Professional Documents

Culture Documents

Fans & Blowers

Uploaded by

Sanjoy Kr. DeyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fans & Blowers

Uploaded by

Sanjoy Kr. DeyCopyright:

Available Formats

Confederation of Indian Industry

Fans & Blowers

Confederation of Indian Industry

Fans & Blowers

v Simple Definition

Machines to move gases (or) gases mixed

with small solid particles

v Operation of fans & pumps similar

v Broad Classification

Centrifugal

Axial

Confederation of Indian Industry

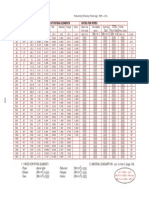

Difference Between Fans, Blowers

and Compressors

- > 1.20 Compressors

1136 2066 1.11 to 1.20 Blowers

1136 < 1.11 Fans

Pressure rise

(mm WG)

Specific

Pressure*

Equipment

As per ASME Definition

* Ratio of discharge pressure to suction pressure

Confederation of Indian Industry

v Capacity (RPM)

v Head (RPM)

2

v Power (Capacity x Head)

(RPM)

3

Fans & Blowers - Formulae

Confederation of Indian Industry

Fans & Blowers Formulae

v Capacity :

v Head :

v Power :

If the RPM is reduced by say 10%, what

will happen to the

reduce by 10%

reduce by 19%

reduce by 27%

Confederation of Indian Industry

Characteristic Curve of Fan

N1 rpm

N2 rpm

Power consumption

80%

76%

74%

Volumetric Flow

S

t

a

t

i

c

P

r

e

s

s

u

r

e

Confederation of Indian Industry

Fan Efficiency

fan

= Q (m

3

/ s) x P (mm WC)

102 x

motor

x kW (I)

Where,

Q = Volumetric Flow

P = Static Head Developed by fan

Typical Efficiencies 40 to 70%

Confederation of Indian Industry

Factors Affecting Fan Performance

v RPM

v Diameter

v Density

v Temperature

RPM Diameter Density Temperature

Volumetric n D

3

- -

capacity

Pressure rise n

2

D

2

1/ T

Power

consumption n

3

D

5

1/ T

Confederation of Indian Industry

Effect of Various Capacity Controls

100

80

60

40

20

20 40 60 80 100

Q in %

k

W

i

n

%

Recirculation

VFD

Damper

On/ off Ideal

VFC

Confederation of Indian Industry

I nlet Guide-vane control

Confederation of Indian Industry

I nlet Guide-vane control

v Different from damper

v Guide-vane gives a twist to the air in the

direction of rotation

q Different characteristic curve

q Useful for marginal capacity reductions

v Useful earlier

q VFDs were not cost economic

q VFD reliability was a question

Confederation of Indian Industry

Throttling of a Fan

v Suction/ Delivery

v Why?

Confederation of Indian Industry

Throttling - Suction

0 mm

-600 mm -700 mm

Average pressure of fan = (10336 - 700) + (10336 0)

2

= 9986 mm WG

Confederation of Indian Industry

Average density higher, power consumption higher

Average pressure of fan = (10336 - 600) + (10336 + 100)

2

= 10086 mm WG

Throttling - Delivery

+100 (120) mm

-600 mm

0 mm

Confederation of Indian Industry

Power Consumption - Oversized Fan

Fan designed

v 1,20,000 m

3

/ h

v 650 mm Wg

Actual requirement

v 90,000 m

3

/ h

v 510 mm Wg

10 mm Wg

Damper 60%

-500 mm Wg -720 mm Wg

Confederation of Indian Industry

Potential in Oversized Fan

Energy saving potential in over sized fan

= x Power Cons.

= [(720 500)/ (10 (-720)] x 289 kW

= (220/ 730) x 289 kW

= 87 kW

P across damper

Total pressure rise

Confederation of Indian Industry

Energy Audit in Fans & Blowers

v Is it off the correct capacity/ head?

v How is the fan controlled?

Damper throttling

Guide vane control

Speed control GRR / SPRS / VFD

Confederation of Indian Industry

v Can the capacity/ head be further fine tuned?

v What is the efficiency of fan?

v Can it be replaced by high fan

v Is it possible to reduce system resistance

Suction / discharge side ?

v Can fan operation be interlocked with

process operation?

Energy Audit in Fans & Blowers

Confederation of Indian Industry

Can fan be replaced by one of

lower capacity / head ?

Confederation of Indian Industry

Coal Mill Ventilation Fan Speed Reduction

v Pressure drop = (90/ 365) X 100

= 24%

v Head required = 0.76 times present head

+ 5 mm

50%

BF

-360 mm

-270 mm

38 kW

Confederation of Indian Industry

Coal Mill Ventilation Fan Speed Reduction

v Fan had belt drive

v RPM of fan reduced by 10%

Annual Savings = Rs. 1.34 Lakhs

I nvestment = Rs.0.05 Lakhs

Payback period = 1 month

Confederation of Indian Industry

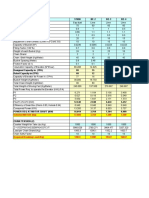

COAL MI LL VENT FAN - 2

Coal Mill Vent Fan

-11 mm

462 m

3

/min

288 mmWC

45 kW

18.3 kW

-140 mm

Confederation of Indian Industry

Fan Characteristic Curve

50 Hz

36 Hz

Volumetric Flow

S

t

a

t

i

c

P

r

e

s

s

u

r

e

288

462

150

333

130

403

54%

Confederation of Indian Industry

v Fan Efficiency - 54%

v Install a correct size higher efficient fan

q At least 70% efficiency

v Total savings - 7.4 kW

I nstall Correct size Fan for Coal Mill

Vent Fan - 2

Confederation of Indian Industry

I nstall Correct size Fan for Coal Mill

Vent Fan - 2

v Annual Savings : Rs. 0.92 Lakhs

v Investment : Rs. 1.00 Lakh

v Payback : 13 months

Confederation of Indian Industry

Control of fans

Confederation of Indian Industry

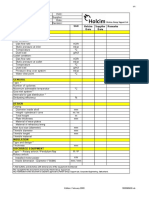

I nstall VFD for Boiler I D Fan

Present Control

v Damper Based on Furnace Draught

v Energy Loss Across Damper

-60 mm -110 mm

50%

ID Fan

53 kW

VFD 29 kW

30

TPH

Boiler

ESP

PIC

VFD

Confederation of Indian Industry

Install VFD for Boiler ID Fan

Install VFD

Control by Varying Speed

Damper - 100% Open

Power with damper = 53 kW

Power with VFD = 29 kW

Savings = 24 kW

Annual Savings - Rs. 7.76 Lakhs

I nvestment - Rs. 6.85 Lakhs

Payback period - 11 Months

Confederation of Indian Industry

System Resistance reduction

Confederation of Indian Industry

Suction side pressure drop

v Extensive discussions held

q Fan suppliers BHEL & ABB

q Fan experts

v Suction pressure drop

q Not more than 15-20mm

v Cooler fans invariably very high - 70-90 mm

q Intentional

Confederation of Indian Industry

Fan inlet pressure drop

- 94 mm

v Total Pr Rise of Fan - 558 mm WC

v I nlet pressure loss - 16.8% of pr developed

v Power consumption - 210.2 kW

Cooler fan - 10

Confederation of Indian Industry

Piezo Ring Characteristic Curve

Confederation of Indian Industry

Suction side pressure drop

v Typically flow measurement

q using Piezometer ring

q Additional pressure difference for accuracy

v Measures to be taken

q Reduce inlet pressure drop

q Measure air flow

v For reducing the inlet pressure drop

q I nlet Air velocity - 10-12 m/ sec

q Reduction in entry loss using bell mouth

Confederation of Indian Industry

Modification of suction side

v Radius of bell mouth

- 0.25 x effective diameter

v Flow measurements using aerofoil

r

Confederation of Indian Industry

Flow measurement

v Aerofoil in cooler fans

q I nitial apprehension dust

q Prone for wear due to dust

v Extensively practiced in power plants FD fans

v Potential in cooler fans no. 5 and 10

v I nlet Pressure not more than 20 mm WC

v Saving potential - 6-7%

Confederation of Indian Industry

Flow Measurement - Alternate

v Majority fitted with VFDs

v After inlet modification

q Speed & discharge pr. thro a software to

determine the flow

Confederation of Indian Industry

Lower inlet suction pressure drop

in identified fans

Annual savings - Rs 8.58 Lakhs

Investment - Rs 2.0 Lakhs

Payback period - 3 Months

Confederation of Indian Industry

VFD for cooling Tower fans

v Conventional control On-Off

v One fan switched Off-during favourable

condition

q Energy Saving Partial

q 50% of heat transfer area not utilised

Confederation of Indian Industry

VFD for cooling Tower Fans

v Latest Trend-I nstallation of VFD

v Operate both fans at 50% speed

q Heat transfer area fully utilised

v Pressure drop (Velocity)

2

v Reduction in Velocity by 50%

q Reduction in pressure drop 75%

v I n axial flow fans, power Pressure drop

q Power savings 75%

Confederation of Indian Industry

Case Study

v Centralized cooling tower

q 2 out of 4 fans operated

v Cooling Tower Fans Provided with TI C

q ON at 32 Deg C

q OFF at 30 Deg C

v Benefits

q Two cells not used

q 20% energy savings achieved

v I nstalled VFD for all fans after revamp

Confederation of Indian Industry

Case Study

v Operate all fans at 50% speed

q All cells area fully utilised

v 50% energy savings achieved

Annual savings = Rs 2.64 lakhs

Investment = Rs 2.50 lakhs

Payback period = 11 months

Confederation of Indian Industry

Thank You

You might also like

- Pipes. Wall Thickness Calculation According ASME - B31.3Document98 pagesPipes. Wall Thickness Calculation According ASME - B31.3acildeNo ratings yet

- Control Valve Training MaterialDocument36 pagesControl Valve Training MaterialSanjoy Kr. DeyNo ratings yet

- Pump AlignmentDocument1 pagePump AlignmentSanjoy Kr. Dey100% (1)

- Orifice and Jet FlowDocument8 pagesOrifice and Jet FlowEngr Arafat Qubati75% (4)

- Introduction To Piping Material ActivitiesDocument23 pagesIntroduction To Piping Material ActivitiesAnh Vân TrầnNo ratings yet

- Anchor Flange Design CalculationDocument6 pagesAnchor Flange Design CalculationJohakim974No ratings yet

- Interstitial Velocity GuidelinesDocument6 pagesInterstitial Velocity GuidelinesnaushadNo ratings yet

- System Curve Fan Curve Operating PointDocument45 pagesSystem Curve Fan Curve Operating PointAnonymous I0JAds2SP100% (1)

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocument2 pagesUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTPradeepNo ratings yet

- Fans & BlowersDocument88 pagesFans & BlowerssunilNo ratings yet

- Combustion Air Fan CalculationDocument2 pagesCombustion Air Fan CalculationVijay BhanNo ratings yet

- Corrosion Protection RatesDocument1 pageCorrosion Protection RatesB Girish82% (57)

- Cooler BalanceDocument16 pagesCooler BalanceIrfan Ahmed100% (1)

- Presentation ConocoPhillips Gas SeparatorDocument24 pagesPresentation ConocoPhillips Gas SeparatorEnyerberht Castañeda BritoNo ratings yet

- Hydraulic SymbolsDocument18 pagesHydraulic SymbolsBhaskar Reddy100% (1)

- Penta Engineering Corp. Fan Power CalculationDocument3 pagesPenta Engineering Corp. Fan Power CalculationManoj ThakurNo ratings yet

- Optimize Distillation ColumnsDocument16 pagesOptimize Distillation Columnscrnewsom100% (3)

- Multipass Tray DesignDocument12 pagesMultipass Tray DesignAyoun Ul HaqueNo ratings yet

- PG-PDC-InL-PL-CAL-002 Pipe Sizing and Wall Thickness Calculation Rev a-IfRDocument9 pagesPG-PDC-InL-PL-CAL-002 Pipe Sizing and Wall Thickness Calculation Rev a-IfRCahyadi YadiNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatordadNo ratings yet

- 4.6 Fans and BlowersDocument6 pages4.6 Fans and Blowerssrimant1984No ratings yet

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldDocument1 pageBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurNo ratings yet

- Fan Tool Kit - Ad Hoc Group - V4ddDocument121 pagesFan Tool Kit - Ad Hoc Group - V4ddhmaza shakeelNo ratings yet

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiNo ratings yet

- Hydrodynamic Bearing-Kingsbury PDFDocument27 pagesHydrodynamic Bearing-Kingsbury PDFMachineryengNo ratings yet

- 6 LubricationDocument20 pages6 LubricationSanjoy Kr. DeyNo ratings yet

- Clinker Cooler Queching Best PracticeDocument1 pageClinker Cooler Queching Best PracticeShukor AzNo ratings yet

- Selecting A Fan From A Fan CurveDocument3 pagesSelecting A Fan From A Fan CurvesivajaNo ratings yet

- 1705 N-Power-calc-for-BEDocument2 pages1705 N-Power-calc-for-BEIrfan AhmedNo ratings yet

- Loss in Weight TrainingDocument22 pagesLoss in Weight TrainingSantrupta PandaNo ratings yet

- CPB Brochure Diaphragms en 2Document12 pagesCPB Brochure Diaphragms en 2ebrahimNo ratings yet

- AWE Kiln Gas DensityDocument2 pagesAWE Kiln Gas DensityNadia AbesNo ratings yet

- Fan Selection & PerformanceDocument63 pagesFan Selection & PerformanceVishva Deepak MishraNo ratings yet

- 22 ATC ARA DebottleneckingDocument15 pages22 ATC ARA DebottleneckingmkpqNo ratings yet

- Breaker KOM PDFDocument50 pagesBreaker KOM PDFnamduong368100% (5)

- Bag Filter Optimization in Cement IndustryDocument89 pagesBag Filter Optimization in Cement IndustryNITITN ASNANINo ratings yet

- Typical Cement Mill Bag Filter Capital Cost CamparisonDocument1 pageTypical Cement Mill Bag Filter Capital Cost CamparisonKenny RuizNo ratings yet

- Oversized Pumps & Fans Energy WasteDocument25 pagesOversized Pumps & Fans Energy Wastebaldonado1No ratings yet

- Cooler Air Distribution CalculationDocument18 pagesCooler Air Distribution CalculationSatish KumarNo ratings yet

- Air CompreesorDocument59 pagesAir CompreesorramprakashpatelNo ratings yet

- TECHNICAL SPECIFICATIONS FOR AN AIR TO AIR HEAT EXCHANGERDocument1 pageTECHNICAL SPECIFICATIONS FOR AN AIR TO AIR HEAT EXCHANGERpawanroyalNo ratings yet

- Calculate Bucket Elevator CapacityDocument2 pagesCalculate Bucket Elevator CapacityBùi Hắc HảiNo ratings yet

- Fuel Savings and Efficiency CalculatorDocument6 pagesFuel Savings and Efficiency Calculatorrajayu20002724No ratings yet

- Identification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsDocument13 pagesIdentification Data: Description Fan - 1 Fan - 2 Fan - 3 Fan - 4 CommentsAngel CarvajalNo ratings yet

- Bag FilterDocument27 pagesBag FiltermkpqNo ratings yet

- Waste Heat Recovery System For Cement PlantDocument6 pagesWaste Heat Recovery System For Cement PlantandrowreganNo ratings yet

- 10 BagHouseDocument32 pages10 BagHouseSrikant Ch100% (1)

- NPTEL Hydraulics Quiz SolutionsDocument22 pagesNPTEL Hydraulics Quiz SolutionsMohammed Sobhi78% (9)

- Pneumatic Transport Pressure Loss CalculationDocument2 pagesPneumatic Transport Pressure Loss CalculationMugurelVasilescuNo ratings yet

- Volume CalculationDocument6 pagesVolume CalculationAnup DoluiNo ratings yet

- Combustion CalculationDocument2 pagesCombustion CalculationRamachandran VenkateshNo ratings yet

- Coal Drying (Dry Basis)Document9 pagesCoal Drying (Dry Basis)billyNo ratings yet

- HPGRSim Openpractica1Document83 pagesHPGRSim Openpractica1Aldo PabloNo ratings yet

- WHRS and PP For Cement Plants - Todays Boiler Spring 2014Document2 pagesWHRS and PP For Cement Plants - Todays Boiler Spring 2014ash22202No ratings yet

- High Air To Cloth Ratio Bag FilterDocument2 pagesHigh Air To Cloth Ratio Bag Filterayaskant751001No ratings yet

- Heat BalenceDocument544 pagesHeat BalenceSantanu PachhalNo ratings yet

- Data Sheet Jet Pulse Bag FilterDocument1 pageData Sheet Jet Pulse Bag FilterHassan SleemNo ratings yet

- FAD and NTP Calculations for Air FlowDocument1 pageFAD and NTP Calculations for Air FlowDurjoy ChakrabortyNo ratings yet

- Bag Filter Design & Gasometer SizingDocument9 pagesBag Filter Design & Gasometer SizingPoovanaan Sathiya SeelanNo ratings yet

- Voltage Drop CalculatorDocument1 pageVoltage Drop Calculatorpandi27No ratings yet

- Aeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramDocument4 pagesAeroduct Program (Duct Sizing) : Characteristics and Functions of The ProgramAshraf KamalNo ratings yet

- Flow Conversion To Normal Meter Cube Per HourDocument2 pagesFlow Conversion To Normal Meter Cube Per HourIrfan AhmedNo ratings yet

- Cyclone Pressure DropDocument8 pagesCyclone Pressure DroppradeepdesaiuchNo ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- Low NOx Rotary Kiln Burner TechnologyDocument6 pagesLow NOx Rotary Kiln Burner TechnologyKristínaNo ratings yet

- Cooler-2 DiagramDocument3 pagesCooler-2 DiagramPraveen Singh Chouhan100% (1)

- Improving efficiency of industrial fansDocument19 pagesImproving efficiency of industrial fansmkpqNo ratings yet

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Document2 pagesCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalNo ratings yet

- Benchmarks IndiaDocument78 pagesBenchmarks IndialafecapoNo ratings yet

- Pneumatic Conveying: There Is Virtually No Limit To The Range of Materials ThatDocument38 pagesPneumatic Conveying: There Is Virtually No Limit To The Range of Materials ThattechbhaskarNo ratings yet

- Preheater Cyclone Dsigns: Tube Dia X EntryDocument6 pagesPreheater Cyclone Dsigns: Tube Dia X EntrynileshNo ratings yet

- Flow Characteristics:: B. Pressure Loss (Head Loss, PressureDocument4 pagesFlow Characteristics:: B. Pressure Loss (Head Loss, PressureLily NurdianaNo ratings yet

- Ministry of Civil Defence Code of Rules on HVAC Fire SafetyDocument28 pagesMinistry of Civil Defence Code of Rules on HVAC Fire SafetyMikhail MalyginNo ratings yet

- FANPOWDocument3 pagesFANPOWElwathig BakhietNo ratings yet

- Cylcone Type Selection RouteDocument75 pagesCylcone Type Selection RouteAnonymous pVoSWn8yh0No ratings yet

- Performance Driven Maintenance Feb 52013Document25 pagesPerformance Driven Maintenance Feb 52013recaiNo ratings yet

- 11 VSD& Harmonics PDFDocument100 pages11 VSD& Harmonics PDFsiruslara6491No ratings yet

- Mech - Seal Drawing 2H-104559 - 42-P-004CDocument1 pageMech - Seal Drawing 2H-104559 - 42-P-004CSanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H-71465 - 41-P-001Document1 pageMech - Seal Drawing 2H-71465 - 41-P-001Sanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H-84182 - 43-P-003D, EDocument1 pageMech - Seal Drawing 2H-84182 - 43-P-003D, ESanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H-107461 - 43-P-107Document1 pageMech - Seal Drawing 2H-107461 - 43-P-107Sanjoy Kr. DeyNo ratings yet

- 2H 73197Document1 page2H 73197Sanjoy Kr. DeyNo ratings yet

- B-232 Model Premium Gearbox - DatasheetDocument1 pageB-232 Model Premium Gearbox - DatasheetSanjoy Kr. DeyNo ratings yet

- Ofd en WebDocument6 pagesOfd en WebSanjoy Kr. DeyNo ratings yet

- 24#150-HB Valve-SWDocument1 page24#150-HB Valve-SWSanjoy Kr. DeyNo ratings yet

- Mech - Seal Drawing 2H 72386 - 47 P 001Document1 pageMech - Seal Drawing 2H 72386 - 47 P 001Sanjoy Kr. DeyNo ratings yet

- Fundamentals of CompressorDocument16 pagesFundamentals of CompressorSanjoy Kr. DeyNo ratings yet

- Vertical and Horizontal Motor Alignment InstructionsDocument3 pagesVertical and Horizontal Motor Alignment InstructionsSanjoy Kr. DeyNo ratings yet

- 24#150-HB Valve-HWDocument1 page24#150-HB Valve-HWSanjoy Kr. DeyNo ratings yet

- CouplingDocument19 pagesCouplingSujitkun NutalayaNo ratings yet

- Catalogo Lovejoy Serie JawDocument26 pagesCatalogo Lovejoy Serie JawJuan Pablo CirizaNo ratings yet

- Welding: Debasis Mitra Inspection DepartmentDocument31 pagesWelding: Debasis Mitra Inspection DepartmentSanjoy Kr. DeyNo ratings yet

- Steps To Check SKF BearingsDocument1 pageSteps To Check SKF BearingsSanjoy Kr. DeyNo ratings yet

- 24#150 HB Valve-BodyDocument1 page24#150 HB Valve-BodySanjoy Kr. DeyNo ratings yet

- Distill TraysDocument2 pagesDistill TraysSanjoy Kr. DeyNo ratings yet

- Distillation Tray DegassingDocument2 pagesDistillation Tray DegassingSanjoy Kr. DeyNo ratings yet

- Cathodic ProtectionDocument36 pagesCathodic ProtectionSanjoy Kr. DeyNo ratings yet

- 4 Mounted BearingsDocument23 pages4 Mounted BearingsSanjoy Kr. DeyNo ratings yet

- Coupling AlignmentDocument1 pageCoupling AlignmentMahmoud AhmedNo ratings yet

- Protech Bearing Isolator Seal TheoryDocument8 pagesProtech Bearing Isolator Seal TheorySanjoy Kr. DeyNo ratings yet

- Harvald Resistance and Propulsion of Ships - Ocred PDFDocument90 pagesHarvald Resistance and Propulsion of Ships - Ocred PDFÖmer Faruk KorkmazNo ratings yet

- FlowconME Valves Catalogue 27Document1 pageFlowconME Valves Catalogue 27mohansafNo ratings yet

- Belt Drive Type: 7,5kW - 45kW 22kW - 250kW 15kW - 250kW 10 - 500 HPDocument2 pagesBelt Drive Type: 7,5kW - 45kW 22kW - 250kW 15kW - 250kW 10 - 500 HPAriantoNo ratings yet

- Priority Pipe ProcurementDocument17 pagesPriority Pipe ProcurementJahangir AlamNo ratings yet

- General Pumping System and The Net Head Developed by A PumpDocument14 pagesGeneral Pumping System and The Net Head Developed by A PumpMohit SharmaNo ratings yet

- Flow Rate Calculations for Venturi Meters and Orifice PlatesDocument4 pagesFlow Rate Calculations for Venturi Meters and Orifice PlatesSC TagleNo ratings yet

- Pastite For Pipe Connection System Bul 4300 PTPDocument6 pagesPastite For Pipe Connection System Bul 4300 PTPanoop9079No ratings yet

- Hydraulic CircuitsDocument25 pagesHydraulic CircuitspriyanthabandaraNo ratings yet

- GE - Frame - 9E - LUBE - OIL - FILTER - LOF11Document14 pagesGE - Frame - 9E - LUBE - OIL - FILTER - LOF11Abbas AkbarNo ratings yet

- 906Document47 pages906LekembauerNo ratings yet

- IFPSA Master Symbol Chart PDFDocument1 pageIFPSA Master Symbol Chart PDFanush_swaminathanNo ratings yet

- E10157-0!08!16 Accessories SchienentechnikDocument8 pagesE10157-0!08!16 Accessories Schienentechnikn_lohrmannNo ratings yet

- Marine ValvesDocument6 pagesMarine ValvesENG PTBBSNo ratings yet

- Nash Compressors enDocument3 pagesNash Compressors enAli MadandarNo ratings yet

- 7 e CHP 8 SMITDocument76 pages7 e CHP 8 SMITNicholas Ward100% (1)

- Flow Equations and Head Loss Calculations for Pipes and OrificesDocument21 pagesFlow Equations and Head Loss Calculations for Pipes and OrificesDexter DoteNo ratings yet

- Regulatoare DKRDocument3 pagesRegulatoare DKRSanimouse MousesaniNo ratings yet

- P Series Top Mount Filter (P350-P700) : Code Model No Filter Area (M) Valve Connections Max Flow Rate Sand (KG)Document1 pageP Series Top Mount Filter (P350-P700) : Code Model No Filter Area (M) Valve Connections Max Flow Rate Sand (KG)Jaka KelanaNo ratings yet

- 6060 Hydraulic Oil CoolingDocument9 pages6060 Hydraulic Oil Coolingedison barrionuevoNo ratings yet