Professional Documents

Culture Documents

OH-6A Misshap Experience Report

Uploaded by

robbertmdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OH-6A Misshap Experience Report

Uploaded by

robbertmdCopyright:

Available Formats

OCTOBER 1 9 7 3

2 0 0 0 1 0 1 6 0 6 6

USAAAVS

PREPARED BY THE UNITED STATES ARMY AGENCY FOR AVIATION SAFETY FORT RUCKER, AL 36360

OH-6 MISHAP EXPERIENCE REPORT

1 July 1 967 through 30 June 1 971

by

LTC David L. Boivin

and

Mr. David T. Forbes, Jr.

LOH Division

Directorate for Aircraft Accident Analysis and Investigation

USAAAVS

U.I.ADMVAalNCVFOR AVIATION BATY

COLONEL FRANCIS MAX McCULLAR

Commander

FOREWORD

Cause factors which contributed to mishaps involving the 0H-6A aircraft

during the period 1 July 1 967 to 30 June 1 971 are identified and analyzed in this

report. Recognition and analysis of these factors are important today if better

operating procedures, maintenance techniques and training methods are evolved

for tomorrow. A study of these factors can also provide statistical data useful

in demonstrating a need for additional design and quality control requirements in

the future. This cumulative report should be of interest to all of us in aviation

since any change in the above related fields would serve to affect and improve

our current flying operations.

As evidenced in this report, materiel and operational problems were the two

major concerns involving OH-6A mishaps during this period. Materiel problems

were predominately caused by engine failures and engine malfunctions. Opera-

tional errors were primarily attributed to low level operations resulting in the

aircraft colliding with obstructions such as wires and trees. Other operational

problems involved autorotation/emergency landing techniques and violation of

regulations and/or unit SOP's.

A review of mishaps involved in low level operations which were not required

by the mission or dictated by weather conditions indicates many mishaps could

have been prevented through proper supervision and training. With this kind of

knowledge, I am confident that commanders at all levels in the Army can meet

the challenge of insuring an effective accident prevention and safety program

within their commands.

I urge you to review this report and apply the lessons in it along with your

professional expertise to the betterment of the Army aviation program.

FRANCIS MAX McCULLAR

Colonel, Infantry

Commanding

TABLE OF CONTENTS

INTRODUCTION 1

SYNOPSIS 1

CONCLUSIONS 1

DISCUSSION 2

SELECTED ACCIDENT BRIEFS 9

SELECTED INCIDENT BRIEFS 1 5

SELECTED FORCED LANDING BRIEFS 1 6

SELECTED PRECAUTIONARY LANDING BRIEFS 1 6

TABLE 1 Number and Classification of Mishaps 1

TABLE 2Types of Mishaps by Location 2

TABLE 3-Injuries 2

TABLE 4-Mishap Cause Factors 3

TABLE 5Materiel and Crew Error Causes 4

TABLE 6Materiel System Causes 5

TABLE 7Phase of Operation 6

TABLE 8-Period of Operation 6

FIGURE 1 -Accident Rates (Worldwide) 2

FIGURE 2-Annual Fatality Rates 3

FIGURE 3-Accident/Incident Dollar Cost 4

OH-6 MISHAP EXPERIENCE REPORT

1 JULY 1 967 THROUGH 30 JUNE 1 971

INTRODUCTION. This report was prepared to

aid commanders, aviation safety officers, mainte-

nance officers, aviators, and related aviation

personnel in accident prevention and the preser-

vation of combat resources through a review of

past OH-6A mishaps and their cause factors.

The term "mishap" includes accidents, inci-

dents, forced landings, and precautionary land-

ings as defined in AR 385-40. "Damaging

mishaps" are those reported as major accidents,

minor accidents, and incidents. "Nondamaging

mishaps" are forced and precautionary landings.

Aircraft losses or damages which were the direct

result of combat action are not included in

this report.

SYNOPSIS. The OH-6A was involved in 1 ,554

mishaps from 1 July 1 967 through 30 June 1 971 .

There were 563 accidents (of which 241 were

classified as total losses), 357 incidents, 1 87

forced landings, and 447 precautionary landings.

Based on 1 ,229,271 flying hours reported during

this 4-year period, the accident rate per 1 00,000

flying hours was 45.81 . These accidents in-

volved 93 fatalities and 362 nonfatal injuries.

There were six in-flight fires and 34 postflight

fires. Aircraft damage occurred in 920 of the

1 ,554 mishaps, costing about $31 ,470,000.

Personnel factors were involved in approxi-

mately 55 percent of the accidents and incidents

and materiel factors were involved in 83 percent

of the forced and precautionary landings.

The primary types of crew errors reported in

damaging mishaps involved practice autorotations

and striking wires, trees, and other objects.

Engine and tail rotor problems were involved in

the majority of materiel failure/malfunction mis-

haps which resulted in damage.

CONCLUSIONS. During this reporting period,

Vietnam accounted for 89 percent of all OH-6A

reported flight time (1 ,1 66,827 hours), 99 percent

of the fatalities (92), 97 percent of the injuries

(351 ), and 98 percent of the accident/incident

cost ($31 ,023,000).

Crew error was reported as the principal cause

for the majority of damaging mishaps. Lack of

discipline on the part of the operatorsstretching

the limitations of the aircraft plus failure to use

standard procedureswas evident.

Supervision-related mishaps were minimal.

The supervisory factor may be one of omission

rather than commission. An active command-

controlled program is required to generate know-

ledgeable, skillful, disciplined aviators.

Mishaps caused by materiel failures and mal-

TABLE 1

Number and Classification of Mishaps

FY FY FY FY

Classification Total 1968 1969 1970 1971

Accidents 563 60 204 1 93 1 06

Incidents 357 16 1 24 1 24 93

Forced Landings 1 87 1 7 85 49 36

Precautionary Landings 447 44 1 03 1 1 3 1 87

Total 1 554 1 37 51 6 479 422

functions can be reduced by adherence to estab-

lished maintenance procedures, an effective qual-

ity control program, and by involved supervisors.

DISCUSSION. Table 1 shows the number and

classification of OH-6A mishaps reported during

this period.

Of the total mishaps reported, approximately

36 percent were classified as accidents. Forty-

two percent of the accidents were classified as

total losses. Fiscal year 1 969 shows a definite

increase in all categories of mishap classifica-

tions. This increase could be attributed to:

(1 ) the total number of aircraft deployed to RVN

during that year; (2) the increase in flying hour

program; (3) the rapid influx of newly trained

aviators; and (4) the environmental condition in

which the 0H-6A was being operated. Although

the number of mishaps increased in FY 1 969, the

accident rate decreased by comparison to FY

1 968.

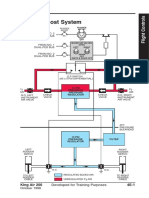

Figure 1 shows annual 0H-6A accident rates,

based on the number of accidents per 1 00,000

flying hours.

The accident rate has gradually declined from

66.7 accidents per 1 00,000 flying hours in FY

1 968 to 36.8 accidents per 1 00,000 flying hours

in FY 1 971 . During FY 1 971 , the flying hour

program and number of aircraft in the Army in-

ventory were also reduced.

Of the 1 ,554 mishaps reported, approximately

89 percent, or 1 ,382, occurred in Vietnam. These

mishaps by classification and location are shown

in table 2.

TABLE 2

Types of Mishaps by Location

Classification Total CONUS Vietnan

23 540

25 332

26 1 61

98 349

1 72 1 382

Accidents 563

Incidents 357

Forced Landings 1 87

Precautionary Landings 447

Total 1 554

As shown in table 3, 455 personnel were

injured or killed during this 4-year period. Fa-

tality rates per 1 00,000 flying hours are shown

in figure 2. The overall fatality rate for the

4-year period was 7.56 per 1 00,000 hours.

TABLE 3

Injuries

Location Total Fatalities Injuries

CONUS 1 2 1 1 1

Vietnam 443 92 351

Total 455 93 362

The total cost of all mishaps which resulted

in damage during this period was $31 ,470,000.

Figure 3 shows the total mishap dollar cost,

plus the dollar cost per flight hour, for each fis-

cal year. Approximately 98 percent ($31 ,023,000)

of the total cost resulted from mishaps which

occurred in Vietnam.

Table 4 shows the number of cause factors by

type mishap. Mishap cause factors outnumber

FY 68

RATE

FLYING HOURS

FY 69 FY 70 FY 71

FIGURE 1

Accident Rates Worldwide

TABLE 4

Mishap Cause Factors

All Total

Forced Precautionary

Cause Factors

Mishaps Losses Accidents Incidents Landings Landings

Materiel (fail/mal) 848 1 23 1 30 44 1 68 383

Flight crew

668 169 240 237 8 1 4

Unknown/other 1 44 6

20 1 04 1 1 3

Maintenance 1 04 1 4

20 5 28 37

Supervision 76 28 42 5 1 0

Weather

58 20 16 17 0 5

Facilities 47 1 4 18 13 1 1

Training

21 11 10 0 0 0

Design

1 7 8 7

0 0 2

Ground crew

8

0 3 2 1 2

Command

4 3 1 0 0 0

Total

1 995 396 507 427 208 457

the total reported mishaps. This is usually the

case because mishap investigation often reveals

that more than one cause contributed to the

mishap.

Materiel factors accounted for approximately

42 percent of all causes, and crew errors ac-

counted for approximately 33 percent. If mishaps

which resulted in damage were grouped together

(discount forced and precautionary landings),

cause factors would realign as crew error approx-

imately 49 percent and materiel as 22 percent.

Table 5 shows significant materiel and crew

error causes. Cause factors resulting in major

accidents were, in order of frequency: engine

malfunctions, unsuccessful emergency automa-

tions, practice autorotations, and tail rotor

system malfunctions and strikes (aircraft struck

trees, wire revetments, antennas, etc.). Of the

409 crew accidents (including total losses), 1 94

(48%) resulted from a single phase of operation-

autorotation. There were 95 practice autorotation

accidents and 99 emergency autorotation acci-

dents.

In table 5, the line "antitorque control" refers

to mishaps identified with the warning note in

chapter 8 of TM 55-1 520-21 4-1 0, change 4, con-

cerning abrupt turn maneuvers. The problem,

normally called "tail spins," can result from

<

l-

<

FY 68

RATE

FATALITIES

FY 69 FY 70 FY 71

FIGURE 2

Annual Fatality Rates

TABLE 5

Materiel and Crew Error Causes

Causes Mishaps Losses Accidents Incidents Landings Land

Materiel

Engine system 390 79 89 17 1 1 9 86

Tail rotor system 1 46 32 36 1 3 34 31

Flight controls system 12 6 0 0 3 3

Chip detector lights 1 36 0 0 0 0 1 36

Main rotor system 43 0 3 0 3 37

Battery 43 0 0 5 5 33

Other 78 6 2 9 4 57

Total 848 1 23 1 30 44 1 68 383

Crew

Strikes (trees, wires, etc.) 1 41 27 22 90 0 2

Practice autorotations 1 1 7 10 85 22 N/A N/A

Emergency autorotations 1 04 35 64 5 0 N/A

FOD into main or tail rotor 49 8 5 36 0 0

Improper landing technique 43 9 1 6 18 0 0

Improper takeoff technique 42 6 8 28 N/A N/A

Lost control 41 17 1 3 1 1 0 N/A

Antitorque control (tail spin) 15 10 4 1 0 N/A

Fuel exhaustion 25 10 12 1 2 N/A

Other 91 37 1 1 25 6 1 2

Total 668 1 69 240 237 8 1 4

abrupt right or left turns, performed downwind at

low altitude, low airspeed, and especially when

the aircraft is over maximum gross weight. Right

turns (to the pilot's side) tend to cause the prob-

lem much more often than left turns. When abrupt

uplift is induced on the horizontal stabilizer, a

tendency to spin to the right occurs. An ECP

has been approved to replace the tail rotor blades

(P/N 369A1 71 0) with new all-metal blades (P/N

369A1 61 3). These new all-metal blades have a

1 2

10

i/>

z

2 8

2

\

O

u

<

o

4 --

2 --

1 2,600,000

23.96

2,1 60,000

FY 70 FY 68 FY 69

COST PER FLYING HOURS

C0ST

FIGURE 3

Accident/Incident Dollar Cost

FY 71

"36

n

32

o

H

28

TJ

m

24

70

-n

20 i-

-<

1 6 z

a

1 2 X

o

8

c

73

\

4

o

r

-

r

-

>

50

modified camber, increased chord, and an in-

creased tail rotor thrust of at least 25 percent.

The increased thrust will do much to reduce the

occurrence of the problem, but aviators could

eliminate all of them by avoiding operation with-

in the combination of conditions that creates

the problem.

Table 6 further identifies materiel mishap

causes.

The phase of operation during which the mis-

hap began is shown in table 7. Approximately

66 percent of the mishaps occurred during cruise

flight. When only accidents (including total

losses) are considered, cruise flight remains

predominate at 62 percent. The majority of

cruise flight accidents occurred during low level

flight where there is little margin for error or

inattention.

The period of operation during which the

mishap occurred is shown in table 8.

As expected, the greatest number of mishaps

(92%) occurred during the day. However, the 74

mishaps occurring during twilight hours (dawn

and dusk) are not in proportion to exposure time

and warrant more attention in aviation accident

prevention programs.

TABLE 6

Materiel Sy stem Causes

All Total Forced Prec.

Mishaps Losses Accidents Inci dents Landings Landings

Engine systemtotal 390 79 89 17 119 86

Fuel Control 96 19 17 6 36 18

Bearings

Compressor

FOD

27

23

15

6

3

5

7

11

7

2

0

0

4

2

3

8

7

0

Other 1 04 6 17 2 29 50

Unknown

1 25 40 30 7 45 3

Tail rotor system- -total 1 46 32 36 13 34 31

Drive shaft

45 13 7 8 15 2

Coupling

Blades

25

25

5

1

10

2

2

0

7

3

1

19

Gearbox 17 2 7 1 5 2

Pitch control 5 3 1 0 0 1

Other

11 1 6 1 1 2

Unknown

18 7 3 1 3 4

Main rotor system -total 43 0 3 0 3 37

Transmission 25 0 3 0 3 20

Blades 10 0 0 0 1 9

Dampers

Other

3

5

0

0

0

0

0

0

0

0

3

5

Flight control system-total

Cyclic

Swashplate

Collective

12

3

3

2

6

1

2

1

0

0

0

0

0

0

0

0

3

1

0

0

3

1

1

1

Other

3 1 0 0 2 0

Unknown 1 1 0 0 0 0

All Metal Shor t/

Mishaps Pa rticles Broken W ire Other Unknown

Chip detector lights-total

Main rotor

1 36

73

67

38

13

7

4

2

52

26

Engine

Tail rotor

41

22

18

11

4

2

2

0

17

9

TABLE 7

Phase of Operation

All Total Forced Precautionary

Phase of Fli ght

Mishaps Losses Accidents Incidents Landings Landings

Cruise 1023 184 166 166 122 385

Autorotation 171 16 100 24 27 4

Landing 150 27 27 42 21 33

Takeoff 97 12 19 37 18 16

Static 98 0 9 81 2 6

Hover 8 1 0 5 1 1

Other 7 1 1 2 1 2

Total 1554 241 322 357 187 447

Problem Areas (EIR's). USAAAVS records

indicate that only 360 EIR reports were submitted

against the 848 materiel failures and malfunc-

tions in which EIR's should have been submitted.

This, however, is only a small portion of the

complete EIR picture for the 4 years. Of the

total EIR's submitted against the OH-6A to

USAAVSCOM, those of significant value were

assigned an AVSCOM case number and were

reported as deficiencies in the Department of

the Army Technical Bulletins (TB 750-992

series), "Equipment Improvement Report and

Maintenance Digest." Several of the EIR defi-

ciencies published in the Digest are being re-

peated here for informational purposes and as a

reminder to commanders, supervisors, and main-

tenance personnel of specific OH-6A problem

areas and what corrective actions were taken or

are being taken to eliminate those deficiencies.

For additional detailed information regarding

any of the EIR deficiencies listed below, refer

to the appropriate TB 750-992, referencing the

USAAVSCOM case number.

TITLE: Tail Rotor S/atfes-USAAVSCOM case

number SA-60-1 90-369A1 71 0.

DEFICIENCY: Tail rotor blades cracking. Skin

cracks occur at all locations and fiberglass

bonding separates at leading and trailing edges

of blades.

ACTION TAKEN: An all-metal tail rotor blade

is currently being developed by Hughes Tool

Company. New blades will also improve tail

rotor thrust.

TITLE: Tail Rotor Drive Sfta/fs-USAAVSCOM

case number SA-90-585-369A551 8.

DEFICIENCY: Tail rotor drive shaft shears in

flight, or is found twisted.

ACTION TAKEN: ECP 2672 was approved for

retrofit by attrition through spares replacement

which provides a more rugged drive shaft featur-

ing an increased wall thickness. This shaft is

identified as P/N 369A551 8-601 .

TITLE: Tail Rotor Drive Shaft Couplings-USA-

AVSCOM case number SA-90-070-369A5501 .

TABLE 8

Period of Operation

All

Mishap Classification Mishaps Dawn Day Dusk Night

Total loss accident 241 1 224 6 10

Major accident 322 3 300 12 7

Incident 357 4 330 18 5

Forced landing 1 87 2 1 69 7 9

Precautionary landing 447 3 41 0 18 16

Total 1 554 1 3 1 433 61 47

DEFICIENCY: Tail rotor drive shaft couplings,

P/N 369A5501 , break in flight, resulting in loss

of antitorque control.

ACTION TAKEN:

a. Properly shim drive shaft per TM 55-1 520-

21 4-35, section V, chapter 7, and inspect cou-

plings and drive shafts for damage as specified

in TM 55-1 520-21 4-20, chapter 3, section II,

"Special Inspections."

b. ECP 2672 was approved for retrofit through

attrition by spares replacement which is part of

the more rugged drive shaft assembly.

TITLE: Tail Rotor Transmission-USAAVSCOM

case number SA 80-1 90-369A5401 .

DEFICIENCY: Tail rotor transmission housing

cracks and breaks in flight, allowing output shaft

support section of housing, together with at-

tached output shaft and tail rotor assembly, to

separate from aircraft, resulting in loss of anti-

torque control.

ACTION TAKEN: Cause of broken housings is

generally a result of an unbalanced condition of

tail rotor blades as a result of loss of abrasion

strip. Hughes Tool Company is developing an

all-metal tail rotor blade which should help

eliminate this problem.

TITLE: Tail Rotor 7Yansmi'ssion-USAAVSCOM

case numbers SA 80-020-369A5408 and SA 80-

372-369A5400.

DEFICIENCIES:

a. Tail rotor transmission output shafts, P/N

369A5408, developed axial and/or excess radial

play, generally causing high frequency vibration.

b. Tail rotor transmissions are being prema-

turely removed due to internal failures, normally

indicated by chip detector illuminations.

ACTION TAKEN: ECP 2890 replacement of au-

tomotive type bearings with higher capacity

aircraft quality bearings at next overhaul period

should correct both deficiencies.

TITLE: Support, Pusft-Pu//-USAAVSCOM case

number SA 01 -020-369A3506.

DEFICIENCY: Push-pull support frames, P/N's

369A3506, 369A3507, and 369A3588, were found

to be wearing excessively around push-pull tube

grommets, P/N 369A3509.

ACTION TAKEN: In an effort to reduce tail

boom frame wear, a class II ECP was approved

which adds a 0.020-inch-thick steel doubler to

tail boom frames.

TITLE: Main Transmission-USAAVSCOM case

number SA 70-381 -369A51 67.

DEFICIENCY: Main transmissions of 369A51 00

series are occasionally found contaminated with

water after flying in rain.

ACTION TAKEN: Investigation reveals that

water may enter transmission near top through

transmission seal (369A51 67). A product im-

provement program will be initiated with prime

contractor to develop an improved seal assembly.

TITLE: Main Rotor Blade P/ns-USAAVSCOM

case number SA 05-1 90-369A1 004.

DEFICIENCY: Main rotor blade pins (369A1 004)

are cracking and corroding in pivot area of

handle.

ACTION TAKEN: A product improvement pro-

gram has been initiated with the prime contractor

to redesign this item. During the interim, con-

tinue to inspect pins daily and occasionally

apply a light coat of turbine engine oil to han-

dlebarrel nut mating surface and cam portion

of handle. Do not oil expanding bushing portion.

TITLE: Main Rotor P/acfes-USAAVSCOM case

number SA 05-020-369A1 1 00.

DEFICIENCY: Main rotor blades (369A1 1 00)

eroding at leading edges, sometimes to the point

where brass weights are visible.

ACTION TAKEN: Apply or reapply antierosion

tape per TM 55-1 520-21 4-30, section II, chapter

8, whenever operating in rain or an abrasive

environment.

TITLE: Rotor Sysfems-USAAVSCOM case num-

ber SA 50-790-369A1 400.

DEFICIENCY: Complaints have been received

concerning rotational drag check on main rotor

dampers. Available breakaway type torque

wrenches are not effective in this application.

ACTION TAKEN: TM 55-1 520-21 4-20, paragraph

8-8b(3), will be changed to require a dial type

torque wrench for this check. Torque wrench,

FSN 51 20-288-8865, has been established as a

special tool for the OH-6A and should be requisi-

tioned by all units supporting OH-6A helicopters.

TITLE: Oil Pressure Senders-USAAVSCOM case

number SA 09-374-369A4534.

DEFICIENCY: Inaccurate oil pressure readout

attributed to defective or internal failure of oil

pressure sender, P/N 369A4534.

ACTION TAKEN: The oil pressure sending unit

has been redesigned, eliminating calibration

provisions of oil unit. A PIP program will be

initiated to reinstate a means of calibration. In

the interim, when installing a new (black) sender

and the cockpit gauge is known to be good,

scrape black paint of sender body at grounding

strap to insure a good ground and hook a direct

reading gauge into oil system. Keep trying dif-

ferent senders until one is found where toler-

ances of gauge and sender cancel each other

and cockpit readout is reasonably accurate.

TITLE: Blower Scro/Js-USAAVSCOM case num-

ber SA 07-1 90-369A5306.

DEFICIENCY: Blower scroll assemblies of

369A5306 series are cracking, mainly at attach-

ing points.

ACTION TAKEN: Cracking and cold-flow of

plastic parts at attachment points are generally

indications of fastener overtorque. Also, the

prime contractor has found this type of plastic

susceptible to damage by hot turbine engine oil

and is in the process of developing a suitable

coating. This coating will be incorporated on

subsequent spare parts.

TITLE: Engine Power-Out Warning Unit-USA-

AVSCOM case number SA 09-374-26530332.

DEFICIENCY: Engine power-out warning unit

(26530332) becomes unserviceable due to intern-

al failure.

ACTION TAKEN: The prime contractor is cur-

rently developing an improved engine-out warning

which provides an earlier indication, coupled

with an automatic restart device.

TITLE: Fuel Quantity Transmitters-USAAVS-

COM case number SA 09-374-369A4245.

DEFICIENCY: Internal failures of fuel quantity

transmitters of 369A4245 series, usually de-

tected by erroneous low fuel light illumination.

ACTION TAKEN: Failures are mainly attribut-

able to shorting, caused by wetting unit with

water, and to corrosion. The prime contractor

has developed a -603 version of the 369A4245

tank unit which has sealant applied to cover

terminals and wiring to eliminate shorting and

corrosion. New version will be implemented on

an attrition basis. As an interim fix concerning

this matter, refer to the above USAAVSCOM case

number in change 1 of TB 750-992-4, dated

July 1 971 .

TITLE: Fuel Shut-Off Valve Control-USAAVS-

COM case number SA 1 0-497-369A81 36.

DEFICIENCY: Fuel shut-off valve control as-

sembly rusts at cockpit end and becomes im-

movable or fails to actuate shut-off valve from

full off to full on.

ACTION TAKEN: The prime contractor is cur-

rently redesigning entire fuel system. In the

interim, lubricate and rig control assembly per

TM 55-1 520-21 4-20, section V, chapter 5. Check

and cycle daily.

TITLE: Helicopter (OH-6A)-\JSAAVSCOM case

number SA 01 -381 -369A2030-1 .

DEFICIENCY: Water has been accumulating in

fuel tank cover (369A81 30), creating corrosion

problems.

ACTION TAKEN: Adding a gasket between the

access cover, P/N 369A2030-1 , and the cargo

floor will eliminate water entry.

TITLE: Oil Coo/er-USAAVSCOM case number

SA 07-381 -369A8302.

DEFICIENCY: Oil cooler assembly leaks, main-

ly at inlet boss.

ACTION TAKEN: Leaks are generally the result

of twisting inlet hose when removing/installing

mating check valve. Use special wrench (VS-

5236) when performing this operation and follow

procedures contained in TM 55-1 520-21 4-35,

section IV, chapter 5.

TITLE: Overrunning Clutch-USAAVSCOU case

number SA 04-381 -369A5350.

DEFICIENCY: Overrunning clutches of 369A-

5350 series are leaking oil at output shaft, some-

times followed by smoke in cabin and shearing

of output shaft.

ACTION TAKEN: Previously, oil leaking past

engine shaft seals (6854086) would fill clutch

housing until oil would leak out top of clutch.

This oil would wash grease out of bearing

(R20FOILO), causing it to overheat and shear

output shaft. TB 55-1 520-21 4-20/38, dated 29

September 1 970, was issued to correct this un-

satisfactory condition.

TITLE: Landing Gear Dampers-USAAVSCOM

case number SA 02-374-369A6300.

DEFICIENCY: Landing gear dampers of 369A-

6300 series are experiencing internal failures

characterized by collapsing or extending beyond

normal limits.

ACTION TAKEN: The contractor is currently

redesigning dampers to increase service life

and correct current deficiencies.

TITLE: Damper Assembly-Landing Gear-USA-

AVSCOM case number SA 02-247-369A6300-501 .

DEFICIENCY: Dampers were being received in

the field with ears of cap assemblies at 90

angles to each other. Ears must be parallel for

proper installation of damper assembly.

ACTION TAKEN: Landing gear damper assem-

blies received in above condition can be cor-

rected by attaching lower end of damper to

landing gear strut as directed by TM 55-1 520-

21 4-30, change 3, page 4-32A. Insert bolt into

top mounting bearing hole and turn strut clock-

wise until cap assembly ears are parallel. Strut

should be turned clockwise to prevent loosening

of end caps on damper.

TITLE: HorizontalStabilizer-\JSAAVSCOM case

number SA 01 -070-369A3600.

DEFICIENCY: Outboard sections of horizontal

stabilizers of 369A3600 series tear off in flight.

ACTION TAKEN: Structural failure of these

stabilizers is the result of vibration-induced

fatigue, resulting mainly from tail rotor imbal-

ance. Under a product improvement program, the

contractor has designed a new strut to replace

the present 369A2001 strut. In the interim, main-

tain tail rotor balance per TM 55-1 520-21 4-35,

section III, chapter 8, and emphasize stabilizer

and strut check on each preflight as required by

TM 55-1 520-21 4-1 0, chapter 3, section II.

TITLE: Lower Vertical Stabilizer-USAAVSCOM

case numbers SA 01 -750-369A3650 and SA 01 -

730-369A3650.

DEFICIENCY: ABC adjustable bolts presently

used in mounting holes of lower vertical stabi-

lizers of 369A3650 series allow stabilizers to

vibrate, resulting in failure of ABC bolts and

in-flight loss of the stabilizer.

ACTION TAKEN: MWO 55-1 520-21 4-30/36 was

initiated for correction of this problem.

TITLE: Troop Seat and Harness Fitting-USA-

AVSCOM case number SA 1 7-020-369A3037/9.

DEFICIENCY: Troop seat and shoulder harness

fittings on airframe (369A3037-1 , -2 and 369A-

3039-1 , -2) are wearing out since mating seat

and harness fittings are of harder metal. Re-

placement parts could not be obtained through

supply.

ACTION TAKEN: These fittings have been

resource coded and can now be requisitioned

and replaced. Refer to TM 55-1 520-21 4-34P.

Selected Accident Briefs

ACCIDENT NO. 1 -Aircraft was flying in mar-

ginal weather on a mission to carry maps and

other papers. Pilot called for and received

special VFR clearance to a field. Weather was

reported as -XM1 7 + 1 SW. Before arrival at the

field, light snowshowers were encountered.

Navigation to the field and over a GCA unit was

accomplished. By this time, the light snow-

showers had turned heavy and the aircraft was

at 1 5-20 feet and 20-30 knots. The pilots de-

cided to land near the GCA unit and in doing so

all visual reference was lost due to blowing

snow. Both pilots experienced vertigo and the

aircraft hit hard with a slight rearward motion

and left side low. The two pilots sustained

minor injuries and the aircraft was destroyed.

The primary cause factor was listed as loss of

ground contact due to heavy snowshowers and

blowing snow from rotorwash. Suspected factors

were a 30 wind shift, pilot disorientation, not

making a go-around, and pilot's inexperience.

Editor's note: Was this trip really necessary?

Hardly, with snow and icing conditions, inex-

perienced pilots, and an aircraft not IFR in-

strumented.

ACCIDENT NO. 1-Both pilots experienced vertigo in blowing snow.

mM^w^$i:

ACCIDENT NO. 2-Two aircraft responding to

a distress call (a land vehicle had hit a mine

and personnel were injured) tried to occupy the

same space at the same time. One aircraft was

flying at 1 00 feet in a right turn looking for the

vehicle. The second aircraft approached the

zone in a fast descending right turn and a colli-

sion occurred. There were five fatalities and

both aircraft were destroyed. Caused by failure

of both pilots to properly clear themselves.

Editor's note: The day was absolutely clear,

too!

ACCIDENT NO. 3-One aircraft in a flight of

two radioed that trouble existed in controlling

excessive engine rpm. For 1 0 minutes this

excessive engine rpm problem continued when

finally the pilot said, "I think I just lost every-

thing." Witness statements indicated that the

engine and rotor had revved up. This was fol-

lowed by relative silence. The main rotor

severed the tail boom and the aircraft fell from

approximately 1 ,500 feet, spinning clockwise,

nose low and erratic. Ground impact showed the

rotor to be nearly, if not completely, stopped.

Pilot was killed and aircraft was destroyed.

Fuel control malfunction caused an overspeed,

but the- pilot failed to land following numerous

indications of a malfunction. Suspect failure of

main rotor dynamic stop or control system com-

ponent caused tail boom chop.

Editor's note: 1. ARADMAC analysis did

not agree with the conclusion that engine had

oversped. It was concluded that the turbine

wheels did not exhibit overspeed stretching.

They recommended that castellated type nuts

(with cotter pin) be used on the power turbine

governor and fuel control adjusting levers.

2. We suspect there was some overspeed and

the pilot used high rotor blade pitch angle to

minimize the rotor overspeed. The engine quit

or was stopped immediately followed by gross

blade stall, coupled with a large alt cyclic input

that caused the tail boom chop and practically

stopped the blades.

ACCIDENT NO. 4-Aircraft departed on staff

reconnaissance mission. It was later seen to be

descending at about a 30 angle. It crashed in

a wooded area, exploded, and burned. The four

occupants were killed. Suspect aircraft was in

autorotation due to some failure, perhaps a fuel

control or tail rotor malfunction.

ACCIDENT NO. 5-Aircraft lifted off ship about

1 925 hours with four people aboard. Surviving

witness indicated they took off straight up,

turned 90 to the right, accelerated forward, and

struck the water about 500 meters from the ship.

Two occupants were killed, one sustained major

injuries, and one is missing. Aircraft was

destroyed. Suspect marginal weather obscured

horizon and pilot, inexperienced in night ship-

board operations, allowed disorientation to occur.

Editor's note: Shipboard night operations at

upper limit gross weights with marginal weather

conditions are demanding of even the most ex-

perienced aviators. Untrained aviators should

not be used.

1 0

ACCIDENT NO. 6-Gunner was dropping frag-

mentation grenades from aircraft in attempt to

destroy footbridge. Explosion occurred in

passenger compartment and compartment was

engulfed in flames. Explosive force knocked

pilot's feet off pedals and broke out chin bubble.

Emergency landing was made and pilot and

observer escaped. Aircraft was consumed by

fire with the gunner still in his seat. There

was one fatality and one major injury. Aircraft

was destroyed. Caused by gunner dropping live

grenade on passenger compartment floor.

ACCIDENT NO. 7-Pilot accepted aircraft from

maintenance and was returning it to his parent

organization. Shortly after takeoff about 1 730

hours, aircraft struck guy wire attached to 400-

foot radio tower and disintegrated. The three

occupants were killed. Suspect pilot was not

familiar with the location of the towers and that

the angle of the sun caused sun blindness.

ACCIDENT NO. 8-Aircraft was flying low level

down highway and hit lambretta. Damage to

ACCIDENT NO 4-Ttie four occupants of this aircraft were

killed.

lambretta and injury to passengers are unknown.

Major damage to aircraft. Caused by unneces-

sary low-level flight.

ACCIDENT NO. 9-Pilot accepted aircraft with-

out visually checking amount of fuel aboard.

Fuel quantity gauge was known to be inaccurate.

Sometime into the mission, pilot reported- 80

pounds of fuel remaining, after which he flew for

approximately 5 minutes, then landed for 2-3

minutes. This time he reported 40 pounds of

fuel and took off heading home. The flight home

was at 90 knots low level. Engine stopped just

after cyclic climb to clear row of trees. Pilot

entered autorotation and aircraft hit nose low on

left side at an estimated 30-50 knots. There

were two fatalities and one major injury. Air-

craft was destroyed. Caused by improper pre-

flight, improper judgment in taking off with 40

pounds of fuel, and unnecessary and erratic low

level flight. Suspect insufficient autorotation

training. Recommendations were: (1 ) Terminate

flight with 40 pounds of fuel indicated, (2) a

flight time limit based on engine time, and

(3) emphasize autorotational proficiency.

ACCIDENT NO. 1 0-Aircraft landed and crew

chief and observer exited. Pilot frictioned down

the collective control and exited. Aircraft lifted

off the ground and tilted forward. Main rotor

blade struck pilot in the chest, causing major

injuries. Aircraft came to rest against revet-

ment. While being sling loaded, OH-6A began

to oscillate, was released, crashed and burned.

Cause of accident was listed as unknown.

ACCIDENT NO. 1 1 -Aircraft was one of a flight

on an early morning mission. About 1 0 minutes

after launch, pilot called and reported his engine

chip detector light was on and that he was re-

turning to base. The last radio transmission

heard was that the TOT was "out of sight,"

aircraft was vibrating severely, and that he in-

tended to land at the closest helipad. A witness

stated that he saw the aircraft circling with the

landing light on and that flames were coming

out the rear. The flames stopped and the engine

quit. The aircraft hit a 60-foot tree, crashed into

a hut, and sank in about 8 feet of water. The

three occupants were killed and the aircraft was

destroyed. The second stage compressor rotor

blade fractured from fatigue, causing engine

1 1

failure. Suspect No. 2 main bearing froze, cre-

ating vibrations and fatigue of rotor blade. Pilot

pulled pitch extremely high, causing low rotor

rpm.

Editor's note: The investigation revealed

there were other landing areas safer than the one

selected. Body identification was hindered be-

cause dog tags were not worn.

ACCIDENT NO. 1 2-Weather was below mini-

mums for takeoff from LZ, and the en route and

destination weather was unknown to the pilot.

He took off and disappeared through a small

hole in the clouds. He reported clear at 1 ,700

feet and then later transmitted a Mayday call

that he had lost control. Aircraft was next seen

at 90 feet where the tail boom separated. Right

spin developed and ground impact was near

vertical and hard. Pilot sustained major injuries

and aircraft was destroyed. Investigation re-

vealed that the pilot experienced vertigo and

panicked. When the aircraft broke out of the

clouds, the pilot abruptly lowered collective

and made a right rear cyclic movement. The

main rotor blades severed the tail boom. Pilot

failed to maintain VFR in an aircraft not

equipped for IFR.

ACCIDENT NO. 1 3-Aircraft was in cruise flight

when tail rotor drive shaft failed. Tail boom

chop occurred and aircraft crashed and burned.

Pilot was killed. Suspect incorrect torquing

resulted in broken drive shaft and improper

cyclic input chopped tail boom.

ACCIDENT NO. 1 4-In-flight fire occurred during

maintenance test flight and aircraft crashed.

Pilot and two passengers died of burns. Aircraft

was destroyed. Suspect gasket/seal for fuel

tank access cover was leaking due to improper

maintenance. Two passengers should not have

been on board during test flight.

ACCIDENT NO. 1 5-Engine stopped while air-

craft was on low turning approach to landing.

Aircraft crashed into trees and was destroyed.

One occupant was killed and two sustained major

injuries. A blade of the engine turbine assembly

broke. Hot start was listed as the cause for

the blade failure.

ACCIDENT NO. 1 6-Tail. boom separated in

cruise flight at 200 feet. Aircraft crashed and

was destroyed. Pilot sustained minor injury.

Cause unknown.

ACCIDENT NO. 1 7-Aircraft struck trees during

low-level flight, crashed, and burned. The two

crewmembers were killed. Caused by chan-

nelized attention. Suspect supervisor ordered

flight beyond capability of aviators.

ACCIDENT NO. 1 8-Engine stopped in straight

and level flight at 1 ,000 feet and pilot entered

ACCIDENT NO. 6-Gunner dropped live grenade on passenger compartment floor.

1 2

autorotation. During approach for touchdown,

incorrect collective control (abrupt down) and

excessive lateral controls were used. Aircraft

struck ground, rolled over, and was destroyed.

Observer was killed when his head hit the ar-

mored seat. Engine stopped because of fuel

exhaustion.

Editor's note: The pilot factors read as:

faulty flight plan, violation of flight discipline

and navigation error, cold wind blast, and over-

confidence. Fatigue and sleep deprivation were

suspected.

ACCIDENT NO. 1 9-Aircraft was making steep,

low-level turn. Pilot applied abrupt up collec-

tive and excessive g forces resulted. Aircraft

struck boulders and burned. One occupant was

killed and the other sustained major injuries.

Pilot selected wrong course of action and failed

to use accepted procedures. Suspect supervisor

ordered flight beyond capability of aviator.

ACCIDENT NO. 20-While aircraft was on the

ground loading and unloading passengers,

another person not boarding aircraft walked into

tail rotor and was decapitated. Caused by inat-

tention and failure to use accepted procedures.

ACCIDENT NO. 21 -Tail rotor drive shaft

sheared during climbing turn. Directional con-

trol was ineffective for touchdown and aircraft

hit hard and was destroyed. There were four

minor injuries. The wind caught unsecured

poncho arid blew it out of aircraft into tail

rotor shaft.

ACCIDENT NO. 22-In response to a request by

the battalion sergeant major, aircraft was to

assist in raising a 25-foot flagpole adjacent to

the operations center. The intent of the maneu-

ver was to raise the flagpole from an inclined

position to an upright position by use of ropes

held in the cockpit. Upon reaching high hover,

aircraft shuddered violently, crashed, and was

destroyed. There were two major injuries and

one minor injury. Accident report stated: "Main

rotor blades came in contact with an obstacle"

i.e., the flagpole.

ACCIDENT NO. 23-Aircraft was at approxi-

mately 600 feet turning right base for landing

when engine stopped. Pilot took controls from

passenger, an E4, and attempted to enter auto-

rotation. Entry to autorotation was somewhat

late and rotor rpm was not regained. Exag-

ACCIDENT NO. 7Aircraft struck guy wire attached to 400-foot radio tower.

1 3

gerated flare allowed tail rotor to strike ground

and aircraft crashed and burned. Pilot and

passenger sustained major injuries. Reason for

engine stoppage is pending analysis.

ACCIDENT NO. 24-Aircraft was shutting down

on landing pad when flight of UH-lH's landed

close by. Decelerating rotor blades dipped down

and severed tail boom. Rotorwash from UH-1 H

flight upset OH-6A rotor blades and caused tail

boom chop.

ACCIDENT NO. 25-Fifteen-minute flight was

made after passenger refueled aircraft. After

another passenger was embarked, engine stopped

at an unspecified altitude at 30 knots during

takeoff. Aircraft landed hard, rolled over, and

was destroyed. There were two major injuries

and one minor injury. Suspect fuel contami-

nation.

ACCIDENT NO. 26-Aircraft lost power during

low-level recon mission. From 50 feet and 60

knots, pilot attempted to maneuver through dead

trees to small stream clearing. Tail boom struck

dead tree and aircraft crashed slightly nose low

and rolled over. Fuel cell ruptured upon impact

and pilot was pinned in aircraft when it rolled

over. Valiant efforts by crewmembers freed pilot.

Shortly thereafter, spilled fuel ignited and burned

wreckage. There was one major and two minor

injuries. Cause of engine failure is unknown.

ACCIDENT NO. 27-Engine quit at approximately

400 feet during takeoff climb. Passenger

blocked flight controls during autorotation and

aircraft touched down hard. Landing gear strut

broke and severed fuel hose, resulting in post-

crash fire. Aircraft was destroyed. Two occu-

pants were killed and one sustained major in-

juries. Main bearing failure caused engine

stoppage. Suspect passenger panicked.

ACCIDENT NO. 28-After refueling, aircraft

took off to 6- to 7-foot hover, with gross weight

of 2,542 pounds. Pilot attempted 1 80 left turn

from hover and lost control. Aircraft crashed,

rolled over, and burst into flames from ruptured

fuel cell. Two major injuries and one minor

injury resulted. Cause was listed as overgross

weight.

Editor's note: The high hover, over alternate

gross weight, and extra power demands of a left

turn indicate that power required exceeded

power available.

ACCIDENT NO. 29-Aircraft started running into

ACCIDENT NO. 9-Result of improper preflight, low fuel, and unnecessary and erratic low level flight.

1 4

small patches of low clouds about midfield on

downwind leg for landing at airport. Descent

did not clear clouds and pilot started left turn.

Aircraft was now in the clouds and attitude

indicator didn't appear to work. Aircraft came

out of clouds in a diving turn. A flare appeared

to be conducted at about 1 50 feet, followed by

impact on PSP taxiway. Initially, aircraft

skidded 83 feet, then became airborne again for

about 1 00 feet. Pilot remembers spinning. After

second impact, aircraft traveled approximately

250 feet airborne, impacted into side of parked

C-47, and was destroyed. Pilot sustained major

injuries. Pilot experienced vertigo in the clouds

and was in an unrecoverable attitude coming

out of the clouds.

ACCIDENT NO. 30-Pilot was hovering to refuel

when he heard loud noise and experienced com-

plete loss of directional control. Aircraft began

to spin in clockwise direction. Pilot closed

throttle and made hovering autorotation. Aircraft

rotated about two and one-half times before it

struck the ground, with major damage. Failure

of forward flexible coupling of tail rotor drive

assembly was caused by corrosion and possible

improper shimming.

ACCIDENT NO. 31 -During low-level cruise

flight, aircraft began right turn, became uncon-

trollable, crashed, and was destroyed. One

occupant was killed and two sustained major

injuries. Cause undetermined.

ACCIDENT NO. 32-Hard landing at conclusion

of practice touchdown autorotation severed tail

boom. Caused by pilot applying collective

pitch too early.

ACCIDENT NO. 33-While cruising low level to

remain clear of low clouds, aircraft struck wire,

crashed, and burned. There were two fatalities.

Caused by low-level flight in limited visibility

conditions and possible distraction or inat-

tention.

ACCIDENT NO. 34-IP was demonstrating

straight-in practice autorotation. Aircraft hit

on heels of skid and main rotor blades flexed

down and severed tail boom. IP misjudged alti-

tude and had excessive aft cyclic applied at

initial contact.

Selected Incident Briefs

Man walked into main rotor blades and was

killed.

Sudden gust of wind caused hovering helicopter

to drift into water tower.

Pilot was observing results of WP grenade

thrown by his observer and flew into tree.

During shutdown, USMC CH-46 hovered nearby

and rotorwash caused blade to flap down and

strike tail boom.

During shutdown, gust of wind caused main

rotor blades to flex down and strike tail boom.

Pilot started engine with one main rotor blade

tiedown still attached.

Pilot smelled smoke in cruise flight. Investi-

gation revealed part of the battery was burned

and charred. Results are pending analysis.

Aircraft was shutting down when person stand-

ing on nearby revetment slipped, fell into rotor

blades, and was killed.

Tail rotor struck trees during low-level cruise

flight.

Pilot was cruising low level when main rotor

blades hit pole. Pilot was distracted by bright

light.

Main rotor blades struck trees during low-level

cruise flight.

Aircraft vibrated severely during cruise flight.

Tail rotor drive shaft sheared from an undeter-

mined cause and skids were damaged during

touchdown.

Pilot landed on PSP for passenger pickup.

During takeoff, right skid hooked PSP and nose

pitched down. Pilot pulled aft cyclic, added

power, and skid separated from aircraft. Pilot

later landed on sandbags.

1 5

Selected Forced Landing Briefs

Engine ran rough during initial start. It was

shut down and no mechanical difficulty was

found. When aircraft reached 1 ,000 feet after

takeoff, engine quit. Fuel was contaminated

with water.

Amperage exceeded limits and pilot secured

battery and generator switches. Cockpit filled

with smoke and pilot landed. Caused by voltage

regulator failure.

Pilot smelled smoke during climbout and ini-

tiated landing. At 1 0 feet, overrunning clutch

failed.

Pilot was making low-level practice autorota-

tion. Zoom climb was initiated and throttle

rolled to flight idle. Engine quit and actual

autorotation resulted. Fuel control linkage had

not been properly adjusted.

Engine and tail rotor drive shaft failed almost

simultaneously during cruise flight. Pilot auto-

rotated successfully. Cause of engine and tail

rotor drive shaft failure is undetermined.

Engine stopped during autorotation. Cause

unknown.

Aircraft was on final at 600 feet and 60 knots

when tail rotor drive shaft sheared. Pilot flew

aircraft home and made running landing.

Selected Precautionary Landing Briefs

Throttle froze during takeoff. Caused by dirt.

Pilot heard loud noise and felt severe vibra-

tions. Tail rotor tip came off.

Pilot thought he had experienced tail rotor

failure because of restricted directional control

and landed to investigate. Minigun brass was.

found under tail rotor control pedals. Brass was

removed and mission continued.

Battery shorted out in cruise flight and part of

battery burned.

All emergency warning system lights illumi-

nated during flight. Battery rack/mount had

broken, allowing battery to short out.

Fuel quantity gauge went to zero during flight

and pilot landed. Gauge malfunctioned.

TOT started to rise, power was reduced, and

pilot landed. Reason for high TOT is unknown.

Transmission chip detector light came on.

Metal particle was found on magnetic plug.

1 6

FOR FURTH UR INFORMATION CONCERNING DISTRIBUTION CALL (703) 767-8040

PLEASE CHECK THE APPROPRIATE BLOCK BELOW:

AQ#

copies are being forwarded. Indicate whether Statement A. B. C. D. E, F. or X applies.

ST

D

D

D

D

D

D

D

D

D

DISTRIBUTION STATEMENT A:

APPROVED FOR PUBLIC RELEASE: DISTRIBUTION IS UNLIMITED

DISTRIBUTION STATEMENT B:

DISTRIBUTION AUTH ORIZED TO U.S. G OVERNMENT AG ENCIES

ONLY; (Indicate Reason and Date). OTH ER REQUESTS FOR TH iS

DOCUMENT SH ALL BE REFERRED TO (Indicate Controlling DoD Office).

DISTRIBUTION STATEMENT C:

DISTRIBUTION AUTH ORIZED TO U.S. G OVERNMENT AG ENCIES AND

TH EIR CONTRACTORS; (Indicate Reason and Date). OTH ER REQUESTS

FOR TH IS DOCUMENT SH ALL BE REFERRED TO (Indicate Controlling DoD Office).

DISTRIBUTION STATEMENT D:

DISTRIBUTION AUTH ORIZED TO DoD AND U.S. DoD CONTRACTORS

ONLY; (Indicate Reason and Date). OTH ER REQUESTS SH ALL BE REFERRED TO

(Indicate Controlling DoD Office).

DISTRIBUTION STATEMENT E:

DISTRIBUTION AUTHORIZED TO DoD COMPONENTS ONLY; (Indicate

Reason and Dats). OTHER REQUESTS SHALL BE REFERRED TO (Indicate Controlling DoD Office).

DISTRIBUTION STATEMENT F:

FURTHER DISSEMINATION ONLY AS DIRECTED BY (Indicatj Controlling DoD Office and Date) or HIGHER

DoD AUTHORITY

DISTRIBUTION STATEMENT X:

DISTRIBUTION AUTHORIZED TOL'S GOVERNMENT AGENCIES

AMD PRIVATE INDIVIDUALS OR ENTERPRISES ELIGIBLE TO OBTAIN EXPORT-CONTROLLED

TECHNICAL DATA IN ACCORDANCE W ITH boDDIRECTIVE 5230.25. W ITH H OLDING OF

UNCLASSIFIED TECHNICAL DAT UROM PUBLIC DISCLOSURE. 6 Nov 1 9S4 (indicate dace of determination).

CONTROLLING DoD OFFICE IS (Indicate Controlling DoD Office).

This document was previously forwarded to DTICon (date) and the

AD number is

[ n accordance with provisions of DoD instructions, the document requested is not supplied because:

llwill be published at a later date. (Enter approximate date, if known).

Other. (G ive Reason)

DoD Directive 5230.24, "Distribution Statements on Technical Documents," l8Mar 87,contalns seven distribution statements, as

described briefly above. Technical Documents must be assigned distribution statements.

y J i ] / Print or Type Name

' ~~-r . ' ' / - A

I l;f/S-~J'' '- /'

U

-' C j/y y &&'?> J " l- I i- y

/

ulriariisd SignaturslData Telephone Number

You might also like

- Airworthiness and Flight Characteristics of The JOH-6A Light Combat Helicopter Configured With A Wire Strike Protection SystemDocument52 pagesAirworthiness and Flight Characteristics of The JOH-6A Light Combat Helicopter Configured With A Wire Strike Protection Systemrobbertmd100% (1)

- The History and Developments of Martin-Baker Ejection SeatsDocument53 pagesThe History and Developments of Martin-Baker Ejection SeatsBobby Chipping100% (1)

- TM 55 1520 400 14Document227 pagesTM 55 1520 400 14Tod A. Wulff100% (1)

- Navair 01-1a-17Document204 pagesNavair 01-1a-17daymonNo ratings yet

- NAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFDocument113 pagesNAVAIR 01-250HDB-1B CH-46D.CH-46F & CH-46D Pocket Checklist (15 June 1970) PDFBlaze123xNo ratings yet

- AV-8B Harrier Assault ManualDocument85 pagesAV-8B Harrier Assault Manualวัฒกิจ มะลิทอง100% (1)

- M-2000C RWR Threat CodesDocument3 pagesM-2000C RWR Threat CodesDave91No ratings yet

- Aargm Data Sheet - Afpr 08-629Document2 pagesAargm Data Sheet - Afpr 08-629sd_hosseini_88100% (1)

- TM 9 1265 373 10 1 HR PDFDocument14 pagesTM 9 1265 373 10 1 HR PDFMilan PitovicNo ratings yet

- Mil HDBK 684Document431 pagesMil HDBK 684Kaung MyatNo ratings yet

- روغن کاری j79 PDFDocument17 pagesروغن کاری j79 PDFemadNo ratings yet

- FM 44-8 Combined Arms For Air DefenseDocument69 pagesFM 44-8 Combined Arms For Air DefenseMike MayrosNo ratings yet

- V-22 Osprey - A Tiltrotor AircraftDocument12 pagesV-22 Osprey - A Tiltrotor AircraftHa Nam TranNo ratings yet

- TM 9-1325-202-50-1 Dispenser & Bomb CBU 1, 2, 3, 9, 12, 26 (May 1967)Document47 pagesTM 9-1325-202-50-1 Dispenser & Bomb CBU 1, 2, 3, 9, 12, 26 (May 1967)Jonn DoughNo ratings yet

- 052892Document84 pages052892starsalingsoul8000No ratings yet

- FF Natops Mirage IIIDocument38 pagesFF Natops Mirage IIIgiuliva67100% (2)

- TM 10-4930-238-12PDocument180 pagesTM 10-4930-238-12PAdvocateNo ratings yet

- Tü-Olo-Abq: An Aerodynamic Database For The MK 82 General Purpose Low Drag BombDocument36 pagesTü-Olo-Abq: An Aerodynamic Database For The MK 82 General Purpose Low Drag BombvishalwinsNo ratings yet

- SA 2E English Advanced V1Document17 pagesSA 2E English Advanced V1CCAV13100% (1)

- AFI11 2A OA 10V1 Aircrew TrainingDocument86 pagesAFI11 2A OA 10V1 Aircrew TrainingTim MorganNo ratings yet

- TR M-70-4 - Off-Road Mobility of 6-Wheeled and 4-Tracked Vehicles in Selected Terrain (Technical Report) - 1970Document218 pagesTR M-70-4 - Off-Road Mobility of 6-Wheeled and 4-Tracked Vehicles in Selected Terrain (Technical Report) - 1970Martin Whitener100% (1)

- T.O. 14p4-15-1 Mcu-2 Series Mask May 2003Document76 pagesT.O. 14p4-15-1 Mcu-2 Series Mask May 2003GLOCK35No ratings yet

- NACA P-51X Wing Data With Various Trailing Edge ModificationsDocument54 pagesNACA P-51X Wing Data With Various Trailing Edge ModificationsavialogsNo ratings yet

- NACA P51 Intermediate Wing Section DataDocument19 pagesNACA P51 Intermediate Wing Section Dataavialogs100% (1)

- Rocket Study - Lesson Learned Vietnam 1968Document45 pagesRocket Study - Lesson Learned Vietnam 1968FrancescoNo ratings yet

- Composhield Add-On ArmorDocument2 pagesComposhield Add-On ArmorSanjay MehrishiNo ratings yet

- SAAB 35 Draken 3.0 Flight ManualDocument80 pagesSAAB 35 Draken 3.0 Flight Manualrpiereck100% (2)

- TM 9-2350-247-20-1 PDFDocument871 pagesTM 9-2350-247-20-1 PDFsergey62No ratings yet

- Aircrew Survival Equipmentman 2: NAVEDTRA 14218Document388 pagesAircrew Survival Equipmentman 2: NAVEDTRA 14218byrd_manNo ratings yet

- Tank Combat Full Tracked 105 MM Gun M60ADocument91 pagesTank Combat Full Tracked 105 MM Gun M60ATenshiJibril50% (2)

- 3710 7uDocument457 pages3710 7uRichard LundNo ratings yet

- AFI11 2A OA 10V3 Operations ProceduresDocument100 pagesAFI11 2A OA 10V3 Operations ProceduresTim MorganNo ratings yet

- Wire Strike Protection System (Helicopter)Document2 pagesWire Strike Protection System (Helicopter)Amy KlezanNo ratings yet

- M1a1 PDFDocument111 pagesM1a1 PDFmetal69100% (1)

- Ejection Seat ReportDocument23 pagesEjection Seat ReportAkhil Anand100% (1)

- Fire Commands For The M1 TankDocument295 pagesFire Commands For The M1 TankbinkyfishNo ratings yet

- AFI11 2A OA 10V2 Aircrew EvaluationDocument54 pagesAFI11 2A OA 10V2 Aircrew EvaluationTim MorganNo ratings yet

- Silent Knight RadarDocument9 pagesSilent Knight RadarThinkDefence100% (2)

- Aircraft OrdnanceDocument78 pagesAircraft OrdnancemariA ANNA100% (1)

- M39 A2 A3Document2 pagesM39 A2 A3jfman100% (1)

- TM 9-2350-230-35 - 2Document435 pagesTM 9-2350-230-35 - 2Jason GreenNo ratings yet

- F 16 Platform BrochureDocument16 pagesF 16 Platform BrochureNick Numlk50% (2)

- T 33 Pitot Static Calibration Technical Report AFFTCDocument35 pagesT 33 Pitot Static Calibration Technical Report AFFTCRadunNo ratings yet

- Pressure Wiring PDFDocument51 pagesPressure Wiring PDFDinesh meemanageNo ratings yet

- Technical Manual of AH 1FDocument333 pagesTechnical Manual of AH 1FNauman Haider Toor100% (1)

- TM 11-5895-474-20P An/tsq-71aDocument25 pagesTM 11-5895-474-20P An/tsq-71aAdvocateNo ratings yet

- TACTS Pod EvolutionDocument16 pagesTACTS Pod EvolutionArthur BarieNo ratings yet

- TM 55 1520 236 23 2 PDFDocument1,029 pagesTM 55 1520 236 23 2 PDFLIVE3ORDIENo ratings yet

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocument361 pagesUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- 1978 - 1512Document1 page1978 - 1512Leovard69No ratings yet

- E-3 Operation ProceduresDocument63 pagesE-3 Operation ProceduresFabian TorresNo ratings yet

- TM 9 2320 366 10 HRDocument37 pagesTM 9 2320 366 10 HRfuckuintheassscribdNo ratings yet

- NTSP Agm 88 HarmDocument79 pagesNTSP Agm 88 HarmBlaze123xNo ratings yet

- Tactical Aircraft Aerodynamic IntegrationDocument14 pagesTactical Aircraft Aerodynamic Integration이승진100% (1)

- Military Searchlight Truck (1937)Document8 pagesMilitary Searchlight Truck (1937)CAP History LibraryNo ratings yet

- Thank You.: Texstars, Inc. TEL: 972.647.1366 FAX: 972.641.2800Document24 pagesThank You.: Texstars, Inc. TEL: 972.647.1366 FAX: 972.641.2800Balwinder GherhaNo ratings yet

- Aerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsFrom EverandAerospace Actuators 1: Needs, Reliability and Hydraulic Power SolutionsNo ratings yet

- All Ahead Full: World War II Memoirs of an Lsm 215 VeteranFrom EverandAll Ahead Full: World War II Memoirs of an Lsm 215 VeteranNo ratings yet

- 13-08 en PDFDocument148 pages13-08 en PDFrobbertmdNo ratings yet

- BK117 C-1 Approved Rotorcraft Flight ManualDocument1 pageBK117 C-1 Approved Rotorcraft Flight ManualrobbertmdNo ratings yet

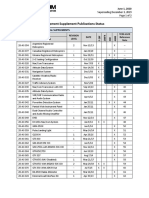

- Enstrom Optional Equipment Supplement Publications Status 6 1 20 PDFDocument2 pagesEnstrom Optional Equipment Supplement Publications Status 6 1 20 PDFrobbertmdNo ratings yet

- Hs 125 Part 2Document289 pagesHs 125 Part 2Damon Leong100% (1)

- Cessna Part 1 PDFDocument264 pagesCessna Part 1 PDFrobbertmdNo ratings yet

- pc-6 Doc 02334r1Document72 pagespc-6 Doc 02334r1robbertmd100% (1)

- Information Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesDocument3 pagesInformation Notice: Subject: SERVICING - Disinfection of The Helicopter Interior and The External HandlesrobbertmdNo ratings yet

- Cessna Part 2 PDFDocument263 pagesCessna Part 2 PDFrobbertmdNo ratings yet

- Component Maintenance Manual, Cargo HookDocument38 pagesComponent Maintenance Manual, Cargo HookrobbertmdNo ratings yet

- Maintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)Document59 pagesMaintenance Manual HTCM-001: Main Rotor Blades (Installation and Maintenance)robbertmdNo ratings yet

- Maintenance Manual HTCM-006: Part Number 204P2100-101 and - 103Document114 pagesMaintenance Manual HTCM-006: Part Number 204P2100-101 and - 103robbertmd100% (1)

- Micro Switch™ Military-Grade Toggle Switches: DatasheetDocument17 pagesMicro Switch™ Military-Grade Toggle Switches: DatasheetrobbertmdNo ratings yet

- Maintenance Manual HTCM-002: Helicopter Technology CompanyDocument45 pagesMaintenance Manual HTCM-002: Helicopter Technology CompanyrobbertmdNo ratings yet

- RR VIPER 522 MAINTENANCE MANUAL REVISIONDocument209 pagesRR VIPER 522 MAINTENANCE MANUAL REVISIONTarmizy MZaki100% (2)

- Installation ManualDocument24 pagesInstallation ManualrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 4 Normal Procedures PDFDocument28 pagesBristow Part B EC155B1 Section 4 Normal Procedures PDFrobbertmdNo ratings yet

- Engine Fire Protection SystemDocument8 pagesEngine Fire Protection SystemrobbertmdNo ratings yet

- Section 13D - Engine Air System PDFDocument6 pagesSection 13D - Engine Air System PDFrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 2 LimitationsDocument4 pagesBristow Part B EC155B1 Section 2 LimitationsrobbertmdNo ratings yet

- Section 13C - Engine Oil System PDFDocument4 pagesSection 13C - Engine Oil System PDFrobbertmdNo ratings yet

- Section 11 - Heating PDFDocument6 pagesSection 11 - Heating PDFrobbertmdNo ratings yet

- Section 13 - B: Engine Controls & IndicationsDocument6 pagesSection 13 - B: Engine Controls & IndicationsrobbertmdNo ratings yet

- Section 15: Emergency Flotation EquipmentDocument6 pagesSection 15: Emergency Flotation EquipmentrobbertmdNo ratings yet

- Bristow Part B EC155B1 Section 3 Emergency Procedures PDFDocument20 pagesBristow Part B EC155B1 Section 3 Emergency Procedures PDFrobbertmdNo ratings yet

- Section 14 - Autopilot PDFDocument23 pagesSection 14 - Autopilot PDFrobbertmdNo ratings yet

- Section 13E - Engine Fuel System PDFDocument18 pagesSection 13E - Engine Fuel System PDFrobbertmdNo ratings yet

- Engine Electrical Monitoring SystemsDocument14 pagesEngine Electrical Monitoring SystemsrobbertmdNo ratings yet

- Section 10 - Ice and Rain PDFDocument14 pagesSection 10 - Ice and Rain PDFrobbertmdNo ratings yet

- Section 17: Audio Voice Alerting Device - AVADDocument4 pagesSection 17: Audio Voice Alerting Device - AVADrobbertmdNo ratings yet

- Section 13H - Engine Malfunctions PDFDocument6 pagesSection 13H - Engine Malfunctions PDFrobbertmdNo ratings yet

- Myanmar Air Force 05 Feb 2013Document12 pagesMyanmar Air Force 05 Feb 2013shahidac100% (2)

- Cessna 100 Series (63-68) MM d637-1tr8Document4 pagesCessna 100 Series (63-68) MM d637-1tr8aviacion gnaNo ratings yet

- Moog AG Aircraft Capabilities Brochure Jun2012Document20 pagesMoog AG Aircraft Capabilities Brochure Jun2012747450calNo ratings yet

- Nambi Rajan Mini ReportDocument45 pagesNambi Rajan Mini ReportNambi RajanNo ratings yet

- B767 ChecklistDocument2 pagesB767 ChecklistVinícius TavaresNo ratings yet

- Cartas JUAN SANTAMARIA INTL City SAN JOSE, Costa Rica, MrocDocument30 pagesCartas JUAN SANTAMARIA INTL City SAN JOSE, Costa Rica, MrocREGINO MARCANONo ratings yet

- Lift-Drag Coefficient and Form Factor Analyses of Hydrofoil Due To The Shape and Angle of AttackDocument5 pagesLift-Drag Coefficient and Form Factor Analyses of Hydrofoil Due To The Shape and Angle of AttackYoel Bagus YektiNo ratings yet

- 05 - Back To School STEM - 6 Icebreaker Teamwork ActivitiesDocument23 pages05 - Back To School STEM - 6 Icebreaker Teamwork ActivitiesAlessandra AleNo ratings yet

- Drones VtolDocument2 pagesDrones VtolBRIAV33-BAOEA- AYUDANTE TE. FLOREZ JUAN CAMILONo ratings yet

- Vragen VACBI A330-200 ATA 29Document3 pagesVragen VACBI A330-200 ATA 29Arkadiy Chernov100% (1)

- PosterDocument1 pagePosterAnjali NagarNo ratings yet

- Service Publications: Number SubjectDocument9 pagesService Publications: Number SubjectLeoNo ratings yet

- Design and Manufacture of A Composite Overwrapped Xenon Conical Pressure VesselDocument14 pagesDesign and Manufacture of A Composite Overwrapped Xenon Conical Pressure VesselHiến Đinh VănNo ratings yet

- Unit 19 Aircraft Structural AnalysisDocument8 pagesUnit 19 Aircraft Structural AnalysisTarik Hassan ElsonniNo ratings yet

- 103Document19 pages103Cleber SouzaNo ratings yet

- TS-75ML: Total Rated LoadsDocument1 pageTS-75ML: Total Rated LoadsHiram LiraNo ratings yet

- Williams SDocument3 pagesWilliams SShivam GawandNo ratings yet

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 pagesRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncNo ratings yet

- X-Plane 1100 Version Installer File ListDocument2,434 pagesX-Plane 1100 Version Installer File ListRyan LuNo ratings yet

- Run-Up Performance Data SheetDocument2 pagesRun-Up Performance Data Sheetdava gladi tataNo ratings yet

- 2014-008-R-Annex To ED Decision 2014-008-R-CS-FCDDocument38 pages2014-008-R-Annex To ED Decision 2014-008-R-CS-FCDMyo Myint AungNo ratings yet

- Repair Manual M28 SKYTRUCK 2014Document237 pagesRepair Manual M28 SKYTRUCK 2014Jose Francisco ColinaNo ratings yet

- Fdocuments - in Chapter 3 Satellite Subsystems 1Document20 pagesFdocuments - in Chapter 3 Satellite Subsystems 1RahulMondolNo ratings yet

- History, Development and Structure of The Mikoyan MiG-29 FighterDocument8 pagesHistory, Development and Structure of The Mikoyan MiG-29 FighterCentral Asian StudiesNo ratings yet

- Airport Handling Manual IATADocument14 pagesAirport Handling Manual IATACarlos MinayaNo ratings yet

- 205a1-Ipb-Ch53 FuselageDocument318 pages205a1-Ipb-Ch53 FuselageWilson BarbosaNo ratings yet

- SBCF - Rnav Gnss Rwy16 - Iac - 20151112Document1 pageSBCF - Rnav Gnss Rwy16 - Iac - 20151112Rodrigo HalzenthNo ratings yet

- RR PatentsDocument7 pagesRR PatentsAlan SmartNo ratings yet

- 20080202-2 F27 TC-MBGDocument9 pages20080202-2 F27 TC-MBGFaisNo ratings yet

- The Concept of Load and Trim Sheet (LTS) and Completing A LTS ManuallyDocument43 pagesThe Concept of Load and Trim Sheet (LTS) and Completing A LTS Manuallyamir.seifi110No ratings yet