Professional Documents

Culture Documents

Coaxial Cable

Uploaded by

Alex Adams0 ratings0% found this document useful (0 votes)

218 views42 pagescable

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcable

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

218 views42 pagesCoaxial Cable

Uploaded by

Alex Adamscable

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 42

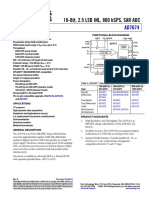

Coaxial cable

From Wikipedia, the free encyclopedia

"Coax" redirects here. For the act of coaxing, see Persuasion.

RG-59 flexible coaxial cable composed of:

A. Outer plastic sheath

B. Woven copper shield

C. Inner dielectric insulator

D. Copper core

Part of a series on

Antennas

Common types[show]

Components[hide]

Balun

Block upconverter

Coaxial cable

Counterpoise (ground system)

Feed

Feed line

Low-noise block downconverter

Passive radiator

Receiver

Rotator

Stub

Transmitter

Tuner

Twin-lead

Systems[show]

Safety and regulation[show]

Radiation sources / regions[show]

Characteristics[show]

Techniques[show]

V

T

E

Electronic symbol for a coaxial cable

Coaxial cable, or coax (pronounced 'ko.ks), is a type of cable that has an inner

conductor surrounded by a tubular insulating layer, surrounded by a tubular conducting

shield. Many coaxial cables also have an insulating outer sheath or jacket. The

term coaxial comes from the inner conductor and the outer shield sharing a geometric

axis. Coaxial cable was invented by English engineer and mathematician Oliver

Heaviside, who patented the design in 1880.

[1]

Coaxial cable differs from other shielded

cable used for carrying lower-frequency signals, such as audio signals, in that the

dimensions of the cable are controlled to give a precise, constant conductor spacing,

which is needed for it to function efficiently as a radio frequency transmission line.

Applications[edit]

Coaxial cable is used as a transmission line for radio frequency signals. Its applications

include feedlines connecting radio transmitters and receivers with their antennas,

computer network (Internet) connections, and distributing cable television signals. One

advantage of coaxial over other types of radio transmission line is that in an ideal

coaxial cable the electromagnetic field carrying the signal exists only in the space

between the inner and outer conductors. This allows coaxial cable runs to be installed

next to metal objects such as gutters without the power losses that occur in other types

of transmission lines. Coaxial cable also provides protection of the signal from

external electromagnetic interference.

Description[edit]

Coaxial cable cutaway (not to scale)

Coaxial cable conducts electrical signal using an inner conductor (usually a solid

copper, stranded copper or copper plated steel wire) surrounded by an insulating layer

and all enclosed by a shield, typically one to four layers of woven metallic braid and

metallic tape. The cable is protected by an outer insulating jacket. Normally, the shield

is kept at ground potential and a voltage is applied to the center conductor to carry

electrical signals. The advantage of coaxial design is that electric and magnetic fields

are confined to the dielectric with little leakage outside the shield. Conversely, electric

and magnetic fields outside the cable are largely kept from causing interference to

signals inside the cable. Larger diameter cables and cables with multiple shields have

less leakage. This property makes coaxial cable a good choice for carrying weak

signals that cannot tolerate interference from the environment or for higher electrical

signals that must not be allowed to radiate or couple into adjacent structures or

circuits.

[2]

Common applications of coaxial cable include video and CATV distribution, RF and

microwave transmission, and computer and instrumentation data connections.

[3]

The characteristic impedance of the cable ( ) is determined by the dielectric

constant of the inner insulator and the radii of the inner and outer conductors. A

controlled cable characteristic impedance is important because the source and load

impedance should be matched to ensure maximum power transfer and

minimum standing wave ratio. Other important properties of coaxial cable include

attenuation as a function of frequency, voltage handling capability, and shield quality.

[2]

Construction[edit]

Coaxial cable design choices affect physical size, frequency performance, attenuation,

power handling capabilities, flexibility, strength, and cost. The inner conductor might be

solid or stranded; stranded is more flexible. To get better high-frequency performance,

the inner conductor may be silver-plated. Copper-plated steel wire is often used as an

inner conductor for cable used in the cable TV industry.

[4]

The insulator surrounding the inner conductor may be solid plastic, a foam plastic, or air

with spacers supporting the inner wire. The properties of dielectric control some

electrical properties of the cable. A common choice is a solid polyethylene (PE)

insulator, used in lower-loss cables. Solid Teflon (PTFE) is also used as an insulator.

Some coaxial lines use air (or some other gas) and have spacers to keep the inner

conductor from touching the shield.

Many conventional coaxial cables use braided copper wire forming the shield. This

allows the cable to be flexible, but it also means there are gaps in the shield layer, and

the inner dimension of the shield varies slightly because the braid cannot be flat.

Sometimes the braid is silver-plated. For better shield performance, some cables have a

double-layer shield.

[4]

The shield might be just two braids, but it is more common now to

have a thin foil shield covered by a wire braid. Some cables may invest in more than

two shield layers, such as "quad-shield", which uses four alternating layers of foil and

braid. Other shield designs sacrifice flexibility for better performance; some shields are

a solid metal tube. Those cables cannot be bent sharply, as the shield will kink, causing

losses in the cable.

For high-power radio-frequency transmission up to about 1 GHz, coaxial cable with a

solid copper outer conductor is available in sizes of 0.25 inch upward. The outer

conductor is rippled like a bellows to permit flexibility and the inner conductor is held in

position by a plastic spiral to approximate an air dielectric.

[4]

Coaxial cables require an internal structure of an insulating (dielectric) material to

maintain the spacing between the center conductor and shield. The dielectric losses

increase in this order: Ideal dielectric (no loss), vacuum,

air, polytetrafluoroethylene (PTFE), polyethylene foam, and solid polyethylene. A low

relative permittivity allows for higher-frequency usage. An inhomogeneous dielectric

needs to be compensated by a non-circular conductor to avoid current hot-spots.

While many cables have a solid dielectric, many others have a foam dielectric that

contains as much air or other gas as possible to reduce the losses by allowing the use

of a larger diameter center conductor. Foam coax will have about 15% less attenuation

but some types of foam dielectric can absorb moistureespecially at its many surfaces

in humid environments, significantly increasing the loss. Supports shaped like stars

or spokes are even better but more expensive and very susceptible to moisture

infiltration. Still more expensive were the air-spaced coaxials used for some inter-city

communications in the mid-20th century. The center conductor was suspended by

polyethylene discs every few centimeters. In some low-loss coaxial cables such as the

RG-62 type, the inner conductor is supported by a spiral strand of polyethylene, so that

an air space exists between most of the conductor and the inside of the jacket. The

lower dielectric constant of air allows for a greater inner diameter at the same

impedance and a greater outer diameter at the same cutoff frequency, lowering ohmic

losses. Inner conductors are sometimes silver-plated to smooth the surface and reduce

losses due to skin effect.

[4]

A rough surface prolongs the path for the current and

concentrates the current at peaks and, thus, increases ohmic losses.

The insulating jacket can be made from many materials. A common choice is PVC, but

some applications may require fire-resistant materials. Outdoor applications may require

the jacket resist ultraviolet light, oxidation and rodent damage. Flooded coaxial cables

use a water blocking gel to protect the cable from water infiltration through minor cuts in

the jacket. For internal chassis connections the insulating jacket may be omitted.

Signal propagation[edit]

Twin-lead transmission lines have the property that the electromagnetic

wave propagating down the line extends into the space surrounding the parallel wires.

These lines have low loss, but also have undesirable characteristics. They cannot be

bent, twisted, or otherwise shaped without changing their characteristic impedance,

causing reflection of the signal back toward the source. They also cannot be buried or

run along or attached to anything conductive, as the extended fields will induce currents

in the nearby conductors causing unwanted radiation and detuning of the line. Coaxial

lines largely solve this problem by confining virtually all of the electromagnetic wave to

the area inside the cable. Coaxial lines can therefore be bent and moderately twisted

without negative effects, and they can be strapped to conductive supports without

inducing unwanted currents in them.

In radio-frequency applications up to a few gigahertz, the wave propagates primarily in

the transverse electric magnetic (TEM) mode, which means that the electric and

magnetic fields are both perpendicular to the direction of propagation. However, above

a certain cutoff frequency, transverse electric (TE) or transverse magnetic (TM) modes

can also propagate, as they do in a waveguide. It is usually undesirable to transmit

signals above the cutoff frequency, since it may cause multiple modes with

different phase velocities to propagate, interfering with each other. The outer diameter is

roughly inversely proportional to the cutoff frequency. A propagating surface-wave

mode that does not involve or require the outer shield but only a single central

conductor also exists in coax but this mode is effectively suppressed in coax of

conventional geometry and common impedance. Electric field lines for this [TM] mode

have a longitudinal component and require line lengths of a half-wavelength or longer.

Coaxial cable may be viewed as a type of waveguide. Power is transmitted through the

radial electric field and the circumferential magnetic field in the TEM00 transverse

mode. This is the dominant mode from zero frequency (DC) to an upper limit

determined by the electrical dimensions of the cable.

[5]

Connectors[edit]

A coaxial connector (male N-type).

Main article: RF connector

The ends of coaxial cables usually terminate with connectors. Coaxial connectors are

designed to maintain a coaxial form across the connection and have the same

impedance as the attached cable.

[4]

Connectors are usually plated with high-conductivity

metals such as silver or tarnish-resistant gold. Due to the skin effect, the RF signal is

only carried by the plating at higher frequencies and does not penetrate to the

connector body. Silver however tarnishes quickly and the silver sulfide that is produced

is poorly conductive, degrading connector performance, making silver a poor choice for

this application.

[citation needed]

What is a Coaxial Cable?

Coaxial cables are a type of cable that is used by cable TV and that is common for data

communications.

Taking a a round cross-section of the cable, one would find a single center solid wire

symmetrically surrounded by a braided or foil conductor. Between the center wire and foil is a

insulating dialectric. This dialectric has a large affect on the fundamental characteristics of the

cable. In this lab, we show the how the permittivity and permeability of the dialectric contributes

to the cable's inductance and capacitance. Also, these values affect how quickly electrical data is

travels through the wire.

Data is transmitted through the

center wire, while the outer braided

layer serves as a line to ground. Both

of these conductors are parallel and

share the same axis. This is why the

wire is called coaxial!

Just like all electrical components,

coaxial cables have a characteristic

impedance. This impedance depends

on the dialectric material and the

radii of each conducting material As

shown in this lab, the impedance

affects how the cable interacts with

other electrical components.

In this lab we used a RG-580/U coaxial cable. This is just one of many types of cables that are

used today to transmit data. The dialectric of the RG-580/U was made of polyethylene. The

radius of our cable's inner copper wire was .42mm and there was 2.208mm of polyethylene

between the inner wire and outer mesh conductors.

Extending a Coaxial Cable Line

If you need to bring a TV signal from

an antenna into your house; set up a

computer network in your home; or

hook up cable TV, an FM radio or a

cable modem chances are you'll be

working with coaxial cable. Coaxial

cable, often simply called "coax," is

that fat black cable that cable TV

companies install. So you probably

already have coax in your house.

What with multiple televisions, a

computer or two and Lord knows what

else is coming down the pike, you're

apt to find a lot more coax in your life.

Here's a primer that will take the

mystery out of working with coax and

show you how to make a couple of

essential coax connections.

About Coax

Coax consists of a center wire

surrounded by insulation, which is in

turn surrounded by an outer conductor

of braided wire that serves as a

grounded shield, enclosed in an outer

jacket of insulation. The shield

minimizes electrical and radio

frequency interference. (Sometimes

there's a layer of foil between the

interior insulation and the outer

conductor as well.)

Coax gets its name because its two

channels run concentrically along the

same axis. It's quite an old product,

originally designed to carry analog

telephone signals at high capacity with

little electronic noise. It's also a

preferred product, virtually

weatherproof and much more durable

than "twinlead," the old-fashioned flat

wire originally used for TV. Signal

performance is also superior. Coax

doesn't pick up unwanted signals, and

it's not affected by contact with metal

structures. And although cable

installers often use special standoff

supports when attaching coax to

exteriors, all you need to route coax

inside your house are coaxial cable

straps.

Coaxial cable is also easy to work with. It's pretty simple to tap into an existing

coaxial line to hook up a second TV or extend a computer network ("splitting"

the line, as it's called). All you need are a few tools, an additional cable and a

splitter, a small device that divides the cable's input signal to provide an equal

signal at each output. Ordinary tools are fine for making a couple of

connections, but if you're making a lot of them, invest in a few inexpensive

specialized tools: the work will be faster and more professional. If you're

hooking up more than one additional unit, buy a splitter with three or four

outputs, or terminals, instead of two. This usually yields better results than

splitting the line at each device, which may weaken the signal.

Splitting and Extending a Line

This illustration shows how you split a

single coaxial cable line and send a

new branch to a new location. First,

let's assume you only have one TV

(the "original device" in the

illustration) connected to a coax line.

Unscrew that screw-on connector

from the back of the TV. Mount the

splitter to a baseboard or similar

location with the mounting screws

provided, or use 1 1/4-inch drywall

screws. Be sure to mount the splitter

within reach of the original coax line.

Screw the original connector into the

tap marked "input" on the splitter.

Next, you'll need two new coaxial

cables, one for the original device and

one for the new device. You can either

buy them with connectors already

attached or put them together yourself

the next page shows you how. Screw

one end of each new cable to an

output tap on the splitter and the other

end into the input jack on the back of

the TV or other device.

Support the cable between the splitter

and the devices with coaxial cable

straps nailed to baseboards every 2 or

3 feet. If you need to run cable

through interior walls, drill passage

holes in corners or other

inconspicuous locations using a spade

bit. You can run cable through exterior

walls almost the same way. To keep

water out of your walls, always make

a drip loop where the cable enters your

home, as shown above. Be sure to seal

the exterior hole with silicone caulk.

Attaching a Coaxial Cable

Connector

Coaxial cable connects to electrical

equipment with F-plugs, which clamp

onto the stripped cable and screw or

slide onto the device or splitter. (If

you're adding a new cable, it'll need F-

plugs on both ends.)

To put an F-plug onto a length of

coax, cut the cable's end square with

lineman's pliers. Next comes a two-

step stripping process. First, use a

coaxial cable stripper or a utility knife

carefully to remove 1/2 inch of the

cable's outer covering. As shown in

the animation, peel back the woven

outer conductor (and foil, if any),

folding it back over the outer

insulation. Second, strip 1/4 inch of

the inner insulation to expose the

slender center conductor. To attach the

connector, first slip its ferrule onto the

cable. Then push the body of the

connector over the white insulation,

fitting the sleeve under the outer

conductor and foil. The white

insulation will bottom out in the

connector, and the inner conductor

will protrude through the hole in the

end of the plug. Finally, crimp the

ferrule with a coaxial cable crimper or

pliers to hold the connector in place.

Tip From the Pros

The woven outer conductor lies in an

irregular cavity just underneath

the cover, and it's virtually impossible

to cut all the way through the outer

jacket without damaging the

conductor beneath. Adjust the blade of

your cable stripper or manipulate your

utility knife to cut just partway

through the jacket. Bend the jacket at

the cut, and you can pull it free

without damaging the outer conductor.

The most common type of antenna feeder used today is undoubtedly coaxial feeder or

coax cable. Coax cable, often referred to as RF cable, offers advantages of

convenience of use while being able to provide a good level of performance. In view of

this vast amounts of coax cable, coax feeder are manufactured each year, and it is also

available in a wide variety of forms for different applications.

Applications of coax cable

Coax cable or coaxial feeder is used in many applications where it is necessary to

transfer radio frequency energy from one point to another. Possibly the most obvious

use of coax cable is for domestic television down-leads, but it is widely used in many

other areas as well. While it is sued for domestic connections between receivers and

aerials, it is likewise also used for commercial and industrial transmission lines

connecting receivers and transmitters to antennas. However it is also sued where any

high frequency signals need to be carried any distance. Its construction means that

signals that the levels of loss and stray pick-up are minimised. In view of this it is also

used in many computer applications. Coax cable was used for some early forms of

Ethernet local area networks, although now optical fibres are used for higher data rates,

or twisted pairs where frequencies are not so high as these cables are much cheaper

than coax.

RF coax cable history

RF coaxial cable is a particularly important part of today's RF and electronics scene. It is

a component that could easily be overlooked with little thought of how it appeared. In

the late 1800s there were a huge number of basic discoveries being made in the field of

electricity. Radio, or wireless as it was originally called was not understood well, and the

first transmissions were made in the 1890s. Some transmissions were made earlier but

not understood.

The first known implementation of coax cable was in 1884 when Ernst von Siemens

(one of the founders of the Siemens empire) patented the idea, although there were no

known applications at this time. It then took until 1929 before the first modern

commercial coax cables were patented by Bell Laboratories, although its use was still

relatively small. Nevertheless it was used in 1934 to relay television pictures of the

Berlin Olympics to Leipzig. Then in 1936 an a coaxial cable was installed between

London and Birmingham in the UK to carry 40 telephone calls, and in the USA an

experimental coaxial cable was installed between New York and Philadelphia to relay

television pictures.

With the commercial use of RF coax cable establishing itself, many other used the cable

for shorter runs. It quickly established itself, and now it is widely used for both

commercial and domestic applications.

What is coax cable? - the basics

Coax cable, coaxial feeder is normally seen as a thick electrical cable. The cable is

made from a number of different elements that when together enable the coax cable to

carry the radio frequency signals with a low level of loss from one location to another.

The main elements within a coax cable are:

1. Centre conductor

2. Insulating dielectric

3. Outer conductor

4. Outer protecting jacket or sheath

The overall construction of the coax cable or RF cable can be seen in the diagram

below and from this it can be seen that it is built up from a number of concentric layers.

Although there are many varieties of coax cable, the basic overall construction remains

the same:

Cross section though coaxial cable

1. Centre conductor The centre conductor of the coax is almost universally made

of copper. Sometimes it may be a single conductor whilst in other RF cables it may

consist of several strands.

2. Insulating dielectric Between the two conductors of the coax cable there is an

insulating dielectric. This holds the two conductors apart and in an ideal world

would not introduce any loss, although it is one of the chief causes of loss in reality.

This coax cable dielectric may be solid or as in the case of many low loss cables it

may be semi-airspaced because it is the dielectric that introduces most of the loss.

This may be in the form of long "tubes" in the dielectric, or a "foam" construction

where air forms a major part of the material.

Outer conductor The outer conductor of the RF cable is normally made from a

copper braid. This enables the coax cable to be flexible which would not be the

case if the outer conductor was solid, although in some varieties made for

particular applications it is. To improve the screening double or even triple

screened coax cables are sometimes used. Normally this is accomplished by

placing one braid directly over another although in some instances a copper foil or

tape outer may be used. By using additional layers of screening, the levels of stray

pick-up and radiation are considerably reduced. The loss is marginally lower.

3. Outer protecting jacket or sheath Finally there is a final cover or outer sheath

to the coax cable. This serves little electrical function, but can prevent earth loops

forming. It also gives a vital protection needed to prevent dirt and moisture

attacking the cable, and prevent the coax cable from being damaged by other

mechanical means.

How RF coax cable works

A coaxial cable carries current in both the inner and the outer conductors. These current

are equal and opposite and as a result all the fields are confined within the cable and it

neither radiates nor picks up signals.

This means that the cable operates by propagating an electromagnetic wave inside the

cable. As there are no fields outside the coax cable it is not affected by nearby objects.

Accordingly it is ideal for applications where the RF cable has to be routed through or

around buildings or close to many other objects. This is a particular advantage of

coaxial feeder when compared with other forms of feeder such as two wire (open wire,

or twin) feeder.

Stripping coax (short for coaxial) cable is not very difficult, and can be mastered with a

little practice. While tools designed specifically for this purpose are available for

relatively little cost, this wiki will explain how to strip RG6 coax (a very popular cable and

satellite TV cable) with a common razor knife and cutters to prepare for a typical "F"

(cable or satellite TV) connector.

Steps

1.

1

Hold the cable in one hand (as if it were a stick to be whittled), with the end to be

stripped pointed away from your body.

Ad

2.

2

Hold the razor knife in your dominant hand and extend the blade if not done so

already.

3

Firmly press the edge of the blade (not the point) into the cable at a right angle

(perpendicular to the cable) about an inch from the end. The object of this cut is to

cut through the outer jacket, layers of foil and / or braids and finally the dielectric foam

(usually white in color) that surrounds the center conductor. There will be some

opposition to the blade as it sinks deeper into the cable. When the blade approaches

the half way point through the cable, ease up on the pressure of the blade. This will

occur when the blade has reached the center conductor of the cable, which is at the half

way point through the cable. It is very important to not damage this center conductor by

nicking it with the blade.

3.

4

Run the blade half way around the cable by rotating the tool around the cable.Do

not allow the blade to nick the center conductor as you continue to cut around the

center conductor.

4. 5

Reposition the cable as needed in the other hand, so that the blade can easily

continue to be rotated around the cable to continue the cut, while still being held

in a comfortable position.

5. 6

Return the blade to the storage position in the tool and put the tool down.Grasp

the the cable between the end and the fresh cut. Firmly pull the end off of the cable

while twisting the end back and forth.

6. 7

Discard the cable end and pick up any stray wires from the "metallic shield" or

braid.

7. 8

Cut off any braid wires that extend beyond the jacket so that they are flush with

the jacket with the knife or wire cutters.

8. 9

Carefully inspect the center conductor for nicks. If it is nicked, it will be required to

repeat the above steps until you are able to perform the steps without damaging the

center conductor. It may take 6, 10 or more attempts before it can be done successfully

if never attempted before.

9. 10

Remove any film or dielectric foam remaining from the length of the center

conductor (if present) by gently scraping the center conductor with fingernail. Be

sure the center conductor is clean all the way around over it's entire length.

10. 11

Hold the cable again as earlier to prepare for removal of the outer jacket.There are

different types of "F" connectors and ways to attach them to the cable. Most common

"F" connectors can be attached to cables prepared with the dimensions used here and

should be used unless the connectors you are using specifies a different dimension.

11. 12

Hold the razor as before, aligning the the blade on the jacket about 5/16 inch back

from the cut made in the previous step. The purpose of this cut is to penetrate the

jacket only, and leave the braid intact. The cut will be perpendicular to the cable like the

first cut. Many "F" connectors specify that the braid not be removed, while others prefer

it removed. Plan to leave it in place for now, as it can be removed later, if needed. The

braids are woven around the length of the dielectric foam, and lie just beneath the outer

jacket. The individual wires that make up the braid are thinner than a hair, and are

easily cut. Gently press the blade into the jacket and run it around the cable, in the

same manner as was done in the first cut to the center conductor. Once the blade has

cut around the circumference of the jacket, press the tip of the blade against the jacket

at this cut and gently cut towards the end of the cable. Again, try not to cut the braid.

12. 13

Return the blade to the storage position in the tool and put the tool down.Peel the

5/16 inch jacket off of the cable, leaving only the braid covering the dielectric.

13. 14

Fold the braid back, over the outer jacket. This should expose the dielectric, which

surrounds the center conductor. There is no concern if some of the braid wires were cut.

Check the requirements (if any) of the "F" connector you will place on the end of the

cable.

14. 15

Inspect the cable end. It is very important that there are no wires, filings or other

conductive bits between the center conductor and the braid. The white dielectric should

show anything that bridges these two parts easily. Remove anything found.

15. 16

Place the "F" connector on the end of the cable. Make one final inspection by

looking into the connector. Make sure that no conductive debris is between the center

conductor and the "F" connector before securing to the cable.

16. 17

The "F" connector is fully seated on the cable if the dielectric is flush with the

"bottom" of the connector, when viewed from the end - looking in. It should not

extend beyond or be recessed more than 1/16 inch from the bottom of the connector.

Under no circumstances should the center conductor be in contact with the "F"

connector.

17. 18

Secure the the "F" connector to the cable only with the tool designed for the

connector.

Coax compression connector tool

Coax connector crimping tool

Inexpensive crimping type tool.

18. 20

Cut the center conductor so that it extends beyond the "F" connector 3/16 to 1/4

inch.

Coax connectors made easy

Step 1

Strip the outer layer of the coax cable to reveal the braid (Earth)

Step 2

Trim back and fold the braid back over the coax cable.

Step 3

Strip off the inner conductor so it can fit into the center pin of the connector.

Step 4

Insert the coax into the connector and trim off the excess and solder the tip. Do not heat up too much or you

may damage the connector. Only use enough solder to fill the tip of the center pin.

Step 5

Using a multimeter test for an open circuit by holding the probes against the center pin and the outer casing.

Three Methods:Initial StepsStrip The CableUsing A Crimp-Style Connector

Coaxial cable is any cable that has an inner wire shielded with an outer conductive

sheath by a dielectric (non-conductive) material. Here's a look at how to attach your own

connectors to cable TV coaxial cable.

Method 1 of 3: Initial Steps

1.

1

Determine your cable size. Cable terminology can be confusing. Look on the side of

your coaxial wire for the size designation. In most homes, the two most common sizes

are RG-6 and RG-59.

RG stands for "Radio Guide." The numbers of the various versions of RG cable refer to

the diameter (59 meaning .059, and 6 meaning .06, etc) and internal characteristics of

the cable, including the amount of shielding and the cable's attenuation, which refers to

how much signal loss there is per length of cable.

You may also see the term RF used with these cables, which stands for "Radio

Frequency."

Most non-industrial coaxial cable is now known as RG-6, although the previous thinner

lower-quality standard of RG-59 is still used in some applications and older homes.

Commercial installers may use a thicker RG cable, like RG-11(which is only used if the

distance from the source tap to your point of termination at the home is greater than 200

feet)

RG cables used in homes for ordinary purposes should be 75 ohm (RG-6 or RG-59).

Be aware that all cables (and their connectors) come in a variety of qualities. Get the

best quality cable you can.

2.

2

Choose the right connectors. Most connectors for home video installations are made

with F-Style connectors. However, it is possible your system uses N-type connectors.

Be aware that there are several types of F-type RG-6 cable available, primarily screw-

on and crimp-style connectors.

Screw-on connectors are easy to use, but are less secure and can leave a small air

pocket. Some people believe this may affect your signal quality.

Crimp-style connectors have two parts: a ring (or crimp) and a terminator. They are

typically more difficult to install, but can attain the greatest lengths and best connections

when used correctly.

Know that to make a connection you will need a male and a female connector of the

same type.

Male connectors have the center wire sticking out, while female connectors have a

space for the center wire to stick into. Be sure to use the opposite gender to the

connector you will be making. Most cables end in male connectors.

Use an SMA (sub-miniature Version A) connector for very small coaxial cable.

Method 2 of 3: Strip The Cable

The first step to attaching your own connector is to prepare the end of the coaxial cable.

1.

1

Cut the cable flush.

2.

2

Trim the outer cover (usually black rubber) back 1/2".

Be very careful not to cut into the metal braiding directly beneath the outer housing. The

braiding may be both "loose" wire and a foil-like metal present in shielded wire.

3.

3

Carefully pull back the inner braiding (second channel) outside the outer

cover. Check to make sure none of the braided wire gets wrapped around or touches

the copper center conductor.

4.

4

Trim back the (usually white, but may be clear) dielectric plastic from the inner

core cable.

Be absolutely sure not to scratch or nick the center conductor. Any damage to this

conductor can severely impact your signal.

5.

5

Push the connector down over the cable end so that the copper core of the

coaxial cable sticks out.

Be sure the dielectric (aluminum foil) is trimmed so that it does not enter into the

terminator of the connector.

6.

6

Screw the connector into the end of the cable. The thread will cut into the outer

housing and wrap the shielding weave, making a tight fit.

Method 3 of 3: Using A Crimp-Style Connector

This is another method which can be used to connect coaxial cable connectors.

1.

1

Place the crimp ring over the cable end.

2.

2

Trim the outer cover back about 1/4".

3.

3

Trim the shielding, wire wrap and dielectric back to the bare inner wire.

4.

4

Leave about 1/8" of dielectric.

5.

5

Place the terminator over the end of the wire so the copper core sticks out

through the hole.

6.

6

Push the crimp-style connector down into the cable end so that the tube of the

connector goes between the foil and the outer housing.

This can be very difficult to do. Try holding the cable end with a pair of pliers, or

clamping it in a vice. Try not to twist when pushing down.

7.

7

Crimp the ring around the outside of the cable.

8.

8

Trim any loose wires.

9.

9

Cut the inner core wire flush with the end of the connector.

10.

10

Tug on the connector to make sure it is attached.

Take a look at this instructional video and learn how to wire a coaxial plug. The coax plug

consists of a body, a pin, a collett, a braid, and a clamp...

Tips

If you have high speed internet and more than two TV's, make sure you use a high

quality RG 6-type connector. When putting a connector on the cable wire, proper

preparation is essential to get a clear picture as well as a good seated connection for

the cable modem. Use a compression style connector available at any popular home

improvement center. Also, when preparing the end of the wire, be sure not to "score" or

nick the copper center conductor as this can cause problems with your internet such as

intermittent connectivity and packet loss.

You can buy crimpers, cutters and strippers specially designed for coaxial cable in

certain diameters. These tools do take some practice to learn how to use and you do

not have to use special tools to make these connections. Regular strippers will do as

long as you're careful.

Do not use the screw-on style F-type connectors. Cable signal will "leak" out of a cheap

or poorly terminated connector such as these. This can cause unwanted signal

"ingress" to get into the cable line and cause odd distortions such as vertical lines, dash

lines moving horizontally across the screen and "beats," or little white dots randomly

over the entire screen.

You might also like

- Question 1 (20 Points) : Answer 1) .............. Answer 2) .............Document6 pagesQuestion 1 (20 Points) : Answer 1) .............. Answer 2) .............Amin DhouibNo ratings yet

- Aircraft Materials HistoryDocument15 pagesAircraft Materials Historymahaprabhu78No ratings yet

- Kaeser CompDocument34 pagesKaeser CompJose LunaNo ratings yet

- Bare-Hand Live-Line Work Safety: BCM Series of Boom Current MonitorsDocument2 pagesBare-Hand Live-Line Work Safety: BCM Series of Boom Current MonitorsRogério Paião0% (1)

- Co-Axial Cable: by Abiram SunilDocument7 pagesCo-Axial Cable: by Abiram Sunilyash girijanNo ratings yet

- CHAPTER 2 Materials TechnologyDocument29 pagesCHAPTER 2 Materials TechnologyAkhi IslamNo ratings yet

- Aluminium AlloyDocument27 pagesAluminium AlloyManicharanNo ratings yet

- NICKEL ALUMINIDES and Titanium AluminidesDocument15 pagesNICKEL ALUMINIDES and Titanium AluminidesArun Gs100% (1)

- Engineering Materials I Notes 2022 METALSDocument15 pagesEngineering Materials I Notes 2022 METALSAliciaNo ratings yet

- Mechanical Fasteners - Part IIDocument24 pagesMechanical Fasteners - Part IIsaded05No ratings yet

- Physical Chemical Properties: Boat Hulls Swimming Pool PanelsDocument5 pagesPhysical Chemical Properties: Boat Hulls Swimming Pool PanelsRobert Jonathan DavidNo ratings yet

- Cleaning and Corrosion QuestionsDocument15 pagesCleaning and Corrosion QuestionsTharrmaselan VmanimaranNo ratings yet

- Accuribbon DC 129 WebDocument2 pagesAccuribbon DC 129 WebraulNo ratings yet

- Aluminum Alloys For AerospaceDocument2 pagesAluminum Alloys For AerospaceNicholas Featherston100% (1)

- Lecture - 05 Welded ConnectionsDocument84 pagesLecture - 05 Welded Connectionssivaenotes100% (2)

- DFMA On Desktop StaplerDocument15 pagesDFMA On Desktop Staplerranjithkraj100% (1)

- Composites Intro To AerospaceDocument40 pagesComposites Intro To AerospacegnitinNo ratings yet

- Solid Rivet InformationDocument6 pagesSolid Rivet InformationKukyong LeeNo ratings yet

- Electron Beam Crosslinking of Wire and Cable InsulationDocument7 pagesElectron Beam Crosslinking of Wire and Cable InsulationDuc Nguyen HuuNo ratings yet

- Optimization of Kerf Quality During Pulsed Laser Cutting of Aluminium Alloy SheetDocument7 pagesOptimization of Kerf Quality During Pulsed Laser Cutting of Aluminium Alloy SheetSyafril AbdillahNo ratings yet

- Introduction To PCB PDFDocument18 pagesIntroduction To PCB PDFOviantoNo ratings yet

- Corrosion and Protective CoatingsDocument51 pagesCorrosion and Protective CoatingsMuhammad AsifNo ratings yet

- Composite Materials For Aerospace ApplicationsDocument11 pagesComposite Materials For Aerospace ApplicationsAina Amieyrah KamarudinNo ratings yet

- 7 BondingCompositesDocument63 pages7 BondingCompositesVisan NaiduNo ratings yet

- Seminar On Non-Destructive Testing: Submitted To: Submitted byDocument25 pagesSeminar On Non-Destructive Testing: Submitted To: Submitted byMahesh TamboliNo ratings yet

- Near Net Shape CastingDocument3 pagesNear Net Shape CastingNURNo ratings yet

- CompositesDocument21 pagesCompositesdrkameshNo ratings yet

- Historyy of WeldingsDocument81 pagesHistoryy of WeldingsSuyash GatkalNo ratings yet

- Applications OverviewDocument124 pagesApplications OverviewSangeetha RangarajanNo ratings yet

- Thermoplastic Composites - Best Practice GuideDocument49 pagesThermoplastic Composites - Best Practice GuidemanikandapriyaNo ratings yet

- 2 Aircraft StructureDocument48 pages2 Aircraft StructureMaheshNo ratings yet

- Boron Steel 1Document7 pagesBoron Steel 1RajanikantJadhavNo ratings yet

- 12326899Document70 pages12326899imranNo ratings yet

- Ribbon Cable (Idc) Test JigDocument3 pagesRibbon Cable (Idc) Test JigseventhsensegroupNo ratings yet

- Composites Classification ProcessingDocument32 pagesComposites Classification ProcessingBhargav BaluNo ratings yet

- Metal RollingDocument17 pagesMetal RollingkxalxoNo ratings yet

- Non-Traditional Machining: Thermal Metal Removal Processes: Electric Discharge MachiningDocument24 pagesNon-Traditional Machining: Thermal Metal Removal Processes: Electric Discharge MachiningSatish SatiNo ratings yet

- Seminar Final AnandDocument43 pagesSeminar Final AnandAnand GargNo ratings yet

- Galvanize ItDocument82 pagesGalvanize ItRajiv Kumar MNo ratings yet

- Workshop PracticeDocument32 pagesWorkshop Practicemanipsg100% (2)

- Workshop Practice: Course Code: Btmp101-18Document12 pagesWorkshop Practice: Course Code: Btmp101-18Dhiraj DhimanNo ratings yet

- LGP - Processo ManualDocument29 pagesLGP - Processo ManualAnonymous mq0U43UsPNo ratings yet

- Metal and Metal Alloys NotesDocument18 pagesMetal and Metal Alloys NotesKshitij SaojiNo ratings yet

- Laser Beam Welding: By, Ramu RajendranDocument19 pagesLaser Beam Welding: By, Ramu RajendranAmal Vikram100% (1)

- Heat Treatment PPTDocument70 pagesHeat Treatment PPTJhonrey QuejadaNo ratings yet

- 912 Installation Manual d04967 PDFDocument199 pages912 Installation Manual d04967 PDFZENAIRSTOLCH701No ratings yet

- K.K.I.W.E.E.R Department of Mechanical Engineering, Nashik 1Document18 pagesK.K.I.W.E.E.R Department of Mechanical Engineering, Nashik 1kshitijNo ratings yet

- Aircraft Material & Production - MANUALDocument45 pagesAircraft Material & Production - MANUALKV Yashwanth100% (1)

- Aircraft Avionics: Learning ObjectivesDocument24 pagesAircraft Avionics: Learning ObjectivesJesus MarianoNo ratings yet

- Types and Applications of Plastics Used in Aerospace IndustryDocument3 pagesTypes and Applications of Plastics Used in Aerospace IndustryHOD Aeronautical Engineering100% (1)

- WeldingDocument56 pagesWeldingIrfan AbdullahNo ratings yet

- Principles of Material HandlingDocument27 pagesPrinciples of Material HandlingManoy BermeoNo ratings yet

- Corrosion (All)Document59 pagesCorrosion (All)trongstaNo ratings yet

- Design & Analysis of Landing GearDocument10 pagesDesign & Analysis of Landing GearConfusionMakesmanperfectNo ratings yet

- Literature ReviewDocument3 pagesLiterature Reviewfradow mudendaNo ratings yet

- WavePro LT Busway GE CatalogDocument40 pagesWavePro LT Busway GE CatalogWei Jiang NgNo ratings yet

- Sheet Metal Forming ProcessesDocument51 pagesSheet Metal Forming ProcessesLeo Dev WinsNo ratings yet

- Coaxial Cable, or Coax, Has An InnerDocument20 pagesCoaxial Cable, or Coax, Has An InnerBharat DwivediNo ratings yet

- Prak-1 Sal - Trans-Coaxial Cable-Twis-Pair-2022Document32 pagesPrak-1 Sal - Trans-Coaxial Cable-Twis-Pair-202220JTD2BTasya Rahma FNo ratings yet

- Coaxial Cable InglesDocument7 pagesCoaxial Cable InglesGianmarco Yllanes LamaNo ratings yet

- Coaxial CableDocument36 pagesCoaxial CableAmit SinghNo ratings yet

- Coaxial CableDocument15 pagesCoaxial CableBonnie ThompsonNo ratings yet

- CISA Exam - Testing Concept-Network Physical Media (Fiber Optic/ UTP/STP/Co-axial) (Domain-4)From EverandCISA Exam - Testing Concept-Network Physical Media (Fiber Optic/ UTP/STP/Co-axial) (Domain-4)No ratings yet

- Soil & Tillage Research: Jeff TullbergDocument7 pagesSoil & Tillage Research: Jeff TullbergAlex AdamsNo ratings yet

- Al-Neama 2021 IOP Conf. Ser. Earth Environ. Sci. 735 012071Document7 pagesAl-Neama 2021 IOP Conf. Ser. Earth Environ. Sci. 735 012071Alex AdamsNo ratings yet

- StrategiesDocument7 pagesStrategiesAlex AdamsNo ratings yet

- KPIs TemplateDocument1 pageKPIs TemplateAlex AdamsNo ratings yet

- Water 13 0Document13 pagesWater 13 0Alex AdamsNo ratings yet

- Soil & Tillage ResearchDocument8 pagesSoil & Tillage ResearchAlex AdamsNo ratings yet

- Compaction Effects On Evaporation and Salt Precipitation in Drying Porous MediaDocument19 pagesCompaction Effects On Evaporation and Salt Precipitation in Drying Porous MediaAlex AdamsNo ratings yet

- Draft Force Prediction For A High-Speed Disc Implement Using Discrete Element ModellingDocument9 pagesDraft Force Prediction For A High-Speed Disc Implement Using Discrete Element ModellingAlex AdamsNo ratings yet

- Bulk Density: An Index For Measuring Critical Soil Compaction Levels For Groundnut CultivationDocument14 pagesBulk Density: An Index For Measuring Critical Soil Compaction Levels For Groundnut CultivationAlex AdamsNo ratings yet

- ArticleText 56506 1 10 20220602Document11 pagesArticleText 56506 1 10 20220602Alex AdamsNo ratings yet

- Idm Serial 1 NumberDocument2 pagesIdm Serial 1 NumberAlex AdamsNo ratings yet

- Prof. B V S Viswanadham, Department of Civil Engineering, IIT BombayDocument38 pagesProf. B V S Viswanadham, Department of Civil Engineering, IIT BombayAlex AdamsNo ratings yet

- How To Keep An Erection Up For Longer in 20 WaysDocument3 pagesHow To Keep An Erection Up For Longer in 20 WaysAlex AdamsNo ratings yet

- Here Are Few Things More Iconic of Particle Physics ThanDocument116 pagesHere Are Few Things More Iconic of Particle Physics ThanAlex AdamsNo ratings yet

- Determining Water Content in SoilDocument2 pagesDetermining Water Content in SoilAlex AdamsNo ratings yet

- 216605-Article Text-533466-1-10-20211026Document7 pages216605-Article Text-533466-1-10-20211026Alex AdamsNo ratings yet

- Binary Phase Diagram Phases: X%b. For Example, Cu - 20%al Is 80% Copper and 20% AluminiumDocument22 pagesBinary Phase Diagram Phases: X%b. For Example, Cu - 20%al Is 80% Copper and 20% AluminiumAlex AdamsNo ratings yet

- Teacher Notes - Activity 26: Electromagnetic Induction-Magnet and CoilDocument5 pagesTeacher Notes - Activity 26: Electromagnetic Induction-Magnet and CoilAlex AdamsNo ratings yet

- Idm Serial 1 NumberDocument2 pagesIdm Serial 1 NumberAlex AdamsNo ratings yet

- The Following Are The Charts That We HaveDocument1 pageThe Following Are The Charts That We HaveAlex AdamsNo ratings yet

- Product: (KJ/KG.K) (Btu/lb. F)Document6 pagesProduct: (KJ/KG.K) (Btu/lb. F)Alex AdamsNo ratings yet

- Paper - Sample 50 PoundsDocument5 pagesPaper - Sample 50 PoundsAlex AdamsNo ratings yet

- Concept PaperDocument2 pagesConcept PaperAlex Adams100% (1)

- Design, Development and Testing of A Screw Press ExpellerDocument9 pagesDesign, Development and Testing of A Screw Press ExpellerAlex Adams100% (2)

- Username AssdirectorDocument1 pageUsername AssdirectorAlex AdamsNo ratings yet

- TECNED Industrial Inverters UPSDocument7 pagesTECNED Industrial Inverters UPSKurt WyleNo ratings yet

- Solid State DevicesDocument79 pagesSolid State Devicesjj0125860% (2)

- Simulation of Single Phase Active Power Factor Pre RegulatorDocument4 pagesSimulation of Single Phase Active Power Factor Pre RegulatorEditor IJTSRDNo ratings yet

- Jagadesh 600 MCQDocument131 pagesJagadesh 600 MCQraajiNo ratings yet

- ABB Industrial Drives: ACS800, Single Drives, 0.75 To 6000 HPDocument60 pagesABB Industrial Drives: ACS800, Single Drives, 0.75 To 6000 HPsr_vaishnaniNo ratings yet

- What's The Difference Between IEEE 802.11af and 802.11ah - PDFDocument10 pagesWhat's The Difference Between IEEE 802.11af and 802.11ah - PDFsorinproiecteNo ratings yet

- Panasonic PTvx430 Projector SpecDocument7 pagesPanasonic PTvx430 Projector SpecUsman GhaniNo ratings yet

- HCPL 7840 AgilentDocument19 pagesHCPL 7840 AgilentJake MotorNo ratings yet

- PJ2500M-C, PJ3000HE, PJ3500M-C, PJ4000U-K & PJ5000U-K: User Manual Volume 2: Technical AppendixDocument132 pagesPJ2500M-C, PJ3000HE, PJ3500M-C, PJ4000U-K & PJ5000U-K: User Manual Volume 2: Technical AppendixErickNo ratings yet

- 4G1Document3 pages4G1Ahmed ShoeebNo ratings yet

- EEG-EP Basic ElectronicsDocument5 pagesEEG-EP Basic ElectronicsamurroNo ratings yet

- PAT Serena New BuildingDocument15 pagesPAT Serena New BuildingMuhammad IsmaildadNo ratings yet

- SMP 4000 en SDocument8 pagesSMP 4000 en SZainal AbidinNo ratings yet

- Beo Technical ManualDocument67 pagesBeo Technical ManualmNo ratings yet

- FS08 - Elec - Tender DrawingDocument5 pagesFS08 - Elec - Tender Drawinglkt_pestechNo ratings yet

- DIGITAL ELECTRONICS Questions and Answers PDFDocument5 pagesDIGITAL ELECTRONICS Questions and Answers PDFBryanOviedoNo ratings yet

- Dumont 79-02A - Dual Trace (Vertical Plugin) Instruction Manual With Maintenance Part - 6704 55l2Document113 pagesDumont 79-02A - Dual Trace (Vertical Plugin) Instruction Manual With Maintenance Part - 6704 55l2jabo499534No ratings yet

- Gate Level Design of A Digital Clock With AsynchronousDocument23 pagesGate Level Design of A Digital Clock With AsynchronousPidikiti Surendra BabuNo ratings yet

- Apollo Experience Report S-Band Sstem Signal Design and AnalysisDocument80 pagesApollo Experience Report S-Band Sstem Signal Design and AnalysisBob Andrepont100% (1)

- Atheros, Wireless LAN, WLAN..Document3 pagesAtheros, Wireless LAN, WLAN..trikers6660% (1)

- Epson FX-880, FX-880T, FX-1180 Service ManualDocument108 pagesEpson FX-880, FX-880T, FX-1180 Service ManualKinder BlackNo ratings yet

- Pioneer Avm-P7000 PDFDocument100 pagesPioneer Avm-P7000 PDFIvan BadjakovNo ratings yet

- TL866 ProgDocument9 pagesTL866 ProgAlonso CoradoNo ratings yet

- Schneider Electric - PowerLogic-PM5000-series - METSEPM5310Document4 pagesSchneider Electric - PowerLogic-PM5000-series - METSEPM5310X X ChongNo ratings yet

- Aplicaciones PIC Con CTMUDocument12 pagesAplicaciones PIC Con CTMUPablo Falagán CanoNo ratings yet

- AD7674Document28 pagesAD7674Chaba Leyva HernándezNo ratings yet