Professional Documents

Culture Documents

Reinforced Concrete Bridge Deck Design PDF

Uploaded by

Francisco FaggioniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reinforced Concrete Bridge Deck Design PDF

Uploaded by

Francisco FaggioniCopyright:

Available Formats

Reinforced Concrete Bridge Deck Design

http://www.childs-ceng.demon.co.uk/tutorial/exrc.html[29/01/2013 17:06:12]

Reinforced Concrete Deck Design to BS 5400 Part 4

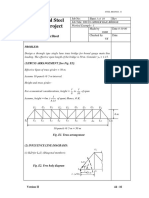

Problem:

Design a simply supported reinforced concrete deck slab using a unit strip method. The deck carries a 100mm depth of

surfacing,

together with a nominal HA live load udl of 17.5 kN/m

2

and knife edge load of 33kN/m . The deck should also be designed to

carry 30 units of HB load. The span of the deck is 12.0m centre to centre of bearings.

?

conc.

= 25kN/m

3

30 units of HB also to be considered.

Use C32/40 concrete to BS 8500.

Use Grade B500B reinforcement to BS 4449.

BS 8500-1

cl. A.2.1

Table A.1

Exposure Class XD1 used for bridge deck soffits.

cl. A.3 Fixing tolerence for reinforcement ?

c

= 15mm for insitu concrete.

Table A.5 Nominal cover for C32/40 concrete = 45 + ?

c

= 60mm with

maximum water-cement ratio = 0.55 and minimum cement content of 320 kg/m

3

Loading per metre width of deck (unit strip)

(Note: The loading has been simplified to demonstrate the method of designing the slab (See BS 5400 Pt2,

or BD 37/01 for full design loading)

Nominal Dead Loads : deck slab = 25 x 0.65 x 1.0 = 16.3 kN/m

surfacing = 24 x 0.1 x 1.0 = 2.4 kN/m

Nominal Live Load : HA = 17.5 x 1.0 + 33.0 = 17.5 kN/m(udl) + 33kN(kel)

30 units HB = 30 x 10 / 4 per

wheel

= 75 kN per wheel

Load factors for serviceability and ultimate limit state from BS 5400 Part 2 (or BD 37/01) Table 1:

SLS ULS

Comb.1 Comb.3 Comb.1 Comb.3

Dead Load ?

fL

concrete 1.0 1.0 1.15 1.15

Superimposed Dead Load ?

fL

surfacing 1.2 1.2 1.75 1.75

Live Load ?

fL

HA 1.2 1.0 1.5 1.25

?

fL

HB 1.1 1.0 1.3 1.1

Temperature Difference ?

fL

- 0.8 -

1.0

#

Key:

#

It is usually assumed that there is local plasticity at the critical sections at Ultimate Limit State and the self

equilibrating stresses due to non linear temperature distribution can be ignored in combination loadings.(Ref:"Concrete bridge

engineering:performance and advances" by R.J.Cope).

Temperature Difference Effects

Apply temperature differences given in BS 5400 Pt2 Fig.9 (Group 4) to a 1m wide deck section.

Cl. 5.4.6 - Coefficient of thermal expansion = 12 x 10

-6

per C.

From BS 5400 Pt4 Table 3 : E

c

= 31 kN/mm

2

for f

cu

= 40N/mm

2

Hence restrained temperature stresses per C = 31 x 10

3

x 12 x 10

-6

= 0.372 N/mm

2

Reinforced Concrete Bridge Deck Design

http://www.childs-ceng.demon.co.uk/tutorial/exrc.html[29/01/2013 17:06:12]

Section Properties

Area = 1000 x 650 = 0.65 x 10

6

mm

2

Second Moment of Area = 1000 x 650

3

/ 12 = 22.9 x 10

9

mm

4

a) Positive temperature difference

Force F to restrain temperature strain :

0.372 x 10

3

x [ 150 x ( 3.0 + 5.05 ) + (195 x 1.5) + (195 x 1.05)] x 10

-3

= 634.2 kN

Moment M about centroid of section to restrain curvature due to temperature strain :

0.372x10

3

x[150x(3.0x250+5.05x275)+175x(0.3x87.5+1.35x116.7)-(20x0.15x6.7)-(195x1.05x260)]x10

-6

= 111.5kNm

b) Reverse temperature difference

Force F to restrain temperature strain :

- 0.372 x 10

3

x [ 130 x ( 1.8 + 2.5 + 1.5 + 1.9 ) + 163 x ( 0.9 + 0.75 )] x 10

-3

= - 472.4 kN

Moment M about centroid of section to restrain curvature due to temperature strain :

- 0.372 x 10

3

x [130 x ( 1.8 x 260 + 2.5 x 282 - 1.5 x 260 - 1.9 x 282 ) + 163 x ( 0.9 x 141 - 0.75 x 141 )] x 10

-6

= -13.34kNm

Note: Sign convention is compressive stresses are positive.

Dead + Superimposed Dead Loading (per metre width of deck)

SLS = Serviceability Limit State

ULS = Ultimate Limit State

Design SLS moment = ?(?

fL

x M) =

[(1.0 x 16.3)+(1.2 x 2.4)] x 12

2

/ 8 = 345 kNm

Design ULS moment = ?

f3

x ?(?

fL

x M) =

1.1 x [{(1.15 x 16.3)+(1.75 x 2.4)} x 12

2

/ 8] = 454 kNm

Live Loading (per metre width of deck)

Nominal HA mid span moment =

17.5 x 12.0

2

/ 8 + 33.0 x 12.0 / 4 = 414kNm

Reinforced Concrete Bridge Deck Design

http://www.childs-ceng.demon.co.uk/tutorial/exrc.html[29/01/2013 17:06:12]

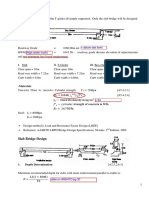

The maximum moment for the HB vehicle occurs at point X in the diagram below with the vehicle positioned as shown.

Nominal HB moment at X = 99.4 x 5.3 - 75 x 1.8 = 392kNm

Combination 1 Loading

Design HA SLS moment = ?

fL

x M = 1.2 x 414 = 497 kNm

Design HB SLS moment = ?

fL

x M = 1.1 x 392 = 431 kNm < 497 kNm ? HA loading critical

Total Design SLS Moment (Dead + Live) = 345 + 497 = 842 kNm

Design HA ULS moment = ?

f3

x ?

fL

x M = 1.1 x 1.5 x 414 = 683 kNm

Design HB ULS moment = ?

f3

x ?

fL

x M = 1.1 x 1.3 x 392 = 561 kNm < 683 kNm ? HA loading critical

Total Design ULS Moment (Dead + Live) = 454 + 683 = 1137 kNm

Combination 3 Loading

Design HA SLS moment = ?

fL

x M = 1.0 x 414 = 414 kNm

Design HB SLS moment = ?

fL

x M = 1.0 x 392 = 392 kNm < 414 kNm ? HA loading critical

Design SLS Moment (Dead + Live) = 345 + 414 = 759 kNm

Design HA ULS moment = ?

f3

x ?

fL

x M = 1.1 x 1.25 x 414 = 569 kNm

Design HB ULS moment = ?

f3

x ?

fL

x M = 1.1 x 1.1 x 392 = 474 kNm < 569 kNm ? HA loading critical

Design ULS Moment (Dead + Live) = 454 + 569 = 1023 kNm

Ultimate Capacity of Deck Slab

Ultimate Design Moment = 1137 kNm

BS 5400 Pt 4

cl. 5.1.2.1

It is usual to design reinforced concrete for the ultimate limit state and check for serviceability

conditions.

cl. 5.4.2 Use clause 5.3.2 for the resistance moments in slabs.

cl. 5.3.2.3 Try 32mm dia. reinforcement at 125mm centres:

Nominal cover to reinforcement in deck soffit = 60mm

d = 650 - 60 -32/2 = 574

A

s

= ?16

2

x 1000 / 125 = 6434mm

2

/m

f

y

= 500N/mm

2

f

cu

= 40N/mm

2

z = [1 - ({1.1f

y

A

s

}/{f

cu

bd})]d

z = [1 - ({1.1 x 500 x 6434}/{40 x 1000 x 574})]d = 0.85d < 0.95 d ? z = 0.85 x 574 = 488mm

M

uSteel

= 0.87f

y

A

s

z = 0.87 x 500 x 6434 x 488 x 10

-6

= 1366 kNm/m

M

uConcrete

= 0.15f

cu

bd

2

= 0.15 x 40 x 1000 x 574

2

x 10

-6

= 1977 kNm/m > 1366

? M

u

= 1366 kNm/m > 1137kNm/m ? OK.

Reinforced Concrete Bridge Deck Design

http://www.childs-ceng.demon.co.uk/tutorial/exrc.html[29/01/2013 17:06:12]

Check Serviceability Limit State

Combination 1 SLS Design Moment = 842 kNm (345DL + 497LL)

Determine depth 'X' to neutral axis of cracked section:

cl. 4.3.2.1

Table 3

Youngs Modulus for concrete for short term loading = E

c

= 31 kN/mm

2

cl. 4.3.2.2

Youngs Modulus for steel reinforcement = E

s

= 200 kN/mm

2

Case 1) When the bridge has just opened (when only a small amount of creep has occurred):

Modular Ratio = E

s

/ E

c

= 200 / 31 = 6.45

Taking first moments of area about the neutral axis:

1000 x X

2

/ 2 = 6.45 x 6434 x (574 - X)

500X

2

+ 41510X - 23.83x10

6

= 0

X = 177 mm

Second Moment of Area of cracked section:

I

xx

= 1000x177

3

/ 3 + 6.45x6434x(574-177)

2

= 8.39x10

9

mm

4

Cl 4.1.1.3

Max compressive stress in concrete = 842x10

6

x 177 / 8.39x10

9

= 17.8 N/mm

2

Table 2

Allowable compressive stress = 0.5f

cu

= 20 N/mm

2

> 17.8 ? OK

Case 2) When creep and shrinkage in the bridge are substantially complete:

cl. 4.3.2.1(b)

Youngs Modulus for concrete for long term loading = E

c

/2 = 15.5 kN/mm

2

Hence Modified E

c

for (345DL + 497LL) = (345 x 15.5 + 497 x 31) / 842 = 24.65 kN/mm

2

cl. 4.3.2.2

Youngs Modulus for steel reinforcement = E

s

= 200 kN/mm

2

Modular Ratio = E

s

/ E

c

= 200 / 24.65 = 8.1

Taking first moments of area about the neutral axis:

1000 x X

2

/ 2 = 8.1 x 6434 x (574 - X)

500X

2

+ 52115X - 30x10

6

= 0

X = 198 mm

Second Moment of Area of cracked section:

I

xx

= 1000x198

3

/ 3 + 8.1x6434x(574-198)

2

= 9.96x10

9

mm

4

Cl 4.1.1.3

Max compressive stress in concrete = 842x10

6

x 198 / 9.96x10

9

= 16.7 N/mm

2

Table 2

Allowable compressive stress = 0.5f

cu

= 20 N/mm

2

> 16.7 ? OK

Tensile stress in reinforcement = 842x10

6

x (574 - 198) x 8.1 / 9.96x10

9

= 257.5 N/mm

2

Table 2

Allowable tensile stress = 0.75f

y

= 375 N/mm

2

> 257.5 ? OK

Crack Control:

Strain in reinforcement = ?

1

= 257.5 / 200000 = 0.00129

Table 13 Notional surface for crack calculation = 35mm cover to reinforcement

5.8.8.2

a

cr

= v[(125/2)

2

+ (16+35)

2

] - 16 = 65

Allow for stiffening effect of concrete:

eqn 25

?

m

= ?

1

- [{3.8b

t

h(a'-d

c

)} / {?

s

A

s

(h-d

c

)}] x [(1-M

q

/M

g

)x10

-9

]

?

m

= ?

1

- [{3.8x1000x650x(625 - 198)} / {0.00129x6434x(650 - 198)}] x [(1 - 497/345)x10

-9

]

?

m

= ?

1

- [-0.00012] but not greater than ?

1

Hence no stiffening effect

?

m

= ?

1

= 0.00129 x (625 - 198) / (574 - 198) = 0.00146

Design crack width = 3 x 65 x 0.00146 / [1 + 2 x (65 - 35) / (650 - 198)] = 0.25 mm

eqn 24 Design crack width = 3a

cr

?

m

/ [1+2(a

cr

-c

nom

)/(h-d

c

)]

Table 1 Maximum allowable crack width = 0.25 mm ? OK

Combination 3 SLS Design Moment = 759 kNm (345DL + 414LL)

Reinforced Concrete Bridge Deck Design

http://www.childs-ceng.demon.co.uk/tutorial/exrc.html[29/01/2013 17:06:12]

Determine depth 'X' to neutral axis of cracked section:

cl. 4.3.2.1

Table 3

Youngs Modulus for concrete for short term loading = E

c

= 31 kN/mm

2

cl. 4.3.2.1(b)

Youngs Modulus for concrete for long term loading = E

c

/2 = 15.5 kN/mm

2

Hence Modified E

c

for (345DL + 414LL) = (345 x 15.5 + 414 x 31) / 759 = 23.95 kN/mm

2

cl. 4.3.2.2

Youngs Modulus for steel reinforcement = E

s

= 200 kN/mm

2

Modular Ratio = E

s

/ E

c

= 200 / 23.95 = 8.35

Taking first moments of area about the neutral axis:

1000 x X

2

/ 2 = 8.35 x 6434 x (574 - X)

500X

2

+ 53724X - 30.84x10

6

X = 200 mm

Second Moment of Area of cracked section:

I

xx

= 1000x200

3

/ 3 + 8.35x6434x(574-200)

2

= 10.18x10

9

mm

4

>

Cl 4.1.1.3

Max compressive bending stress in concrete = 759x10

6

x 200 / 10.18x10

9

= 14.9 N/mm

2

Max compressive stress due to positive temperature difference = ?

fL

x 2.31 = 0.8 x 2.31 = 1.8 N/mm

2

Total compressive stress in concrete = 14.9 + 1.8 = 16.7 N/mm

2

Table 2

Allowable compressive stress = 0.5f

cu

= 20 N/mm

2

> 16.7 ? OK

Tensile stress in reinforcement = 759x10

6

x (574 - 200) x 8.35 / 10.18x10

9

= 232.8 N/mm

2

Tensile stress due to reverse temperature difference =

?

fL

x 8.35x[{(1.43+0.06)x(130-60-16)/130}-0.06] = 0.8 x 4.7 = 3.8 N/mm

2

Total tensile stress in reinforcement = 232.8 + 3.8 = 237 N/mm

2

Table 2

Allowable tensile stress = 0.75f

y

= 375 N/mm

2

> 237 ? OK

Hence B32 bars at 125 centres are adequate for the mid span.

Shear Design

Shear is designed for ultimate limit state.

cl. 5.4.4 V = shear force due to ultimate loads.

Maximum Dead Load V = ?

f3

x 12 x (1.15 x 16.3 + 1.75 x 2.4) / 2

Maximum Dead Load V = 1.1 x 137.7 kN = 151 kN

Determine shear effects at distance d away from the

support. Try 32mm dia. bars at 125 c/c : d = 574mm

Maximum HA V = ?

f3

x 1.5 x (12 x 17.5 / 2 + 33 x 11.426 / 12 - 17.5 x 0.574)

Maximum HA V = 1.1 x 190 kN = 209 kN

Maximum HB V = ?

f3

x 1.3 x 75 x (11.426 + 9.626 + 3.626 + 1.826) / 12

Maximum HB V = 1.1 x 215 kN = 237 kN > 209 ? HB loading critical

Maximum V = 151 + 237 = 388 kN

Shear stress = V / bd = 388x10

3

/ (1000 x 574) = 0.68 N/mm

2

Design for no shear reinforcement condition then ?

s

v

c

> 0.68 N/mm

2

Table 9

?

s

= (500/d)

1/4

= (500/574)

1/4

= 0.97

Table 8

v

c

= 0.27/?

m

(100A

s

/b

w

d)

1/3

(f

cu

)

1/3

v

c

= (0.27 / 1.25) x [100 x 6434 / (1000 x 574)]

1/3

x (40)

1/3

= 0.77 N/mm

2

?

s

vv = 0.97 x 0.77 = 0.75 N/mm

2

> 0.68 ? OK

cl 5.3.3.1 Check that the maximum allowable shear stress is not exceeded:

Maximum allowable shear stress = 0.75vf

cu

or 4.75 N/mm

2

0.75vf

cu

= 0.75v40 = 4.74 > 0.68 ? OK

Hence B32 bars at 125 centres are adequate for shear at the ends of the deck.

Note: Intermediate sections between mid span and the ends of the deck will have a smaller moment than at

mid span and a small shear than at the ends of the deck. These sections need to be checked to determine

Reinforced Concrete Bridge Deck Design

http://www.childs-ceng.demon.co.uk/tutorial/exrc.html[29/01/2013 17:06:12]

where the reinforcement may be reduced to B25 at 125c/c.

cl. 5.8.4.1

Minimum area of reinforcement = 0.15% of b

a

d = 0.15 x 1000 x 574 / 100 = 861 mm

2

/m ? use B12 bars at

125 centres (A

s

= 905 mm

2

/m) for distribution reinforcement.

You might also like

- Bridge Design - Reinforced Concrete Bridge Deck Design To BS 5400Document11 pagesBridge Design - Reinforced Concrete Bridge Deck Design To BS 5400Lavanyan Satchithananthan100% (1)

- Bridge Design - Precast Concrete Bridge Beam Design To BS 5400Document16 pagesBridge Design - Precast Concrete Bridge Beam Design To BS 5400Lavanyan Satchithananthan100% (2)

- Box Girder Bridge DesignDocument7 pagesBox Girder Bridge DesignSharath ChandraNo ratings yet

- Analysis and Comparative Study of Composite Bridge GirdersDocument11 pagesAnalysis and Comparative Study of Composite Bridge GirdersIAEME PublicationNo ratings yet

- Design of 11m RC Slab BridgeDocument11 pagesDesign of 11m RC Slab Bridgeeph100% (1)

- Abutment Design Example To BD 30Document16 pagesAbutment Design Example To BD 30Muzammil Moosafeer100% (1)

- M54 Unit 10 Skew Deck & Intergral BridgesDocument25 pagesM54 Unit 10 Skew Deck & Intergral BridgesPhilip YapNo ratings yet

- Bridge Design Using STAADDocument46 pagesBridge Design Using STAADfermonmir50% (2)

- 1.6 Design Example-Simple Span Precast-Pretensioned I-Girder BridgeDocument32 pages1.6 Design Example-Simple Span Precast-Pretensioned I-Girder BridgeglaydelleNo ratings yet

- Integral Bridge DesignDocument58 pagesIntegral Bridge Designemmanuel100% (3)

- Specification For LoadsDocument67 pagesSpecification For LoadsNoorhazlinda100% (3)

- Final-Presentattion-JEP Midas PDFDocument34 pagesFinal-Presentattion-JEP Midas PDFRaymart Bulagsac100% (1)

- Box Culvert Structural Design Report TemplateDocument10 pagesBox Culvert Structural Design Report Templaterhon100% (1)

- Bridge Deck DesignDocument32 pagesBridge Deck DesignChukwuma Ogbonna100% (2)

- Design of AbutmentsDocument70 pagesDesign of Abutmentsnour6495% (20)

- LRFD Design Example Precast Balanced Cantilever Bridge DesigDocument43 pagesLRFD Design Example Precast Balanced Cantilever Bridge DesigAnonymous HrZXzhBNo ratings yet

- Truss DesignDocument10 pagesTruss DesignselvakumarNo ratings yet

- Paper - Integral BridgesDocument10 pagesPaper - Integral BridgesviralisursNo ratings yet

- Concrete Bridge Design GuideDocument11 pagesConcrete Bridge Design GuideJared MakoriNo ratings yet

- Detail Design of Bridge Abutment 1Document4 pagesDetail Design of Bridge Abutment 1mohammad azimNo ratings yet

- Concrete Bridge Design To BS 5400 L A Clark 1981 PDFDocument96 pagesConcrete Bridge Design To BS 5400 L A Clark 1981 PDFkhx2No ratings yet

- 25m Single Lane Bridge Design Calculations Latest PDFDocument16 pages25m Single Lane Bridge Design Calculations Latest PDFshafiullahNo ratings yet

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- The Design of Integral BridgesDocument27 pagesThe Design of Integral BridgesBridgy mcbridgeNo ratings yet

- Redesign of Pedestrian Bridge at Kaneshie Market, Accra-GhanaDocument97 pagesRedesign of Pedestrian Bridge at Kaneshie Market, Accra-GhanaGagbe semanu kwameNo ratings yet

- Eurocodes for steel bridge designDocument118 pagesEurocodes for steel bridge designwearplayNo ratings yet

- Bridge Design Guide - Types, Components & Load CalculationsDocument27 pagesBridge Design Guide - Types, Components & Load CalculationsGagan ShrivastavaNo ratings yet

- Bridge Deck Behaviour, Second EditionDocument17 pagesBridge Deck Behaviour, Second EditionChrisYapNo ratings yet

- 03.12 - General Design - Design of Integral BridgesDocument15 pages03.12 - General Design - Design of Integral BridgesOscar Mendoza100% (1)

- BS ABUTMENT DESIGNDocument17 pagesBS ABUTMENT DESIGNEng Venance Masanja100% (1)

- RC Slab Bridge DecksDocument24 pagesRC Slab Bridge DecksKeyur Patel100% (1)

- Bridge Substructure Analysis & DesignDocument193 pagesBridge Substructure Analysis & Designamit457392% (12)

- Design Considerations for BridgesDocument64 pagesDesign Considerations for BridgesSukhwinder Singh Gill89% (9)

- Loads and Load Combination-Bridge Design PDFDocument50 pagesLoads and Load Combination-Bridge Design PDFrenishkavukatt100% (3)

- PSC Design Sample Reinforcement DefinitionDocument3 pagesPSC Design Sample Reinforcement DefinitionNabeel Ahmad100% (1)

- Integral Bridge DesignDocument24 pagesIntegral Bridge DesignMaitrabarun Karjee100% (2)

- Pier Column Design PDFDocument6 pagesPier Column Design PDFJaycee Bareng PagadorNo ratings yet

- Recent Integral BridgesDocument54 pagesRecent Integral Bridgeskunjal_radiaNo ratings yet

- Bridge AnalysisDocument16 pagesBridge AnalysisNuelboborNo ratings yet

- Design of Reinforced Slab & Deck Girder Bridge-AASHTODocument39 pagesDesign of Reinforced Slab & Deck Girder Bridge-AASHTOWaqas AnjumNo ratings yet

- Pile Cap Design at AbutmentDocument4 pagesPile Cap Design at AbutmentAzwani Abdullah100% (1)

- Grillage Analysis SampleDocument6 pagesGrillage Analysis SamplerenandNo ratings yet

- Other - LECTURE 2d BRIDGE LOADINGDocument62 pagesOther - LECTURE 2d BRIDGE LOADINGAmalina Ng100% (1)

- Chapter 3-0Document45 pagesChapter 3-0chaltu TerefeNo ratings yet

- Structural Design of RCC BridgeDocument101 pagesStructural Design of RCC BridgeShambhu Sah92% (48)

- Skew Bridges Calculation MethodsDocument9 pagesSkew Bridges Calculation MethodsIsidro P. BuquironNo ratings yet

- Strut and Tie ModelDocument3 pagesStrut and Tie ModelBenard OmondiNo ratings yet

- Temperature Distribution in Concrete Bridge EC HamblyDocument6 pagesTemperature Distribution in Concrete Bridge EC Hamblygks6043No ratings yet

- Action On Bridges: BS EN 1991-2: Traffic Loads On Bridges (EC 1, Part 2)Document24 pagesAction On Bridges: BS EN 1991-2: Traffic Loads On Bridges (EC 1, Part 2)Jan GnatNo ratings yet

- Integral Bridges Skew EffectsDocument32 pagesIntegral Bridges Skew EffectsSuryaNo ratings yet

- Why Midas Civil (Small)Document47 pagesWhy Midas Civil (Small)Kapil Dev BansalNo ratings yet

- PSC Girder Design For ContinuityDocument7 pagesPSC Girder Design For ContinuitypajipitarNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Bridge Deck DesignDocument11 pagesReinforced Concrete Bridge Deck DesignAhmad AlamNo ratings yet

- DeckDocument9 pagesDeckSamuel AntobamNo ratings yet

- Dead Lod Brige DesignDocument6 pagesDead Lod Brige DesigntizazuNo ratings yet

- PSC Bridge Girder Design To BS5400 by D ChildsDocument321 pagesPSC Bridge Girder Design To BS5400 by D ChildsDuke50% (2)

- Comparative Analysis of Tubular and RC StructuresDocument47 pagesComparative Analysis of Tubular and RC StructuresVinod MJNo ratings yet

- Management For Construction Materials and Control of CONSTRUCTION WASTEDocument6 pagesManagement For Construction Materials and Control of CONSTRUCTION WASTEMohamed WayrahNo ratings yet

- MG University BTech Course RegulationsDocument14 pagesMG University BTech Course RegulationsJaibharath AdmnNo ratings yet

- S3300ap-Brochure Ascensor PDFDocument20 pagesS3300ap-Brochure Ascensor PDFStephanie García100% (1)

- Heriot Watt UniversityDocument2 pagesHeriot Watt UniversityMaryanne TanaNo ratings yet

- MphasisJD - T2 - 2020F PDFDocument1 pageMphasisJD - T2 - 2020F PDFDeepthi DeepuNo ratings yet

- Research Papers On Automotive EngineeringDocument4 pagesResearch Papers On Automotive Engineeringnodahydomut2100% (1)

- Jurnal Internasional Penahan Dinding TanahDocument12 pagesJurnal Internasional Penahan Dinding TanahYansen Ejha DeconantaNo ratings yet

- LICODocument16 pagesLICOAmrNo ratings yet

- NASA welding standard for aerospace metalsDocument33 pagesNASA welding standard for aerospace metalstoadstooll100% (1)

- OOSE Unitwise QuestionsDocument11 pagesOOSE Unitwise QuestionsJayaramsai Panchakarla100% (1)

- Corrugated Steel Manhole Assemblies: Standard Specification ForDocument8 pagesCorrugated Steel Manhole Assemblies: Standard Specification ForGilvan SilvaNo ratings yet

- Cr-Mo API 934Document13 pagesCr-Mo API 934Daniel Jimenez Merayo100% (1)

- International Practices For Connecting One Pass Precast Segmental Tunnel LiningsDocument7 pagesInternational Practices For Connecting One Pass Precast Segmental Tunnel LiningsMehdi BakhshiNo ratings yet

- An Introduction to Software Testing Techniques and VisualizationDocument2 pagesAn Introduction to Software Testing Techniques and VisualizationSaraswathy KNo ratings yet

- 07-Division 2-Section 02206 VC Pipelines-Version 2.0Document9 pages07-Division 2-Section 02206 VC Pipelines-Version 2.0Avaan IvaanNo ratings yet

- Repair of Pile Cap Foundations Using Strut and Tie ModelsDocument8 pagesRepair of Pile Cap Foundations Using Strut and Tie ModelsMyat NoeNo ratings yet

- Technical Information Date: 02/2011Document12 pagesTechnical Information Date: 02/2011Satya0% (1)

- Mechanical Engineering BookDocument2 pagesMechanical Engineering BookvikasmaeNo ratings yet

- Check List For FiCheck List For Fire Protection Planre Protection PlanDocument4 pagesCheck List For FiCheck List For Fire Protection Planre Protection Planismail_gdiNo ratings yet

- Math156 Ie Feb 2019Document7 pagesMath156 Ie Feb 2019Josef CatiggayNo ratings yet

- Mix Design With Superplasticizers: by Er. Kaushal Kishore, Materials Engineer, RoorkeeDocument12 pagesMix Design With Superplasticizers: by Er. Kaushal Kishore, Materials Engineer, RoorkeeSantoshNo ratings yet

- Jis G3458 PDFDocument14 pagesJis G3458 PDFhbookNo ratings yet

- Hardy Cross - Moment DistributionDocument8 pagesHardy Cross - Moment Distributionlakshmi1011No ratings yet

- 02 - Lean Project Selection & Implementation Flow ChartDocument2 pages02 - Lean Project Selection & Implementation Flow ChartYo GoldNo ratings yet

- 9013 Commercial Pressure Switches Type G: 9013 PumptrolDocument32 pages9013 Commercial Pressure Switches Type G: 9013 Pumptrolingreyes7No ratings yet

- Lizmontagens Group ProfileDocument5 pagesLizmontagens Group ProfileRui Carlos Delgado Lopes AlvesNo ratings yet

- Sample Final Intern ReportDocument56 pagesSample Final Intern ReportBirhan SeteNo ratings yet

- C1361 PDFDocument5 pagesC1361 PDFLucas CamposNo ratings yet

- Yesterday, Today and Future of The Engineering Management Body of KnowledgeDocument4 pagesYesterday, Today and Future of The Engineering Management Body of KnowledgeAtish KissoonNo ratings yet