Professional Documents

Culture Documents

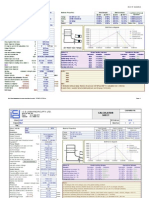

1-Clamp Design For Flange 4 Inch 300 Psi RF

Uploaded by

ziaulmananOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1-Clamp Design For Flange 4 Inch 300 Psi RF

Uploaded by

ziaulmananCopyright:

Available Formats

BOX-UP SOFTWARE

Developed by abbas_nasir@yahoo.com

T

o

=

o

C

P

o

=

kg/cm

2

D = inch

# =

lb/in

2

D

f

= 280 168 mm

T

f

= 25.5 mm

A = 16 15 mm

D

l

= mm

=

S

c

= 20.0 15.7 ksi

P

i

/P

o

= --

P

i

= 14.4

kg/cm

2

N

i

= Nos.

Force due to Operating Pressure F

P

= P

o

*D

f

*A = kg

Force due to Injection Pressure F

i

= P

i

* *D

f

*A/N

i

= kg

Maximum Force F

max

= Max (F

p

,F

i

) = kg

Max. Bending Moment (F

max

= F

p

or F

i

) M

c

= F

max

*D

f

/4 = kg-mm

Section Modulus Z

c

= M

c

/S

c

=

mm

3

Width of Clamp W

c

= 2T

f

+A = 66 mm

Thickness of Clamp (Section Modulus) T

s

= (6Z

c

/W

c

)

= mm

Thickness of Clamp (Pressure Vessel) T

p

= P

i

(D

f

/2)/(S

c

-0.6P

i

) = mm

Calculated Thickness of Clamp T

c

= Max (T

s

,T

p

) = 13.6 mm

W

p

= mm

F

applied

/F

max

= times

S

b

= 25.0 ksi

N

b

= Nos.

Load on Each Bolt F

b

= F

applied

/N

b

= kg

Required Root Area of Bolts X

b

= F

b

/S

b

=

mm

2

D

b

= 1/2 in

B = mm

R

r

= mm

E = mm

Lug Width W

l

= B+(N

b

/2)*E = 64 mm

Lug Length L

l

= R

r

+E = 32 mm

Max. Load on Lug F

l

= F

applied

/2 = kg

Moment M

l

= F

l

* L

l

/2 = kg-mm

Section Modulus Z

l

= M

l

/S

c

=

mm

3

Lug Thickness T

l

= (6Z

l

/W

l

)

= 7 13 mm

E

w

= %

S

c

= ksi

Max. Allowable Shear Stress S

s

= E*S

c

=

kg/mm

2

Applied Force per Weld F

w

= F

applied

/4 = kg

Total Welding Length for Each Lug L

w

= 2{Min (W

l

,W

c

)+T

l

} = mm

Required Weld Throat W

t

= F

w

/(L

w

*S

s

) = mm

Required Weld Leg W

lg

= W

t

*( 2)

= 0.3 mm

Width of Packing Groove (square shape)

9

Max. Allowable Stress (A-193 Gr. B7)

Total Number of Bolts (in all Lugs, EVEN number)

161

2.00

4

4

Bolt Calculations

Lug Calculations

Weld Calculations

5,161

468

323

Bolt Edge Distance (from TEMA, table D-5) 16

Bolt Radial Distance (from TEMA, table D-5)

32

16

4.97

0.2

161

153

45 Weld Joint Efficiency

Max. Allowable Stress of Clamp at T

o

15.7

1.8

6

76

323

22,579

323

Others

1.2

Bolt Spacing (from TEMA, table D-5)

Bolting / Tightening Force Factor

12

OD of Flanges (Clamp ID)

Clamp Calculations

Injection Pressure Factor

No. of Injection Points 16

Operating Pressure

13.6

Diameter of Bolts

2,046

Operating Conditions & Flange Geometry

Nominal Flange Size

Operating Temperature

Depth of Lip (from field)

at 6:59 AM

Run on 27/Sep/14

Flange Rating

Leakage from "6 150 # FUEL GAS LINE

233

Max. Allowable Stress at T

o

150

Injection Pressure

Thickness of Flange

Material of Clamp

Max./Min. Gaps between Flanges (from field)

17

Dimensions, as mentioned in Drawing:

D

d = 134 mm , W

l = 64 mm , P

i = 14

kg/cm

2

D

f = 168 mm , B = 32 mm , N

i = 16 nos.

D

p = 176 mm , L

l = 32 mm , W

lg = 0.3 mm

D

c = 203 mm , E = 16 mm , x = 3.3 mm

W

c = 66 mm , T

l = 13 mm ,

W

p = 4 mm , N

b = 4 nos. ,

A = 15 mm D

b = 1/2 inch

Leakage from "6 150 # FUEL GAS LINE

Dated: Designed By: Reviewed By: Approved By:

September 27, 2014

Dimensions, as mentioned in Drawing:

D

d = 134 mm 5.276 Inch , W

l = 64 mm 2.520 Inch , P

i = 14

kg/cm

2

D

f = 168 mm 6.614 Inch , B = 32 mm 1.260 Inch , N

i = 16 nos.

D

p = 176 mm 6.929 Inch , L

l = 32 mm 1.260 Inch , W

lg = 0.3 mm 0.012 Inch

D

c = 203 mm 8.003 Inch , E = 16 mm 0.630 Inch , x = 3.3 mm 0.130 Inch

W

c = 66 mm 2.598 Inch , T

l = 13 mm 0.500 Inch ,

W

p = 4 mm 0.157 Inch , N

b = 4 nos. 0.157 Inch ,

A = 15 mm 0.591 Inch D

b = 1/2 inch 0.020 Inch

Dated: Designed By: Reviewed By: Approved By:

Leakage from "6 150 # FUEL GAS LINE

September 27, 2014

You might also like

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Pipe Under Clamping ForceDocument6 pagesPipe Under Clamping ForceJaya DiNo ratings yet

- Clamp DesignDocument4 pagesClamp DesignDilip Reddy100% (1)

- Stream box flange clamp design calculationsDocument4 pagesStream box flange clamp design calculationsnike_y2kNo ratings yet

- Clamped Cover Plate DesignDocument7 pagesClamped Cover Plate DesignChiedu OkonduNo ratings yet

- Pipe Clamp DesignDocument3 pagesPipe Clamp DesignLarry Bea100% (1)

- Saddle design calculationsDocument9 pagesSaddle design calculationsduf fuNo ratings yet

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- Design of Repair Clamp For Online Elimination of Leakage From Bolted Flanged JointsDocument7 pagesDesign of Repair Clamp For Online Elimination of Leakage From Bolted Flanged JointsAlberto Fernando Leon Arismendy100% (1)

- Boxup Clamp DesignDocument5 pagesBoxup Clamp DesignGohar ZamanNo ratings yet

- Standard Pad Eye 10T SWL-modifDocument8 pagesStandard Pad Eye 10T SWL-modifrustamriyadiNo ratings yet

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- Lifting ClampDocument10 pagesLifting ClampwallachiaNo ratings yet

- Structural Design Calculations FOR Retensioning of ClampDocument13 pagesStructural Design Calculations FOR Retensioning of ClampFeroz Khan PatthanNo ratings yet

- Calculating bolt torque for sealing a 30Document4 pagesCalculating bolt torque for sealing a 30souren1975No ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- Nozzle loads heat exchangersDocument1 pageNozzle loads heat exchangersPeja JusohNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Cover Plate CalculationDocument1 pageCover Plate CalculationSachin5586No ratings yet

- Design Calculation Anchor Flange ASME VIII Div 1Document4 pagesDesign Calculation Anchor Flange ASME VIII Div 1Dhia SlamaNo ratings yet

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFRakeshNo ratings yet

- Blind Flange Thickness Calculation ASME B31.3Document4 pagesBlind Flange Thickness Calculation ASME B31.3bkprodhNo ratings yet

- Design Calculation Anchor Flange - ASME VIII Div 1 App.2Document3 pagesDesign Calculation Anchor Flange - ASME VIII Div 1 App.2losmoscasbr100% (2)

- Bolt Torque Calculation - Apr19Document69 pagesBolt Torque Calculation - Apr19Raj SNo ratings yet

- Vessel lifting lug design data and stress analysisDocument3 pagesVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Blind Calculation - RoarkDocument10 pagesBlind Calculation - Roarkrustamriyadi100% (2)

- FlangeCalc AS1210 v1.5Document28 pagesFlangeCalc AS1210 v1.5Ben100% (1)

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- Bolt torque calculation for sealing flangesDocument6 pagesBolt torque calculation for sealing flangessouren1975No ratings yet

- WRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)Document1 pageWRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)miteshpatel191No ratings yet

- Allowable Nozzle Load Calculation PDFDocument5 pagesAllowable Nozzle Load Calculation PDFSAGARNo ratings yet

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Calculation of Pipe SupportDocument6 pagesCalculation of Pipe Supportnaveen_86No ratings yet

- Hinge Calculation FormulasDocument2 pagesHinge Calculation FormulasamaNo ratings yet

- Calculate bolt clamp load and tightening torque using Nord-Lock washersDocument34 pagesCalculate bolt clamp load and tightening torque using Nord-Lock washersochappui100% (1)

- Design of Flanges - Optional Type 2010Document59 pagesDesign of Flanges - Optional Type 2010bakellyNo ratings yet

- AES Type Heat ExchangerDocument8 pagesAES Type Heat ExchangerSudhanshu67100% (1)

- Calculation of Trunnions Rev3Document3 pagesCalculation of Trunnions Rev3Bilel MahjoubNo ratings yet

- Bolt TorqueDocument20 pagesBolt TorqueArjun Singh AroraNo ratings yet

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 pagesBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Calculation sheet for M20 and M16 bolts torque and tensionDocument2 pagesCalculation sheet for M20 and M16 bolts torque and tensionUmesh ChamaraNo ratings yet

- Bolt Torque DeterminationDocument11 pagesBolt Torque DeterminationRatna Giridhar Kavali100% (1)

- Minimum Distance BW WeldsDocument2 pagesMinimum Distance BW Weldsroyalcom100% (1)

- Design Calculations For Pressure VesselsDocument54 pagesDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNo ratings yet

- Blind Flange With StiffenersDocument4 pagesBlind Flange With Stiffenersshahid khan100% (1)

- Flange Design Tablated FormDocument4 pagesFlange Design Tablated Formmukesh100% (1)

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- 0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsDocument29 pages0 GRP Pipe Support Calculation Clamped Shoes Flange SupportsmohdnazirNo ratings yet

- Lift Lug SpreadsheetDocument2 pagesLift Lug Spreadsheetpgarrett775814233100% (1)

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm Calculationnitin400No ratings yet

- Reinforcement Pad DesignDocument3 pagesReinforcement Pad DesignAkshat JainNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- Weight Estimation of Vessels AppsDocument28 pagesWeight Estimation of Vessels AppsAlvin Smith60% (5)

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Piping Material Chart-ModelDocument1 pagePiping Material Chart-ModelziaulmananNo ratings yet

- SubseaHotTapping TheStateoftheArtDocument24 pagesSubseaHotTapping TheStateoftheArtGeoff SuttonNo ratings yet

- Flexibility RequirementDocument2 pagesFlexibility RequirementziaulmananNo ratings yet

- Pages From c2TRDocument15 pagesPages From c2TRsammar_10No ratings yet

- Fossil Fuel Fired Power PlantDocument176 pagesFossil Fuel Fired Power PlantRawan El Hadary100% (3)

- ADD MATH ProjectDocument13 pagesADD MATH Projectmegazat27No ratings yet

- Axis Bank Placement Paper Interview Questions 48072Document3 pagesAxis Bank Placement Paper Interview Questions 48072Ravi RanjanNo ratings yet

- Some Technical Aspects of Open Pit Mine Dewatering: Section2Document11 pagesSome Technical Aspects of Open Pit Mine Dewatering: Section2Thiago MarquesNo ratings yet

- 4mb1 02r Que 20220608Document32 pages4mb1 02r Que 20220608M.A. HassanNo ratings yet

- Chapter 4 and 5 - For StudentsDocument6 pagesChapter 4 and 5 - For Studentsdesada testNo ratings yet

- Froyen06-The Keynesian System I - The Role of Aggregate DemandDocument40 pagesFroyen06-The Keynesian System I - The Role of Aggregate DemandUditi BiswasNo ratings yet

- Entrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Document35 pagesEntrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Ameen KolachiNo ratings yet

- Chapter 3-The Hospitality & Travel Marketing SystemDocument14 pagesChapter 3-The Hospitality & Travel Marketing SystemCharis AbadNo ratings yet

- New Pacific Timber v. Señeris, 101 SCRA 686Document5 pagesNew Pacific Timber v. Señeris, 101 SCRA 686Ishmael AbrahamNo ratings yet

- CSIR AnalysisDocument1 pageCSIR Analysisசெபா செல்வாNo ratings yet

- Vestax VCI-380 Midi Mapping v3.4Document23 pagesVestax VCI-380 Midi Mapping v3.4Matthieu TabNo ratings yet

- A Study On Consumer Buying Behaviour Towards ColgateDocument15 pagesA Study On Consumer Buying Behaviour Towards Colgatebbhaya427No ratings yet

- P-H Agua PDFDocument1 pageP-H Agua PDFSarah B. LopesNo ratings yet

- Unit 4 AE Scan OCRed PDFDocument44 pagesUnit 4 AE Scan OCRed PDFZia AhmedNo ratings yet

- Youtube SrsDocument23 pagesYoutube Srsabhinandan PandeyNo ratings yet

- Naruto Vol 4Document171 pagesNaruto Vol 4Andrew WongNo ratings yet

- The English Center Articulation AgreementDocument9 pagesThe English Center Articulation AgreementJose CabreraNo ratings yet

- Awwa c207 Flanges Spec SheetDocument13 pagesAwwa c207 Flanges Spec SheetVincent DiepNo ratings yet

- FRP/HDPE septic tank specificationDocument2 pagesFRP/HDPE septic tank specificationpeakfortuneNo ratings yet

- Counter Circuit Types, Components and ApplicationsDocument22 pagesCounter Circuit Types, Components and Applicationsnavin_barnwalNo ratings yet

- Supply Chain Management of VodafoneDocument8 pagesSupply Chain Management of VodafoneAnamika MisraNo ratings yet

- As 1926.1 - 2012 Swimming Pool SafetyDocument49 pagesAs 1926.1 - 2012 Swimming Pool SafetyrteteNo ratings yet

- Course Code: Hrm353 L1Document26 pagesCourse Code: Hrm353 L1Jaskiran KaurNo ratings yet

- Television: Operating InstructionsDocument40 pagesTelevision: Operating InstructionsNitin AgrawalNo ratings yet

- Borang JPK CA 01 Tahap 2Document2 pagesBorang JPK CA 01 Tahap 2ajai1010No ratings yet

- Lab 1 Boys CalorimeterDocument11 pagesLab 1 Boys CalorimeterHafizszul Feyzul100% (1)

- Case Study (DM)Document28 pagesCase Study (DM)Jai - Ho100% (1)

- Brief Cop27 Outcomes and Cop28 EngDocument24 pagesBrief Cop27 Outcomes and Cop28 EngVasundhara SaxenaNo ratings yet

- Cambridge IGCSE: Computer Science 0478/12Document16 pagesCambridge IGCSE: Computer Science 0478/12Rodolph Smith100% (2)

- ASTRO UserguideDocument1,054 pagesASTRO UserguideMarwan Ahmed100% (1)