Professional Documents

Culture Documents

SEM EDS Analysis

Uploaded by

RosemaryCarlaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEM EDS Analysis

Uploaded by

RosemaryCarlaCopyright:

Available Formats

Scanning Electron Microscopy (SEM EDS Analysis)

Scanning Electron Microscopy (SEM Analysis) can produce images of almost any sample at magnifications of 15-300,000X.

The SEM has tremendous depth of field allowing for imaging that cannot be accomplished using optical microscopy.

Conductive and nonconductive samples can be imaged. When operated in the backscatter (BSE) detection mode,

differences in material composition can be observed. Elemental analysis can be performed on any feature observed with an

integrated Energy Dispersive Spectroscopy (EDS) detector.

SEM EDS analysis or SEM EDX analysis can be used to provide chemical analysis in areas as small as one micrometer in

diameter.

Scanning Electron Microscopy (SEM)

In the SEM, an electron beam is focused into a fine probe and rastered over a small rectangular area. As the electrons

interact with the sample, various signals, including those from secondary electrons, are created and detected. These

highly localized signals are used to modulate the brightness of a CRT display rastered synchronously with the electron

beam. The image formed on the CRT is a highly magnified image of the sample. The technique is usually nondestructive,

although instrumental sample requirements often mandate alteration of the sample before analysis. Magnification is

from 10X to 300,000X and lateral resolution is 10-50nm, allowing features as small as 100 to be seen. The analysis

depth is 20-50 . SEM Analysis provides excellent topographical data, and in backscatter mode atomic number

information (compositional) also. Images can be e-mailed or delivered on various storage media for client manipulation.

Back-Scattered Electron Images

Back-scattered electron (BSE) images are useful for locating phase differences and finding specific features on a sample.

When a high energy electron interacts with an atom, it undergoes either inelastic scattering with the nucleus. BSEs result

from elastic scattering and leave the sample with energies comparable to the primary beam. The likelihood of

backscattering increases with the atomic number (Z) of the material. High-Z materials give a stronger signal (brightness)

than low-Z materials, thereby giving image contrast from elemental differences. Visit SEM EDS Analysis for more

information.

Contact Us:-Rocky Mountain Laboratories, Inc.

602 Park Point Drive, Suite 101

Golden, Colorado 80401

Tel: (303) 526-9449 Fax: (303) 526-0877

Toll Free: (800) PRO-LABS / (800) 776-5227

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Alugbati and Kangkong Nutrition FactsDocument2 pagesAlugbati and Kangkong Nutrition FactsIsidro Matteo de AmaNo ratings yet

- SME LendingDocument8 pagesSME LendingAmit GiriNo ratings yet

- Eco 359 M 2013934607asdfDocument2 pagesEco 359 M 2013934607asdfEdward ZhouNo ratings yet

- Josefa Mercado V Alfredo RizalDocument1 pageJosefa Mercado V Alfredo RizalSj EclipseNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireMayur RathodNo ratings yet

- Activity 4 periodic table questionsDocument2 pagesActivity 4 periodic table questionsJorenAndradeNo ratings yet

- Angler FishDocument5 pagesAngler Fishbuffylovez100% (1)

- Molybdovanadic ReagentDocument2 pagesMolybdovanadic ReagentCeyhun Babac CetinNo ratings yet

- Cranberry & Cherry TiffinDocument5 pagesCranberry & Cherry TiffinRosca RodicaNo ratings yet

- Elecs Suarez CDocument8 pagesElecs Suarez CDivina Aguilar-Dela CruzNo ratings yet

- Coll PPDocument4 pagesColl PPRishi SinhaNo ratings yet

- Differential CalculusDocument2 pagesDifferential CalculusCresencio Genobiagon JrNo ratings yet

- Bengali Fish Curry (Doi Maach) Recipe Print Page - MyRecipesDocument2 pagesBengali Fish Curry (Doi Maach) Recipe Print Page - MyRecipesPradyumna Kumar BarikNo ratings yet

- Lion Air eTicket Itinerary SummaryDocument1 pageLion Air eTicket Itinerary SummaryBasten Jeremiah SiahaanNo ratings yet

- Mineduc Adet/Tevsa P.O.Box 3830 Kigali-RwandaDocument3 pagesMineduc Adet/Tevsa P.O.Box 3830 Kigali-RwandaEng Bagaragaza RomualdNo ratings yet

- Introduction to Mechanisms FundamentalsDocument54 pagesIntroduction to Mechanisms Fundamentalsccharp123No ratings yet

- Igi 2 Covert Strike CheatsDocument3 pagesIgi 2 Covert Strike CheatsMuhammad Nadeem AtifNo ratings yet

- American Tattoo Piercing FormDocument1 pageAmerican Tattoo Piercing Formhbabe97No ratings yet

- 4.25.11.WPE - Lab. Personal Power Stairs LabDocument4 pages4.25.11.WPE - Lab. Personal Power Stairs LabArra VillanuevaNo ratings yet

- Chemical Processes Material Cost and Compatibility - UC Riverside, CHE175B Chemical Process DesignDocument4 pagesChemical Processes Material Cost and Compatibility - UC Riverside, CHE175B Chemical Process DesignGabriel S. Gusmão (Freddie)67% (3)

- Saints Sinners Mug Cake RecipeDocument1 pageSaints Sinners Mug Cake RecipeMaryse LapointeNo ratings yet

- Quasi-linear Utility and Corner SolutionsDocument2 pagesQuasi-linear Utility and Corner Solutionssaswat1953419No ratings yet

- Merchandising AccountsDocument3 pagesMerchandising AccountsJenifer GaliciaNo ratings yet

- Case Study on Company Growth and Sales FluctuationDocument12 pagesCase Study on Company Growth and Sales FluctuationChristian JimmyNo ratings yet

- In The Horsegate' Hotseat: Our Experts Score The CeosDocument1 pageIn The Horsegate' Hotseat: Our Experts Score The Ceosapi-205873997No ratings yet

- 1931 GoldenAge 1931 E PDFDocument833 pages1931 GoldenAge 1931 E PDFjanineNo ratings yet

- Islamic Accounting Exercise on Salam and Parallel Salam FinancingDocument2 pagesIslamic Accounting Exercise on Salam and Parallel Salam Financingwokyoh91No ratings yet

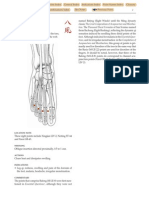

- BAFENG (M-LE-8) : Eight WindsDocument1 pageBAFENG (M-LE-8) : Eight Windsray72roNo ratings yet

- Holophane 02454 Series Brochure 1971Document2 pagesHolophane 02454 Series Brochure 1971Alan MastersNo ratings yet

- Topic 5 Wing-Design Page 26Document1 pageTopic 5 Wing-Design Page 26thomastan02No ratings yet