Professional Documents

Culture Documents

Calculation For Technical Water Supply System PDF

Uploaded by

Võ Duy GiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation For Technical Water Supply System PDF

Uploaded by

Võ Duy GiaCopyright:

Available Formats

Customer Comments:

Name

Date

Name

Date

A

Name

Date

FIRST ISSUE /2012.07.09 GFA

REV

PREPARED

CHECKED

APPROVED

MODIFICATIONS

STATUS

THE SOCIALIST REPUBLIC OF VIET NAM

NAM NON HYDROPOWER PROJECT

CONTRACT 08/HD-BVC-P2

Package TB-01

SUPPLY OFELECTRO-MECHANICAL EQUIPMENT

BETWEEN

PURCHASERBAN VE HYDROPOWER JOINT STOCK COMPANY

EVNHPC BAN VE

SUPPLIER

ZHEFU-HYDROCHINA ZHONGNAN

TITLE

Calculation for Technical water supply system

DOCUMENT

NUMBER

ZFH- NON- 20 - GAA- ED- 00

- 0 01

DATE 2012.07.05

SHEET 9

July 10, 2012

1

NAM NON Hydropower Plant

Auxiliary System Calculation

Calculation for Technical water supply system

HYDROCHINA ZHONGNAN ENGINEERING CORPORATION

2012. 07

Reviewed by:

Checked by:

Designed by:

CATALOGUE

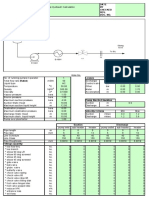

1 BASIC INFORMATION OF THE POWER PLANT ................................................................ - 1 -

2 COMPOSITION OF COOLING WATER SYSTEM ................................................................. - 1 -

3 WATER CONSUMPTION AND PRESSURE OF COOLING WATER, AND CAPACITY OF

WATER SUPPLY PUMP ...................................................................................................................... - 1 -

4 WATER SUPPLY PUMP HEAD CHECK ................................................................................... - 2 -

4.1 PIPELINE HEAD LOSS CALCULATION ........................................................................................ - 2 -

4.2 PUMP HEAD CHECK ................................................................................................................... - 4 -

5 CONCLUSION .............................................................................................................................. - 5 -

- 1 -

1 Basic information of the power plant

Installed capacity 210MW

Setting elevation of unit 61.80m

Full supply level 83.00m

Maximum head H max=9.87m

Rated head Hr=7.20m

Minimum head H min=6.34m

Runner diameter D1=4.80m

2 Composition of cooling water system

According to the requirements of technical specification Chapter B2.2, the cooling

water system will use pumps, and each unit shall be provided with two (2) water

pumps for technical water supply.

Type: horizontal shaft centrifugal pumps (one service, one standby)

Rated flow: no less than 86 m

3

/h

Rated head: H=35m

3 Water consumption and pressure of cooling water, and capacity of water

supply pump

The information provided by the unit manufacturer (Zhefu) is as below:

Name of equipment

pressure

mH

2

O

Pressure

drop

mH

2

O

Water

consumption

(m

3

/h)

Inlet elevation*

m

D (inlet)

mm

D(outlet)

mm

Generator air cooler 20-30 3 75 64.60 DN80 DN80

Shaft seal 20-30 3 1.2 62.00 DN40

Oil Cooler 20-30 3 10.2 54.70 DN40 DN40

- 2 -

The value marked with*is estimated.

Considering that the water consumption of common equipment is 10 m

3

/h,

The total water consumption of one unit is 96.4 m

3

/h.

Two sets of 86 m

3

/h-capacity water supply pumps (one service, one standby) as

indicated in the Bidding Documents can not meet the cooling system requirements.

4 Water supply pump head check

4.1 Pipeline head loss calculation

1For the sections of the pipeline, see the calculation sketch diagram. The pipeline

is sectioned by discharge and diameter. The flow velocity in water supply pipe is 2 to

4m/s, and the flow velocity in drainage pipe is 2 to 3m/s.

2Pipeline Head loss

1Head loss at the water supply side

a. Head loss from the intake to water supply mains 1-1-2-3-4-5-6

5.36+1.38(T joint) =6.74 (mH

2

O)

b. Head loss of each section of pipeline on the water supply side

Equipment

Pipe routing on the

water supply side

Head loss

(excluding T joint)

T joint

(mH

2

O)

Total

head

loss

(mH

2

O)

Air coolers of

generator

1-6-7-12 6.74+0.22+0.96 0.23+0.2 8.35

Shaft seal 1-6-7-8-9-10-11 6.74+0.97+1.53 0.032+0.032+0.32 9.62

Oil Cooler 1-17-18 6.74+5.74 0.02+0.02 12.52

- 3 -

2Head loss at the drainage side

Equipment

Pipe routing on the

drainage side

Head loss

(excluding T joint)

T joint

(mH

2

O)

Total head loss

(mH

2

O)

Air cooler of

generator

14-15-16 0.02+0.2+3.2 0.3 3.72

Shaft seal

Oil Cooler 20-21 0.02+0.12+3.06 0.3 3.5

3Total head loss

Equipment

Pipe routing

Head loss

on supply

side

mH2O

Pressure

drop

mH

2

O

Head loss

on

drainage

side

mH

2

O

Total

head loss

h

1

mH

2

O

Supply

side

Drainage

side

Air cooler of

generator

1-6-7-12

12-13-14-1

5-16

8.35 3 3.72 15.07

Shaft Seal

1-6-7-8-9

-10-11

9.62 9.62

Oil Cooler 1-17-18

18-19-20-2

1

12.52 3 3.5 19.02

- 4 -

4.2 Pump head check

For this project, the technical water is pumped from the upstream and drained to the

downstream. The pump head is calculated by the formula below:

- 5 -

HB=H1+ hw +

g

v

2

2

-(1-2)

where, HBtotal head of pumpm

H1pressure at cooler inlet, taking 0.2MPa

1reservoir level at minimum head (m)

2corresponding downstream water level at minimum head (m)

hw pipe head loss (m)

g

v

2

2

velocity head at pipe outlet (m)

It is obtained:

HB =20+19.02+0.32-9.93=29.41m

5 Conclusion

As indicated in the contract document, each unit shall be provided with two sets of

the vertical shaft centrifugal pumps (KQL125-315-15/5), with a rated flow of

100m

3

/h, a maximum flow of 120m

3

/h, a minimum flow of 60m

3

/h, a rated head of

32m, an efficiency of 74.1%, a motor power of 15 kW, and a voltage of 380V. The

check results show it can meet the requirements. Please refer to Drawing

No.ZFH-NON-20-PAC-TC-00-001 Principle Diagram of Cooling Water Supply

System.

You might also like

- Water Distribution ManualDocument20 pagesWater Distribution ManualOxfamNo ratings yet

- IRR On Proper Sewage HandlingDocument51 pagesIRR On Proper Sewage HandlingDexter G. BatalaoNo ratings yet

- Pool Hydraulic Analysis FormDocument6 pagesPool Hydraulic Analysis FormtonyonlyNo ratings yet

- Oil Interceptor CombinedDocument19 pagesOil Interceptor CombinedNiong DavidNo ratings yet

- Calorifier - Heat Recovery Time EtcDocument5 pagesCalorifier - Heat Recovery Time Etcmahmed111No ratings yet

- Hot Water-Plumbing Lect - 2015 BAUDocument60 pagesHot Water-Plumbing Lect - 2015 BAUAbed BaayounNo ratings yet

- Rheem 310 Series Heat Pump Hot WaterDocument68 pagesRheem 310 Series Heat Pump Hot WaterDavid HarpleyNo ratings yet

- QCS-2010 Section 19 Part 5 Hot Water StorageDocument9 pagesQCS-2010 Section 19 Part 5 Hot Water Storagebryanpastor106No ratings yet

- WHA Water Hammer ArrestorsDocument5 pagesWHA Water Hammer ArrestorsvitgahiNo ratings yet

- Distributed Pumping ConceptDocument52 pagesDistributed Pumping ConceptRichard Richard100% (1)

- Hot Water Plumbing Systems: Pdhonline Course M151 (3 PDH)Document64 pagesHot Water Plumbing Systems: Pdhonline Course M151 (3 PDH)Supun ThilakawardanaNo ratings yet

- Designing efficient centralized hot water systemsDocument36 pagesDesigning efficient centralized hot water systemsAbhik BhattacharjeeNo ratings yet

- Global Water Storage Tanks BrochureDocument44 pagesGlobal Water Storage Tanks Brochureعبد السميع بن أحمد100% (1)

- Pumping Stations Design Lecture 2Document25 pagesPumping Stations Design Lecture 2Nestor Augusto OyarceNo ratings yet

- Calculating Energy Savings of Indoor Swimming Pool MeasuresDocument4 pagesCalculating Energy Savings of Indoor Swimming Pool MeasuresAmeer AbbasNo ratings yet

- Wastewater Pump Station Design Problems and SolutionsDocument37 pagesWastewater Pump Station Design Problems and Solutionssinduh100% (2)

- Technical Specification Volume II-Part IDocument244 pagesTechnical Specification Volume II-Part Inawajha0% (1)

- Fripex-San Export Englisch Druckbogen 08-2015 75dpi PDFDocument5 pagesFripex-San Export Englisch Druckbogen 08-2015 75dpi PDFMuhammad ArslanNo ratings yet

- HVAC CalculationDocument2 pagesHVAC Calculationengrhabib07100% (1)

- Ato Abdulkader Residence Plumbing DesignDocument15 pagesAto Abdulkader Residence Plumbing Designdawitggg0% (1)

- Water Curtain (20.04.16)Document3 pagesWater Curtain (20.04.16)احمد الجزار2007No ratings yet

- Typical Schematic For Single Hot Water Heat PumpDocument12 pagesTypical Schematic For Single Hot Water Heat PumpVin Bds100% (1)

- High Rise Water DistributionDocument2 pagesHigh Rise Water DistributionzueklateNo ratings yet

- Water Heater Calculation Rev ADocument1 pageWater Heater Calculation Rev AalvinchuanNo ratings yet

- Proposed Sethsiripaya Office Project Water Demand CalculationDocument6 pagesProposed Sethsiripaya Office Project Water Demand CalculationThilanka NuwanNo ratings yet

- Birhane Design Report For Residence BuildingDocument10 pagesBirhane Design Report For Residence BuildingHaymanot BaynesagnNo ratings yet

- Waste Water PumpsDocument87 pagesWaste Water PumpsGrundfosEgypt100% (4)

- تصميم حمامات السباحةDocument63 pagesتصميم حمامات السباحةمحمد مصطفي100% (1)

- Calculation ReportDocument29 pagesCalculation Reportvictor.sNo ratings yet

- Aqua ChlorinatorDocument2 pagesAqua ChlorinatorSumit MishraNo ratings yet

- CHAPTER 4 Hot Water Supply PDFDocument27 pagesCHAPTER 4 Hot Water Supply PDFnurul atiqahNo ratings yet

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- L13-Water Supply and PumpDocument24 pagesL13-Water Supply and PumpShahrul Salleh100% (1)

- Water Booster Pump Calculations - Plumbing Engineering - Eng-TipsDocument3 pagesWater Booster Pump Calculations - Plumbing Engineering - Eng-TipsNeal JohnsonNo ratings yet

- Potable Water Pumps: Lamah EstDocument18 pagesPotable Water Pumps: Lamah Estفتحى أحمدNo ratings yet

- Water Heating and Data CollectionDocument41 pagesWater Heating and Data CollectionDGGNo ratings yet

- Exhaust Fan SelectionDocument81 pagesExhaust Fan Selectionprabhuselva22100% (1)

- Photovoltaic Systems: OutlineDocument21 pagesPhotovoltaic Systems: OutlineGeorge Mavromatidis100% (1)

- SyncroFlo - Sizing Booster Pumps - Latest Tricks and Trends - 2009 ASPE Technical SymposiumDocument71 pagesSyncroFlo - Sizing Booster Pumps - Latest Tricks and Trends - 2009 ASPE Technical SymposiumGecko1987No ratings yet

- Pump CalculationDocument7 pagesPump CalculationPiping_SpecialistNo ratings yet

- Perfect Chloro Systems - Gas ..Document6 pagesPerfect Chloro Systems - Gas ..nazar750No ratings yet

- Pump CalculationDocument17 pagesPump CalculationDiaa ElbayyomyNo ratings yet

- Variable Speed Pumps KSBDocument12 pagesVariable Speed Pumps KSBMuhammadUsmanNo ratings yet

- 2013-Pump Sizing With Exercises r1Document25 pages2013-Pump Sizing With Exercises r1edhy_03No ratings yet

- TRIPLEX WATER BOOSTERDocument1 pageTRIPLEX WATER BOOSTERSharon LambertNo ratings yet

- Commercial Hot Water (Reference)Document2 pagesCommercial Hot Water (Reference)binhjukiNo ratings yet

- Isometric Plumbing Drawing RequirementsDocument8 pagesIsometric Plumbing Drawing RequirementsHatake KakasiNo ratings yet

- University's 500 kW Biomass Boiler Cuts Carbon by 500 Tonnes AnnuallyDocument4 pagesUniversity's 500 kW Biomass Boiler Cuts Carbon by 500 Tonnes AnnuallySuppachai DanpreechakulNo ratings yet

- Hot Water Storage Systems GuideDocument11 pagesHot Water Storage Systems GuideNadeesha BandaraNo ratings yet

- Indoor Pool Application Examples - Load CalculationDocument4 pagesIndoor Pool Application Examples - Load CalculationfireoniceNo ratings yet

- Chilled Water Storage Western AustraliaDocument9 pagesChilled Water Storage Western AustraliaWilson WongNo ratings yet

- VentilationDocument131 pagesVentilationtae walaNo ratings yet

- Design Water Supply Lasanod HospitalDocument5 pagesDesign Water Supply Lasanod HospitalsubxaanalahNo ratings yet

- Thermal Storage Vessel Sizing - 1-9Document9 pagesThermal Storage Vessel Sizing - 1-9Tomás CVNo ratings yet

- Unvented Calorifiers Installation & Commissioning GuideDocument10 pagesUnvented Calorifiers Installation & Commissioning GuidePaul KwongNo ratings yet

- District Cooling in the People's Republic of China: Status and Development PotentialFrom EverandDistrict Cooling in the People's Republic of China: Status and Development PotentialNo ratings yet

- Vietnam HPP Low-Pressure Air System CalculationDocument11 pagesVietnam HPP Low-Pressure Air System CalculationVõ Duy GiaNo ratings yet

- Southern Generating StationDocument34 pagesSouthern Generating Stationrishav ghosh100% (1)

- 2.va1 Gedi 00HTF M M5 PHL 0001 - 1Document23 pages2.va1 Gedi 00HTF M M5 PHL 0001 - 1hoangduythanhqbNo ratings yet

- ATP Parts Guide-B3Z Z-Frame Pump BerkeleyDocument1 pageATP Parts Guide-B3Z Z-Frame Pump BerkeleyRony FloresNo ratings yet

- TurbomachineryDocument64 pagesTurbomachineryStefan Arichta100% (1)

- Pipe Flow Rate CalculationDocument33 pagesPipe Flow Rate CalculationSALVADOR VARGAS DIAZNo ratings yet

- Piping Class - GD30Document3 pagesPiping Class - GD30Dmitriy RybakovNo ratings yet

- 4239 - MTO Shortage Piping Around Equipment - Area1,2,3&PPU For MR - Bestrack CORRECTEDDocument9 pages4239 - MTO Shortage Piping Around Equipment - Area1,2,3&PPU For MR - Bestrack CORRECTEDRescos KasarachiNo ratings yet

- H-005 Ecc Piping Design InstructionsDocument39 pagesH-005 Ecc Piping Design Instructionsvermaakash22No ratings yet

- Flow Straightener Reduces Upstream Pipe RequirementsDocument2 pagesFlow Straightener Reduces Upstream Pipe RequirementssenthilNo ratings yet

- Sistema Hidraulico CAT 966FDocument24 pagesSistema Hidraulico CAT 966FNicolas AvocNo ratings yet

- Hydraulic Valves GuideDocument60 pagesHydraulic Valves GuideAyenewe mNo ratings yet

- Pipe Flow AdditionalDocument11 pagesPipe Flow AdditionalKefene GurmessaNo ratings yet

- Pump hydraulic calculationDocument1 pagePump hydraulic calculationJk KarthikNo ratings yet

- PRO - DV-, DRV - 06 To 16 Flow Control ValvesDocument4 pagesPRO - DV-, DRV - 06 To 16 Flow Control ValvespeterNo ratings yet

- Hydraulic TestDocument3 pagesHydraulic TestSaurabh BarangeNo ratings yet

- SANITARY SCIENCE BUILDINGSDocument12 pagesSANITARY SCIENCE BUILDINGSVholts Villa Vitug71% (7)

- Water Distribution ManualDocument20 pagesWater Distribution ManualOxfamNo ratings yet

- Wellbore Skematic DrawingsDocument74 pagesWellbore Skematic DrawingsMino MinoNo ratings yet

- Replacement Parts: 21 Gallon 2.5 HP 125 PSI Cast Iron Vertical Air CompressorDocument1 pageReplacement Parts: 21 Gallon 2.5 HP 125 PSI Cast Iron Vertical Air CompressorRicky DaleNo ratings yet

- Allied Autovent 2000 3000 ManualDocument28 pagesAllied Autovent 2000 3000 ManualwiroarNo ratings yet

- Line Index Table For Miano-18 Wellhead CompressionDocument2 pagesLine Index Table For Miano-18 Wellhead CompressionHafiz AkhtarNo ratings yet

- ME320 Professor John M. Cimbala: Water Draining From A TankDocument6 pagesME320 Professor John M. Cimbala: Water Draining From A TankShohag HossainNo ratings yet

- Piping Tie-Ins The BasicsDocument4 pagesPiping Tie-Ins The BasicsashokNo ratings yet

- Trumpet Valve ManifoldDocument4 pagesTrumpet Valve Manifoldmahonde100% (1)

- FF Series (50hz) PDFDocument5 pagesFF Series (50hz) PDFTin Htun MyintNo ratings yet

- Hydraulic SymbolsDocument18 pagesHydraulic SymbolsBhaskar Reddy100% (1)

- Chemgaurd Bladder Tank Design and System Installation PDFDocument7 pagesChemgaurd Bladder Tank Design and System Installation PDFVignesh WaranNo ratings yet

- Pump Sizing Calculation Step-by-StepDocument3 pagesPump Sizing Calculation Step-by-StepBegenkzNo ratings yet

- MeasurIT Tideflex Project Dun Laoghaire 0803Document1 pageMeasurIT Tideflex Project Dun Laoghaire 0803cwiejkowskaNo ratings yet

- Form 1.2Document2 pagesForm 1.2Jayvee AgarpaoNo ratings yet

- Updated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Document31 pagesUpdated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Francisco Wilson Bezerra FranciscoNo ratings yet

- Technical Specification - 8X40Mtrs UV Vessel - Rev1Document15 pagesTechnical Specification - 8X40Mtrs UV Vessel - Rev1Basheer AhmedNo ratings yet