Professional Documents

Culture Documents

DX Free Cooling

Uploaded by

SuDokuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DX Free Cooling

Uploaded by

SuDokuCopyright:

Available Formats

Order No.: 18176-20-03/2004. Supersedes order No.

: 18176-20-02/2002

The manufacturer reserves the right to modify the specifications without notice.

Printed in the Netherlands.

Amember of the United Technologies Corporation family

D

X

F

R

E

E

-

C

O

O

L

I

N

G

D

X

F

R

E

E

-

C

O

O

L

I

N

G

DX FREE-COOLING

30RB CHILLER 262 302 342 372 402 432 462 522

Nominal cooling capacity kW 257.8 293.4 327.6 358.6 391.1 417.7 446.9 506.4

Energy efficiency ratio EER kW/kW 2.7 2.6 2.7 2.7 2.5 2.6 2.5 2.4

Free-cooling operation*

Cooling capacity kW 116.7 144.7 144.7 172.6 172.6 211 211 247.9

Energy efficiency ratio EER kW/kW 14.7 14.9 14.9 15.0 15.0 15.9 15.9 16.5

Total heat reclaim operation**

Heating capacity kW 328.3 357.9 421.7 453 495.9 530.8 578.4 653.1

Energy efficiency ratio EER kW/kW 3.6 3.6 3.6 3.6 3.5 3.5 3.5 3.3

Partial heat reclaim operation**

Heating capacity kW 41 46 52 56 62 65 71 80

Nominal operating conditions, cooling: air 35C, water 12/7C

Nominal operating conditions, heating: air 7C, water 40/45C

* With free-cooling option: air 0C, water 15/10C

** With total heat reclaim option: cold water 12/7C, hot water 40/45C

*** With partial heat reclaim option: cold water 12/7C, hot water 50/60C

30RQ HEAT PUMP 262 302 342 372 402 432 462 522

Nominal cooling capacity kW 248.6 277.8 307.2 331.3 366.1 389.4 429.7 465

Energy efficiency ratio EER kW/kW 2.5 2.7 2.5 2.6 2.5 2.6 2.6 2.4

Mechanical operation

Nominal heating capacity kW 274.7 300.6 333 364.1 404.5 442.2 502 548

Coefficient of performance COP kW/kW 2.8 2.7 2.5 2.6 2.5 2.6 2.6 2.4

Total heat reclaim operation***

Heating capacity kW 60 66 74 78 88 93 102 113

30XA CHILLER 252 302 352 402 452 502 602 702 752 802 852 902 1002

Nominal cooling capacity kW 267.7 293.4 319.7 382.2 437.4 491.5 604.9 653 706.4 763.7 802.2 868.8 951.7

Energy efficiency ratio EER kW/kW 3.2 3.2 3.2 3.4 3.4 3.5 3.5 3.6 3.4 3.5 3.5 3.5 3.4

Free-cooling operation*

Cooling capacity kW 146 146 145.6 187.6 190.6 213.8 259.6 280.5 282 280.4 326.4 329.8 369.8

Energy efficiency ratio EER kW/kW 24 24.6 24.6 23.1 24 24 23.6 23.4 24.1 23.6 23.5 23.9 24.1

Total heat reclaim operation**

Heating capacity kW 335.9 372.9 401.2 481.5 554.4 620.4 759.6 832.1 894.1 974.3 1027 1105 1229

Coefficient of performance COP kW/kW 4.1 4.1 4.1 4.3 4.3 4.5 4.4 4.6 4.4 4.5 4.4 4.4 4.4

HEAT RECLAI M

WASTED ENERGY SERIOUSLY

HARMS THE ENVIRONMENT

Wasting energy means contributing to the

inevitable consequences of the irreversible

pollution of our planet, of the environment and

of our eco system.

Remembering that electricity production

generates greenhouse gases such as CO

2

but

also nitrogen oxyde, means understanding the

vital necessity to act quickly in order to find

carefully considered and lasting solutions.

Better energy use means finding a responsible

attitude towards the environment - a simple

gesture, a natural reflex for future generations.

Why not use the outside

temperature to cool the

circuit water naturally

Traditional hydronic FREE-COOLING systems are designed for technical applications: IT

rooms, telephone exchanges etc. that are characterised by a constant cooling requirement -

summer and winter.

These systems that are designed for specific applications are used in commercial buildings

and require the use of a water/glycol solution, oversized circulation pumps, reduced energy

efficiency outside the free-cooling operating period and increased investment cost.

A simple principle, patented by CARRIER and

unique world-wide - a refrigeration cycle without

compressors where only a circulation mini-pump

and the fans ensure water cooling. In the

evaporator, the water circulating in the building

gives up its heat to the refrigerant that evaporates.

These vapours rejoin the condenser directly without

passing through the compressor.

In this heat exchanger the liquid refrigerant gives up

its heat to the cold outside air and returns from the

vapour status to the liquid status. A circulation

mini-pump ensures the return of the liquid

refrigerant to the evaporator and allows the

refrigeration cycle to repeat.

The cooling capacity is controlled by the opening of

the expansion device that regulates the amount of

refrigerant entering the evaporator. The PRO-

DIALOG control automatically manages the

changeover from mechanical cooling to free-cooling

and vice versa. The control algorithms continuously

compare the cooling capacity available in FREE-

COOLING with the thermal load of the building and

stop the compressors, if the capacity is sufficient or

restart them, if this is not the case.

This guarantees comfort conditions inside the

building while realising energy savings.

Responsible actions

A lasting strategy

Using less energy and committing to the

dynamics of progress means making savings,

a new profit centre that enhances everybodys

comfort.

Computer equipment is more and more

important. There are more and more

occupants in offices. Certain technologies

reclaim cooling even in winter. Comfort every-

where is a daily requirement in commercial

centres, cinemas etc. All this means that we

must reconsider the air conditoning equipment,

design buildings that are less sensitive to the

outside temperature, optimise cooling and

heating requirements and considerably reduce

our energy consumption.

This new strategy is proof of a commitment to

comply with environmental standards accepting

the responsability for our actions.

Reduced CO

2

emissions to

the atmosphere,

now it is possible

CARRIER REINVENTS

COMFORT FREE-

COOLING

ENERGY

SAVINGS

During DX FREE-COOLING operation, the

compressors are stopped, and only the fans and

the circuation mini-pump work.

The energy efficiency of the chiller reaches record

values: up to 24 kW cooling capacity for only 1 kW

power consumption - that is six times more than

with the compressors (for a 10 K difference between

the ambient air temperature and the leaving

chilled-water temperature).

De-energising the compressors during DX

FREE-COOLING operation increases

equipment life and the interval between

maintenance operations.

JUST PURE WATER

In contrast to traditional hydronic free-cooling

systems requiring the use of a water/glycol solution

that is toxic for the environment, the CARRIER

chillers operate with pure water.

This saves energy due to the improved heat

exchange coefficient of pure water compared to a

water/glycol solution. If the system shuts down, an

electric resistance heater protects the hydronic

circuit against frost.

Compared to hydronic free-cooling, the

investment is lower and the return on invest-

ment is faster. Plus: The DX FREE-COOLING

system does not require any additional floor

space and is factory-assembled and tested to

facilitate the assembly for the installer and

save time - thus optimising installation cost.

2

1

3

4

Free-cooling

capacity, kW

Note: Leaving water temperature: 10C,/outside air temperature (OAT)

OAT: 0C

OAT: -8C

OAT: -10C

DX FREE-COOLING

A NATURAL INNOVATION

TO BENEFIT THE PLANET

OPTIMISED

INVESTMENT

MINIMISED

MAINTENANCE

COST

TOTAL HEAT RECLAIM

A simple principle: if there is a demand for heating, the

hot gases leaving the compressor are directed

towards the heat reclaim condenser, the gases give up

their heat to the hot water leaving the condenser at a

temperature of up to 60C. 100% of the heat rejected

by the chiller can be used to produce the hot water

required by your installation. When the demand for

heating is satisfied, the hot gases are automatically

directed to the initial air condenser circuit where the

heat is rejected to the air by the fans.

Why reject and lose the heat generated by the

refrigeration system and not benefit from it free-of-

charge. In many activity sectors, such as agriculture,

the food industry, industrial processes, hospitals and

hotels heat reclaim permits a considerable reduction

of the energy bill for the heat generation equipment.

This controlled optimisation contributes towards a

responsible commitment to reduce wasted energy

and the harm done to our planet.

NATURAL ECONOMICAL

HEATING

PARTIAL HEAT RECLAIM

At a leaving temperature of up to 80C this system is particularly suited to the production

of sanitary hot water. A heat exchanger placed upstream of the condenser ensures the

desuperheating of the gases before they enter the condenser.

Another advantage, available with the Aquasnap heat pumps: the

system guarantees sanitary hot water production all year round, summer and winter.

Heat reclaim is often associated with the

generation of solar heat; it offers energy

savings and is a significant step forward

towards safeguarding our environment.

HEATING - A

CONSTANT

REQUIREMENT

FREE HOT WATER,

NOTHING IS LOST,

EVERYTHING IS RECOVERED

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Europe's Onshore and Offshore Wind Energy PotentialDocument91 pagesEurope's Onshore and Offshore Wind Energy PotentialSuDokuNo ratings yet

- 13 Steps Manage FlashbacksDocument1 page13 Steps Manage FlashbacksSuDoku100% (1)

- Coping With Narcissistic PatternDocument209 pagesCoping With Narcissistic PatternJokerJack100% (1)

- Shrinking Outer CriticDocument7 pagesShrinking Outer Criticxyhm100% (2)

- Green Building GlossaryDocument17 pagesGreen Building GlossarySuDokuNo ratings yet

- 14 AmtaDocument6 pages14 AmtaSuDokuNo ratings yet

- 13 Steps Manage FlashbacksDocument1 page13 Steps Manage FlashbacksSuDoku100% (1)

- Coping With Narcissistic PatternDocument209 pagesCoping With Narcissistic PatternJokerJack100% (1)

- CONDENSATOR - DimensionatDocument3 pagesCONDENSATOR - DimensionatSuDokuNo ratings yet

- Wilo Condensator PompaDocument2 pagesWilo Condensator PompaSuDokuNo ratings yet

- Goal Setting NotebookDocument3 pagesGoal Setting NotebookSuDoku100% (1)

- BL-E 32/210-7,5/2-R1: Wilo Se Nortk Irche Nstr. 100 D 44263 Dortm Und 0231/4102-0 0231/4102-7363 Phone FaxDocument3 pagesBL-E 32/210-7,5/2-R1: Wilo Se Nortk Irche Nstr. 100 D 44263 Dortm Und 0231/4102-0 0231/4102-7363 Phone FaxSuDokuNo ratings yet

- Instructiuni EcotectDocument1 pageInstructiuni EcotectSuDokuNo ratings yet

- YangB Pag29Document300 pagesYangB Pag29SuDokuNo ratings yet

- Home LiftDocument2 pagesHome LiftSuDokuNo ratings yet

- SEGRASTREYTDocument20 pagesSEGRASTREYTSuDokuNo ratings yet

- w1305 - Olesen - Pag 2-3 PDFDocument9 pagesw1305 - Olesen - Pag 2-3 PDFSuDokuNo ratings yet

- Melikov Etal Energy and BuildingsDocument8 pagesMelikov Etal Energy and BuildingsSuDokuNo ratings yet

- Depliant Infra Plus en 01-02-2006Document4 pagesDepliant Infra Plus en 01-02-2006SuDokuNo ratings yet

- Personalised Ventilation MelikovDocument15 pagesPersonalised Ventilation MelikovSuDokuNo ratings yet

- Depliant Infra Plus en 01-02-2006Document4 pagesDepliant Infra Plus en 01-02-2006SuDokuNo ratings yet

- Pandurilor 51-1Document14 pagesPandurilor 51-1SuDokuNo ratings yet

- Systema Cu DefaultsDocument8 pagesSystema Cu DefaultsSuDokuNo ratings yet

- Airflow Dampers enDocument44 pagesAirflow Dampers enSuDokuNo ratings yet

- Wood Fuels Handbook BTC enDocument83 pagesWood Fuels Handbook BTC enfelramNo ratings yet

- Trnsys 16: Weather DataDocument55 pagesTrnsys 16: Weather DataMilovan MedojevicNo ratings yet

- Plan Proiect ModelDocument1 pagePlan Proiect ModelSuDokuNo ratings yet

- Home LiftDocument2 pagesHome LiftSuDokuNo ratings yet

- 3 LabVIEWBasicprogrammingStructures (Partb)Document12 pages3 LabVIEWBasicprogrammingStructures (Partb)SuDokuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Position: Reduced Runway Separation Minima For Night OperationsDocument2 pagesPosition: Reduced Runway Separation Minima For Night OperationsHENIGUEDRINo ratings yet

- History of UASDocument44 pagesHistory of UASAswin BalasubramaniamNo ratings yet

- CraftDocument15 pagesCraftImamMukhri100% (1)

- Selangor-Physics P2-Trial SPM 2009Document24 pagesSelangor-Physics P2-Trial SPM 2009kamalharmozaNo ratings yet

- HK102H To-92Document3 pagesHK102H To-92The FatherNo ratings yet

- Equipment Damage Curves TransformersDocument8 pagesEquipment Damage Curves TransformersrobertoseniorNo ratings yet

- PowerLogic ION 8600 Product Part Number Guide 052006Document2 pagesPowerLogic ION 8600 Product Part Number Guide 052006Magistra AkbarNo ratings yet

- C Basic ExercisesDocument7 pagesC Basic ExercisesAngelo MartinNo ratings yet

- JSP BasicsDocument41 pagesJSP BasicsSandeep KavuriNo ratings yet

- 04Document2 pages04Vishesh negiNo ratings yet

- COMSOL Release NotesDocument142 pagesCOMSOL Release NotesAngel VelasquezNo ratings yet

- Casting DefectsDocument22 pagesCasting DefectsDeepakKaushik100% (1)

- Mekaniko On The Go: An Online Mechanic Mobile Application: A System Analysis and Design ProjectDocument8 pagesMekaniko On The Go: An Online Mechanic Mobile Application: A System Analysis and Design ProjectMarco MagdaelNo ratings yet

- Imp25 PDFDocument8 pagesImp25 PDFEng Marwa ElsherifNo ratings yet

- LIDO Introduction PDFDocument127 pagesLIDO Introduction PDFStiliyana Bakalova100% (2)

- Brochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Document20 pagesBrochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Fernando Cesar PérezNo ratings yet

- Engineering Major: Brandon University Courses by YearDocument2 pagesEngineering Major: Brandon University Courses by YearnavidNo ratings yet

- Oracle IdeasDocument45 pagesOracle Ideashamdy2001No ratings yet

- 2010 Batch (Sem 1 11-12)Document10 pages2010 Batch (Sem 1 11-12)prateek_7892No ratings yet

- Digital Image Correlation - Tracking With MatlabDocument20 pagesDigital Image Correlation - Tracking With MatlabrajibmeNo ratings yet

- Case/Duct System (Automobile)Document7 pagesCase/Duct System (Automobile)Tran xuan ThuyNo ratings yet

- TR-7551 Wiring & Typical Connection DiagramDocument1 pageTR-7551 Wiring & Typical Connection Diagramlakshitha sandaruwanNo ratings yet

- Electrical Type Flow MetersDocument22 pagesElectrical Type Flow MetersAnuNarayan R0% (1)

- OpenSAP Sac1 Week 2 All SlidesDocument17 pagesOpenSAP Sac1 Week 2 All SlidesTheJackNo ratings yet

- Asr 903 DatasheetDocument4 pagesAsr 903 DatasheetDiaz WildanNo ratings yet

- Via Fill PlugDocument7 pagesVia Fill PluganeeshdNo ratings yet

- Liebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDocument4 pagesLiebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDaniel Castillo PeñaNo ratings yet

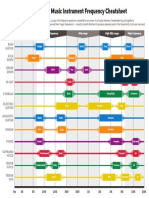

- Music Frequency Cheat SheetDocument1 pageMusic Frequency Cheat SheetLeonel Molina AlvaradoNo ratings yet

- Oncell 5004/5104-Hspa Series: Industrial Five-Band Gsm/Gprs/Edge/Umts/Hspa Cellular RoutersDocument2 pagesOncell 5004/5104-Hspa Series: Industrial Five-Band Gsm/Gprs/Edge/Umts/Hspa Cellular Routersudaya kumarNo ratings yet

- Cat 772 Catálogo de Peças PDFDocument937 pagesCat 772 Catálogo de Peças PDFTom Souza100% (1)