Professional Documents

Culture Documents

Starter Motor

Uploaded by

fieraminaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Starter Motor

Uploaded by

fieraminaCopyright:

Available Formats

What is a

Motor Starters??

When the stator windings of an induction

motor are connected directly to its 3-phase supply, a

very large current (5-8 times full load current) flows

initially.

This lage current reduces as the motor

accelerates up to its running speed.

nduction motors can !e "irect-on #ine ("$#)

started in this way.

The starting current will not cause damage to

the motor unless the motor is repeatedly started and

stopped in a short space of time.

This is called %fast cycling&. When very large

motors are started direct-on-line they cause a

distur!ance of voltage (voltage dip) on the supply lines

due to the large starting current surge.

This voltage distur!ance may result in the

malfunction of other electrical e'uipment connected to

the supply.

To limit the starting current some large

induction motors are started at reduced voltage and

then have the full supply voltage reconnected when they

have run up to near rated speed.

"irect-on-line starting is the method most

commonly used, the most usual consideration !eing

whether the generator and the distri!ution system can

withstand the starting current without e(cessive voltage

dips.

n the case of loads involving considera!le

inertia, such as centrifugal oil separators, the starting

time may also !e a factor. n case of dou!t, the motor

manufacturer should !e consulted.

The starting current as we have already seen

may !e five to eight times the full load current, and the

heating of the windings is proportional to the s'uare of

the current.

)t starting it will therefore !e *5-+, times

normal.

-urthermore, at the instant of start there is no

windage and no radiation. Therefore a very long starting

period may result in overheating.

-or these reasons it is also undesira!le to

ma.e repeated successive starts without intervening

periods for cooling.

The contactor coil is connected in series with a

start !utton, stop !utton and overload trip contacts.

This is called the control circuit and is

energised from two lines of the 3-phase supply / usually

via a step-down transformer.

When the start !utton is pressed the control

supply is connected to the contactor coil.

The contactor closes and then starts the

motor. When the start !utton is released its contacts

spring open.

)n au(iliary contact on the contactor .eeps

the contactor coil energised after the start !utton is

released.

0ressing the stop !utton !rea.s the control circuit to

the contactor coil1 the contactor trips and the motor

stops.

f the motor ta.es too much current !ecause it

is mechanically overloaded or stalled, the overload coils

will either magnetically or thermally open the overload

trip contacts which will stop the motor and prevent

overheating.

2ote, the correct term is %overcurrent& rather

than the commonly used %overload&.

3educed voltage starting is used for large motors

driving loads li.e cargo pumps and !ow thrusters.

Two methods of reduced voltage starting are star-delta

starting and autotransformer starting.

)fter "$# starting, the ne(t most common method is the

star-delta method.

4oth ends of each phase of the motor starter

windings must !e !rought out and connected to starter.

n the start position the windings are

connected in star1 in the running position they are

reconnected in delta.

The voltage across each phase winding in the

start position is 585 (6783) of line voltage, with

conse'uent reduction of starting current.

The starting tor'ue is also reduced to one-

third of that which would o!tain with d.o.l. starting.

With a single-cage or dou!le-cage rotor of

average performance, this represent a!out 895 of full-

load tor'ue, assuming normal line voltage, !ut if there is

apprecia!le line drop the tor'ue will !e proportionately

lower.

These factors must !e ta.en into account

when deciding whether star-delta starting is accepta!le

for the driven machine.

t will !e accepta!le for centrifugal fans and

pumps if, in the latter case, the friction at starting is not

e(cessive.

When the operating handle is placed in the %start&

position the motor stator windings are connected in star

across the supply.

)s the motor approaches normal running speed the

operator must 'uic.ly change the handle to run position

which changes the motor connection from star to delta.

f the operator does not move the handle

'uic.ly from start to run the motor may !e disconnected

from the supply long enough for the motor speed to fall

considera!ly.

When the handle is eventually put into the run

position the motor will ta.e a large current may !e large

current and accelerate up to speed again.

This surge current may !e large enough to

cause apprecia!le voltage dip. The prevent this, a

mechanical interloc. is fitted to the operating handle.

The handle must !e moved 'uic.ly from start to run

otherwise the interloc. :ams the handle in the start

position.

)n automatic change over is prefera!le and this is

achieved !y using contactors.

;tar-"elta starter se'uence<

$perator closes motor isolator ; then presses start

!utton.

;tart !utton connects the supply to contactor coil ;.

=ontactor contacts ; close and au(iliary contacts ;6

close.

# close, motor windings are star connected to 3-phase

supply, motor starts.

)u(iliary contacts #6 close at the same time as

contactor contacts #.

The operator may now release the start !utton since

supply to # is maintained through #6.

)fter a time interval which allows the motor to run up to

speed, au(iliary contacts #* and #3 close.

=ontactor coil ; is de-energised and its contacts ;

open1 so do the au(iliary contact ;6.

=ontactor coil " is energised and the motor is

now delta connected to the 3-phase supply.

n some cases a mechanical interloc. is fitted

!etween the contactor contact ; and " so that !oth

cannot !e closed at the same time.

The auto-transformer starter is more e(pensive

than two type so far descri!ed and is generally used

only for the larger types of motor.

t is suita!le for motors in which each end of

the three phases is not !rought out, and which would

therefore !e unsuita!le for star-delta starting.

The starting conditions depend on the position

of the tapping on the transformer winding, i.e. on the

secondary voltage.

>sually three or more tappings are provided so

that there is a choice of starting conditions such as ,9,

+9 or ?55 of line voltage.

The starting tor'ues on these different

tappings can !e estimated as they are proportional to

the s'uare of the voltage.

$n the +95 tapping the tor'ue will !

appro(imately the same as with star-delta starting, and

on the ,9 and ?55 tapping it will !e proportionately

lower and higher respectively.

;tarting large motors with long-run up periods

demands a very high current surge from the supply

generator.

This causes a severe voltage dip which affects

every load on the system. 3educed voltage starting will

limit the starting surge current.

$ne way to reduce the initial voltage supplied

to the motor is to step it down using a transformer.

Then, when the motor has accelerated up to

almost full speed, the reduced voltage is replaced !y the

full mains voltage.

The transformer used in this starter is not the

usual type with separate primary and secondary

windings.

t is an autotransformer which uses only one

winding for !oth input and output.

This arrangement is cheaper, smaller and

lighter than an e'uivalent dou!le-wound transformer.

-or induction motor starting, the autotransformer is a 3-

phase unit, and !ecause of e(pense, this method is only

used with large motor drives, e.g. electric cargo pumps.

The autotransformer with its range of tapping

points gives a set range of starting voltages to limit the

motor starting surge current to a reasona!le value.

)s with the star-delta starter, the

autotransformer may use what is called an open

transition switching se'uence or a closed transition

switching se'uence !etween the start and run

conditions.

n the former, the reduced voltage is rapidly

reconnected to the motor.

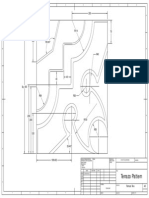

The circuit diagram !elow shows a manually operated

open transition, autotransformer starter.

The pro!lem with open transition is that a very

large surge current can flow after the transition from

reduced to full voltage.

)n arrangement which overcomes the

transition switching pro!lem is the closed transition

%@orndorfer& starting method. ) typical circuit is shown

!elow.

When the start !utton is pressed the first stage

contactor coil is energised which closed the main 6

st

contacts and also 6

st

76 and 6

st

7*.

The timer relay coil and the second stage

contactor coil are also energised.

The main *st contacts close, which applies a

reduced voltage from the autotransformer to the motor

windings.

The motor starts. )fter a preset time interval

the times relay opens tr7* which drops out the second

stage contactor.

The star point of the transformer is opened !y

*st so that transformer action no longer ta.es place.

The transformer winding no :ust acts as an

inductive voltage dropping impedance in the supply

lines to the motor.

The voltage applied to the motor is now higher

than !efore !ut is still less than the full supply voltage.

)fter a further time interval the timer relay

closes tr73, which energises the changeover relay.

The changeover relay closes the run contactor

which puts full voltage on to the motor.

)u(iliary contacts rn7* and rc76 on this

contactor drop out the first stage contactor and

maintain the supply to the run contactor coil,

respectively.

The stop !utton or overcurrent relay trips out

the run contactor to stop the motor.

The windings of the autotransformer are short-

time rated and the starting period must not !e unduly

prolonged.

The rating for %ordinary& during is usually

suita!le for not more than two starts per hour.

)fter two consecutive starts a minimum

su!se'uent cooling period of +9 minutes is necessary.

f more fre'uency starting is re'uired, starters

rated for intermittent duty (,9 starts per hour) should !e

specified.

Alectronic starters often referred to as %soft

start&, are finding acceptance in the marine industry.

;olid-state technology is employed to provide

a method of starting without the current and tor'ue

surges mentioned previously.

Thyristors or a com!ination of thyristors and

diodes are used to control the current flow during motor

starting.

The !asic circuit diagrams for these two

alternatives are shown !elow.

The electronics for controlling the firing of the

thyristors is normally accommodated on a small printed

circuit !oard within the motor controller.

)lthough the thyristor7diode configuration is

cheaper it has the disadvantage that it generates third

and even harmonic currents in the motor windings,

whereas the all-thyristor arrangement restricts the even

harmonics.

With this type of starter there are normally three

ad:ustments that have to !e set to suit the drive

machinery<

6. Boltage ramp - This sets the time for the starter to

achieve full voltage output. t should !e noted that the

ramp time is the time ta.en for the output voltage to

reach its ma(imum and not for the motor to reach its full

speed.

f a motor is lightly loaded it may well achieve full speed

!efore full voltage is applied.

*. =urrent limit - This ad:ustment is used to prevent the

starting current e(ceeding a preset value. 4ecause

tor'ue is proportional to the s'uare of the current it

must !e set sufficiently high that ade'uate tor'ue is

developed to accelerate the load from rest.

3. nitial firing angle - t is often important that a drive

should start as soon as voltage is applied, e.g. if the

drive is stand!y to a duty unit.

f the initial firing angel is set too small there

will !e a delay in starting the drive until the voltage has

!een ramped to a value permitting sufficient tor'ue to

!e developed to accelerate it from the rest. f the initial

firing angle is set too large the load may !e suddenly

gra!!ed rather than accelerated smoothly.

Triacs can also !e used for electronic starters. Cowever,

since they have relatively low current ratings and

!rea.down voltages they are generally suita!le only for

low-current low-voltage applications.

You might also like

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Motor StartersDocument9 pagesMotor Startersanon_896479742No ratings yet

- Theory of Operation - Autotransformer Starter PDFDocument3 pagesTheory of Operation - Autotransformer Starter PDFDiago100% (1)

- Motor StarterDocument8 pagesMotor StartercalecaleNo ratings yet

- Starting Methods of Three Phase Induction Motors: Direct-On-Line (DOL) StartersDocument4 pagesStarting Methods of Three Phase Induction Motors: Direct-On-Line (DOL) Startersrajat nimjeNo ratings yet

- Electrical Machines QuestionsDocument9 pagesElectrical Machines QuestionsmaakbdNo ratings yet

- Induction Generator Starting MethodsDocument5 pagesInduction Generator Starting MethodsChathuranga NagasingheNo ratings yet

- Unit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorDocument13 pagesUnit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorPratik SarkarNo ratings yet

- Starting and Speed Control MethodsDocument20 pagesStarting and Speed Control MethodsRajeev ValunjkarNo ratings yet

- EE6504-Electrical Machines - II-306544629-Em II Unit 4Document20 pagesEE6504-Electrical Machines - II-306544629-Em II Unit 4Rajeev ValunjkarNo ratings yet

- MOTORS: PRINCIPLES AND TYPESDocument11 pagesMOTORS: PRINCIPLES AND TYPESAbishek AbiNo ratings yet

- Three Phase Electrical Wiring Installation in HomeDocument10 pagesThree Phase Electrical Wiring Installation in HomeMeetoo SharvamNo ratings yet

- Motor Starter Ac Motor StartersDocument6 pagesMotor Starter Ac Motor StartersShukor Az100% (1)

- STAR DELTA STARTERDocument13 pagesSTAR DELTA STARTERnazar750No ratings yet

- Starting & Speeed Control of Three Phase Induction MotorsDocument9 pagesStarting & Speeed Control of Three Phase Induction MotorsAshutoshNo ratings yet

- 1VGA677015 - ZVC-At Auto Transformer Motor StarterDocument2 pages1VGA677015 - ZVC-At Auto Transformer Motor StarterMyo SeinNo ratings yet

- Types of Motor StarterDocument8 pagesTypes of Motor StarterRane Siddesh100% (1)

- Unit Iv Starting and Speed Control of Three Phase Induction MotorDocument19 pagesUnit Iv Starting and Speed Control of Three Phase Induction MotorVamshiNo ratings yet

- Lab 6 Kawalan MotorDocument20 pagesLab 6 Kawalan MotorMohd FiqrieNo ratings yet

- Electrical Machines - II (Unit 4)Document13 pagesElectrical Machines - II (Unit 4)kumararguruNo ratings yet

- Auto Transformer StarterDocument9 pagesAuto Transformer Starterdiana100% (2)

- DC Motor StartersDocument6 pagesDC Motor StartersAreeb KhanNo ratings yet

- STAR DELTA Connection Diagram and Working PrincipleDocument2 pagesSTAR DELTA Connection Diagram and Working PrincipleJabir QuadriNo ratings yet

- AC motors starting and protection guideDocument32 pagesAC motors starting and protection guideTarek MohamedNo ratings yet

- Auto XmerDocument5 pagesAuto XmerWaghNo ratings yet

- Starting Method1Document6 pagesStarting Method1neo100% (5)

- Electrical Engineering Portal - Com StarDelta Motor StarterDocument9 pagesElectrical Engineering Portal - Com StarDelta Motor StarterRicardo A VergaraNo ratings yet

- Types of Motor StarterDocument10 pagesTypes of Motor StarterEngr. CasmirNo ratings yet

- Bee Unit4Document66 pagesBee Unit4DOMAKONDA NEHA SE(H)2019No ratings yet

- STAR DELTA motor starter diagram and working principleDocument2 pagesSTAR DELTA motor starter diagram and working principlePradeepChandraVarmaMandapatiNo ratings yet

- AIM: Comparative Study of Different Types of Starters Used For Three-Phase Induction MotorDocument8 pagesAIM: Comparative Study of Different Types of Starters Used For Three-Phase Induction MotorRD GamingNo ratings yet

- STAR DELTA Connection Diagram and Working PrincipleDocument2 pagesSTAR DELTA Connection Diagram and Working PrincipleKsr AkhilNo ratings yet

- Direct On Line DOL Motor StarterDocument6 pagesDirect On Line DOL Motor StarterFebrian Nugroho WinartoNo ratings yet

- STAR DELTA Connection Diagram and Working PrincipleDocument2 pagesSTAR DELTA Connection Diagram and Working PrinciplePrasant Kumar100% (5)

- Starting Methods For Induction MotorsDocument3 pagesStarting Methods For Induction MotorsKrishnamoorthy Ayyasami100% (1)

- Star-Delta Motor Starter Explained in DetailsDocument10 pagesStar-Delta Motor Starter Explained in DetailsFrenzy TaherNo ratings yet

- DC MOTOR STARTER GUIDEDocument25 pagesDC MOTOR STARTER GUIDESrinivasan PrakashNo ratings yet

- Starting Methodologies PDFDocument10 pagesStarting Methodologies PDFReynee Shaira Lamprea MatulacNo ratings yet

- IJRPR3553Document4 pagesIJRPR3553everhealthlifesciencesNo ratings yet

- 8 Indution MotorDocument4 pages8 Indution MotorSandrawarman BalasundramNo ratings yet

- Star DeltaDocument15 pagesStar DeltaAbdul HaleemNo ratings yet

- Introduction To Star-Delta Motor StarterDocument9 pagesIntroduction To Star-Delta Motor StarterBala SrivasNo ratings yet

- Star Delta starter reduces motor starting currentDocument2 pagesStar Delta starter reduces motor starting currentlcmscheid9954No ratings yet

- Chapter-2: Dynamic Behavior of Electric DrivesDocument43 pagesChapter-2: Dynamic Behavior of Electric DrivesMuket AgmasNo ratings yet

- Star-Delta motor starter guideDocument12 pagesStar-Delta motor starter guideCharles NunezNo ratings yet

- Operation of PumpsDocument25 pagesOperation of PumpsPrajval ChauhanNo ratings yet

- KAWALAN MOTOR English VersionDocument59 pagesKAWALAN MOTOR English VersionSuzaini Supingat0% (1)

- Good Day!: Tanjuatco, Jahriel P. BseeDocument32 pagesGood Day!: Tanjuatco, Jahriel P. BseeTanjuatco JahrielNo ratings yet

- Auto Transformer StarterDocument13 pagesAuto Transformer StarterarunNo ratings yet

- Ee6365 Electrical Engineering LaboratoryDocument75 pagesEe6365 Electrical Engineering LaboratoryNarasimman DonNo ratings yet

- 3 Point or 4 Point StarterDocument5 pages3 Point or 4 Point StarterAmar PandaNo ratings yet

- Starting High Inertia LoadsDocument9 pagesStarting High Inertia LoadsviswajdNo ratings yet

- Gandhinagar Institute of TechnologyDocument25 pagesGandhinagar Institute of TechnologyMohammed Jalaluddin RayeenNo ratings yet

- EELabReport@#7 WDSC AbajenzaDocument6 pagesEELabReport@#7 WDSC Abajenzaปุลื้ม ปุริมNo ratings yet

- Pertanyaan 3 Point StarterDocument21 pagesPertanyaan 3 Point StarterbrianlaksonoNo ratings yet

- Star-Delta Motor Starter PDFDocument9 pagesStar-Delta Motor Starter PDFWrya Saeed0% (1)

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- A New System of Alternating Current Motors and TransformersFrom EverandA New System of Alternating Current Motors and TransformersRating: 1 out of 5 stars1/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Lecture 6Document72 pagesLecture 6fieraminaNo ratings yet

- Lecture 5Document80 pagesLecture 5fieraminaNo ratings yet

- Dongshin PRO-WD Series High Precision Intelligent Injection Molding Machines GuideDocument60 pagesDongshin PRO-WD Series High Precision Intelligent Injection Molding Machines Guidefieramina100% (1)

- 8 JoiningDocument7 pages8 Joiningdawoodabdullah56No ratings yet

- Lecture 1Document56 pagesLecture 1fieramina100% (1)

- Design Guidelines for Turned Parts and Rapid Prototyping MethodsDocument19 pagesDesign Guidelines for Turned Parts and Rapid Prototyping MethodsfieraminaNo ratings yet

- Book Review On Linsu Kim's Imitation To InnovationDocument3 pagesBook Review On Linsu Kim's Imitation To InnovationdonghaoliNo ratings yet

- Lecture 2Document93 pagesLecture 2fieraminaNo ratings yet

- Action Plan For The Project2Document1 pageAction Plan For The Project2fieraminaNo ratings yet

- Plastic Injection Mold CalculationsDocument10 pagesPlastic Injection Mold CalculationsfieraminaNo ratings yet

- 3 Phase Induction Machines 1 (Construction)Document75 pages3 Phase Induction Machines 1 (Construction)fieraminaNo ratings yet

- LectureDocument3 pagesLecturefieraminaNo ratings yet

- Example of Different DC MotorsDocument22 pagesExample of Different DC MotorsfieraminaNo ratings yet

- Single PhaseDocument23 pagesSingle PhasefieraminaNo ratings yet

- Synchronous Machine Fundamentals and Static Stability AnalysisDocument32 pagesSynchronous Machine Fundamentals and Static Stability AnalysisfieraminaNo ratings yet

- DCDocument25 pagesDCfieraminaNo ratings yet

- Three Phase TransformerDocument27 pagesThree Phase Transformerfieramina100% (1)

- DC Motor and Magnetism GuideDocument18 pagesDC Motor and Magnetism GuidefieraminaNo ratings yet

- Metals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkDocument4 pagesMetals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkfieraminaNo ratings yet

- Rotational Dynamics and Motor ModelsDocument22 pagesRotational Dynamics and Motor ModelsfieraminaNo ratings yet

- Absolute MotionDocument1 pageAbsolute MotionfieraminaNo ratings yet

- Engineering Drawing Handbook PDFDocument120 pagesEngineering Drawing Handbook PDFRobert Nixon100% (1)

- Terazzo Two - Sheet1 PDFDocument1 pageTerazzo Two - Sheet1 PDFfieraminaNo ratings yet

- 23 Shaft and Its Design Based On StrengthDocument9 pages23 Shaft and Its Design Based On StrengthPRASAD326No ratings yet

- Cabo de Mão GoproDocument1 pageCabo de Mão GoproTiago BorinNo ratings yet

- Briefcases and Bags4 PDFDocument22 pagesBriefcases and Bags4 PDFfieraminaNo ratings yet

- 19 Introduction To Design of Helical SpringsDocument12 pages19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- Bags, Boxes, Bowls, and Beyond: Portable Collections ProgramDocument20 pagesBags, Boxes, Bowls, and Beyond: Portable Collections ProgramfieraminaNo ratings yet

- Cane Sugar PDFDocument633 pagesCane Sugar PDFbernie_bph50% (2)

- Datasheet PDFDocument16 pagesDatasheet PDFSergio Daniel BarretoNo ratings yet

- Oscillation MCQDocument7 pagesOscillation MCQUmer KhalidNo ratings yet

- ParkerDocument106 pagesParkerJoseJSanchezNo ratings yet

- Hibbeler D14 e CH 12 P 23Document2 pagesHibbeler D14 e CH 12 P 23Mona fabrigarNo ratings yet

- Redirection & PipingDocument16 pagesRedirection & PipingPraveen PatelNo ratings yet

- Visual Studio C++ TutorialDocument324 pagesVisual Studio C++ TutorialFahadNo ratings yet

- Atlas Copco Compressed Air Manual: 8 EditionDocument25 pagesAtlas Copco Compressed Air Manual: 8 EditionRajNo ratings yet

- Powtech Pt100 ManualDocument112 pagesPowtech Pt100 ManualNisar AhmedNo ratings yet

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDocument14 pagesAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALANo ratings yet

- Bayesian Network Approach To Root Cause DiagnosisDocument17 pagesBayesian Network Approach To Root Cause DiagnosisDhinesh GanesanNo ratings yet

- Surveying - Traverse Surveying - TraverseDocument13 pagesSurveying - Traverse Surveying - Traversebills100% (1)

- LSE MA100 Background CheckDocument5 pagesLSE MA100 Background CheckAlternative EgoNo ratings yet

- Pavan Kumar 1Document8 pagesPavan Kumar 1Anji ChNo ratings yet

- Cocoa Fermentation ManualDocument18 pagesCocoa Fermentation ManualJimena Rios100% (1)

- Is.10919.1984 ESP StandardDocument6 pagesIs.10919.1984 ESP StandardhbookNo ratings yet

- Battery ModelingDocument6 pagesBattery ModelingmusabnajeebNo ratings yet

- Valuation and Risk ModelsDocument226 pagesValuation and Risk Models1690295017qq.comNo ratings yet

- LEMBARAN KERJA BI TAHUN 4 (m7-10) PDPRDocument9 pagesLEMBARAN KERJA BI TAHUN 4 (m7-10) PDPRnurulwaznahNo ratings yet

- Explorer - Help RESCODocument18 pagesExplorer - Help RESCOTomás Oteros OrdóñezNo ratings yet

- Custom Objects, Fields, Tabs, Related Lists, List ViewsDocument7 pagesCustom Objects, Fields, Tabs, Related Lists, List ViewsAjay GhugeNo ratings yet

- Modern Scoring BRASS Manual1Document25 pagesModern Scoring BRASS Manual1Pepe ChorrasNo ratings yet

- Hysys For Aspen Plus Users PDFDocument11 pagesHysys For Aspen Plus Users PDFKarim KholeifNo ratings yet

- TVS Apache RTR 180 Service ManualDocument25 pagesTVS Apache RTR 180 Service ManualSandino JoseNo ratings yet

- Mebs7014 2223 03Document78 pagesMebs7014 2223 03Yuki ChanNo ratings yet

- Vasu Chourasia Sde-01 ResumeDocument1 pageVasu Chourasia Sde-01 ResumeDhaval MailNo ratings yet

- Filter 7Document480 pagesFilter 7Pranjal TripathiNo ratings yet

- Electrochemical Cleaningof Artificially Tarnished SilverDocument11 pagesElectrochemical Cleaningof Artificially Tarnished SilverRahmi Nur Anisah Nasution 2003114489No ratings yet

- Calculation of Optimum Fishing TimeDocument11 pagesCalculation of Optimum Fishing TimeÇağlar Öztürk100% (2)

- Ray OpticsDocument41 pagesRay OpticsHannah VsNo ratings yet

- Manual Handbook Ripping Cat Selection Techniques Applications Production CompatibilityDocument32 pagesManual Handbook Ripping Cat Selection Techniques Applications Production CompatibilityPoPandaNo ratings yet