balayan Batangas MaterialsDocument1 pagePipe Laying For Balayan Batangas MaterialsFritz NatividadNo ratings yet

- HMT 2Document2 pagesHMT 2Yathish YathiNo ratings yet

- Agar50series MPFM SpecDocument4 pagesAgar50series MPFM SpecJADNo ratings yet

- PLAXIS 2D 2017 Tutorial Lesson07Document13 pagesPLAXIS 2D 2017 Tutorial Lesson07Boni TamaNo ratings yet

- Lab Manual of Hydraulics PDFDocument40 pagesLab Manual of Hydraulics PDFJULIUS CESAR G. CADAONo ratings yet

- EG502A (FINAL) Well Test - Analysis and DesignDocument5 pagesEG502A (FINAL) Well Test - Analysis and DesignMohamed-DeqSabriyeNo ratings yet

- 000 My PPT - Mod 3 Open ChannelDocument31 pages000 My PPT - Mod 3 Open ChannelChinnu NinanNo ratings yet

- 5-Summary of The Fifth TrainingDocument16 pages5-Summary of The Fifth Trainingamine aouamNo ratings yet

- Pag 27Document77 pagesPag 27camilokun95No ratings yet

- MEC2404 Frictional Flow in Pipe Lab RepoDocument10 pagesMEC2404 Frictional Flow in Pipe Lab Repoatik100% (1)

- EpplerDocument5 pagesEpplersumon1314No ratings yet

- Analysis of Heat and Mass Transfer On Cooling Tower FillDocument8 pagesAnalysis of Heat and Mass Transfer On Cooling Tower FillabdulazizrohmanhakimNo ratings yet