Professional Documents

Culture Documents

Informacion de Compresores PDF

Uploaded by

style303Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Informacion de Compresores PDF

Uploaded by

style303Copyright:

Available Formats

P Seri es

Air Compressors

8/20en - jan. 2003

Since 1923 Pneumofore produces industrial air compressors

and vacuum pumps featuring original solutions, the result of

constant efforts in research and development.

Thanks to decades of experience in design and construction of

industrial installations, Pneumofore offers turnkey solutions for

compressed air production and treatment.

The P series reciprocating air compressors, with installed

power from 0,75 to 9 kW, are a versatile, reliable and

cost-effective solution for the small- to medium-sized

needs of compressed air.

The P range includes more than 90 different compact and

noiseless models: stationary or mobile, with or without

packaged air tank, filters and air dryer, gas engine (PED

series) or electric motor driven with packaged star-delta

starter.

Made with state of the art material and numerically

controlled machining tools, the P compressors feature

reliability and high performance.

PC series: single-stage coaxial air compressors, with single or double cylinder block,

installed power from 1,1 to 1,5 kW and delivery pressure from 8 to 10 bar. With crank shaft

directly coupled to the electric motor, these compressors are powerful, compact,

silent and reliable. The PC compressors require very low maintenance: the cylinder block is

copper-nickel cast iron made, the intake and delivery blade valves are stainless steel made,

the splash lubrication is fully automatic. PC compressors are equipped with pressure gauge,

run/stop selector switch, safety valve and pressure reducer.

PM series: single-stage air compressors, with single or double cylinder block assembled on

a stationary or mobile iron sheet air tank, with installed power from 0,75 to 3 kW and 8 bar

delivery pressure. The V belt coupling between the electric motor and the air end is fully

protected by a safety cage. Compact and versatile, the PM compressor is an easy to displace

and operate source of compressed air. PM compressors are equipped with pressure gauge,

run/stop selector switch, safety valve and pressure reducer.

PB series: dual-stage air compressors with double cylinder block, installed power from 2,2 to

7,5 kW and 10 bar delivery pressure, state of the art design for 30% higher capacity than

single-stage compressors with the same installed power. According to the present automotive

technology, the compressor crank shaft is iron-forged or made of nodular cast iron.

PB compressors are equipped with pressure gauge, run/stop selector switch, safety valve and

pressure reducer.

PP series: tandem air compressors with two pistons air ends assembled on an iron sheet air

tank, each one with single cylinder block, installed power from 3 to 5,5 kW and 10 bar delivery

pressure. Tandem compressors are designed to ensure the highest reliability: the cylinder

head and block are cast iron made, the valves are stainless steel made and the electric

control system automatically split the working time between the air ends.

PP compressors are equipped with motor protector and timer or with star-delta starter and

solenoid valve on request, pressure gauge and door interlock.

PE series: electric driven or portable gas (PED) double-stage air compressors suitable for

building yard, with installed power from 2 to 10 kW and 7 bar delivery pressure. The

gas engine, air cooled, with silenced exhaust and protection against the lack of lubricant, is

linked on the trailer frame with vibration-proof rubber bushings. PE compressors are

equipped with safety valve, glycerine pressure gauge, condensate drainer, two outlet

connections, safety valve circuit breaker and check valve for venting to the atmosphere the

compressed air exceeding the request capacity.

PS series: compressors with sound proof cabinet with or without packaged air tank,

installed power from 1,5 to 7,5 kW and delivery pressure from 8 to 10 bar, in a soundproof

cabinet with high density deadening panel to prevent the working environment from noise.

The space-saving vertical layout and silent operation enable the user to install these

compressors as plug-and-play equipment. The control panel includes power switch, hour

counter and pressure gauge. PS compressors are equipped with pressure gauge, check

valve and safety valve.

PPHO series: skid-mounted with air filters and dryer to suit the requirements of hospitals,

pharmaceutical and food processing plants. Thanks to the redundancy of the double air

end, the tandem compressors are particularly recommended for applications requiring the

highest reliability. Pneumofore supplies the full package with 500 liters air tank, refrigeration

air dryer and three stages of filtrations for breathing air.

PC1,5T24

PM1,5T50

PB7,5T500

PS2,2T200

PPHO7,5T500

PP5,5T500

PE5,5T200

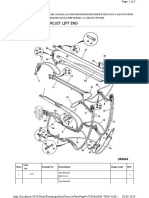

Dual-stage piston air-end

Pneumofore strives to constantly improve its products and reserves the right to modify technical data with no prior

notification. Contents of this documents are for informational purposes only and do not constitute a guarantee

extension of any kind. Trademark and logo Pneumofore are registered worldwide. Copyright Pneumofore SpA

All rights reserved. Any unauthorized reproduction or dissemination of this document is strictly prohibited.

Pneumofore SpA

Headquarters

Via N. Bruno, 34

10090 - Rivoli - Italy

Tel: +39 011.950.40.30

Fax: +39 011.950.40.40

Email: info@pneumofore.com

Web: www.pneumofore.com

Since 1923 Air Compressors and Vacuum Pumps

Plant Engineering Worldwide Service

ISO 9001

ISO 14001

CERTIFIED

P Ser i es

Air Compressors

Pneumofore supplies the uf series air filters: a wide range

of solutions that protect the pipeline from solid particles and

oil pollution, thereby reducing the overhaul corrosion and

maintenance.

To avoid the water condensation in the compressed air

circuit, the uf series use a cyclonic condensate drainer

packaged with electronic control. If the application requires

dew point down to 3

0

C, Pneumofore supplies the DS series

refrigerated air dryers, air cooled, with capacity from 65 to

8.750 m

3

/h, operating at high efficiency thanks to the

packaged electronic control.

Thanks to decades of experience in system integration

of industrial plants, Pneumofore supports the customer by

defining the technical specifications, installing machinery

and accessories, servicing and maintaining turnkey

installations.

To reduce the overhaul power consumption and extend the

operating life of the air compressors, Pneumofore

supplies the Q series air tanks, with capacity from

0,3 to 10 m

3

, vertical layout, with packaged safety valve,

pressure gauge and condensate discharge valve.

Solutions for medical, chemical-pharmaceutical applica-

tions, food processing or whenever the application requires

compressed air with highest class of purity up to

breathing and sterile air.

Pneumof or e Sol ut i ons f or Pl ant Ai r

length x width x height

640 x 250 x 600

580 x 310 x 640

580 x 310 x 640

1200 x 460 x 780

950 x 420 x 720

870 x 330 x 630

950 x 420 x 750

1170 x 470 x 790

1170 x 470 x 790

1430 x 540 x 920

1430 x 540 x 920

1430 x 530 x 970

1280 x 510 x 940

1550 x 640 x 1230

1550 x 640 x 1230

1970 x 600 x 1200

1970 x 600 x 1230

1970 x 600 x 1170

1970 x 600 x 1170

2700 x 750 x 1500

1970 x 600 x 1200

2700 x 750 x 1500

2150 x 1300 x 2250

830 x 600 x 760

1000 x 760 x 970

1000 x 760 x 970

1000 x 760 x 970

1100 x 880 x 1000

900 x 610 x 700

1000 x 610 x 800

1100 x 740 x 950

1100 x 750 x 960

700 x 500 x 790

700 x 500 x 790

1470 x 540 x 1140

1470 x 540 x 1140

1300 x 600 x 1300

1300 x 640 x 1300

860 x 740 x 1170

2000 x 610 x 1470

970 x 800 x 1300

kg

24

24

25

60

33

33

45

63

63

100

101

96

80

134

136

235

292

280

280

470

345

490

700

72

158

163

178

200

88

128

190

205

68

84

140

144

195

198

185

298

265

dB (A)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

75

75

75

75

75

78

78

78

78

65

65

65

64

64

65

70

70

70

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

F/C

C

C

C

C

C

C

C

C

C

-

-

F/C

F/C

F/C

F/C

-

F/C

-

bar

8

8

8

8

8

8

8

8

8

8

8

8

10

10

10

10

10

10

10

10

10

10

10

7

7

7

7

7

7

7

7

7

8

10

10

8

10

10

10

10

10

m

3

/h

7,2

9

12

14,4

14,4

7,2

9

13

17

24

29

19

20

30

34

52

72

60

67

67

102

102

144

39

52

90

102

132

30

42

54

96

17

19

21

26

30

34

52

52

72

rpm

1400

2800

2800

1400

2800

1400

1240

1230

1240

1000

1240

890

985

872

970

1035

1150

872

970

970

1035

1115

1150

1000

1050

900

1050

1000

1340

1100

1160

950

1230

890

985

1075

872

970

1035

1115

1150

HP

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

5,5

9

11

13

-

-

-

-

-

-

-

-

-

kW

-

-

-

-

-

-

1,1

1,1

1,5

2,2

3

2,2

2,2

3

4

5,5

7,5

2 x 3

2 x 4

2 x 4

2 x 5,5

2 x 5,5

2 x 7,5

3

4

5,5

7,5

9

-

-

-

-

1,5

2,2

2,2

3

3

4

5,5

5,5

7,5

kW

0,75

1,1

1,5

1,5

1,8

0,75

1,1

1,1

1,5

2,2

-

2,2

-

-

-

5,5

7,5

-

2 x 4

-

2 x 5,5

-

-

-

-

-

-

-

-

-

-

-

1,5

-

2,2

-

-

-

-

-

-

PC0,75

PC1,1*

PC1,5F

PC1,5

PC1,8

PM0,75

PM1,1

PM1,1F

PM1,5

PM2,2

PM3

PB2,2

PB2,2F

PB3

PB4**

PB5,5**

PB7,5

PP3

PP4**

PP4HO**

PP5,5**

PP5,5HO**

PP7,5HO**

PE3

PE4

PE5,5

PE7,5

PE9

PED5,5***

PED9***

PED11***

PED13***

PS1,5

PS2,2

PS2,2F

PS3F

PS3

PS4**

PS5,5**

PS5,5F**

PS7,5**

10

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

15

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

25

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

50

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

100

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

150

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

200

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

270

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

500

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Model Motor data Delivery Pressure Type Air tank Capacity Dimensions

Weight

max

Noise

level

230V

1 ph

400 V

3 ph

Diesel liters mm

F/C: packaged with stationary or mobile air tank.

C: packaged with mobile air tank.

* also available with air tank capacity from 2 to 6 liters

** packaged with motor protection (230V / single phase) or star-delta starter (400V / three phase).

*** engine preset for electric start up.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 55 J Master List of Standard Quality Plan DTD 28.03.2023Document20 pages55 J Master List of Standard Quality Plan DTD 28.03.2023Jaya Prakash RapoluNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Codes and StandardsDocument6 pagesCodes and StandardsZaid ImranNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Pelton Turbine - Basic Working PrincipleDocument5 pagesPelton Turbine - Basic Working Principlerpal0960No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Multistage Pump RepairDocument5 pagesMultistage Pump RepairCheyanSathishNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Duocheck SBMDocument1 pageDuocheck SBMNicolás FriasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Determining Thrust, Torque and Rimpull PDFDocument20 pagesDetermining Thrust, Torque and Rimpull PDFNurul Ain IbrahimNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Egger Iris LeafletDocument2 pagesEgger Iris LeafletEdg MerlínNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- SP1206 39 D4C Cartridge High Pressure PumpDocument2 pagesSP1206 39 D4C Cartridge High Pressure PumpMarcin WersockiNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- PSD Pumps PDFDocument12 pagesPSD Pumps PDFUdielh VelezNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Partes Compresor Gar 5Document6 pagesPartes Compresor Gar 5rolando mora zapataNo ratings yet

- Il200 en PDFDocument1 pageIl200 en PDFFirshatul UlaNo ratings yet

- Valves AssignmentDocument16 pagesValves AssignmentAdil Jutt GNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Pipe ClassDocument5 pagesPipe Classmokie305100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Tib 10 Pump InducersDocument5 pagesTib 10 Pump InducersscubazNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Performance Curves - LKH - LKHPF - LKHI - LKH Evap-35 60 HZ - EN PDFDocument1 pagePerformance Curves - LKH - LKHPF - LKHI - LKH Evap-35 60 HZ - EN PDFJuan Camilo RestrepoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hydreco@: HydraulicsDocument12 pagesHydreco@: HydraulicsMauricio Hermosilla OrellanaNo ratings yet

- Topaire Air Cooled Split Unit AG3 Series Catalgoue 2023Document5 pagesTopaire Air Cooled Split Unit AG3 Series Catalgoue 2023bitalohNo ratings yet

- Erp Material Master File As On 17.11.2023Document310 pagesErp Material Master File As On 17.11.2023UTTAL RAYNo ratings yet

- Manual de La Bop 3.06 15M PDFDocument28 pagesManual de La Bop 3.06 15M PDFJack FosterNo ratings yet

- World Wide Fittings Catalog - BodyDocument230 pagesWorld Wide Fittings Catalog - BodywarrentimeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CR 3-11 pump specsDocument3 pagesCR 3-11 pump specsLuis Miguel MartinezNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- AMT Landing Gear-Operacion Trenes PDFDocument6 pagesAMT Landing Gear-Operacion Trenes PDFALBA VIVIANA MOLINA RADANo ratings yet

- Nasa Rotor67Document12 pagesNasa Rotor67prakulmittal2No ratings yet

- Recommended Spare Parts (Grundfosliterature-5995012)Document1 pageRecommended Spare Parts (Grundfosliterature-5995012)PROTOTYPE TESTNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 9802/7860 E1-2-1 Circuit Lift EndDocument3 pages9802/7860 E1-2-1 Circuit Lift EndAnonymous japNfeNo ratings yet

- Arflu Valves ManufacturerDocument8 pagesArflu Valves ManufacturerAlejandro VazquezNo ratings yet

- FM 100.08 Bernoulli Theorem Apparatus - EdLabQuip 10.12Document18 pagesFM 100.08 Bernoulli Theorem Apparatus - EdLabQuip 10.12yonasNo ratings yet

- Bladder-Type Accumulator: HAB10-330 - DDocument24 pagesBladder-Type Accumulator: HAB10-330 - DTonyCerqueraNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 5c3319910a969 - Komatsu PC750-7, PC800-7 LC-SE - Section 90 - Hyd and Elect DiagramDocument9 pages5c3319910a969 - Komatsu PC750-7, PC800-7 LC-SE - Section 90 - Hyd and Elect DiagramGeorge ZormpasNo ratings yet

- 5.15 FluidaDocument7 pages5.15 FluidaMuhammadNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)