Professional Documents

Culture Documents

Group 9 Post Tensioning

Uploaded by

kictoddCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Group 9 Post Tensioning

Uploaded by

kictoddCopyright:

Available Formats

1 | P a g e

Summary

Two post-tensioned beams made out of Styrofoam, rubber bands and match sticks were

investigated when specific loads were placed at the mid-span. The main purpose of this report

was to obtain the engineering characteristics of post-tensioned beams using scaled models. The

beam when loaded is supposed to show similar characteristics to that of a simply supported

beam. Each beam contains the same material, but when constructed the rubber band, which

represent the neutral axis was placed at different locations. The beam whose neutral axis is

located 8mm from the base is initially hogging, and when a load is placed the beam neutralizes

and it begins to sag as load is increased. The beam with the neutral axis through the centre

behaves similarly except when constructed it was at a neutral position, rather than hogging.

2 | P a g e

I ntroduction

Post-tensioning is a type of reinforcement that is used on materials that contains tendons.

In most cases post-tensioning is used in the construction industry for the construction of bridges,

sport stadiums and apartment buildings. It is basically used on structures that have a great

downward force and large spans. Post-tensioning is widely used because it offers longer clear

spans, thinner slabs, fewer beams and more slender, dramatic elements as well as a high degree

of flexibility in the column layout. Since it offers thinner slabs this mean that less concrete is

required thus reducing the cost. It also reduces the weight of the building when compared to a

conventional concrete building which has the same number of floors. The foundation load is

greatly reduced thus making it a great advantage in seismic areas. The slabs and beams can also

be continuous. A slab or beam can run continuously from one end of the building to the other

end of it thus making it more efficient. Post-tensioning is also used to strengthen concrete when

it is under tensional stress, as concrete works well under compression but not under tension.

For this project post-tensioning was analysed by using a model made out of Styrofoam

which represents concrete and a rubber band which acted as a tendon/reinforcement that has been

stretched by hydraulic jacks which was kept in place by two match sticks which acted as an

anchorage device. Investigation was made on the beam as to how it would react when a

significant amount of load was placed at the mid-span of it, based on where the rubber band was

placed within the Styrofoam.

3 | P a g e

Background Information

Bending of Beams

When a beam experiences a bending moment it will change its shape and internal stresses

will be developed. Bending in a beam produces either hogging or sagging. Hogging and sagging

describe the shape of a beam or similar long object when loading is applied. Hogging describes a

beam which curves upwards in the middle, and sagging describes a beam which curves

downwards. In a post-tensioned beam it is expected that it will initially hog then as loads are

added, it will move from that position to a neutral one, then one of sagging.

The lower the neutral axis and the centre of gravity, the better the beam is expected to

behave under a tensional stresses. Thus as the load is increase on the beam, it is expected that the

beam with the lower neutral axis will be more sturdy and would fail at a higher load than a beam

with the neutral axis in the centre or higher from the base.

Uses of post-tensioned beams

As stated in the introduction, concrete is very strong in compression but weak in tension,

therefore it will crack when forces act to pull it apart. In conventional concrete construction, if a

load such as a truck is applied to a beam, the beam will tend to deflect or sag causing the bottom

of the beam to elongate slightly which then leads to cracking.

Steel reinforcing bars (rebar) are typically embedded in the concrete as tensile

reinforcement to limit the crack widths and are called passive reinforcement however, it does not

carry any force until the concrete has already deflected enough to crack. Post-tensioning tendons

are considered active reinforcing since it is pretested and the steel is effective as reinforcement

even though the concrete may not be cracked.

4 | P a g e

APPARATUS AND MATERIALS

30x30x30mm Styrofoam cubes

Rubber bands

Roller support (Cork)

Fixed support (styrofoam cube)

Ruler

25 cent coins

Matchsticks

BEAM 1 BEAM 2

RUBBER BAND AT CENTER

RUBBER BAND 8mm FROM THE BASE

1. 0

5 | P a g e

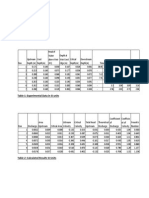

RESULTS

Weight of one twenty five cent coin=3.5g

BEAM WITH RUBBER BAND AT CENTER (12.5mm from base)

u

(mm)=

325

Number of

coins

Weight (g)

Load

Applied (N)

u (mm) u (mm)

5 17.5 0.17168 325 0

10 35.0 0.34335 320 5

15 52.5 0.51503 315 10

20 70.0 0.6867 300 25

25 87.5 0.85838 180 145

30 105.0 1.03005 110 215

6 | P a g e

Graph1: Showing load (N) against deflection (mm) for beam with neutral axis at 12.5 mm

BEAM WITH RUBBER BAND 8mm FROM THE BASE

u (mm) = 355.5

Number of

coins

Weight

Load Applied

(N)

u (mm) u (mm)

5 17.5 0.171675 355.5 0

10 35 0.34335 335.5 20

15 52.5 0.515025 335.5 20

20 70 0.6867 325.5 30

25 87.5 0.858375 325.5 30

30 105 1.03005 305.5 50

35 122.5 1.201725 295.5 60

40 140 1.3734 225.5 130

0

0.2

0.4

0.6

0.8

1

1.2

0 50 100 150 200 250

L

o

a

d

(

N

)

Deflection (mm)

Load vs Deflection

7 | P a g e

Graph2: Showing load (N) against deflection (mm) for beam with neutral axis at 8mm

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

0 20 40 60 80 100 120 140

L

o

a

d

(

N

)

Deflection (mm)

Load vs Deflection

8 | P a g e

Discussion

In this experiment two model bridges made of Styrofoam, elastic bands and matches were

used to test the effect that loads would have on post-tensioned beams. The models were created

by inserting a hole through the Styrofoam (one 8mm from the base and the other 12.5mm from

the base), then inserting the elastic band into the hole, ensuring it spans the entire beam. After

this was done the match sticks were used to secure the ends and then the beams were placed on

the supports.

Initially it was observed that both beams were hogging, with the beam containing the

neutral axis 8mm from the base experiencing a greater hogging moment. This is expected as the

elastic bands are pulling the Styrofoam pieces at the ends together thus causing tension to occur

within the structure. The models were set up like simply supported beams, i.e. one end of the

beam was placed on a roller support, while the other end was placed on a fixed support.

When the initial set of loads was applied to the beams it was observed that the beams

would have reached a neutral point, with regards to bending moment. During the experiment it

was clearly seen that both beams behaved quite differently as they were being loaded.

The beam with the elastic band through the centre was observed to hog very little at the

beginning of the experiment, this is quite different when compared with a normal beam that is

not post-tension, which would be neutral. This hogging characteristic allows the beam to have

more strength and be able to take more loading, since it requires loading to bring it to a neutral

point, the same load would produce sagging in an unstressed beam. This beam was observed to

deflect to the datum line (0) under the load of 30 coins (1.03N).

The beam with the elastic band off centre, i.e. 8mm from the base was observed to have a

greater hog than the beam with the elastic band through the centre, when it was constructed. This

shows that this beam would have a greater capacity for bearing loads than the beam containing

its neutral axis in the centre. This beam was observed to deflect to the datum line (0) under the

load of 40 coins (1.37N).

9 | P a g e

Limitations

The surface used to test the models was not completely flat.

The roller support and the fixed support were not the same height.

Parallax errors occur during measurement in the experiment

The holes of the cubes were not at the exact same position.

Placing the coins singly would have been a more accurate approach than loading in fives

(5).

The coins were not stacked straight, there was a slight deviation to one side, which at

times resulted in toppling of coins.

Recommendations

Use a completely flat surface when testing the model.

Ensure that the supports are the exact same height from the surface to the beam

Ensure the coins are stacked straight and exactly at the centre of the beam.

Take more than one set of readings and find the average of the values to reduce errors

and increase accuracy of the data.

Stack the coins in smaller intervals.

Ensure that the holes are punched at the exact same position for each cube.

Use new rubber bands to ensure a high degree of elasticity.

10 | P a g e

Conclusion

From the experiment it can be seen that post tensioned beams allow structures to be able

to sustain greater loads than simple unstressed beams. It can also be seen from the results

obtained that it is better to offset the neutral axis to a point closer to the base than having it

remain in the centre, as the hogging component produced by the lower neutral axis added

significant strength. This was shown in the experiment as the beam with the lower neutral axis

was able to support a greater load (1.37N) than the beam with the neutral axis at the centre

(1.03N), before reaching the datum line.

11 | P a g e

References

http://www.princeton.edu/~humcomp/bikes/design/desi_63.htm

http://www.scribd.com/doc/9590230/Post-Tensioning-Study-Material-for-students-of-

Artchitecture

Beer, Ferdinand P., E. Russell Johnston Jr., John T. DeWolf. Mechanics of Materials. 4

th

Edition. McGraw Hill

http://www.web.mit.edu/emech/dontindex-build/full-text/emechbk_7.pdf

http://www.dsiamerica.com/uploads/media/DSI-USA_What_is_Post-

Tensioning_us_02.pdf

http://www.fhwa.dot.gov/bridge/pt/pt01.cfm

12 | P a g e

Appendix

Beam with neutral axis at center

10 coins

25 coins

13 | P a g e

Beam with neutral axis 8mm from bottom

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- cp3 TrussdesignDocument106 pagescp3 Trussdesignznyaphotmail.comNo ratings yet

- PETREL 1 Structural Modeling PDFDocument42 pagesPETREL 1 Structural Modeling PDFKuala Tambora100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lifting Hook Calculation: 90° Standard Hook Development LengthDocument2 pagesLifting Hook Calculation: 90° Standard Hook Development LengthSi Chini100% (3)

- Angles of ElevationDocument25 pagesAngles of ElevationAngelu bonaganNo ratings yet

- Truss Full ReportDocument23 pagesTruss Full ReportMoganraj90% (136)

- Design and testing of an oil-based pressure-compensated underwater hydraulic systemDocument12 pagesDesign and testing of an oil-based pressure-compensated underwater hydraulic systemGanesh ChodisettiNo ratings yet

- E 881511 Om GSCTP C P RC GBR 6-A4Document72 pagesE 881511 Om GSCTP C P RC GBR 6-A4winarnobNo ratings yet

- Weir Flow Experiment Results and CalculationsDocument1 pageWeir Flow Experiment Results and CalculationskictoddNo ratings yet

- Direct ShearDocument7 pagesDirect ShearkictoddNo ratings yet

- Atterberg LimitDocument8 pagesAtterberg LimitSalem AlbarkiNo ratings yet

- Importance of Effective Road Drainage SystemsDocument2 pagesImportance of Effective Road Drainage SystemskictoddNo ratings yet

- Consistency Limits (Revised)Document4 pagesConsistency Limits (Revised)Samir RahmanNo ratings yet

- Health & SafetyDocument2 pagesHealth & SafetykictoddNo ratings yet

- Central Bank Risk Management Literature ReviewDocument4 pagesCentral Bank Risk Management Literature ReviewkictoddNo ratings yet

- Fluids LabDocument14 pagesFluids LabkictoddNo ratings yet

- Karl Todd - Building Services ProjectDocument47 pagesKarl Todd - Building Services ProjectkictoddNo ratings yet

- CXC Past Paper June 2006 GeneralDocument18 pagesCXC Past Paper June 2006 Generalkictodd0% (1)

- Civ Desgn Post TentionngDocument4 pagesCiv Desgn Post TentionngkictoddNo ratings yet

- 23 Electronic TheodolitesDocument4 pages23 Electronic TheodolitesEmaNo ratings yet

- Week 1 ScienceDocument38 pagesWeek 1 ScienceEyphrille UmandapNo ratings yet

- Thermoelectric Mini Fridge & WarmerDocument37 pagesThermoelectric Mini Fridge & WarmerDinu RamanattukaraNo ratings yet

- Three-Phase Power Flow Calculations Using Direct ZBUS Method For Large-Scale Unbalanced Distribution NetworksDocument8 pagesThree-Phase Power Flow Calculations Using Direct ZBUS Method For Large-Scale Unbalanced Distribution NetworksApikShafieeNo ratings yet

- Triple Deck Theory ExplainedDocument18 pagesTriple Deck Theory ExplainedkrishnamurthyVishNo ratings yet

- Online Courses From Top UniversitiesDocument3 pagesOnline Courses From Top Universitiesephrem0% (2)

- فاينلDocument133 pagesفاينلعلياسماعيلNo ratings yet

- MS27069GDocument7 pagesMS27069Gawesome_600No ratings yet

- Circle TheoryDocument8 pagesCircle Theoryapi-278074538100% (3)

- Measure Density & Test Hooke's LawDocument2 pagesMeasure Density & Test Hooke's LawArt Angel GingoNo ratings yet

- Analysis of The Light J 3 Mesons in QCD Sum RulesDocument11 pagesAnalysis of The Light J 3 Mesons in QCD Sum Rulesubik59No ratings yet

- Wooden Windows CatalogueDocument17 pagesWooden Windows CatalogueVIJAY VATSALNo ratings yet

- GulfSea Diesel GE 40 PDFDocument2 pagesGulfSea Diesel GE 40 PDFObydur RahmanNo ratings yet

- GCSE Mini Test 4: Foundation Maths QuestionsDocument2 pagesGCSE Mini Test 4: Foundation Maths QuestionsSuiatz (Suiatz)No ratings yet

- AAnalyst 800 Detection Limits-Chromium DataDocument2 pagesAAnalyst 800 Detection Limits-Chromium DataЂорђе РадојичићNo ratings yet

- PhysicsX PDFDocument124 pagesPhysicsX PDFcitsNo ratings yet

- Demolition of BuildingDocument6 pagesDemolition of BuildingMAITRI ADUGENo ratings yet

- Gribs PacketDocument10 pagesGribs Packetapi-213645632No ratings yet

- Nuclei QB XiiDocument23 pagesNuclei QB XiiToshani GuptaNo ratings yet

- IAST Lect23 SlidesDocument30 pagesIAST Lect23 SlideskyleNo ratings yet

- BASF Styrodur Basement Insulation PDFDocument20 pagesBASF Styrodur Basement Insulation PDFakajsiNo ratings yet

- 6 14D 13 PDFDocument17 pages6 14D 13 PDFRiyon Sanjaya IrmalNo ratings yet

- Civil Engineering: Reinforced Cement Concrete & Pre-Stressed ConcreteDocument33 pagesCivil Engineering: Reinforced Cement Concrete & Pre-Stressed ConcreteDebendra Dev KhanalNo ratings yet

- Emft Iii (T2)Document73 pagesEmft Iii (T2)athembo georgeNo ratings yet