Professional Documents

Culture Documents

TKF00MEMST0007Rev 2MethodstatementofFlushingandHydrotestingforStationPiping

Uploaded by

hasan_676489616Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TKF00MEMST0007Rev 2MethodstatementofFlushingandHydrotestingforStationPiping

Uploaded by

hasan_676489616Copyright:

Available Formats

2 31-12-2012 REVISED AND RE-ISSUED FOR IMPLEMENTATION M.Kara A. Yildirim M.

Kopuz

1 27-08-2012

REVISED AS PER J ESA-TKF-DCS-1605

RE-ISSUED FOR IMPLEMENTATION

M.Kara A. Yildirim M.Kopuz

0 15-08-2012

REVISED AS PER J ESA-TKF-DCS-1548 AND RE-

ISSUED FOR IMPLEMENTATION

M.Kara A. Yildirim M.Kopuz

A 30-06-2012 ISSUED FOR REVIEW M.Kara A. Yildirim M.Kopuz

Rev.

No.

Date Description

Prepared Checked Reviewed

ORIGINATOR TEKFEN

Groupe OCP S.A.

Casablanca, 2, rue Al Abtal, Hay Erraha,

Morocco

KHOURIBGA JORF LASFAR

PHOSPHATE SLURRY PIPELINE SYSTEM

EPC CONTRACTOR

Document Title

METHOD STATEMENT OF FLUSHING AND

HYDROTESTING FOR STATION PIPING

SUBCONTRACTOR

Document No.

Rev. No. Total pages

Org. Code Area Code Disc. Code Doc. Type Seq. No.

TKF 00 ME MST 0007 2 41

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 2 of 31

TABLE OF CONTENTS

1.0 Purpose

2.0 Scope

3.0 General Requirement of pressure test of pipework

4.0 Definitions

5.0 Reference Documents

6.0 Codes and Standards

7.0 Organization

8.0 Responsibilities

9.0 Determination of Test Fluid

10.0 Determination of Test pressure

10.1 Flushing

10.2 Execution Conditions

11.0 Execution of Hydrostatic Test Pipework

12.0 Acceptance of Pressure Test for Pipework

13.0 Safety in Pressure Testing & Flushing for Pipework

14.0 Pressure Test activity flow chart

15.0 Hazard effect and management plan for flushing and hydrotesting

16.0 Emergency Response Plan

17.0 Attachments

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 3 of 31

1.0 PURPOSE

The purpose of this method statement is to ensure that all activities related to flushing and

hydrotesting are carried out in a controlled manner in accordance with Project specifications.

2.0 SCOPE

This method statement covers the detailed requirements for pressure testing and flushing of

fabricated spools and piping system at the Pump station under the OCP Khouribga-J orf Lasfar

Phosphate Slurry Pipeline project.

3.0 GENERAL REQUIREMENT OF PRESSURE TEST FOR PIPEWORK

3.1 General

3.1.1 All work shall be performed in compliance with the HSE Plan for OCP slurry pipeline project

TKF-00-HS-PLN-0010 Hazards and Effect Management Plan.

3.1.2 Contractor shall, submit a copy of each test package and attachments for Company review and

approval 7 days in advance of subject test. Test package prior to testing shall contain below

listed items as minimum :

Scope of work (site specific )

Details of the piping pressure test sections.

Schematic drawing of test sections.

Drawing of test equipment arrangement and connections, which include component

material and pressure rating.

Drawing of test header.

Hydrostatic pressure diagram for test section.

Water analysis.

List of lines in the package, test media and test pressures

Marked up P& IDs showing limits of testing

Test Piping Isometrics

Welding, heat treatment and NDE clearance

Cleaning and Flushing certificate

Safety requirement (site specific).

List of test team personal with responsible

3.1.3 Piping systems which are open to atmosphere (such as drains, vents, outlets of safety valves,

perforated pipes etc.) and not subjected to internal pressure during operation, shall not be

pressure tested, but cleaned and flushed using water or compressed air.

3.1.4 Packaged units such as hydraulic pump sets, compressors, generators and diesel drives etc.

shall be isolated and by-passed if necessary.

3.1.5 Pressure gauges used to indicate and record test pressure . The gauges shall be calibrated

prior to use and thereafter at a frequency of every 10 tests and witnessed by Company when

requested .

3.1.6 The ambient temperature of the pipework shall be recorded continuously and the record shall

be included in the test packages.

2

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 4 of 31

3.1.7 If defect is found, it shall be repaired in accordance with the Approved method statement for

Station piping Fabrication and Installation TKF-00-ME-0001 and re-testing shall be carried out in

accordance with this method statement.

3.1.8 The overall pressure testing philosophy shall be based as far as possible on the testing of

complete systems including valves, vessels, and in-line instruments with the same design and

consequently the same test pressure.

3.1.9 A leak test shall be performed following reinstatement to prove a sub-system or system and / or

untested joints. The leak test will be carried out at 95 % of the stage relief valve setting or the

maximum dead head pressure of any pump in the system not protected by a relief valve

3.1.10 There are two types of performing strength test related to the media that is used to obtain

pressure:

Hydrostatic Test

Pneumatic Test

4.0 DEFINITIONS

Definitions of the terms and Legend for the abbreviations used in this document and its

Employer, Company, Client : Groupe OCP S.A

Engineer, PMT,Consultant : J acobs Engineering S.A. (Owners Engineer)

Contract : The main contract between the Owner and the Contractor.

Contractor, Buyer : Tekfen Construction and Installation Co. Inc., acting as

main EPC contractor to owner for execution of the Project.

Works, Facilities : All the system, equipment, material, provided by the Contractor

in connection with the design, engineering, construction and/or

installation of the Project

Drawing : Related drawings approved by the Company for Construction.

Approved : The revision of the related Contractors document such as

procedure, plan, drawing etc. which was approved by the

Company.

Minimum Test Pressure : The lowest allowable test pressure gage reading. (The calculated

test pressure plus the additional pressure resulting from the static

head of the test fluid).

Maximum Test Pressure : The highest allowable test pressure gage reading. (The pressure

test rating of the weakest component in the test system).

Piping : An assembly of piping components being tested at one time using a

single test method statement.

Test Temperature : The minimum temperature occurring during the test period of

either the metal temperature of the piping being tested (including

any vessels or equipment included in the test) or the test fluid

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 5 of 31

temperature.

System Test : A test that includes multiple sections of piping, having the same or

different design pressures, but which are tested together at one

time using a single test method statement and pressure.

5.0 REFERENCE DOCUMENTS

Following parts and clauses of the contract documents are referred.

1593-S-M-046 Technical Specification for Station Piping Materials

1593-S-M-051 Technical Specification for Station Piping Works

1593-S-P-011 Technical Specification for hydrostatic testing of cross-country

pipelines.

1593-S-P-017 Technical Specification for Non Destructive Examination of Field Welds

1593-S-P-020 Technical specification for Welding and Qualification Procedures

PAC-00-PP-SPE-0005 Technical Specifications for Station Piping and Valves.

PAC-00-PP-SPE-0007 Technical Specification for Rubber Lining of Pipes and

Pipe Fitting

PAC-00-PP-SPE-0008 Technical Specification for Polyurethane Lining

PAC-00-PP-SPE-0009 Technical Specification for Fabrication of Pipe Spools

PAC-00-PP-DAT-0300 Station Piping Class Data Sheet Pack.

TKF-00-QA-PLN-0001 Project Quality Plan

TKF-00-QA-PLN-0002 Inspection and Test Plan

TKF-00-QA-PLN-010 Corrective and Preventive Action Procedure

TKF-00-HS-PLN-0001 HSE Execution Plan

TKF-00-HS-PLN-0003 Personnel Transportation Management Plan

TKF-00-HS-PLN-0009 The Equipment and Materials Transportation

Management Plan

TKF-00-GE-PRO-0002 General Welding Procedure

TKF-00-GE-PRO-0003 NDT Works Procedure

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 6 of 31

6.0 CODES and STANDARTS

All work shall be performed in accordance with the requirements of the latest editions

of all applicable codes, rules and regulations.

API 5L Specification for Line Pipe.

API 1104 Welding of Pipelines and Related Facilities

ASME B 31.11 Slurry Transportation Piping Systems

ASTM American Society for Testing Materials

ISO International Organization For Standardization

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 7 of 31

7.0 ORGANIZATION

CONSTRUCTION

MANAGER

ENGINEERING

DEPARTMENT

QC

DEPARTMENT

SITE

ENGINEER

TEST

ENGINEER

TESTING

TEAM

TEST PACK

COORDINATOR

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 8 of 31

8.0 RESPONSIBILITIES

8.1 Construction Manager

Under the guidance of Construction Manager the Site Engineer / HSE Engineer and

Hydrotest Engineer shall be responsible for the implementation of the procedure within

the OCP slurry pipeline Project.

Under the guidance of Construction Manager the Site Engineer / Hydro test Engineer

shall be responsible for the management of all pressure testing on the work site of the

Project

Engineering Department

Engineering Department shall prepare a comprehensive Test Pack showing the test limits

(In P&ID, isometric and GA Drawing), test media, test pressure, operating pressure,

concessions and deviation approvals and the relevant forms.

8.2 Engineering Department

Engineering Department shall prepare a comprehensive Test Pack showing the test limits

(In P&ID, isometric and GA Drawing), test media, test pressure, operating pressure,

concessions and deviation approvals and the relevant forms.

8.3 Site Engineer

Site Engineer shall be responsible for the Test Pack punch list clearance for the pressure

test.

8.4 QC Department

QC Department shall be responsible for verification of punch list item clearance,

correctness of the Test Pack document, the test coverage of the documented test circuit

with respect to P&ID , As Built Drawings / Mark up Drawings and GA Drawings,

Witnessing the test and preparation of documentation.

8.6 Hydro-Test Engineer

Hydro-test Engineer shall be responsible to organize the test, after Quality Control

clearance of the Test Pack for the test .Hydro test Engineer or designated Test Pack

coordinator is responsible for the flow of Test Pack. Over all responsibility of conducting

the test, in a safe manner, lies with the Hydro test Engineer.

Before Start up hydrotest activities , SPA have to prepare in three Languages

(Turkish, Arabic and English) and all hydrotesting team shall be trained by Hydrotest Engineer

about the risk related these activities.

These Method Statement shall be dispatched by Hydrotest Engineer to all people

concerned about the method statement

8.7 HSE Engineer

HSE Engineer shall be responsible to ensure that the correct safety precautions detailed

in this method statement are implemented by the pressure testing team.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 9 of 31

9.0 Determination of Test Fluid

9.0.1Test fluid shall be in accordance with Company Specification for Hydrostatic Testing

Doc. No.: 1593-S-P-011

9.0.1 Following tests may be applied in lieu of the hydrostatic strength test subject to

Companys approval.

9.0.2 Pneumatic strength test instead of hydraulic test will be applied for conditions below.

a. For testing linings or internal coating of Station Piping.

b. Where hydrostatic test would contaminate a process which would be hazardous,

corrosive, or inoperative in the presence of moisture,

c. Where it is difficult to obtain water having a Cl (chloride ion) content within the

specified limits for pipes made of austenitic stainless steel,

d. Where piping system is not designed to carry full water load and it is difficult to

support the weight of water with additional temporary support.

9.1 Line Punching and Test Pack Processing Prior Pressure Test

9.1.1 According to the project schedule, Engineering Dept shall prepare the Test pack and

transmit to the Test pack coordinator. TP Coordinator shall transmit the TP to

construction Manager to confirm that the piping system in the concerned TP is ready for

test. No punch items are balance.

Punch Item Code

A Item -Items if not completed, shall not proceed with pressure test on the grounds of

safety to the system or personnel and/or incomplete test parameters.

B Item -items if not completed, can proceed for pressure test, but shall not

proceed for commissioning.

C -Item which are to be completed in a timely manner before commissioning.

Where A items are activities which can affect the performance/integrity of the system

during hydrostatic / pneumatic / leakage testing namely hot work on the pressure contain

proper supports to the pipe etc. The above activities shall be completed before testing. QC

Manager shall have the final authority to decide the punch item code.

If no A item pending in the Test Pack received by the site engineer, he may transmit the

TP to TP Coordinator for further processing after completing his part in the document. TP is

then transmitted to QC Dept. for punching . The assigned QC Inspector shall punch the line

and verify NDT completion and documentation, attach weld control sheet. If any A item

balance, TP goes back to Construction Manager through TP Coordinator and returns

through the same channel after A item clearance. After clearance from QC Dept, TP is

transmitted to Company inspector for verification. Once the TP is cleared by Company

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 10 of 31

inspector and returned to TP Coordinator, it is transmitted to the Hydro-test Engineer for

performance of the test.

Once the test pack received at the test centre, testing team shall check that all the sensitive

instruments are isolated; valves in the test circuits isolated/opened (As the case may be)

test limits are bolted properly, expansion bellows removed or secured and pre -test

checklist signed off , correct test medium available, test area barricaded and KEEP

AWAY sign boards ready. Issue Inspection request to the concerned QC personnel for test

witnessing according to relevant ITP, well in advance to the test, but at any case not less

than twenty four hour before the commencement of the test.

9.2 Equipment / Instruments / Tools

The following equipments, instruments and tools shall be available for performing the

pressure test. All test equipment must be rated at an equal or greater working pressure

than the test requirements.

9.2.1 Pressurizing Pump .Two type pressure test pump will be used

a-Hand operated test pump :Test pressure 2-200 bar

b-Electric or petrol engine driven test pump : 2-200 bar

9.2.2 Air Compressor(if necessary)

9.2.3 Pre tested Testing manifold complete with isolation valve, PSV, hose etc

9.2.4 Two nos. of pressure gauges with current calibration status and serial number.

9.2.5 Filling pumps -With Sufficient capacity and suitability

9.2.6 Calibrated torque Wrench

9.2.7 Thermometer

9.2.8 Test Gaskets, Spades, Blanks and other fittings to conduct the test.

9.2.9 Pipe Cleaning Prior to Test

Piping system to be tested shall be cleaned before hydrostatic/pneumatic/leakage testing of

piping.

Pipe cleaning shall be done with compressed air before erecting the pipe spools and also

before pressure testing.

For piping spools DN20 and above ,pipe cleaning shall be documented with a pipe cleaning

report to ensure that the pipe was cleaned and erected.

Test water will be stored at the sufficient volume mobile tank for feeding test pump or will be

flushed line .Second sufficient volume mobile tank will be used for discharge of tested or

flushed line water.

9.2.10 General Requirements

One pressure gauge shall be on the lowest point (On manifold) and the other on the highest

point of the test circuit.

2

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 11 of 31

Vents shall be provided at high points of loops to be tested. Consideration shall be given

to the position of the entire test circuit geometric configuration while providing venting

arrangement to ensure entrapped air is vented out fully.

Piping sub-assemblies may be tested either separately or assembled.

All joints, including welded and bonded, are to be left unpainted and exposed for

examination during testing.

Piping shall be provided with necessary supports in order to support the weight of

test medium

If a pressure test is to be maintained for period of time in extreme temperature variation

and the test fluid is subject to thermal expansion, precautions shall be taken to avoid

excessive pressure built up due to this climatic factor. Temperature of test medium shall

not go below 5 degree centigrade.

Where ever permanent gaskets and bolts are provided, material correctness shall be

cross checked and proper tightness to be reconfirmed by QC Inspector as a Key

Performance area

10.0 Determination of Test Pressure

10.0.1 The hydrostatic and pneumatic test pressures shall be as indicated on the line list

(PAC-00-ME-DAT-0002) and shall be based on the requirements of ASME 31.11,

ASME B31.1, ASME B31.4 and ASME B31.8 as appropriate for piping and piping

systems. Systems, which are, open to atmosphere and not subjected to internal

pressure during operation, shall not be pressure tested, but cleaned and flushed using

water or compressed air.

10.1 Flushing

10.1.1 General

10.1.1.1 Flushing shall be performed prior to hydro test.

10.1.1.2 Package units that have been flushed and tested and sealed at the

manufacturers shall not be flushed again unless specified otherwise.

10.1.1.3 Instrument measurement devices shall not be installed until flushing and

hydrostatic testing is completed.

10.1.1.4 Ball valves shall be in fully open position during flushing .

10.1.1.5 Lines which do not require flushing but shall be blown down with either air or

nitrogen to ensure that lines are not blocked or restricted.

10.1.1.6 Main headers shall be flushed out first and then all the branches, which connect

to any equipment. All necessary precautions shall be taken to ensure that

debris is not flushed into associated equipment or dead ends. Flushing will be

done by discharging hydrostatic test fluid or air.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 12 of 31

10.1.1.7 Flushing through mechanical equipment (i.e. vessels, pumps, exchangers and

skid units) shall not be permitted. However, testing may be undertaken when

considered practical.

10.2 Execution conditions

10.2.1.1 For the flushing, Contractor shall provide all necessary pumping units, any

vessel, tanks or reservoirs, filters and strainers to the site in required quantities.

10.2.1.2 The medium used for flushing shall be the same as that required for the

pressure test.

10.2.1.3 Where the flushing medium is water the flow velocities should be 11/2 to 2

times the normal operating velocity or 3 to 4 m/sec whichever is the greater.

Where flushing velocities cannot be attained the piping shall be high-pressure

jet cleaned.

10.2.1.4 Where the flushing medium is air or steam, the flow velocity should not be less

than 20 m/sec.

10.2.1.5 Circulation of the flushing media shall continue until the piping system has been

free from slags, dirts any other foreign materials. Company supervisors shall

witness the process and check cleanness of flushing water visually at any time

they require.

10.2.1.6 Flushing through mechanical equipment ( i.e vessels, pumps, exchangers, and

skid units) shall not be permitted. However flushing into tanks and vessels may

be allowed at the discretion of the Company site Engineer providing that the

flushing water discharges shall be lead to suitable drainage system.

Flushing air discharge shall be routed to a suitable safe location as regards personnel

protection.

11 EXECUTION OF HYDROSTATIC TEST FOR PIPEWORK

11.0 General

11.0.1 All in-line valves shall be in fully open position during the test

11.0.2 At least two pressure gauges shall be provided for strength test in consideration with the

following conditions:

a. One gauge shall be installed at piping system near pressure source.

b. One gauge shall be installed at piping system as far as possible from pressure source.

c. Pressure range of gauge shall be of 1.6 2.0 times of test pressure.

d. All pressure gauges used for the test shall be calibrated and certified.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 13 of 31

e. One pressure gauge will be installed at the lowest point of the piping system and the test

pressure will be considered as, at this gauge, if these pressure difference in between

gauges, due to height.

11.0.3 The following piping components shall be removed, isolated, or replaced with temporary test

spool:

a. Expansion bellows having a test pressure less than the systems test pressure,

b. Disk of check valve locating at opposite against the flow of pressure source,

c. Relief valve and rupture disc,

d. In-line instrument designated by the Company.

11.0.4 Blinds used for isolation at a flanged joint of piping system shall be provided as follows:

a. Minimum thicknesses of blinds are provided and selected acc.to ANSI 16.5 standard as

resist of test pressure

b. A handle colored in red will be provided at outside of blinds for identifying the purpose of

test use.

11.0.5 Blind flange shall be the same rating as piping system.

11.0.6 Any tie-in welds that cannot be hydrotested require additional NDT testing in accordance with

Technical Specification for Non Destructive Examination of Field Weld No. 1593-S_P-017 must

be identified in advance by contactor and procedures approved in advance by the Owner.

11.0.7 J oints, including welds, shall be left un-insulated and exposed for examination during the test,

except that joints previously tested in accordance with this method statement may be insulated or

covered. However, by getting Companys approval, it should be possible to make the strength and leak

test of the process piping systems after coating and wrapping in some practical cases. The joints

which are left un-insulated for testing purpose shall be insulated after test.

11.0.7 Underground portions of piping systems may be tested and covered before testing

aboveground portions.

11.0.10 Lines that are supported by counterweight shall be temporarily blocked during

testing in order to sustain the weight of the test fluid. Spring hangers that have been provided

with stops for carrying the test load normally do not require additional temporary supports; if this

is not the case, temporary support must be provided before filling the system.In case of using

temporary support will be provided calculation note from Engineering Department.

11.0.8 Before testing, the following procedures shall be carried out:

a. Verify that any required heat treatment has been performed.

b. Piping systems shall have been completely checked (punched out).

c. Lines, vessels, and equipment shall be checked to ensure that the entire system can be

completely drained after testing.

d. Vents or other high point connections shall be opened to eliminate air from lines that are

to receive a hydrostatic test.

e. Verify that there are not any obstacles in the pipework, if any big obstacles found it should

be checked and removed from the inside of the pipework by lifting up and down or any

other applicable methods.

f. Before testing, test team has to verify that mechanical equipment is well isolated and

protected.

g. For communication of testing team mobile phones or hand radios will be used at site

before (prechecking) and during test.

11.0.9 Field personnel shall review all vessels and internals in order to determine best method

2

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 14 of 31

to prevent air entrapment when filling and to prevent vacuum when draining.

For prevention of system ; vents or other high point connections shall be checked and

opened before test and after test during water filling and drain time by test team to

eliminate air and vacuum from lines .

11.0.10 Short pieces of piping that must be removed to permit installation of a blind or blank

shall be tested separately.

11.0.11 Flanged joints at which a blind is inserted to isolate a system from other equipment

during a test shall be leak tested as per para 3.1.11 after reinstatement.

11.0.12 Lines containing check valves shall have the source of pressure located in the piping

upstream of the check valve so that the pressure is applied under the seat. If this is not

possible, remove or jack up the check valve closure mechanism or remove check valve

completely, and provide necessary filler piece or blinds.

11.0.13 When conducting tests at freezing temperatures, the test shall not take more than 1

hours, and special precautions such as warming the line test water or adding anti-

freezing solutions to the test water shall be done to avoid freezing damage. Heating

machines, insulating the pipework are other examples of suitable precautions.

11.0.14 Systems that include expansion joints shall be investigated to see that any required

temporary restraints, anchors, or guides are installed or removed prior to test. When a

pressure test is required to be maintained for a period of time during which the testing

medium in the system would be subject to thermal expansion, provision shall be made

for relief of any pressure greater than the maximum test pressure.

11.0.15 During strenght testing an exclusion zone shall be marked out with plastic barrier tape

and warning notice displayed announcing that Pressure Testing is being undertaend.

Only personnel that are directly invovled in the testing method statement shall be

allowed inside teh exclusion zone and only when absolutely necessary. The Site Piping

Engineer in consultation with the Site Safety Officer shall determine the exclusion zone.

Only competent personnel shall be involved in the hydrotesitng process.

11.0.16 All personnel directly invovled with Pressure Testing will attend a Task Risk Assessment

Meeting prior to testing commencing.

11.1 Hydrostatic Test

11.1.01 Procedure for hydrostatic test shall be as follows:

a. Fill with water in piping system. Approved water will be used. A water analysis must be

performed 14 days prior to using water obtained for the pressure test.

b. Release all air from piping system,

c. Pressurization must be carried at a steady rate of not more than 2 bars per minute as

follows:

c.1.Pressurize to %75 of approved test pressure.

c.2. Pressurize to %90 of approved test pressure. Hold the pressure for half an hour.

c.2. Pressurize to %100 of approved test pressure.

d. Hold test pressure at least 1 hours minimum, then check joints and confirm no leaks.

e. The following measurements must be recorded:

e.1.Initial test pressure reading from pressure gauge..

2

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 15 of 31

e.3.Continuous test pressure vs. time measurement and recording.

e.4.pipe/soil temperature vs.time at least every 0.5 hours.

e.5. If necessary pipe/soil temperature measurement and recording.

e.6. Recording for pressure/temperature (ambient) .

11.1.02 Water to be used for test shall be fresh and clean. Chloride (Cl

-

) ion content of water

used for austenitic stainless steel and other Ni-Cr alloy shall be less than 30 p.p.m, and all

water shall be immediately drained and completely blown out after testing. The system will be

dried if specified.

11.1.03 The pipe system shall remain pressurized until all connections have been

checked for tightness, but in no case shall the duration of the test be less than 1 Hours .

The entire line should be walked to determine whether there is any evidence of leakage.

Any leaks found at the time shall be marked and repaired after first depressurizing the

line. For repair of leakage; first reason of leakage have to verify, decide necessary work

that will done and after depressurizing the line repair works have to start.

11.1.04

11.1.05 After the test has been completed, the pressure must be bled down slowly at a rate of

not more than 3 bar per minute to a pressure not less than atmospheric pressure.

11.1.06 All drained lines shall be thoroughly dried after testing by blowing through with warm,

dry, oil free air with velocities in excess of 20m/sec.

11.1.07 When ever possible, flushing shall be undertaken during daylight hours and during dry

weather.

11.1.08 In order to hydrostatic testing as much piping as possible at one time, a systems

test may be employed. This test shall include one or more lines and, if possible,

connected pumps and equipment.

11.1.09 The maximum system test pressure shall not exceed the pressure test rating of

any piping component, or the shop test pressure of any vessels or equipment included in

the test system.

11.1.10 Where a suitable valve is not available, vessels, equipment, or other piping not

included in the system pressure test shall be either disconnected from the system or

isolated by blinds or other means during the test.

11.1.11 Hydrostatic test pressure shall not be applied until the vessel or equipment and

its contents are at approximately the same temperature.

11.1.12 Ball valves shall be half closed during strength test.

11.1.13 Check valves shall have their disk removed or jacked open.

11.1.14 Bonded joints shall not be put in pressure testing before 24 hrs after bonding of

the joints completed.

11.2 Pneumatic Test

11.2.01 The test medium shall be oil free air or any inert gas.

2

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 16 of 31

11.2.02 After lining of piping system ,liner shall successfully complete low pressure pneumatic

air test. The liner shall be tested minimum pressure of 200 psig for a minimum of ten

(10) minutes ,or as required by owner, to determine that no measurable pressure loss

has occurred. See PSI doc 1593-S-P-009 Rev 0 section 7.2.

11.2.03 Pneumatic test shall not be executed when the ambient temperature is below 5

o

C.

11.2.04 The use of air testing shall be limited to a maximum pressure of 6.8 barg above this

pressure nitrogen shall be used.

11.2.05 Procedure for pneumatic strength test shall be as follows:

a. Increase pressure at the lesser of .35 barg or 10 % of the test pressure gradually by

using air compressor, gas holder, line air or the combination of those pressure sources.

Then check joints and confirm no leaks as a preliminary tightness check.

b. Thereafter, increase pressure gradually to 60 % and wait for a sufficient length of time to

allow the piping equalize strains for a period of time not less than ten minutes. The

pressure shall then be reduced to 50 % of the indicated test pressure and all joints re-

tested for leaks.

c. Pressurize the system in steps of not more than 10 % until the required test pressure

has been reached. The pressure shall be held at each step during the pressurizing

sequence for a period of time not less than 10 minutes. The required test pressure shall

be held 30 minutes and reduced to the maximum working pressure and held for a

sufficient length of time to permit the testing of all joints, but under no circumstances

shall this period be less than 30 minutes. J oints and welds shall be covered with soap

solution in order to detect any leakage. Soap shall be a commercial preparation made

specifically for leak detection.

11.2.06 A bubble-forming solution shall be used to detect leaks.

11.2.07 Each reinforcing pads and similar attachments shall be tested at a pressure of at

least 1 barg with air, a soap solution shall be used to detect the leaks.

11.2.08 At time of testing, the minimum pipe metal temperature shall be in accordance

with Table 4:

TABLE 4 Minimum pipe metal temperatures

Materials and W/T Minimum Temperature

Carbon Steel,W/T 40mm & less 15

o

C

Post Heated Ferritic Steel, W/T 25 mm &

less

15

o

C

Austenitic Steel, W/T 25 mm & less 4

o

C

Minimum temperatures for materials not listed above shall be determined by

Company when required by field construction.

11.2.09 Clear the test area before bringing the line up to test pressure. It may be

desirable to conduct pneumatic tests during weekends when fewer personnel are

present.

11.2.10 A pressure relief device shall be provided, having a set pressure no higher than

the test pressure plus the lesser of 50 kPa or 10 % of the test pressure.

11.2.11 Before soaping the joints, the entire line should be walked to determine whether

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 17 of 31

there is any audible evidence of leakage. Any leaks found at the time shall be marked

and repaired after first depressurizing the line. For repair of leakage; first reason of

leakage have to verify, decide necessary work that will done and after depressurizing

the line repair works have to start.

11.3 Line Service Fluid Test (Commodity Test) for Category D Fluid Service

11.3.01 A piping system used only for Category D Fluid Service, not previously

hydrostatic or pneumatic tested in accordance with this method statement, may be

tested at the normal operation conditions of the system during operation by examining

for leaks at every joint.

11.3.02 A preliminary check shall be made at no more than 172 kPa pressure when the

contained fluid is a gas or vapor. The pressure shall be increased gradually in steps

providing sufficient time to allow the piping to equalize strains and to check leaks.

11.3.03 Unless dictated otherwise by contractual provision, line service fluid test shall be

performed by Companys Designated Inspector prior to mechanical completion.

11.3.04 Lines which require Line Service Fluid testing shall be clearly identified on the

piping drawings and line lists.

11.4 System Reinstatement

11.4.01 When the strength tests are completed, all strainers shall be removed, cleaned

out and reinstalled. Temporary strainers shall be kept in the lines during normal

operation. They will be removed and discarded when deemed no longer necessary by

the Operations Engineer.

11.4.02 If it is impossible to remove the water with air.

11.4.03 All connections broken after shall be made up with new gaskets in the presence

of the Companys Inspectors and they shall be leak tested after reinstatement. The

bolting shall be torqued to the requirements of the Company Specification .

11.4.04 If leaks are found, their location shall be marked, the pressure shall be gradually

released, and the piping shall be drained or vented. Appropriate repair or replacement

shall be made. The affected piping shall be retested at the pressures originally specified

for the test. Retesting of minor repairs or additions may be waived, provided approval of

Company is obtained and the welding is nondestructively examined.

11.4.05 After completion of testing, all temporary blanks and blinds shall be removed, all

operating blinds returned to proper position, and all lines and piping components shall

be completely drained. Valves, orifice plates, expansion joints, and short pieces of piping

that have been removed shall be reinstalled with proper new gaskets in place.

11.4.06 Lines being drained after testing shall have all vents open. Piping systems

downstream of check valves should be inspected to ensure complete drainage.

11.4.07 Direct connected transmitters at orifice flanges must be disconnected when

replacing orifice plates to avoid distorting the connections.

11.4.08 Care shall be exercised in controlling the rate of drainage from vessels with

respect to the inflow of air through the vent to ensure that the vessel is not subjected to

vacuum. After vessels have been completely drained, vents, cyclones, and other internal

closures that were opened before testing shall be closed.

11.4.09 After lines have been drained, temporary supports shall be removed, and

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 18 of 31

insulation and painting completed. Spring hangers provided with stops to carry the test

load shall have these stops removed.

11.4.10 General items for the re-assembly works as listed below:

a. Instruments which were removed or blocked out for test shall be reinstalled and blocks

placed in the normal operating position.

b. Temporary bolts and gaskets used for pressure testing shall be removed and replaced

with new line class bolts and gaskets.

c. Check valves that were jacked open or the internals were removed for pressure testing

shall be returned to their proper operating position.

d. Vessel and equipment internal closures which were opened specifically for pressure

testing shall be closed.

e. Instruments and process lead lines that were subjected to the hydrostatic pressure test

shall be blown out with dry air or nitrogen.

f. All vents and drain connections that are added solely for pressure testing shall be screw

plugged and seal welded . Drains shall have either the valve closed and plugged or, if the

valve is removed, the connection plugged and seal welded. Seal welded vent and drain

connections shall be inspected by visually and by magnetic particle inspection.

g. Painting and lining shall be completed after NDE inspection of seal welded vents and

drains.

h. Strainer screens shall be removed, cleaned, and reinstalled

12.0 ACCEPTANCE OF PRESSURE TEST FOR PIPEWORK

No leaks shall be acceptable for the piping systems.

13.0 SAFETY IN PRESSURE TESTING & FLUSHING FOR PIPEWORK

Site piping engineer in consultation with the site Safety officer shall determine the exclusion

zone.

Only one personnel (site supervisor or foreman) shall be involved in the hydrostatic testing.

All tests shall be coordinated with regard to other construction activities.

If required, a risk analysis may be done for special and difficult conditions by Site piping

engineer and Site safety officer.

13.1 Hydrostatic Pressure Testing

Precautions for hydraulic pressure testing include the following:

a. To avoid the risk of freezing, the temperature of the water during the test should not

be less than +4 C

o

.

b. Steps should be taken to ensure that blanking devices and items such as screwed

plugs or connections are not liable to be ejected during testing, particularly as the

result of thread failure.

c. Pipe work being tested must be totally filled with liquid and properly vented to exclude

air pockets.

d. Hydrotesting testing should be carried out by a person trained for the purpose and

have experience in such works.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 19 of 31

e. The pressure should be applied gradually or increased by steps of approximately 10

% until the required test pressure is reached. At this stage the pressure should not be

further increased.

f. The pipe work should not be approached for close examination until a reasonable

period of time has elapsed. For the safety of personnel, it may be necessary to

consider remote viewing procedures rather than close physical examination related to

the hydraulic test pressure.

g. The pipe work shall not be subjected to any form of shock loading such as hammer

testing while undergoing a pressure test.

h. If a leak is observed, pressure shall be decreased and tightening of the bolts can be

executed.

i. Test area shall be barricaded for the entrance of the personnel.

j. Safety warning signs and warning lights in foggy weathers shall be used for the

information of the personnel.

13.2 Pneumatic Testing

13.2.1 This method of testing is potentially more dangerous because the energy stored within the

pressure system could be released explosively in the event of failure under test. Pneumatic testing

should be avoided unless there are technical reasons for it.

13.2.2 Before testing, an assessment of the equipment or pipe work should be made and a detailed

inspection should be carried out.

13.2.3 Where practicable, steps should be taken to reduce to a minimum the internal volume of the

system to be tested. This has the effect of reducing the consequences of a rupture under test. It

may be practicable to isolate sections of the complete system and to test them separately,

followed by reassembly and leak testing.

13.2.4 Local chilling during filing and emptying of the pipe work should be reduced by exercising

sufficient control to avoid sudden changes in flow rate across inlet and exhaust control valves or

nozzles.

13.2.5 Full number of studs or bolts provided for blanking flanges shall always be used. Any studs or

bolts with worn or damaged threads shall be replaced.

13.2.6 Test gas shall be controlled by using reducing valves and other valves that regulate the flow of

test gas into the pipe work or equipment.

13.2.7 Flexible pipes and their connections shall be regularly examined to reduce the risk of failure.

The risk of injuries to personnel nearby may be reduced by the use of safety restraints attached

of the connection.

13.2.8 Test area shall be barricaded for the entrance of the personnel.

13.2.9 Safety warning signs and warning lights in foggy weathers shall be used for the information of

the personnel.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 20 of 31

13.2.10 Interchangeable pressure test components such as blank flanges, studs,

pressure gauges, pressure relief devices and flexible connections shall be regularly

examined by an appointed personnel.

13.2.11 Pressure test components shall be stored and identified to assist correct

selection and use for the warning intended.

13.2.12 A range of air pressures may be required from a common source of supply. In

order to reduce the risk of an incorrect pressure being connected, it may be advisable to

have different sizes or types of connections on hose ends, and to arrange that the

equipment or the pipework being tested has compatible connections.

13.2.13 Where flexible tube connections are used, they shall be securely fastened.

13.2.14 Proper pressure relief devices should always be provided and used for pressure testing. As it

is vital that safety valves are supplied and maintained in proper working order, a test of the setting is

required at the initial and subsequent periodic examination, repair or replacement. Safety valves shall

be removed regularly and be stripped, cleaned, examined and before re-use the set pressure checked

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 21 of 31

14.0PRESSURETESTACTIVITYFLOWCHART

2

7

3

8

5 6 4

10

121111

ENGINEERING DEPT.

To prepare TP with as

built and forms

CONSTRUCTION

for confirmation of

line completion and

punching

TP

COORDINATOR

for processing

WITNESS

TEST,SIGN TEST

,RECORD

FLUSHING

COMPLETE

REINSTATEME

NT COMPLETE

,B ITEM

CLEARED

QC J ESA-QC

TEKFEN TEST

PACK RELEASE

RECORD

J ESA for

approval

QC DEPARTEMENT

Line Punch

NDT/PWHT/ITR/Weld

log input

HYDROTEST

ENGINEER raise

RFI-Perform test

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 22 of 31

15.0 HAZARD EFECT AND MANAGEMENT PLAN FOR FLUSHING AND HYDROTESTING

15.1 INTRODUCTION

15.1.1 Hazard Assessment

Hazard assessments form the basis of controlling hazards. That should be seen as an

important tool in ensuring that the activities dont present risks and that the controls

implemented are appropriate.

Hazard assessment is something that we do every day so we shall not be scared of

it. For example: When pouring water into a bath, we check the water temperature by

sampling with our hand. This is the tool to control the hazard of scalding because the

water may be too hot. In the same way, we use hazard assessments for activities such as

lifting a box. By following the activity in steps, and identifying the potential hazards in a

logical way, we can perform the activity in a safely manner.

Hazard assessment for the project activities is a systematic process whereby Workers,

Foremans, Supervisors, Engineers and Managers identify, assess and control hazards

that may affect anybody involved in the project activities or third party.

Once the hazards are identified, an action plan is prepared and hazards are then

controlled by being eliminated or minimized. Workers, Foremans, Supervisors, Engineers

and Managers are an essential part of the Hazards Assessment process.

Hazard assessment is and can be a pro-active way of preventing an accident or incident

occurring and can be useful in preventing an incident/accident reoccurring.

15.1.2 Scope

The Hazards and Effects Management Plan (HEMP) is a live document, which will be

updated during the project execution. The scope of this document is as follows:

Assess the significant HSE hazards associated with all the construction activities of the

OCP Slurry Pipeline Project.

To propose realistic control measures which can minimise the risks associated with

the identified hazards.

To define certain recovery measures to ensure minimum harm to Health of

Employees, Equipment and Environment if any of the controls fail.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF

FLUSHING AND HYDROTESTING

FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 23 of 31

15.2 METHODOLOGY

15.2.1Process

Hazards and Effects Management Process (HEMP) comprises five steps as follows:

Identify and list activities for Specific work

Identify hazards, threats and potential hazardous events

Assess the risks against accepted screening criteria, taking into account the likelihood

of occurrence and severity of the consequences to people, assets and the

environment

Record the significant hazards and effects

Implement suitable risk reduction measures (control and mitigate)

Plan for recovery in the event of a loss of control

15.2.2 Hazard Identification

Hazard identification is carried out based on the judgment of the experts in the fields. This

process is based on brainstorming, think of the activities to be performed and then think

what could go wrong.

15.2.3 Risk Assessment

After identifying the hazards of the activities of the proposed scope of work of the OCP

Slurry Pipeline project, the associated risks are assessed on the following RAM (Risk

Assessment Matrix).

(Ref-HSEP 2.22- Hazard Identification and Risk Assessment)

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING AND

HYDROTESTING FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev.2 Page 24 of 31

Incident Severity

Incident Likelihood or Probability

Improbable Remote Occasional Probable Frequent

Productivity

or Downtime

Environment Property Personnel

Severity

Level

A B C D E

> 2 weeks

Permanent damage

beyond project

boundary

Total facility loss

Fatality or total

permanent

disability

5

1 week to

2 weeks

Permanent damage

within project boundary

or reportable release

beyond boundary

Damage to an

entire facility or

loss of multiple

systems in a

facility

Permanent

partial disability

4

> 1 day to

< 1 week

Reportable release

within project boundary

with no permanent

damage

Damage to an

entire facility or

multiple systems

in a facility

requiring repair

or replacement

Days away 3

day to

1 day

Release within project

boundary below

reporting quantity with

clean-up by external

source

Damage to a

facility element or

system requiring

repair or

replacement

OSHA

Recordable or

E-1

2

< day

Release within project

boundary below

reporting quantity with

clean-up by internal

source

Damage to a

facility element or

system requiring

negligible or no

repair

First aid 1

Risk Mitigation Controls

High

(H)

Operation not permitted;

must implement controls to

reduce risk to an acceptable

or manageable level.

Medium

(M)

Operation

permitted with a

time limited

waiver endorsed

by management.

Low

(L)

Operation permitted with

implementation of core

HSE program elements.

L

M

H

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING AND

HYDROTESTING FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 25 of 31

Job / Task 4.7 HEMP - 012 - Hydro Testing Piping (Pressure, Flushing)

ACTIVITY

SIGNIFICAN

T HAZARDS

HAZARD

EFECTS

What could go wrong?

How serious would that

be?

RISK

RATIN

G

CONTROL MEASURES

How to prevent it?

Elimination (E), Prevention (P), Control (C) or Mitigation (M)

RESIDUAL

RISK

RATING

(After the

controls are in

place)

RECOVERY

MEASURES

HYDRO

TESTING OF

PIPING

Incompetent/

Untrained

Personnel.

Inadequate

Supervision

Fatality,

Injury,

Asset Damage

H

H

Discuss SPA

Toolbox talk.

Ensure all persons in the crew are attended HSE induction.

Prepare the method statement, SPA approval, and the work

permit system shall be obtained prior to start activities.

All persons involved on the job have to discuss and

understand the work permit, method statement and the SPA.

Approved hydro test engineer and competent supervision.

L

L

FOLLOW

EMERGENCY

RESPONSE

PROCEDURE

Call

HSE Manager

0661775749

Dy HSE Manager

Stations

0652706957

HSE Supervisor

JORF

0662164708

Construction Site

Chief Stations

0652706963

Site Engineer JORF

Terminal station

Defective

Equipments

and Tools

Fatality,

Injury,

Asset Damage

Ensure all equipment shall be inspected and certified.

Ensure the relief valves and pressure gauges calibrated.

Check all the emergency systems and devices are functional

and current certification provided.

Follow Method statement.

All the hoses must be inspected before the activity starts for

the defects

Ensure whip line check safety cables are installed on all the

hose connections / couplings

suitable fire extinguishers to be placed on site

use only good quality and proper size of spanners and hand

tools

use only standard torque wrenches and pressure hoses

High pressure Personal Injury

Property Damage

Proper and specific toolbox talk

Pressure systems are depressurized, drained, vented and

made safe and that all preparatory work is completed

All the equipment used for the activity should be tested and

certified

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING AND

HYDROTESTING FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 26 of 31

Job / Task 4.7 HEMP - 012 - Hydro Testing Piping (Pressure, Flushing)

ACTIVITY

SIGNIFICAN

T HAZARDS

HAZARD

EFECTS

What could go wrong?

How serious would that

be?

RISK

RATIN

G

CONTROL MEASURES

How to prevent it?

Elimination (E), Prevention (P), Control (C) or Mitigation (M)

RESIDUAL

RISK

RATING

(After the

controls are in

place)

RECOVERY

MEASURES

All the certificates shall be made available at site

Ensure Whip check safety cables are installed on all the

hose connections / Couplings

Barricade the area and display sufficient warning signs

Inform the other close by work activity supervisors

No other activity shall be allowed in the vicinity

No one except the experienced test group people shall be

allowed with in the 30 meter distance on both the ends

Emergency response team shall be informed

Medics with standby ambulance

All the high pressure flexible hoses must be anchored with

sand bags or satisfying weight / loads to prevent undue

movement

0655247378

TIGHTENING

THE FLANGE

TO ARREST

THE LEAK

WHILE PIPE

IS UNDER

PRESSURE

Bursting the

gasket / pipe

Defective

spanner

Untrained

manpower

Inadequate

supervision

Fatality,

Injury,

Asset Damage

H

H

Do not tight any flange when the pipe is under pressure

Depressurize the line before tightening the flange

Use only good tools and spanners

Deploy only trained manpower under close supervision

Use proper PPEs specific to the work

L

FOLLOW

EMERGENCY

RESPONSE

PROCEDURE

Call

HSE Manager

0661775749

Dy HSE Manager

Stations

0652706957

Inadequate

communication

system.

Injury,

Asset Damage

Follow Method statement.

2 way radio/GSM, flags and signals.

Stored

mechanical

energy

Isolation failure.

Fatality, Injury

Damage to

equipment.

Isolation shall be verified by walking the plant and

reviewing the Drawings prior to start-up of pressure testing.

All Isolation shall only be conducted by a qualified and

competent Isolating Authority.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING AND

HYDROTESTING FOR STATION PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 27 of 31

Job / Task 4.7 HEMP - 012 - Hydro Testing Piping (Pressure, Flushing)

ACTIVITY

SIGNIFICAN

T HAZARDS

HAZARD

EFECTS

What could go wrong?

How serious would that

be?

RISK

RATIN

G

CONTROL MEASURES

How to prevent it?

Elimination (E), Prevention (P), Control (C) or Mitigation (M)

RESIDUAL

RISK

RATING

(After the

controls are in

place)

RECOVERY

MEASURES

All pressure gauges shall be properly calibrated prior to start

of pressure testing.

Isolate the work area, authorized personnel only allowed

near test area.

HSE Supervisor

JORF

0662164708

Construction Site

Chief Stations

0652706963

Site Engineer JORF

Terminal station

0655247378

2

DRAINING

AND DRYING

THE PIPE

AND

EQUIPMENT

Water spreading

all over the area

Dewatering

Partial drainage

of water from

the pipe

Personal Injury

Environmental

damage

Development of

corrosion

Drain the water to a designated area

Inspection prior to start the work

Dry completely all the system

WASTE

MANAGEMENT

Used Test water

Scrape material

Damage to

environment

Collect all the tools and material and dispose as per waste

management procedure.

Vacuum truck.

controlled disposal

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING

AND HYDROTESTING FOR STATION

PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 28 of 31

16.0 EMERGENCY RESPONSE PLAN

During the activity all staff must be aware of the ERP for that activity. Medical coverage must

be available with a trained Nurse at site. Minor injuries shall be treated at the scene in the first

instance. Should further treatment be required the IP shall immediately be transferred to the

Ambulance and to be shifted to the Hospital 9Hassan-II-Khouribga and Settat) (Oum Arrabia) at

J ORF) for further treatment.

In the unlikely event that somebody is struck by debris or the trencher itself the casualty shall not be

moved at all unless there is an immediate threat to life by the location they are in or by the nature of

the injuries sustained. RLIC ambulance shall immediately be called to the scene; in the meantime the

Primary First Aider shall ensure the stability of the casualty.

In the event of a fire during the activity then the fire extinguishers at the scene should be used to

tackle the blaze if possible, all un required staff should be evacuated from the location to the nearest

Assembly Point. Local Civil fire service should be called immediately to assist if necessary. All

engines and electrical sources should be switched off and isolated.

During in any ERP all other activities in the area shall immediately be stopped until advised otherwise

by the Senior Staff at the scene. Once the ERP has been activated and the immediate threat is

controlled the Project Management including HSE must be informed of the incident or accident.

The scene should be sealed, either by staff or barriers if possible to ensure that this area remains the

same for photographs and other investigation steps that may be required. Depending on the nature

and severity of the incident the Police may be required to attend the scene and to carry out their own

investigation. For investigation purposes all people who were involved in the activity are to identify

themselves to the HSE Supervisor to assist in the investigation process.

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING

AND HYDROTESTING FOR STATION

PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 29 of 31

Project Manager 0652706939

Deputy Project Manager 0661754502

Sr. Const. Manager. P/L & Stations 0661050035

Sr. Const Manager. Feeder P/L 0655247041

Construction Manager Pump Stations 0652706931

Construction Manager

(Main P/L)

0661748625

Construction Manager for Const. E &I

Works

0661079671

Administration Manager 0652305111

Camps Manager 0661742894

HSE Manager 0661775749

Dy HSE Manager 0652706957

HSE Supervisor 0662164708

Doctor 0652305099

Nurse 0673239318

Nurse 0672336678

Driver

Plate #: by -893- wt

0675064890

Nurse 0633762444

Driver

Plate #: 19683 - 57-

0665162838

Nurse 0673239318

DRIVER

42415 -72-

0600721188

Nurse 0670860067

Driver

Plate #: 58353- 8-

0673682057

Nurse 0653367457

Driver

Plate #: 25496 - 48 -

0648058753

Nurse 0668151042

Driver

Plate #: 19682 - 57-

0677844600

Nurse 0633744372

Driver

Plate #: 24489 - 34-

0673202568

Nurse 0679689108

Driver

Plate #: 62017 - 8-

0666994488

Doctor 0661715561

Nurse 0668151042

Nurse 0676130602

Doctor 0661696119

Nurse 0670228021

Nurse 0655435848

LGC - AMBULANCE DRIVER

Plate #: 19901 -40-

0671534026

0650388372

0523492003

177

19

SETTAT CAMP- NIGHT

SETTAT CAMP- DAY

Overall project Mustafa TEZER

Overall project Ali Nejdet BAKKAL

Ahmet YILDIRIM

Khouribga Kenan SEKERYAPAN

AMINE MORABIT

FIHER YOUSEF

BOUCHRA HAJLI

WASSIM FATIHA

HICHAM CHAKIB

AMINE MAHHDDAR

AYOUB HANANE

DAOUI STATION

Head Station / TSF

KHOURIBGA CAMP-NIGHT

ROW - PAINTING/ COATING

CREW

ABDELWAHED ADLI

LEHSEN LOJINI

AZIZ HAFDI

ROW - WELDING CREW

ROW - STRINGING CREW

ABDELAH EL MEZAH

ISSAM TAYEB

HELASSA STATION

YOUNES ARBANI

JAMAL KASAROUI

GSM

Necmettin SENGUN

Ali HAMZALIOGLU

Abid FAYYAZ

Anouar SADIQ

Deniz CAYMAZ

Name

Mustafa KOPUZ

A. Fatih ISILDAR

Mustafa ERCIN

AMRI NOUREDDINE

ABDELAH ABOUTOUM

MHAMMED ABOUTOUM

YOUNES ERRAKI

ANAS EL ATTARY

ZAHRA BENSADA

Revised - 08 August-2012

Location

Overall project

Overall project

Overall project

Civil Protection Khouribga

Gendarmerie

TSF

Head Station / TSF

JORF LASFAR

Job Title

LGC WORK LOCATIONS

NAJIB DAKHILI

ROW - BENDING CREW

YOUNES MOUNDA

Reda SAAA

TEKFEN CONSTRUCTI ON OCP

SLURRY PI PELI NE PROJ ECT

Overall project

Overall project

Overall project

In case of emergency call the numbers above.

Acil durumlarda yukaridaki numaralari arayabilirsiniz.

En cas D'Urgence appeler les numeros ci dessus.

Police

Head Station / TSF

KHOURIBGA CAMP-DAY

Emergency Contacts & Response Team

EL FAKIR MOHAMMED

ABDELHAMID TALITE

Overall project

HAFIDA EL FETTAHI

TERMINAL STATION

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING

AND HYDROTESTING FOR STATION

PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 30 of 31

17.0 ATTACHMENT

17.0.1 Test Header

17.0.1 Pump Station Line List (PAC-00-ME-DAT-002) for Test Pressure

KHOURIBGA JORF LASFAR PHOSPHATE SLURRY PIPELINE SYSTEM

Groupe OCP S. A.

Casablanca

Morocco

Document Title:

METHOD STATEMENT OF FLUSHING

AND HYDROTESTING FOR STATION

PIPING

Issue date 31-12-2012 Doc. No : TKF-00-ME-MST-0007 Rev. 2 Page 31 of 31

7 10 Oct 12 NT

6 24 Jul 12 NT

5 17 Jul 12 NT

4 15 Jun 12 HG

3 10 Apr 12 HG

2 20 Mar 12 HG

1 07 Mar 12 HG

0 04 Jan 12 HG

B 07 Dec 11 HG

A 01 Aug 11 -

Reviewed

TEKFEN

Org. Code Area Code Disc. Code

1305 PAC 00 ME 7 10

Issued for Construction Code A (Design Update) AR MK

PUMP STATION LINE LIST

Checked

MK

Total pages

(w.

attachmts)

Issued for Internal Review

Prepared

Rev.

No.

AR MK

Issued for Construction Code A (Design Update) AR MK

Issued for Construction Code A (Design Update) AR

MK

MK

DAT 0002

Description

SUBCONTRACTOR

PAC Proj.

No.

Document No.

Doc. Type Seq. No.

Groupe OCP S.A.

Casablanca, 2, rue Al Abtal, Hay Erraha,

Morocco

EPC CONTRACTOR

ORIGINATOR

KHOURIBGA JORF LASFAR

PHOSPHATE SLURRY PIPELINE SYSTEM

Document Title

Date

Rev.

No.

Issued for Construction Code A (Design Update) AR MK

MK

Issued for Construction Code A (Design Update)

Issued for Construction Code A per JESA-TKF-DCS-0472 (No

Comments)

Issued for Information

AR

AR

AR

Issued for Construction Code A (Design Update) AR MK

Issued for Construction Code A (Design Update) AR MK

No Tag

Sequence

Number

Contents Area From To Pipe Class

Size

(NB)

Internal

Diameter

(mm)

Max Flow

Rate

(m/h)

Max Velocity

(m/s)

Operating

Pressure

(kPa)

Pressure

Rating

(kPa)

Test Pressure

(kPa)

P&ID

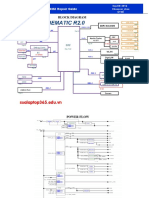

1 03-0101-RL31-400-PS 0101 PS 03 Low grade thickener 1216-TH-001 & -002 underflow pumps 03-LR-001 RL31 400 363.3 1350 3.6 1100 5100 5610 PAC-03-PR-PID-0001

2 03-0103-UL30-400-PS 0103 PS 03 03-LR-001 03-0104-PL34-400-PS UL30 400 363.3 1350 3.6 1100 5100 5610 PAC-03-PR-PID-0001

3 03-0104-PL34-400-PS 0104 PS 03 03-0103-UL30-400-PS Head Station receiver PL34 400 377.8 1350 3.3 1100 1965 2162 PAC-03-PR-PID-0001

4 03-0105-EL21-400-PW 0105 PW 03 03-0001-EL21-400-PW 03-0101-RL31-400-PS EL21 400 387.3 1350 3.2 600 1965 2950 PAC-03-PR-PID-0001

5 03-0001-EL21-400-PW 0001 PW 03 Process water supply - EL21 400 387.3 1350 3.2 600 1965 2950 PAC-03-PR-PID-0001

6 03-0201-RL31-300-PS 0201 PS 03 High grade thickener 1216-TH-003 underflow pumps 03-LR-002 RL31 300 280.7 675 3.0 1100 5100 5610 PAC-03-PR-PID-0001

7 03-0202-UL30-300-PS 0202 PS 03 03-LR-002 03-0203-PL35-300-PS UL30 300 280.7 675 3.0 1100 5100 5610 PAC-03-PR-PID-0001

8 03-0203-PL35-300-PS 0203 PS 03 03-0202-UL30-300-PS Head Station receiver PL35 300 301.4 675 2.6 1100 1965 2162 PAC-03-PR-PID-0001

9 03-0205-EL21-300-PW 0205 PW 03 03-0001-EL21-400-PW 03-0201-RL31-300-PS EL21 300 304.7 675 2.6 600 1965 2950 PAC-03-PR-PID-0001

10 03-1103-EL22-150-PS 1103 PS 03 03-0101-RL31-400-PS Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-03-PR-PID-0001

11 03-1104-SS20-50-PW 1104 PW 03 03-LR-001 Hose connection SS20 50 49.2 20 2.9 600 1965 2947 PAC-03-PR-PID-0001

12 03-1105-EL22-150-PS 1105 PS 03 03-LR-001 Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-03-PR-PID-0001

13 03-1203-EL22-150-PS 1203 PS 03 03-0201-RL31-300-PS Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-03-PR-PID-0001

14 03-1204-SS20-50-PW 1204 PW 03 03-LR-002 Hose connection SS20 50 49.2 20 2.9 600 1965 2947 PAC-03-PR-PID-0001

15 03-1205-EL22-150-PS 1205 PS 03 03-LR-002 Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-03-PR-PID-0001

16 03-1301-SS20-50-PW 1301 PW 03 Process water supply Hose connection SS20 50 49.2 20 2.9 600 1965 2947 PAC-03-PR-PID-0001

17 07-0001-RL31-450-PS 0001 PS 07 Low grade thickener 1116-TH-001 & 002 underflow pumps 07-TK-001 RL31 450 413.9 1350 2.8 350 5100 5610 PAC-07-PR-PID-0001

18 07-0003-RL21-450-PS 0003 PS 07 07-TK-001 Feeder line pumps RL21 450 413.9 1350 2.8 350 1965 2160 PAC-07-PR-PID-0001

19 07-1401-RL21-200-PS 1401 PS 07 07-PU-201 Low grade thickener RL21 200 178.7 250 2.8 675 1965 2160 PAC-07-PR-PID-0001

20 07-1003-EL22-500-PS 1003 PS 07 07-TK-001 overflow Drain to station pad EL22 500 488.9 - - 0 N/A N/A PAC-07-PR-PID-0001

21 07-1004-EL22-350-PS 1004 PS 07 07-TK-001 Drain to station pad EL22 350 336.5 - - 0 N/A N/A PAC-07-PR-PID-0001

22 07-1008-SS20-80-PW 1008 PW 07 07-0003-RL21-450-PS Hose connection SS20 80 73.7 40 2.6 600 1965 2947 PAC-07-PR-PID-0001

23 07-1301-EL21-400-PW 1301 PW 07 Process water supply - EL21 400 387.3 - - 600 1965 2950 PAC-07-PR-PID-0001

24 07-1302-SS20-100-PW 1302 PW 07 07-1301-EL21-400-PW Blank flange SS20 100 97.2 - - 600 1965 2947 PAC-07-PR-PID-0001

25 07-1303-SS20-50-PW 1303 PW 07 07-1302-SS20-100-PW Hose connection SS20 50 49.2 20 2.9 600 1965 2947 PAC-07-PR-PID-0001

26 07-1304-SS20-50-PW 1304 PW 07 07-1302-SS20-100-PW Hose connection SS20 50 49.2 20 2.9 600 1965 2947 PAC-07-PR-PID-0001

27 07-1305-SS20-80-PW 1305 PW 07 07-1302-SS20-100-PW Sump SS20 80 73.7 - - 600 1965 2947 PAC-07-PR-PID-0001

28 07-1306-SS20-50-PW 1306 PW 07 07-1302-SS20-100-PW Hose connection SS20 50 49.2 20 2.9 600 1965 2947 PAC-07-PR-PID-0001

29 07-1307-SS20-80-PW 1307 PW 07 07-1301-EL21-400-PW Hose connection SS20 80 73.7 40 2.6 600 1965 2947 PAC-07-PR-PID-0001

30 07-1001-SS20-40-PW 1001 PW 07 07-0003-RL21-450-PS Spillage sump SS20 40 40.9 27 5.7 600 1965 2947 PAC-07-PR-PID-0002

31 07-0101-RL21-450-PS 0101 PS 07 07-0003-RL21-450-PS 07-PU-001 RL21 450 413.9 1350 2.8 350 1965 2160 PAC-07-PR-PID-0002

32 07-0105-RL31-450-PS 0105 PS 07 07-PU-004 07-0004-RL31-450-PS RL31 450 413.9 1369 2.8 3296 5100 5610 PAC-07-PR-PID-0002

33 07-0201-RL21-450-PS 0201 PS 07 07-0003-RL21-450-PS 07-PU-011 RL21 450 413.9 1350 2.8 350 1965 2160 PAC-07-PR-PID-0002

34 07-0205-RL31-450-PS 0205 PS 07 07-PU-014 07-0004-RL31-450-PS RL31 450 413.9 1369 2.8 3296 5100 5610 PAC-07-PR-PID-0002

35 07-1311-EL21-200-PW 1311 PW 07 07-1301-EL21-400-PW - EL21 200 202.7 - - 600 1965 2950 PAC-07-PR-PID-0002

36 07-1312-EL21-150-PW 1312 PW 07 07-1311-EL21-200-PW 07-0101-RL21-450-PS EL21 150 154.1 - - 600 1965 2950 PAC-07-PR-PID-0002

37 07-1313-EL21-150-PW 1313 PW 07 07-1311-EL21-200-PW 07-0201-RL21-450-PS EL21 150 154.1 - - 600 1965 2950 PAC-07-PR-PID-0002

38 07-1314-SS20-100-PW 1314 PW 07 07-1311-EL21-200-PW - SS20 100 97.2 - - 600 1965 2947 PAC-07-PR-PID-0002

39 07-1315-EL21-400-PW 1315 PW 07 07-1301-EL21-400-PW 07-0003-RL21-450-PS EL21 400 387.3 1350 3.2 600 1965 2950 PAC-07-PR-PID-0002

40 07-1316-EL21-150-PW 1316 PW 07 07-1315-EL21-400-PW 07-1315-EL21-400-PW EL21 150 154.1 180 2.7 600 1965 2950 PAC-07-PR-PID-0002

41 07-1102-EL22-150-PS 1102 PS 07 07-0101-RL21-450-PS Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-07-PR-PID-0002

42 07-1201-EL22-150-PS 1201 PS 07 07-0201-RL21-450-PS Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-07-PR-PID-0002

43 07-0004-RL31-450-PS 0004 PS 07 Pump train discharge 07-LR-001 RL31 450 413.9 1369 2.8 3296 5100 5610 PAC-07-PR-PID-0003

44 07-0005-UL30-450-PS 0005 PS 07 07-LR-001 Overland pipeline to Head Station UL30 450 413.9 1369 2.8 3296 5100 5610 PAC-07-PR-PID-0003

45 07-1109-EL22-150-PS 1109 PS 07 07-0105-RL31-450-PS Drain to station pad EL22 150 154.1 - - 0 N/A N/A PAC-07-PR-PID-0003