Professional Documents

Culture Documents

Welding PDF

Uploaded by

indikumaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding PDF

Uploaded by

indikumaCopyright:

Available Formats

SUPPLEMENTAL INFORMATION 2

PIPE WELDING

Welding pipe is like welding any other structural shape and welding can take place in any of

the normal positions for welding. When welding pipe flanges and some joints configurations

the weld applied may be a fillet weld. When welding pipe to pipe the joint is similar to a vee

groove and is often open root. Welding pipe to pipe requires a higher degree of skill and is the

topic of this supplement.

The pipe welding positions covered are the 1G flat and rolled position, the 2G horizontal

position, the 5G vertical position and the 6G fixed position as shown below.

Page 1 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

PIPE WELDING EDGE PREPERATION

The pipe coupons for welding are cut using the pipe beveling machine. The slag is removed and

the edges are ground smooth for welding a 1/8 landing or flat is applied to the pipe. The

pictures below show the pipe beveling machine and the edge preparation.

Page 2 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

PIPE ASSEMBLY

The pipe is assembled for welding by placing one piece on top of the other with a 1/8 electrode

without flux on it between the pipe.

Page 3 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

It is extremely important to set up and tack weld the pipe properly, if the pipe is not aligned on

the inside it is difficult to obtain the proper penetration through the pipe.

The root gap around the pipe must be consistent. If part of the root gap is too wide the key hole

will open up too much while welding and instead of penetration you may have burn through

(more than 1/8 reinforcement) on the inside. If part of the root gap is too narrow you may not

be able to penetrate through the pipe in those areas.

At least 4 tack welds should be placed around the pipe at 12 oclock 6 oclock 3 oclock and 9

oclock.

The tacks must be strong enough to hold alignment while welding the root pass and should

penetrate enough to become a part of the root pass. When testing the tack may be removed

using a cutting wheel to get a consistent root weld around the joint.

The picture below shows the tacks in a flat position pipe.

Chill ring

For some applications a chill ring may be used instead of an open root. The chill ring works

like a backing bar in groove welding and becomes a part of the welded joint. When the chill

ring is used the root opening is determined by the pins on the chill ring. After tacking the chill

ring on the inside of the pipe, the pins are removed. If a chill ring is used the root pass may be

made using E-7018 since it is not necessary to penetrate through the pipe.

Page 4 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

PIPE WELDING IN THE FLAT 1G POSITION

Pipe Welding in the flat position requires that the Welder make some adjustments to the

normal angles and length of the welds during welding. In the flat position with the pipe being

rolled or rotated the push travel angle works best. Shorter lengths of weld are used so that you

do not change your travel angle by stretching out of position. The pipe is then rotated before

continuing. Stringer beads are used to weld the root, fill passes and cover pass on six inch

schedule 80 pipe.

Page 5 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

Technique for welding the 1 G Rolled Pipe

The root pass is made using the E-6010 Electrode to penetrate through the open root pipe.

Make sure the amperage (heat) is set correctly to open and maintain the keyhole where the

root is s good fit. Use scrap metal and weld in the flat position with the amperage on

approximately 100 and adjust the heat as necessary.

The root pass should be flat to convex in appearance on the groove side of the pipe with no

holes and should be flush to 1/8 maximum reinforcement on the inside of the pipe.

Page 6 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

After completing the root pass and evaluating the penetration, grind the groove side of the

weld in preparation for the fill passes.

Set the amperage for the E-7018 1/8 Electrode at approximately 120-150 amps to weld the fill

passes and the cover passes. Use the stringer bead technique for welding the fill passes and

cover passes.

Page 7 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

PIPE WELDING IN THE 2G HORIZONTAL POSITION

When welding in the 2g pipe position the pipe is vertical and the weld is horizontal. The pipe is

not moved during welding and the welder must move around the fixed position pipe. The

preparation and amperage setting should be the same as for the flat position pipe with E-6010

Electrodes used for the root and E-7018 Electrodes used for the fill and cover passes. It is

important to layer the fill passes and cover passes from the bottom pipe up to the top pipe,

while keeping the weld beads straight and properly overlapped.

Page 8 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

Page 9 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

PIPE WELDING IN THE VERTICAL 5G POSITION

In the 5G pipe position the pipe is horizontal and the weld axis is vertical so that the welding is

essentially a vertical weld. When welding some pipes for low pressure applications or small

diameter pipe it may be acceptable to weld vertical downward with an electrodes like the

E6010 however; most pipes are welded vertical upward with an E-6010 root pass and E-7018

fill and cap.

When welding in the 5G pipe position the weld beads may be either stringers or weaves

depending on the job requirements.

At the Delta School Of Trades we use the E-6010 electrode for the open root pass and E-7018

for the fill and cover passes using the vertical upward weave technique.

TECHNIQUE FOR VERTICAL 5G PIPE WELDING

AS always make sure the correct amperage is set for tacking the pieces and the root pass using

E-6010 electrodes. Check the machine setting and use an amperage from 90-110.

Page 10 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

Use E-7018 for the fill passes and cover pass set at approximately 120-150 Amps.

Use a slight U shape technique with the E-6010 electrode to open and maintain the keyhole. It

may be necessary to ride up very slightly on the inside edge of the groove to chill the keyhole if

it opens up too much. If the keyhole is too tight, slow down and force it open with the electrode

while welding or stop and increase the amperage (heat).

Use a Z motion weave with the E-7018 Electrode keeping the ripples close together and the

weld profile flat for the fill and cover passes.

VERTICAL UPWARD WEAVES FOR 5G PIPE

Stringer Weaves may also be used to weld the fill passes and cover passes. This is an important

technique to learn in preparation for welding in the 6G position

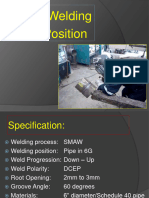

PIPE WELDING IN THE 6G FIXED POSITION

Page 11 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

In the 6G Pipe welding position the pipe is set on a 45 degree inclined angle. The

weld in this position covers all position welding because the bottom of the pipe is

an overhead weld; the top of the pipe is a flat weld and the front and back sides

are a vertical upward weld. The pipe is welded using stringer beads except that a

slight weave motion must be used to prevent the sides or vertical upward part

from sagging and lumping up in the middle of the weld bead.

The Electrode angle should remain the same for all passes. Use a slight push angle from

bottom to top.

CRITICAL ELEMENTS FOR WELDING THE 6G FIXED PIPE

As for all pipe welding take the time to set up the pipe properly with a consistent root gap and

4 evenly spaced tacks.

Make sure you have set the correct amperage for the electrode type and size as mentioned

earlier.

After running the root, grind the root pass lightly before starting with the E-7018 Electrode.

Page 12 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

Remember to use a slight weave motion with the E-7018 to prevent the weld lumping in the

middle and to get proper fusion.

Each filler pass should overlap the prior pass without leaving a depression (called wagon

tracks) and should show good fusion.

The 6G pipe position is the one used extensively for testing, since it qualifies the welder for all

position welding of pipe, grooves, and fillets.

When testing; it is advisable to remove the tacks instead of weld over them to ensure

penetration at the root. A wire wheel brush and grinder may be used to keep each pass clean

and prevent slag inclusions.

Although there are many Codes and Standards that govern the welding and testing of Pipe, the

one most widely used and recommended at the school is the AWS D1.1 Structural Welding

Code.

The test for SMAW is usually a 6 inch schedule 80 pipe with an open root, and is welded in the

6G position. This test qualifies the welder for welding fillets grooves and pipe in all positions.

Also qualifies the welder for pipe sizes from 4 inches to unlimited and wall thickness from 3/16

inch to unlimited.

An optional SMAW test on 4 inch schedule 40 pipe in the 6G position qualifies the welder for

all positions welding and pipe sizes from 3/4 to 4 inch with wall thickness from 1/8 to 3/4.

The pipe size recommended for GTAW Certification is the 4 inch sch 40 pipe.

Page 13 of 13 SUPPLEMENTAL INFORMATION 2

22/09/2012 http://deltaschooloftrades.com/supplemental_information_2.htm

You might also like

- Medical Abbreviations and Symbols ListDocument6 pagesMedical Abbreviations and Symbols ListdffdgdhdgNo ratings yet

- Upplemental Information 2 WeldDocument16 pagesUpplemental Information 2 WeldMasih BelajarNo ratings yet

- Master Pipe Welding PositionsDocument13 pagesMaster Pipe Welding PositionsFord Katim100% (4)

- Pipe Welding Positions and TechniquesDocument14 pagesPipe Welding Positions and TechniquessnilkanthNo ratings yet

- Grade 12welding Carbon Steel Pipes Pipe Edge PreparationDocument21 pagesGrade 12welding Carbon Steel Pipes Pipe Edge PreparationVanessa HadJeanxNo ratings yet

- Remediation Lesson in SMAW NC IIDocument49 pagesRemediation Lesson in SMAW NC IIemmabentonioNo ratings yet

- Practices Pipe 01: Practice Name Process Position Filler Machine SettingsDocument4 pagesPractices Pipe 01: Practice Name Process Position Filler Machine SettingsPradip Tapan BanerjeeNo ratings yet

- SMAW Welding Technique for Chilled Water PipingDocument48 pagesSMAW Welding Technique for Chilled Water PipingParag NaikNo ratings yet

- Procedures For Stud WeldignDocument4 pagesProcedures For Stud WeldignJulius KulvinskasNo ratings yet

- Root Pass: Vertical-Up Method Root Pass: Vertical-Down MethodDocument7 pagesRoot Pass: Vertical-Up Method Root Pass: Vertical-Down MethodWilly UioNo ratings yet

- V Blocks and Clamps: Hold Square or Round Work 2 Inch Round-1 7/16 Inch Square Hardened and Ground NO. 568Document1 pageV Blocks and Clamps: Hold Square or Round Work 2 Inch Round-1 7/16 Inch Square Hardened and Ground NO. 568Chris McLeanNo ratings yet

- Welder Guide Book: All-Positional Rutile Flux Cored Wires For Non and Low Alloyed SteelsDocument30 pagesWelder Guide Book: All-Positional Rutile Flux Cored Wires For Non and Low Alloyed SteelsMl JainNo ratings yet

- EmeDocument13 pagesEmeAnkur SagarNo ratings yet

- Validated TVL Smaw11 q3 M 4Document11 pagesValidated TVL Smaw11 q3 M 4tibo bursioNo ratings yet

- Bow Thruster Installation InstructionsDocument9 pagesBow Thruster Installation InstructionsRovert AlonzoNo ratings yet

- Safety Warning for Hex Beam Antenna AssemblyDocument11 pagesSafety Warning for Hex Beam Antenna AssemblyMario Jorge AlvarezNo ratings yet

- E Plus Kit ManualDocument27 pagesE Plus Kit ManualJCMNo ratings yet

- Rolling InstallnstructionsDocument8 pagesRolling InstallnstructionsANDINo ratings yet

- Welding PositionDocument27 pagesWelding Positionsgt estreroNo ratings yet

- Tender BOQ CPCBDocument19 pagesTender BOQ CPCBFaquruddin AliNo ratings yet

- SS Schenectady tanker failure causesDocument4 pagesSS Schenectady tanker failure causesguru_terexNo ratings yet

- Method Statement For Fab of Pipework and FittingsDocument13 pagesMethod Statement For Fab of Pipework and FittingsAllan EscobarNo ratings yet

- Installation Guidelines For C&I Laying of Impulse PipeDocument9 pagesInstallation Guidelines For C&I Laying of Impulse PipeCharu ChhabraNo ratings yet

- Plastics Mold Eng Hand 42Document151 pagesPlastics Mold Eng Hand 42eduardo_umNo ratings yet

- Proses Kimpalan 6GDocument41 pagesProses Kimpalan 6Gshahaljawaie87No ratings yet

- Phase Iv Welder Module 1.5Document15 pagesPhase Iv Welder Module 1.5Magdi SiamNo ratings yet

- Hot TapingDocument61 pagesHot TapingMuzaffar100% (1)

- Chap 9-SMAW Beads Fillet WeldsDocument47 pagesChap 9-SMAW Beads Fillet WeldsSally Java SenayoNo ratings yet

- SMAW Welding in 6G PositionDocument41 pagesSMAW Welding in 6G PositionJessel Mejia OnzaNo ratings yet

- SMAW 6G Pipe Welding Guide: Electrodes, Processes, and TipsDocument41 pagesSMAW 6G Pipe Welding Guide: Electrodes, Processes, and TipsRey SombreroNo ratings yet

- Job 15-J51 Welding A Single-V Butt JointDocument8 pagesJob 15-J51 Welding A Single-V Butt JointWilly UioNo ratings yet

- Sheet Metal Ar15 LowerDocument12 pagesSheet Metal Ar15 LowerCharles Keeney100% (4)

- Wema Sending Unit Install PDFDocument1 pageWema Sending Unit Install PDFAndy PriceNo ratings yet

- Tubing and Casing Thread Inspection 2014Document44 pagesTubing and Casing Thread Inspection 2014xmacaba100% (3)

- Methodology of PSC Girder StressingDocument8 pagesMethodology of PSC Girder StressingRavikant TyagiNo ratings yet

- Item 449 Anchor Bolts: 1. DescriptionDocument3 pagesItem 449 Anchor Bolts: 1. DescriptionIbrahim AlrabibNo ratings yet

- ESAB Welder PocketguideDocument32 pagesESAB Welder PocketguidenunosobralNo ratings yet

- Piping Olets: Branching Fittings GuideDocument3 pagesPiping Olets: Branching Fittings Guiderenger20150303100% (1)

- ESABNA-Welders Guide BookDocument32 pagesESABNA-Welders Guide BookCarlos Bermejo Alvarez100% (1)

- Field Welding InstructionsDocument6 pagesField Welding InstructionsErickNo ratings yet

- Mounting Hyport series ceiling supply pendant base rackDocument5 pagesMounting Hyport series ceiling supply pendant base rackgenjunkNo ratings yet

- Welding: IntrdutionDocument10 pagesWelding: IntrdutionJoseph George KonnullyNo ratings yet

- 20ft Steel Pole DatasheetDocument3 pages20ft Steel Pole DatasheetDVTech EngineeringNo ratings yet

- Practicum ISO 9606 GTAW On The Work FloorDocument6 pagesPracticum ISO 9606 GTAW On The Work FloorapNo ratings yet

- Pipe-To-Pipe: Lignment OF IPEDocument2 pagesPipe-To-Pipe: Lignment OF IPEMunir KadernaniNo ratings yet

- Welding TechniquesDocument21 pagesWelding Techniquessharafudheen_sNo ratings yet

- Pipe Welding Guide: Essential Tips & TechniquesDocument8 pagesPipe Welding Guide: Essential Tips & TechniquesviptoneytNo ratings yet

- Nut Bolt Installation PracticesDocument8 pagesNut Bolt Installation PracticesArjun SharmaNo ratings yet

- Fitters Guide 2017 Ver5Document48 pagesFitters Guide 2017 Ver5Bogdan GeorgeNo ratings yet

- Why Use Stop CollarsDocument4 pagesWhy Use Stop Collarsdeivy123No ratings yet

- Specified Anchor Bolt Category Bolt Standards Nut StandardsDocument3 pagesSpecified Anchor Bolt Category Bolt Standards Nut StandardsrefaeNo ratings yet

- AT-502 - AT-504 - OM-5-Repairs 10-12-2019Document3 pagesAT-502 - AT-504 - OM-5-Repairs 10-12-2019Vinicius RodriguesNo ratings yet

- Metal BenderDocument6 pagesMetal Benderbula10100% (1)

- 2C Flanges 9-01Document33 pages2C Flanges 9-01Javier GarcíaNo ratings yet

- CutoffsawDocument4 pagesCutoffsawFrenchwolf420No ratings yet

- O-Ringing The Block or Cylinder HeadDocument3 pagesO-Ringing The Block or Cylinder Headgreg monroeNo ratings yet

- WelderDocument20 pagesWelderadminNo ratings yet

- Stub Onin ConnectionsDocument4 pagesStub Onin ConnectionsMehman NasibovNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Radiography SafetyDocument59 pagesRadiography SafetymeetvandanapatelNo ratings yet

- Earth DirectionDocument1 pageEarth DirectionmeetvandanapatelNo ratings yet

- Latest PDFDocument19 pagesLatest PDFmeetvandanapatelNo ratings yet

- Latest PDFDocument19 pagesLatest PDFmeetvandanapatelNo ratings yet

- Distributed Control Systems (DCS)Document2 pagesDistributed Control Systems (DCS)Syamkumar Sasidharan25% (4)