Professional Documents

Culture Documents

N0. QP-013, General Fabric Inspection Manual, Rev 0

Uploaded by

Iksan Adityo MulyoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

N0. QP-013, General Fabric Inspection Manual, Rev 0

Uploaded by

Iksan Adityo MulyoCopyright:

Available Formats

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 1 of 14

Gener al Fabr i c

I nspec t i on Manual

(Gener al I nspec t i on)

CI CO QP I NSP 013

APPROVAL

T i t l e N a m e Signature D a t e

E&C Manager Patrick A Cox

MI & QA Superintendent Steve Adrianto Feb. 18, 2002

Originator Zakianto Qohar May 19, 2001

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 2 of 14

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 3 of 14

CONTENTS

1.0 PURPOSE

2.0 SCOPE

3.0 REFERENCES

4.0 RESPONSIBILITIES

5.0 DEFINITIONS

6.0 INSPECTION AREA

7.0 QUALIFICATION AND CERTIFICATION

8.0 INSPECTION PROCESS FOR GENERAL FABRIC

CONDITION

9.0 CLOSURE

10.0 ATTACHMENT

10.1 Check list for General Fabric Condition Offshore

10.2 Check list for General Fabric Condition Onshore

10.3 Sketch(es) or Photo(s)

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 4 of 14

1.0 PURPOSE

The principal objective of this inspection manual is to provide a general guidance and to

ensure that the general fabrics are well inspected and having acceptable inspection result

in order to serve certain operating condition safely.

This manual is intended as Level I General Inspection Manual System for facilities.

2.0 SCOPE

This manual is applicable in inspecting general structure and general facility condition

visually that includes general condition of pressure containment system.

3.0 REFERENCES

Migas Government Regulations

CICO-QP-M-002 : Inspection Manual for Pressure Containment System

API Standards

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 5 of 14

4.0 RESPONSIBILITIES

4.1 MI & QA Superintendent

Mechanical Integrity & Quality Assurance (MI & QA) Superintendent shall mean

a person who responsible for ensuring the facilities are in order to withstand

normal operation condition. In case substandard conditions found by Field

Inspector during walk through inspection, Inspection Result and Recommendation

shall be generated timely.

4.2 MI & QA Senior Specialist

MI & QA Senior Specialist shall mean a person who is responsible for

coordinating inspection work, reviewing the correctness of initial recommendation

that is received from Field Inspector(s) and preparing a formal recommendation for

the Superintendent approval. This position shall also be responsible to judge risk

level of fabric and to develop annual or quarter inspection program.

4.3 Field Inspector(s)

Field Inspector shall mean person(s) having certain inspection certifications and

qualifications who is responsible for performing walk through inspection in

general facility condition.

The Inspector(s) shall also have abilities to perform initial analysis and initial

recommendations before it is reviewed by Senior Specialist and approved by MI &

QA Superintendent.

4.4 MI & QA System Administration

The administrator shall mean person who is responsible for administering every

recommendation issued, closing status and updating the historical record of

general facility.

4.5 MI & QA Engineer

MI & QA Engineer shall mean a person who is responsible for preparing repair

procedures.

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 6 of 14

5.0 DEFINITIONS

Inspection Result Disposition

5.1 A - Satisfactory

This condition represents an excellent condition about above normal acceptable

industrial standards.

5.2 B - Good

This condition is within normal industrial standard and facilities have been

maintained properly.

5.3 C - Moderate

This condition is still within normal industrial standard; however, indicates some

areas require adequacy of maintenance.

5.4 D - Bad

This condition is about below industrial standard and indicates maintenance

program is inadequate.

5.5 E - Worst

This condition is below industrial standards and requires proper maintenance /

repair immediately.

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 7 of 14

6.0 INSPECTION AREA

Structure and General Facility Condition

The General Fabric Inspection covers visual inspection at glance to the following area or

section of platform and onshore plant. The General Fabric Inspection is intended to inspect

the current condition that may effect to the further loss, damage, etc. The following areas

are needed to inspect for general condition,

6.1 Top of J acket Area

6.2 Boat Landing Area

6.3 Below Cellar Deck

6.4 Above Cellar Deck

6.5 Below Main Deck

6.6 Above Main Deck

6.7 Plant - Onshore

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 8 of 14

7.0 QUALIFICATIONS AND CERTIFICATIONS

FIELD INSPECTORS

An authorized inspector employed by or under contract to and under the direction of an

owner-user inspection organization shall be equal to at least one of the following

qualifications and certifications,

Qualifications,

A degree in engineering plus 1 year of experience in the design, construction,

repair, operation, or inspection of structural or pressure containment item.

A 2-year certificate in engineering or technology from a technical college plus

2 years of experience in the design, construction, repair, operation, or

inspection of structural or pressure containment item.

The equivalent of a high school education plus 3 years of experience in the

design, construction, repair, operation, or inspection of structural or pressure

containment item.

Five years of experience in the inspection of structural or pressure containment

item

Certifications,

A jurisdictional agency certification They must have qualified by written

examination under the laws, rules, and regulations of jurisdiction, (Migas) or

A Certified AWS Welding Inspector.

8.0 INSPECTION PROCESS FOR GENERAL FABRIC CONDITION

During walk through inspection, Field Inspector shall check at glance the overall

condition of platform and general facility which is includes structural and pressure

containment system. Once the substandard item found, the preliminary recommendation

should be forwarded to Sr Specialist for further analysis and then MI & QA

Superintendent will issue recommendation timely.

9.0 CLOSURE

The inspection result shall be reported immediately to the Operations when findings are

revealed during walkthrough inspection. MI & QA Section will monitor in a monthly basis

the resolution status of The Inspection and Recommendation issued

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 9 of 14

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 10 of 14

10.0 ATTACHEMENT

10.1 Check list for General Fabric Condition Offshore

10.2 Check list for General Fabric Condition Onshore

10.3 Sketch(es) or Photo(es)

ooooo0ooooo

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 11 of 14

ATTACHMENT

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 12 of 14

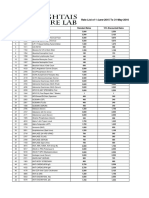

10.1 Chec k l i st f or Gener al Fabr i c Condi t i on

Of f shor e

Field : _________________________ Facility : ______________________

Year in Service : _________________________ Inspector name : ______________________

Date of Inspection : _________________________ ID Badge # : ______________________

Sketches : Yes N/A Inspectors signature :

No

INSPECTION AREA

Inspection

Disposition

RECOMMENDATION

1 Top of Jacket Area

General Structure

Handrail

Grating

Ladder

Stair

Walkway

Sump Caisson

General Piping

Valves

Instrumentation

Electrical

Cable trays

Pressure Vessels

General Rotating equipment

Safety Equipment

Other Equipment

2 Boat Landing Area

General Structure

Handrail

Grating

Ladder

Stair

Walkway

Rubber Fenders

Barge Bumpers

Riser Guards

Safety Equipment

Swing Rope

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 13 of 14

ESD Station

Safety Equipment

Etc.

No

INSPECTION AREA

Inspection

Disposition

RECOMMENDATION

3 Below Cellar Deck Area

General Structure

General Piping

General Cable Trays

Instrumentation

General Drain Lines

Safety Equipment

Etc

4 Above Cellar Deck

General Structure

Handrail

Grating

Ladder

Stair

Walkway

Deck Plating

Pipe Support

General Piping

Flow Lines

Vent Lines

Drain Lines

Process Piping

General Vessel and

Equipment Support

Instrument Support

Electrical Support

Deck Drain System

General Rotating Equipment

Safety Equipment

Etc.

5 Below Main Deck

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 14 of 14

General Structure

Pipe Supports / Hangers

General Piping

Cable Trays

Fire Water System

Drain System

Safety Equipment

Etc.

No

INSPECTION AREA

Inspection

Disposition

RECOMMENDATION

6 Above Main Deck

General Structure

Handrail

Grating

Ladder

Stair

Walkway

Deck Plating

Hats Cover

Deck Drain

Crane Pedestal

Electrical Stanchion

Instrumentation Stanchion

Safety Equipment

Etc.

INSPECTION RESULT DISPOSITION

1 A Satisfactory Excellent condition about above normal acceptable industrial standards.

2 B Good Within normal industrial standard and facilities have been maintained properly.

3 C Moderate Within normal industrial standard; however, indicates some area require adequacy of maintenance.

4 D Bad About below industrial standard and indicates maintenance program is inadequate.

5 E Worst Below industrial standards and require proper maintenance / repair immediately.

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 15 of 14

10.2 Chec k l i st f or Gener al Fabr i c Condi t i on

Onshor e

Field : _________________________ Facility : ______________________

Year in Service : _________________________ Inspector name : ______________________

Date of Inspection : _________________________ ID Badge # : ______________________

Sketches : Yes N/A Inspectors signature :

No

INSPECTION AREA

Inspection

Disposition

RECOMMENDATION

1 Onshore

General Structure

Handrail

Grating

Ladder

Stair

Walkway, Pavement

Drain System

Ditch

Pressure Vessel Foundation

Piping Foundation

Pipe Support

General Piping

Pressure Vessel

Instrumentation

Electrical

Cable Tray

Fire Water System

Tank Foundation

Tank Shell

Tank Ladder

Tank Cathodic Protect Syst.

Floating Roof tank

Lightning Protection

Insulation

General Rotating Equipment

Piping at Air to Soil Zone

Safety Equipment

Etc

QP-

013,_General_Fabric_Insp

ection_Manual,_Rev_0.doc

Rev. 0 Feb.18, 2002

Chevron Indonesia Company

GENERAL FABRIC

INSPECTION MANUAL

Page 16 of 14

INSPECTION RESULT DISPOSITION

1 A Satisfactory Excellent condition about above normal acceptable industrial standards.

2 B Good Within normal industrial standard and facilities have been maintained properly.

3 C Moderate Within normal industrial standard; however, indicates some area require adequacy of maintenance.

4 D Bad A position which is a lower level industrial standard and indicates maintenance plan is inadequate.

5 E Worst Below industrial standards and require proper maintenance / repair immediately.

10.3 SKETCH(ES) OR PHOTO(ES)

You might also like

- P&IDDocument18 pagesP&IDhectornicolauNo ratings yet

- QP - 02 Magnetic Particle Test, Rev 01Document13 pagesQP - 02 Magnetic Particle Test, Rev 01Iksan Adityo MulyoNo ratings yet

- List Kekurangan Isometric DrawingDocument8 pagesList Kekurangan Isometric DrawingIksan Adityo MulyoNo ratings yet

- Welding QualificationDocument5 pagesWelding QualificationIksan Adityo MulyoNo ratings yet

- Hse CommitteeDocument1 pageHse CommitteeIksan Adityo MulyoNo ratings yet

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselDocument7 pagesF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoNo ratings yet

- F.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearDocument3 pagesF.sq-wI.013.3 WORK INSTRUCTION For Visual Check Inspection at Switch GearIksan Adityo MulyoNo ratings yet

- TA1179-D-5212-100X-3 - P&ID (Marked-Up)Document40 pagesTA1179-D-5212-100X-3 - P&ID (Marked-Up)Iksan Adityo Mulyo100% (1)

- 23 - PT Q&a 1-3 - PDFDocument49 pages23 - PT Q&a 1-3 - PDFbassamNo ratings yet

- Handout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Document96 pagesHandout Liquid Penetrant Test Level II - Rev. 3 - 28 August 2009Iksan Adityo Mulyo100% (1)

- S-900-3120-001 - 2 - 0001 (Concreate Building)Document23 pagesS-900-3120-001 - 2 - 0001 (Concreate Building)Iksan Adityo Mulyo100% (1)

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocument17 pagesF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNo ratings yet

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- Indra: A NA Const/Pip/QC K. Tsunoda/M. Sakaki 04-Jun-2012 S. KuritsuboDocument17 pagesIndra: A NA Const/Pip/QC K. Tsunoda/M. Sakaki 04-Jun-2012 S. KuritsuboIksan Adityo MulyoNo ratings yet

- Section 01 - Typical Duties of Welding InspectorsDocument12 pagesSection 01 - Typical Duties of Welding InspectorsIksan Adityo MulyoNo ratings yet

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocument6 pagesF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument26 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- Indra: Donggi Senoro LNG ProjectDocument17 pagesIndra: Donggi Senoro LNG ProjectIksan Adityo MulyoNo ratings yet

- Indra: For ConstructionDocument13 pagesIndra: For ConstructionIksan Adityo MulyoNo ratings yet

- PROJ 1051 FAB 001 - 2 Fabrication ProcedureDocument13 pagesPROJ 1051 FAB 001 - 2 Fabrication ProcedureIksan Adityo MulyoNo ratings yet

- 2 Inflow PerformanceDocument36 pages2 Inflow PerformanceIksan Adityo MulyoNo ratings yet

- JSA Process Piping Inspection Onshore - 2006Document1 pageJSA Process Piping Inspection Onshore - 2006Iksan Adityo MulyoNo ratings yet

- Vertical Multiphase Flow: Instructional ObjectivesDocument23 pagesVertical Multiphase Flow: Instructional ObjectivesIksan Adityo MulyoNo ratings yet

- JSA Pipeline Riser Inspection New Untuk DisimpanDocument1 pageJSA Pipeline Riser Inspection New Untuk DisimpanIksan Adityo MulyoNo ratings yet

- 2 - Oil PropDocument38 pages2 - Oil PropIksan Adityo MulyoNo ratings yet

- Magnetic Particle Test: Job Safety Analysis WorksheetDocument1 pageMagnetic Particle Test: Job Safety Analysis WorksheetIksan Adityo MulyoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Version 2 Dog Legged Stair ES EN 1992-1-1 2015Document29 pagesVersion 2 Dog Legged Stair ES EN 1992-1-1 2015Khaja100% (2)

- XL4016 Step Down Buck DC DC ConverterDocument7 pagesXL4016 Step Down Buck DC DC ConverterCésar Fernando Rueda PortillaNo ratings yet

- Text For Number 1-3: How To Make Passion Fruit Juice IngredientsDocument4 pagesText For Number 1-3: How To Make Passion Fruit Juice Ingredientsakmal maulanaNo ratings yet

- VK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualDocument76 pagesVK-53 (ВК-53) Erecting Cut-Out Switch: Maintenance ManualhaileNo ratings yet

- IoT & WSN - Module 5 - 2018 by Prof - SVDocument43 pagesIoT & WSN - Module 5 - 2018 by Prof - SVVignesh MJ83% (6)

- NSO SPRDocument9 pagesNSO SPRADITYA SINGHNo ratings yet

- TEF5-OFF Frontal Electronic TimerDocument4 pagesTEF5-OFF Frontal Electronic TimerWhendi BmNo ratings yet

- Critical Thinking and It's Importance in Education: I. Lenin Assistant Professor Auce KaraikudiDocument5 pagesCritical Thinking and It's Importance in Education: I. Lenin Assistant Professor Auce KaraikudiPABLO RAMIRO AGUILAR GONZALEZNo ratings yet

- E2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsDocument3 pagesE2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsSatya kaliprasad vangaraNo ratings yet

- E2870-13 Standard Test Method For Evaluating RelativDocument6 pagesE2870-13 Standard Test Method For Evaluating RelativA MusaverNo ratings yet

- Gurps Fallout HandgunsDocument1 pageGurps Fallout HandgunsAndrew Scott100% (1)

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDocument25 pagesRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarNo ratings yet

- Bendable ConcreteDocument21 pagesBendable ConcreteJulia Sebastian0% (1)

- Paracetamol BPDocument4 pagesParacetamol BPjaimurugeshNo ratings yet

- Urgent Medical Device CorrectionDocument4 pagesUrgent Medical Device CorrectionVladimir OsunaNo ratings yet

- Ambitious Academy Lahore: Annual Revision Test SystemDocument2 pagesAmbitious Academy Lahore: Annual Revision Test SystemAmir HabibNo ratings yet

- Asms 02 0033Document6 pagesAsms 02 0033Delfia AkiharyNo ratings yet

- DE (Diatomaceous Earth) BenefitsDocument9 pagesDE (Diatomaceous Earth) BenefitsIlqa116100% (1)

- DHI-ITALE-060AA-P: White Strobe LampDocument2 pagesDHI-ITALE-060AA-P: White Strobe LampXlabs MedanNo ratings yet

- RT Offer L-Seam-14.01.2023Document1 pageRT Offer L-Seam-14.01.2023Eswar Enterprises QcNo ratings yet

- FEED Deliverable List (Sample) : Project InformationDocument3 pagesFEED Deliverable List (Sample) : Project Informationamilasri100% (1)

- Unipoxy LiningDocument3 pagesUnipoxy LiningDien Thoai Nguyen HuuNo ratings yet

- Clinical Science of Guilen Barren SyndromeDocument2 pagesClinical Science of Guilen Barren SyndromemanakimanakuNo ratings yet

- hw10 PDFDocument10 pageshw10 PDFTahok24No ratings yet

- 120Document349 pages120xdyj2005No ratings yet

- Nelson Tables All in One PDFDocument618 pagesNelson Tables All in One PDFAmulya Ramakrishna100% (7)

- Morning in Nagrebcan - Manuel E. ArguillaDocument8 pagesMorning in Nagrebcan - Manuel E. ArguillaClara Buenconsejo75% (16)

- A Lightweight True Random Number Generator For Root of Trust ApplicationsDocument11 pagesA Lightweight True Random Number Generator For Root of Trust ApplicationsMADDULURI JAYASRINo ratings yet

- Improving Performance, Proxies, and The Render CacheDocument13 pagesImproving Performance, Proxies, and The Render CacheIOXIRNo ratings yet

- CCNP 300 410 ENARSI NetworkTUT 26 5 2021Document104 pagesCCNP 300 410 ENARSI NetworkTUT 26 5 2021Olga BradyNo ratings yet