Professional Documents

Culture Documents

Spin It! - Designing Your Own Motor Drive and Control System (Part 2)

Uploaded by

Hüseyin Murat PolaterOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spin It! - Designing Your Own Motor Drive and Control System (Part 2)

Uploaded by

Hüseyin Murat PolaterCopyright:

Available Formats

17 9 2014 Spin It!

- Designing Your Own Motor Drive and Control System (Part 2) - Motor Drive & Control - Blogs - TI E2E Community

http://e2e.ti.com/blogs_/b/motordrivecontrol/archive/2013/10/10/spin-it-designing-your-own-motor-drive-and-control-system-part-2.aspx?DCMP=hval-mdbu- 1/1

Subscribe w/ Email Address

Subscribe

Subscribe to this Blog by Email

Motor Drive & Control

RSS for posts

RSS for comments

More from Motor Drive &

Control

Our MCUs keep the motors

spinning in electric

vehicles

e-Traction , a company that develops

powertrain technology for electric

vehicles...

17 hours ago by ChrisClearman

15 exotic electric motors

1 month ago by RE

A chip that is as versatile as the

designs you create

1 month ago by Brian Fortman

If you missed it - #TImotorHr

recap

1 month ago by Michael Firth

Save the date: #TImotorHr on

July 31

1 month ago by Dave (Wisconsin) Wilson

Spin It! - Designing Your Own Motor Drive and Control

System (Part 2)

3 Nicholas Oborny Oct 10 2013 18:46 PM

Part 2: Component selection

Howdy!

Welcome back or if this is your first time here you can check out the introduction to this series, Spin It! - Designing Your Own

Motor Drive & Control System (Part 1).

Now that introductions are over, its time to dig in and get our hands dirty. They say one of the hardest parts of any project is

determining where to start. You have a fantastic idea in your head, but now what?! Well I am here to help..at least in the

motor area.

In the DC voltage world, three main types of electric motors exist: the Brushed DC motor (BDC), Brushless DC motor (BLDC),

and Stepper motor. Each motor has its upsides and downsides and your application will determine the right motor type for

you.

I am working on a Motor Drive BoosterPack for TIs MCU LaunchPad evaluation platform and have a few key requirements.

First, I need fairly accurate position control. This is crucial in applications such as 3-D printers, robots, and CNC machines

(popular hobby projects). I am not too concerned with initial designs costs, but I want the solution to be low cost and simple.

Last, I want this system to support a broad range of motor voltages/currents. With these elements in mind, it looks like I want

to design a system that can drive a broad range of Stepper motors for minimal cost!

Well now we understand what we want to do; how do we accomplish this? First, lets go over some background on how a

motor system operates. In a motor drive and control systems there are two key elements.

First, we have the motion control system. This is generally managed by a dedicated MCU or tasked to a more powerful,

centralized processor. This system provides higher level control (ramping up, ramping down, speed profiles, commutation,

etc) to the motor drive system and then processes the feedback signals that return. These control signals

can include:Digital Outputs to manipulate settings, PWM to manage motor speed, SPI/UART/I2C for communication, and

a DAC for varying a reference voltage. The feedback signals often include: fault reporting to Digital Inputs and current

feedback from a shunt resistor to an ADC. A microcontroller takes many of these peripherals and integrates them into a

single IC.

Next, we have the motor drive system. This consists of either a discrete solution with power FETs to create H-Bridges,

anintegrated motor driver IC with internal power FETs and additional features/protection, or a motor pre-driver IC that drives

external power FETs but also incorporates the additional features/protection of an integrated IC. Solutions that utilize a

dedicated motor driver IC generally provide additional protection, size reduction, and more fine-tuned control. You can check

out this blog for more information on discrete vs. integrated solutions.

Now that we have a basic understanding of how a motor drive and control system operates, we can begin searching for

components. For this BoosterPack, I am looking to offload the stepper microstepping and current regulation to the Motor

Drive IC. This will allow me to utilize a simpler, lower cost microcontroller and reduce the component count of my design. I

already know that I would like an integrated solution to reduce my development time, but I would also like the ability to provide

significant power to the motor. A quick Google search brings up a plethora of options. Lets see..taking the ones that

closest meet my needs, we have the DRV8818, DRV8825, and the DRV8711.

In the table you can see an obvious cost vs. feature tradeoff. In the end, my need for currents in the 5A range over rode the

cost difference of utilizing a completely integrated, lower power motor driver. With the DRV8711 and appropriately sized

power FETs, I can design a highly flexible solution capable of driving the power I am looking for.

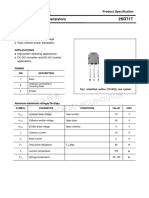

If you decide to utilize a pre-driver, the next step will be choosing the appropriate power FETs. The DRV8711 drives 2 N-

channel MOSFET H-bridges, so we will require 8 N-channel power MOSFETs. Now I am going to take advantage of some

advance knowledge and utilize dual 60V N-channel power MOSFETs that are in development at TI. Some keys things to keep

in mind when selecting external FETs are the R

DS(ON)

(on resistance of the FET), C

G

(gate capacitance), max continuous

current, package size, and cost.

The DRV8711 allows me to significantly reduce the processing power required by the microcontroller. The only requirements

now are a few GPIO, SPI, and UART in order to implement a GUI. The MSP430 Value Line LaunchPad (MSP-EXP430G2) with

an ultra-low-power MSP430G2553 MCU fits the bill perfectly!

Wow!! That was a mouthful and we are just getting started. But now we have the main building blocks of a motor drive and

control system. Next time we will get to actually putting them down on a schematic and filling out all the components in

between.

Thanks for reading and feel free to leave comments! For more information, you can visit the TI Motor Driver Forums or check

out the TI Motor Drive & Control Home Page. You can check out the Build You Own BoosterPack page to start your own

design!

Nick Oborny, Motor Applications Team, Texas Instruments

You might also like

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- RoboticsDocument30 pagesRoboticsSarvesh Naik100% (1)

- Design and Prototyping Methods For Brushless Motors and Motor ControlDocument135 pagesDesign and Prototyping Methods For Brushless Motors and Motor Controlscardig0% (1)

- ATA 27 EFCS Troubleshooting TipspdfDocument57 pagesATA 27 EFCS Troubleshooting TipspdfMiguelSabino100% (5)

- Beyond: Motor Control EditionDocument64 pagesBeyond: Motor Control EditionAffan Khan100% (2)

- Statcon Company ProfileDocument91 pagesStatcon Company ProfileArun das100% (1)

- 12th Physics Full Book MCQs PDFDocument43 pages12th Physics Full Book MCQs PDFshahid abbas82% (11)

- Manual Pic Lab 1Document44 pagesManual Pic Lab 1Mustafa Arif100% (2)

- RF Training Module OverviewDocument56 pagesRF Training Module Overviewriskalltowin50% (2)

- Speed Control For Brushless DC MotorsDocument50 pagesSpeed Control For Brushless DC MotorsMiladShahabiNo ratings yet

- Titan Ecu User Manual Ver2.4.0.0Document103 pagesTitan Ecu User Manual Ver2.4.0.0SelloNo ratings yet

- Embedded Systems Course IntroductionDocument75 pagesEmbedded Systems Course IntroductionpandiNo ratings yet

- Introduction To SR and GR by Hans Stephani PDFDocument418 pagesIntroduction To SR and GR by Hans Stephani PDFDvij252580% (5)

- EE2036 2 MarksDocument19 pagesEE2036 2 MarksSaravanan RameshNo ratings yet

- Iec 61000-4-01 2000Document20 pagesIec 61000-4-01 2000hkrx2001100% (3)

- Piezo COMSOL 50.compressed PDFDocument55 pagesPiezo COMSOL 50.compressed PDFKamel Fedaoui0% (1)

- Conductímetro Hach 8310Document168 pagesConductímetro Hach 8310prancesi100% (1)

- Figure 1. Schematic - Ev-100Zx SCR Control For Traction MotorDocument43 pagesFigure 1. Schematic - Ev-100Zx SCR Control For Traction MotorMario AguirreNo ratings yet

- 0383.team ψ senior designDocument13 pages0383.team ψ senior designaku bulletNo ratings yet

- Parsian Team Description For Robocup 2011Document10 pagesParsian Team Description For Robocup 2011Chris 'Whumew' MichalakNo ratings yet

- How To Easily Design Sinusoidal, Sensorless Control For 3-Phase BLDC Motors - Industrial - Technical Articles - TI E2E Support ForumsDocument4 pagesHow To Easily Design Sinusoidal, Sensorless Control For 3-Phase BLDC Motors - Industrial - Technical Articles - TI E2E Support ForumsalirezamohamadNo ratings yet

- First PageDocument3 pagesFirst PageMd Samee MNo ratings yet

- FPGAs Enable Energy-Efficient Motor Control - Industrial Embedded SystemsDocument7 pagesFPGAs Enable Energy-Efficient Motor Control - Industrial Embedded SystemsRintuMathunniNo ratings yet

- Mems Controlled Intelligent Wheel ChairDocument87 pagesMems Controlled Intelligent Wheel ChairShaik Ashwaq JavedNo ratings yet

- S-90 Go KartDocument70 pagesS-90 Go KartTodLee GamingNo ratings yet

- Speed Control of DC Motor Literature ReviewDocument5 pagesSpeed Control of DC Motor Literature Reviewea4gaa0g100% (1)

- The S-90 Go-Kart Optimal Design ReportDocument70 pagesThe S-90 Go-Kart Optimal Design ReportshauuuuuuuuuuuuuuuuNo ratings yet

- K1-K3 GSXR 600-750 K-Line Bootloader ExplainedDocument1 pageK1-K3 GSXR 600-750 K-Line Bootloader ExplainedAnthony August ArcherNo ratings yet

- Drive By Wire System Controlled With Brushless DC MotorDocument4 pagesDrive By Wire System Controlled With Brushless DC MotoranishmohantcrNo ratings yet

- Literature Review DC Motor Speed ControlDocument5 pagesLiterature Review DC Motor Speed Controlnynodok1pup3100% (1)

- Fault Tolerant Capability For Brushless Direct Current (BLDC) Motor Using Pic MicrocontrollerDocument14 pagesFault Tolerant Capability For Brushless Direct Current (BLDC) Motor Using Pic MicrocontrollerIAEME PublicationNo ratings yet

- Thesis Stepper MotorDocument8 pagesThesis Stepper Motorbsr3rf42100% (1)

- MaxTune Intelligent Servo DriveDocument10 pagesMaxTune Intelligent Servo DrivejuliangoalNo ratings yet

- Research Paper On DC Motor PDFDocument4 pagesResearch Paper On DC Motor PDFafeawldza100% (1)

- Iot Embedded Login For Stepper Motor Speed ControlDocument10 pagesIot Embedded Login For Stepper Motor Speed ControlThrisul KumarNo ratings yet

- Titan Ecu User Manual Ver2.2.2.0Document91 pagesTitan Ecu User Manual Ver2.2.2.0หนิง หมื่นทิ50% (2)

- DC Motor Research PaperDocument7 pagesDC Motor Research Papervshyrpznd100% (1)

- Spansion® Hybrid & Electric Vehicle SolutionsDocument2 pagesSpansion® Hybrid & Electric Vehicle SolutionsMohammad Seemab AslamNo ratings yet

- Research Papers On Speed Control of DC MotorDocument7 pagesResearch Papers On Speed Control of DC Motoreh0vmbmp100% (1)

- Micro-2407 User Must ReadDocument124 pagesMicro-2407 User Must ReadShyam SundarNo ratings yet

- Live Human Being Detection Using Robot Using DTMF TechnologyDocument93 pagesLive Human Being Detection Using Robot Using DTMF TechnologySpandana Invincible100% (2)

- Engine Management Systems - Explaning The Common Terms Used Sam BorgmanDocument8 pagesEngine Management Systems - Explaning The Common Terms Used Sam Borgmanakrm89No ratings yet

- RoboTurk Team DescriptionDocument12 pagesRoboTurk Team DescriptionkfuScribdNo ratings yet

- The Smart Motion Cheat SheetDocument6 pagesThe Smart Motion Cheat Sheettonysworld_89No ratings yet

- 138 - Pritam More Main PaperDocument11 pages138 - Pritam More Main PaperBharath KumarNo ratings yet

- BLDC Engines Enable The Future of MotorsDocument8 pagesBLDC Engines Enable The Future of MotorsKEVIN SNo ratings yet

- Intelligent Motor ManagementDocument3 pagesIntelligent Motor ManagementjunfaNo ratings yet

- Cukurova University Faculty of Engineering and Architecture Department of Mechanical Engineering Experiment ReportDocument8 pagesCukurova University Faculty of Engineering and Architecture Department of Mechanical Engineering Experiment ReportSülbiye İşçi TemizciNo ratings yet

- 1.speed Synchronization of Multiple MotorsDocument89 pages1.speed Synchronization of Multiple MotorsBhanu TummalapalliNo ratings yet

- TITAN ECU Manual IntroductionDocument96 pagesTITAN ECU Manual IntroductionZanko FitnessNo ratings yet

- Controls Final ReportDocument14 pagesControls Final Reportapi-244906204No ratings yet

- Final ReportDocument83 pagesFinal ReportCallme PrinceNo ratings yet

- Special-Purpose Designs: Embedded ApplicationsDocument2 pagesSpecial-Purpose Designs: Embedded ApplicationsrajaNo ratings yet

- Metro Train Prototype: A Summer Training Report OnDocument34 pagesMetro Train Prototype: A Summer Training Report OnPooja SharmaNo ratings yet

- Smart Motion Cheat SheetDocument6 pagesSmart Motion Cheat SheetSerx Armendariz100% (1)

- Servo Motor ThesisDocument4 pagesServo Motor Thesisafloattaxmxufr100% (1)

- New Microsoft Word DocumentDocument10 pagesNew Microsoft Word DocumentTejas KadamNo ratings yet

- Embedded Sysyem PDFDocument89 pagesEmbedded Sysyem PDFVINAY VNo ratings yet

- Fundamentals of MicrocontrollerDocument23 pagesFundamentals of Microcontrollerashley panganNo ratings yet

- Summer Training Report Line Following Robot Bachelor of Technology ECE (2010-14)Document38 pagesSummer Training Report Line Following Robot Bachelor of Technology ECE (2010-14)Ashutosh DabasNo ratings yet

- ABS User ManualDocument40 pagesABS User ManualAntonio NavarreteNo ratings yet

- Group DiscussionDocument194 pagesGroup Discussionabdulyunus_amir100% (1)

- Ti MotorDocument25 pagesTi MotorBruno SilvaNo ratings yet

- Thesis On BLDC Motor ControlDocument7 pagesThesis On BLDC Motor ControlScientificPaperWritingServicesKansasCity100% (1)

- Technologiebroschuere E-Drives 2013-07-130913 EbookDocument60 pagesTechnologiebroschuere E-Drives 2013-07-130913 EbookSertug BaşarNo ratings yet

- Automotive Electronics - Top 5 Tech Trends of Tomorrow's Smart CarsDocument5 pagesAutomotive Electronics - Top 5 Tech Trends of Tomorrow's Smart CarsKusumavathi KNo ratings yet

- Automobile Dashboard Integration With IOT Google AssistanceDocument17 pagesAutomobile Dashboard Integration With IOT Google AssistanceaaNo ratings yet

- Dd03 Proiect Self ParkingDocument29 pagesDd03 Proiect Self ParkingIlie IulianNo ratings yet

- How Car Computers Work: SEFI, ECUs, Sensors & DiagnosticsDocument20 pagesHow Car Computers Work: SEFI, ECUs, Sensors & DiagnosticsGaurao WarungaseNo ratings yet

- Jurnaallllll Inggris RevisiDocument8 pagesJurnaallllll Inggris RevisiYahya Nyanyuk EndahNo ratings yet

- WHITE PAPER VFDs and Soft Starters Offer Built-in IntelligenceDocument4 pagesWHITE PAPER VFDs and Soft Starters Offer Built-in IntelligencebcostiucNo ratings yet

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveFrom EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHNo ratings yet

- Abcs of AdcsDocument69 pagesAbcs of AdcsHüseyin Murat PolaterNo ratings yet

- Readinglist HarleyDocument1 pageReadinglist HarleyHüseyin Murat PolaterNo ratings yet

- Linear & Switching Voltage Regulator HandbookDocument118 pagesLinear & Switching Voltage Regulator Handbookzack9mm2003No ratings yet

- MagneticsDocument1 pageMagneticsHüseyin Murat PolaterNo ratings yet

- 16 RegenerationDocument3 pages16 RegenerationHüseyin Murat PolaterNo ratings yet

- The Ten Commandments of Digital ControlDocument14 pagesThe Ten Commandments of Digital ControlHüseyin Murat PolaterNo ratings yet

- Input Stability of DC DCDocument5 pagesInput Stability of DC DCHüseyin Murat PolaterNo ratings yet

- Automatic ControlDocument255 pagesAutomatic ControlAlfa BetaNo ratings yet

- DB or Not DBDocument36 pagesDB or Not DBHüseyin Murat PolaterNo ratings yet

- Smart-Power H-Bridges Control The Speed and Torque of DC Brush MotorsDocument4 pagesSmart-Power H-Bridges Control The Speed and Torque of DC Brush MotorsHüseyin Murat PolaterNo ratings yet

- Slva462 PDFDocument4 pagesSlva462 PDFlu1agpNo ratings yet

- 7 Modeling Ferrite Core LossesDocument7 pages7 Modeling Ferrite Core LossesHüseyin Murat PolaterNo ratings yet

- 13 Proximity LossDocument9 pages13 Proximity LossHüseyin Murat PolaterNo ratings yet

- ECE 320 Chapter 4: DC MotorsDocument7 pagesECE 320 Chapter 4: DC MotorsHüseyin Murat PolaterNo ratings yet

- Slva462 PDFDocument4 pagesSlva462 PDFlu1agpNo ratings yet

- V15 Apex Precision Power Databook (Complete)Document964 pagesV15 Apex Precision Power Databook (Complete)Hüseyin Murat PolaterNo ratings yet

- 13 Proximity LossDocument9 pages13 Proximity LossHüseyin Murat PolaterNo ratings yet

- How To Read Component DatasheetsDocument8 pagesHow To Read Component DatasheetstekellamerZ aka tekellamerNo ratings yet

- Brushless DC Motor Drives Chjapter 5Document70 pagesBrushless DC Motor Drives Chjapter 5Ahmed58seribegawanNo ratings yet

- The Ten Commandments of Digital ControlDocument14 pagesThe Ten Commandments of Digital ControlHüseyin Murat PolaterNo ratings yet

- The Ten Commandments of Digital ControlDocument14 pagesThe Ten Commandments of Digital ControlHüseyin Murat PolaterNo ratings yet

- Slva462 PDFDocument4 pagesSlva462 PDFlu1agpNo ratings yet

- The Ten Commandments of Digital ControlDocument14 pagesThe Ten Commandments of Digital ControlHüseyin Murat PolaterNo ratings yet

- EE595S: Class Lecture Notes Chapter 14: Induction Motor DrivesDocument66 pagesEE595S: Class Lecture Notes Chapter 14: Induction Motor DrivesTalha MehmoodNo ratings yet

- Modelling Phtsical SystemsDocument9 pagesModelling Phtsical SystemsHüseyin Murat PolaterNo ratings yet

- Antennas and Wave PropagationDocument35 pagesAntennas and Wave PropagationGowtham BaskerNo ratings yet

- Mosfet NotesDocument65 pagesMosfet NotesAnmol DubeyNo ratings yet

- Enraf-Nonius Radarmed 650 950 EN PDFDocument3 pagesEnraf-Nonius Radarmed 650 950 EN PDFLipin SidhartaNo ratings yet

- Manual SH Arc-m3-Hub v0400 enDocument20 pagesManual SH Arc-m3-Hub v0400 enhomaNo ratings yet

- Product Data Sheet: Switch-Disconnector Compact INS400 - 400 A - 3 PolesDocument2 pagesProduct Data Sheet: Switch-Disconnector Compact INS400 - 400 A - 3 PolesOki MahendraNo ratings yet

- VX-1700 Owners ManualDocument32 pagesVX-1700 Owners ManualVan ThaoNo ratings yet

- Eee 306 Lab DocumentsDocument17 pagesEee 306 Lab DocumentsNazneenSultanaNo ratings yet

- EE 2013 SolvedDocument16 pagesEE 2013 SolvedJammalaVenkataramanaNo ratings yet

- DatasheetDocument4 pagesDatasheetkarim karimNo ratings yet

- Durosol Pure Sine Wave UPS - LCDDocument4 pagesDurosol Pure Sine Wave UPS - LCDsanjayinftngNo ratings yet

- Tabela Comercial de Capacitores de PoliesterDocument1 pageTabela Comercial de Capacitores de PoliesterMarcelo Japa100% (2)

- 2SD 717 - IscDocument3 pages2SD 717 - IscStevenNo ratings yet

- GBU200 (6F2S1926) 0.10 - Part6Document38 pagesGBU200 (6F2S1926) 0.10 - Part6Azrul Alif ZailanNo ratings yet

- Enertec Systems ProductsDocument1 pageEnertec Systems ProductsIsrael ExporterNo ratings yet

- 2006 International Conference on Power System Technology Overvoltage Analysis and Events in ThailandDocument7 pages2006 International Conference on Power System Technology Overvoltage Analysis and Events in ThailandBalajiNo ratings yet

- 65162e PDFDocument658 pages65162e PDFSergio Trujillo CerroNo ratings yet

- Energy Meter Parameters and UnitsDocument56 pagesEnergy Meter Parameters and UnitsLeoKing16No ratings yet

- SIGNAL & TOWER LIGHT GUIDEDocument11 pagesSIGNAL & TOWER LIGHT GUIDEJafet CabreraNo ratings yet

- MeasurIT Red Valve Pinch Series 5200E 0802Document2 pagesMeasurIT Red Valve Pinch Series 5200E 0802cwiejkowskaNo ratings yet

- Decoupling and Coupling Capacitors ExplainedDocument12 pagesDecoupling and Coupling Capacitors ExplainedCezanne CruzNo ratings yet