Professional Documents

Culture Documents

RCC Detailing Guide for Building Construction

Uploaded by

Anonymous nwByj9L100%(1)100% found this document useful (1 vote)

97 views21 pagesThis document discusses guidelines for detailing reinforced concrete structural elements. It provides guidelines for labeling and arranging reinforcement bars, determining proper concrete cover, and adopting standard hook shapes. The document also outlines general considerations for preparing structural drawings, such as specifying grades of materials, dimensions, and other construction information. Key aspects of detailing beams, slabs, and other members are described, including reinforcement sizes and spacing.

Original Description:

RCC Detailing on buildings

Original Title

Power Point1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses guidelines for detailing reinforced concrete structural elements. It provides guidelines for labeling and arranging reinforcement bars, determining proper concrete cover, and adopting standard hook shapes. The document also outlines general considerations for preparing structural drawings, such as specifying grades of materials, dimensions, and other construction information. Key aspects of detailing beams, slabs, and other members are described, including reinforcement sizes and spacing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

97 views21 pagesRCC Detailing Guide for Building Construction

Uploaded by

Anonymous nwByj9LThis document discusses guidelines for detailing reinforced concrete structural elements. It provides guidelines for labeling and arranging reinforcement bars, determining proper concrete cover, and adopting standard hook shapes. The document also outlines general considerations for preparing structural drawings, such as specifying grades of materials, dimensions, and other construction information. Key aspects of detailing beams, slabs, and other members are described, including reinforcement sizes and spacing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 21

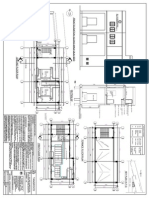

PRACTICAL ASPECTS ON DETAILING OF

RCC MEMBERS IN BUILDING CONSTRUCTION

BY

V.M.RAJAN

CE/CIVIL/MTPP

Detailing is important factor to be considered in Design.

Most of structural distress is caused not due to inaccurate analysis or

incorrect design but by improper or in adequate detailing practice.

Good detailing gives safety, economy and simplicity of layout.

Proper detailing practice will go on long way reducing cracking,

deformation of the structure.

The design ideas normally need to be communicated for construction at

site, by translating them into detailed structural drawings.

The detailed drawings acts as a guide in order to perform certain operation

on the site in a specified manner.

The drawing serves as a record of some important assumption made in the

design.

Engineering drawing prepared should specify grades of concrete & steel,

Live load, dimensions, reinforcement, lap lengths, concrete cover and other

information need for detailing the reinforcement, building the forms,

fabricating reinforcement and placing concrete.

For preparing structural drawings the following codes are used:

IS 5526-1969 & SP 34-1987.

General guide lines for preparing detailing:

1. Label each bar and show its shape clearly.

2. Prepare bar bending schedule.

3. Indicate proper cover to reinforcement.

4. Adopt U-type hooks for mild steel and L-type hooks for deformed

bars.

5. Adopt commonly available sizes of bars &spirals in the market.

6. For a single member the number of different sizes of bars shall be

kept minimum.

7. Show enlarge details at corners, intersections of walls, beams &

column joints etc.

8. Indicate all expansion, construction and contraction joints on plans

and provide details for such joints.

9. Reinforcement shall not extend across an expansion joint and the

break between the sections shall be complete.

10. The location of construction joints shall be at the point of

minimum shear approximately at mid or near the mid points. It shall

be formed vertically and not in a sloped manner.

11. Congestion of bars should be avoided at points where members

intersect and make certain that all reinforcement can be properly

placed.

12. In case of bundled bars, lapped splice of bundled bars shall be

made by splicing one bar at a time, such individual splices within

bundle shall be staggered.

13. Lap splice shall be not be used for bars larger than 36mm dia

except where welded.

STAGES IN STRUCTURAL DESIGN:

The structural design involves the following stages.

1) Structural planning.

2) Computation of loads.

3) Analysis.

4) Member design.

5) Detailing, Drawing and Preparation of schedules.

STRUCTURAL PLANNING:

1. Position and orientation of columns.

2. Positioning of beams.

3. Spanning of slabs.

4. Layouts of stairs.

5. Selecting proper type of foundation.

Scheme Grid Reference

Structural Lay-Out Drawing:

Two axes marked one side with alphabets and the other with

numbers.

Columns are marked at the intersection of grids

Beams are marked using two parallel lines

Slabs are indicated either as one way or two way

Structural Layout of Footing

Column Position:

1.Column can be provided at the intervals of 12 , 15, 18, 20 and so

on based on our requirement.

2. Provide Columns at beam-beam junctions.

3.Provide columns symmetric or at regular intervals not zig-zag.

Orientation of columns:

1. Structural point of view : place depth of column where B.M. is

more i.e in the plane of maximum bending.

2. Functional point of view : orient column merge with wall without

any offset. The column must have sufficient strength in the plane

of maximum bending. This can be made possible by arranging

longitudinal steel at the faces in the plane of bending.

Positioning of beams:

1.Based on functional requirement of buildings.

2. Beams shall normally be provided under the walls or below a heavy

concentrated load to avoid these loads directly coming on slabs.

3. Avoid larger spacing of beams from deflection and cracking criteria.

Positioning of Slab:

1. Based on their aspect ratio (Ly/Lx) slabs are either spanned only

one direction or along both directions.

SLAB

1. Standard Slab

thickness:100,110,120,125,130,140,150,160,180,200mm (In

multiples of 5mm)

2. Dia of bars used in practice:

Main rod : 8mm, 10mm &12mm dia Fe415 grade steel.

Distributors: 8mm dia Fe415 grade steel.

3. Spacing :

Main steel : 3 d or 300 mm whichever is smaller.

Max spacing 200mm (8)

Distribution Steel : 5d or 450mm whichever is smaller.

Max spacing 250mm (10)

4. Minimum Reinforcement : 0.15% for Fe 250(Mild steel)

0.20% for HYSD bars Fe415.

.

5.Maximum dia of bars : Not more than 1/8 of slab thickness.

6. Cover : Not less than 20mm nor less than dia of bar whichever is

higher.

Notation : 20 Y 10-2- 150 T.

This means 20 Nos. Deformed bars 10mm dia marked No.2 at

150mm centre to centre at top.

ONEWAY SLAB:

Using Straight bars

TWO WAY SIMPLY SUPPORTED SLAB

TWO WAY CONTINUOUS SLAB

Torsion Rods at Discontinuous edges

Rectangular opening in a slab

Circular Openings in a slab

Detailing of beams:

1. Size of beams:

Rectangular Beams : Depth 1/10 to 1/20 of span.

Tee beam : in multiples of 25 mm up to 500mm.

Ell beam : in multiples of 50mm for greater sizes.

Width : 1/3 to of depth.

Correspond to supporting members.

Practical beam size:

9 x (9 +4) =9 x 13

9 x (12 +4) =9 x 16

9 x (15 +4) =9 x 19

9 x (18 +4) =9 x 22

9 x (21 +4) =9 x 25

9 x (24 +4) =9 x 28

2. Longitudinal reinforcement:

Minimum Reinforcement =0.20% for Fe415 bars

=0.34% for Mild steel Fe250.

Maximum Reinforcement =4% of c.s. area for both tension and compression

reinforcement.

3. Normal Dia of bars used:

Main bars: 12,16,20 &25

Stirrups : 8 &10mm RTS

4. Spacing between bars:

Minimum spacing:

Not less than dia of large bar nor less than max. size of

aggregate +5mm whichever is greater.

Max. spacing : For Fe415=180mm & for Fe500=150 mm.

5. Cover : Not less than25mm nor less than dia of bar.

6. Stirrups:

Minimum dia : 8mm

Maximum dia : 16mm

Spacing : minimum 80mm C/c

Maximum 0.75 d or 450mm whichever is minimum.

For width of beam > 350mm, use 4 legged stirrups.

Side face reinforcement:

7.Depth > 750mm

Longitudinal bars have to provided at a spacing of >300mm.

Area of bar: 0.1% of cross sectional area of beam rib.

Dia of longitudinal spacer bars (hanger bars)-12 to 16mm.

8.Splicing :

Lap length- 2 Ld or 30 dia whichever is greater (Direct tension)

Development Length: Ld or 30 dia whichever is grater.(for flexural

tension)

Straight lap length > 15 dia or 20mm.

Lap length in compression< 24 times dia

Splicing is effected through welding sleeves.

Notation used for beam detailing:

Main Longitudinal bars:

4 Y 25-1 i.e. 4 Nos. Deformed bars, 25mm dia, mark No. 1.

Notation for stirrups :

12 R 10-6-200 i.e. 12 Nos. mild steel links, 10mm dia, mark No.6

spaced at 200mm centres.

You might also like

- Lifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamDocument20 pagesLifting Beam Deign Staad 82187560 Design Calc 10T Spreader BeamJurie_sk360888% (8)

- Staad Pro NotesDocument134 pagesStaad Pro NotesAnonymous nwByj9L100% (31)

- Staad Design and Code ChecksDocument26 pagesStaad Design and Code Checkskhantha velNo ratings yet

- IStructE Sustainability Articles August - December 2020Document99 pagesIStructE Sustainability Articles August - December 2020zaidiamna9No ratings yet

- Strength Design MethodDocument12 pagesStrength Design MethodaltavanoarNo ratings yet

- SAFE VerificationDocument7 pagesSAFE VerificationRahul AggarwalNo ratings yet

- Design in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Document66 pagesDesign in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)rashmiNo ratings yet

- LECTURE NOTES ON REINFORCED CONCRETE BEAMSDocument84 pagesLECTURE NOTES ON REINFORCED CONCRETE BEAMSshambel asfawNo ratings yet

- British Rebar CodesDocument32 pagesBritish Rebar CodesManoj RautNo ratings yet

- Chapter-3 Structural Design of Reinforced Concrete FrameDocument19 pagesChapter-3 Structural Design of Reinforced Concrete FrameEmin Can ÖzenNo ratings yet

- Reinforced concrete stair design exampleDocument8 pagesReinforced concrete stair design exampleHawaiiChongNo ratings yet

- Is 808-1989 Steel TableDocument24 pagesIs 808-1989 Steel TableAtul Kumar Engineer86% (28)

- RCC Notes III II Strctral-EngineeringDocument84 pagesRCC Notes III II Strctral-Engineeringvenu madhavNo ratings yet

- Column New EC2 LastDocument81 pagesColumn New EC2 LastsuniljayaNo ratings yet

- PSC Single SpanDocument59 pagesPSC Single SpanNabeel Ahmad100% (1)

- STAAD PRO V8i Continuous BeamDocument6 pagesSTAAD PRO V8i Continuous BeamAnonymous nwByj9LNo ratings yet

- Example 6.1Document11 pagesExample 6.1Misz_10_ScorpioNo ratings yet

- Reinforced Concrete Cantilever Beam Analysis and Design (CSA A23.3 14)Document33 pagesReinforced Concrete Cantilever Beam Analysis and Design (CSA A23.3 14)sachin shingadeNo ratings yet

- Lec 5 (1) - Design of BeamsDocument62 pagesLec 5 (1) - Design of BeamsMuhammad Faisal AsifNo ratings yet

- DESIGN OF CANTILEVER BEAM AND LINTEL SUNSHADEDocument31 pagesDESIGN OF CANTILEVER BEAM AND LINTEL SUNSHADENirina ArimananaNo ratings yet

- Eurocode - Load Combinations For Steel Structures - R1Document26 pagesEurocode - Load Combinations For Steel Structures - R1anil97232No ratings yet

- Example 1.4 - Perpendicular To FlightDocument14 pagesExample 1.4 - Perpendicular To FlightHawaiiChongNo ratings yet

- 08-04 Church Design Concepts Guidelines For Designing A ChurchDocument4 pages08-04 Church Design Concepts Guidelines For Designing A ChurchMarielle G. CastilloNo ratings yet

- R60 Slab Design SpecificationDocument8 pagesR60 Slab Design SpecificationNasrulNo ratings yet

- Litanies and PrayersDocument51 pagesLitanies and PrayersYeng SantosNo ratings yet

- Elements of Steel Structure: Aniendhita Rizki Amalia, ST. MTDocument36 pagesElements of Steel Structure: Aniendhita Rizki Amalia, ST. MTirfananda hutomoNo ratings yet

- RCC Detailing GuideDocument22 pagesRCC Detailing GuidejadeaachiNo ratings yet

- Staad ExamplesDocument35 pagesStaad ExamplesvisharamNo ratings yet

- Conceptual Seismic DesignDocument91 pagesConceptual Seismic Designshubham2395No ratings yet

- CE-Materials, Construction, DesignDocument3 pagesCE-Materials, Construction, DesignMohan PatilNo ratings yet

- Circular Water Tank Design and Reinforcement LayoutDocument28 pagesCircular Water Tank Design and Reinforcement LayoutLachu M. SharmaNo ratings yet

- Presentation On Reinforcing Detailing of R.C.C MembersDocument19 pagesPresentation On Reinforcing Detailing of R.C.C MembersDominic FernandesNo ratings yet

- 2016 2Document8 pages2016 2Siddhanatha boobathiNo ratings yet

- Training Report at Structural ConsultancyDocument111 pagesTraining Report at Structural ConsultancyKaushal Patel100% (1)

- ETABS Extended 3D Analysis Building System ExampleDocument41 pagesETABS Extended 3D Analysis Building System ExampleAnonymous nwByj9L100% (2)

- Building RegulationsDocument65 pagesBuilding RegulationsCip ZerkopNo ratings yet

- Staad FoundationDocument25 pagesStaad FoundationAnonymous nwByj9L100% (2)

- ASD-LRFD For Wood Construction (Provisions For Wind and Seismic)Document33 pagesASD-LRFD For Wood Construction (Provisions For Wind and Seismic)weerapon100% (1)

- Abutment 45+705 110110Document106 pagesAbutment 45+705 110110AmbrishNo ratings yet

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument47 pagesDesign and Drawing of RC Structures: Dr. G.S.Suresher_mahmoodNo ratings yet

- PEB Structural Components GuideDocument312 pagesPEB Structural Components GuidejjjhassanNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement Detailingsomumallidi100% (1)

- Dedication Preface Chapter 1: Introduction To STAAD - Pro CONNECT EditionDocument5 pagesDedication Preface Chapter 1: Introduction To STAAD - Pro CONNECT EditionCharles AjayiNo ratings yet

- Design and Analysis of RC BeamsDocument12 pagesDesign and Analysis of RC BeamsmyidmaranNo ratings yet

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- Comb Foot MCNDocument22 pagesComb Foot MCNmohanty_anantakumar6332No ratings yet

- Columns 1Document16 pagesColumns 1ShahriazSAMNo ratings yet

- Design of RCC SlabsDocument7 pagesDesign of RCC SlabsprashmceNo ratings yet

- Sohar Mall Strip Footing - 01Document38 pagesSohar Mall Strip Footing - 01MIHDI PALAPUZNo ratings yet

- Memorial Hall ReportDocument19 pagesMemorial Hall ReportMike CarraggiNo ratings yet

- Design and Reanalysis of Pile Cap With Five Piles Under Eccentricity PDFDocument7 pagesDesign and Reanalysis of Pile Cap With Five Piles Under Eccentricity PDFNfs TarTonNo ratings yet

- R C C Beam DesignDocument6 pagesR C C Beam DesignBehroozNo ratings yet

- Calculating Basic Wind Pressure and Total Wind Load on Buildings Using STAAD ProDocument1 pageCalculating Basic Wind Pressure and Total Wind Load on Buildings Using STAAD ProKNo ratings yet

- Short RCC Column Performances in Different ConditionsDocument16 pagesShort RCC Column Performances in Different ConditionssjmorabadNo ratings yet

- Unit 3 Limit State of ServiceabilityDocument55 pagesUnit 3 Limit State of ServiceabilityManoj SharmaNo ratings yet

- Designing eccentric footingsDocument3 pagesDesigning eccentric footingsindrajit sodhaNo ratings yet

- RCC Slab Design CalculationDocument2 pagesRCC Slab Design CalculationVikram GaikwadNo ratings yet

- RCC Foundation-Unit 3Document18 pagesRCC Foundation-Unit 3ayeshaNo ratings yet

- Story Force per Wind LoadDocument1 pageStory Force per Wind Loadkukadiya127_48673372No ratings yet

- Two Pile GroupDocument12 pagesTwo Pile GroupJammy KingNo ratings yet

- Construction JointDocument1 pageConstruction JointNumair Ahmad FarjanNo ratings yet

- SP Is CODE Masonary DesignDocument167 pagesSP Is CODE Masonary DesignKumar PallavNo ratings yet

- Seismic Analysis and Design of Vertically Irregular Mutistoried RC Concrete Building Using Staad Pro V8iDocument6 pagesSeismic Analysis and Design of Vertically Irregular Mutistoried RC Concrete Building Using Staad Pro V8iEditor IJTSRDNo ratings yet

- Calculation of CG For Mat/Combined Footing: ProjectDocument2 pagesCalculation of CG For Mat/Combined Footing: ProjectKazi Shahazada Shahanewaz HossainNo ratings yet

- Analysis and Design of One-Way SlabsDocument6 pagesAnalysis and Design of One-Way SlabsricardoNo ratings yet

- Moment DistributionDocument153 pagesMoment DistributionHerbert P. BacosaNo ratings yet

- Revision of Is - 1893 Part 1Document8 pagesRevision of Is - 1893 Part 1BMSF khaliqeNo ratings yet

- FOUNDATION PLAN & DETAILSDocument21 pagesFOUNDATION PLAN & DETAILSIzri AndayaNo ratings yet

- Presentation On Reinforcing Detailing of RCC MembersDocument20 pagesPresentation On Reinforcing Detailing of RCC MembersprakashNo ratings yet

- Reinforcement Detailing Guide for Concrete StructuresDocument6 pagesReinforcement Detailing Guide for Concrete StructurescherogonyaNo ratings yet

- Steel BarsDocument8 pagesSteel BarsJerome Barra AbreaNo ratings yet

- Pages From Civil EngineeringDocument50 pagesPages From Civil EngineeringRagavanNo ratings yet

- Pushover CE&CRDocument9 pagesPushover CE&CRAnonymous nwByj9LNo ratings yet

- Planwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingDocument4 pagesPlanwin / RCDC Is A Total End To End Solution For RCC Building Design and Drawing. It Offers FollowingAnonymous nwByj9LNo ratings yet

- Staad Pro-Open ChannelDocument5 pagesStaad Pro-Open ChannelAnonymous nwByj9LNo ratings yet

- Staad Auto Load CombinationDocument1 pageStaad Auto Load CombinationAnonymous 48jYxR1CNo ratings yet

- ETABS Example-1Document64 pagesETABS Example-1Anonymous nwByj9L0% (1)

- Compound WallDocument3 pagesCompound WallAnonymous nwByj9L0% (1)

- Steps To E-Filing For ITDocument4 pagesSteps To E-Filing For ITAnonymous nwByj9LNo ratings yet

- WindDocument9 pagesWindAnonymous nwByj9LNo ratings yet

- Staad Pro-Open ChannelDocument5 pagesStaad Pro-Open ChannelAnonymous nwByj9LNo ratings yet

- Section Viii AnnexuesDocument11 pagesSection Viii AnnexuesAnonymous nwByj9LNo ratings yet

- Section IIDocument105 pagesSection IIAnonymous nwByj9LNo ratings yet

- Section VDocument18 pagesSection VAnonymous nwByj9LNo ratings yet

- Section IDocument37 pagesSection IAnonymous nwByj9LNo ratings yet

- Section VIIDocument29 pagesSection VIIAnonymous nwByj9LNo ratings yet

- sch-2 - 06.01.2014Document1 pagesch-2 - 06.01.2014Anonymous nwByj9LNo ratings yet

- Trench 1Document1 pageTrench 1Anonymous nwByj9LNo ratings yet

- Trench 2Document1 pageTrench 2Anonymous nwByj9LNo ratings yet

- Fire Barrier Wall: Cable TrenchDocument1 pageFire Barrier Wall: Cable TrenchAnonymous nwByj9LNo ratings yet

- WindDocument139 pagesWindAnonymous nwByj9LNo ratings yet

- Schematic Layout of Bazaar Road SSDocument1 pageSchematic Layout of Bazaar Road SSAnonymous nwByj9LNo ratings yet

- Bazzar Road SS-GFDocument1 pageBazzar Road SS-GFAnonymous nwByj9LNo ratings yet

- 8 7 Battery Room: S C A D A RTCCDocument1 page8 7 Battery Room: S C A D A RTCCAnonymous nwByj9LNo ratings yet

- Schematic Layout of Bazaar Road SSDocument1 pageSchematic Layout of Bazaar Road SSAnonymous nwByj9LNo ratings yet

- Bazzar Road Control Room Building DesignDocument39 pagesBazzar Road Control Room Building DesignAnonymous nwByj9LNo ratings yet

- Comparative Study of Multistorey Building Using Various Types of DampersDocument32 pagesComparative Study of Multistorey Building Using Various Types of DampersJayant ShaligramNo ratings yet

- Stiffness Modifier For Beam, Column, Wall, Slab - Computers and Structures - ETABS - Eng-TipsDocument4 pagesStiffness Modifier For Beam, Column, Wall, Slab - Computers and Structures - ETABS - Eng-Tipsgreat2008No ratings yet

- Jurnal Dinding Penahan TanahDocument11 pagesJurnal Dinding Penahan TanahAnonymous 7npIQ1kYDNo ratings yet

- Structural Steel Solution: Beams - Columns - Angles - ChannelsDocument24 pagesStructural Steel Solution: Beams - Columns - Angles - ChannelsPradeepNo ratings yet

- Schedule of Pile Cap ProjectDocument2 pagesSchedule of Pile Cap ProjectAqilahNasihahNo ratings yet

- Electrical Conduit Work for Four Seasons Park ProjectDocument3 pagesElectrical Conduit Work for Four Seasons Park Projectkamil arnousNo ratings yet

- Numerical Analysis of Castellated Beam DesignDocument8 pagesNumerical Analysis of Castellated Beam Designvenkata369No ratings yet

- Folded Plates PDFDocument8 pagesFolded Plates PDFAshneet KaurNo ratings yet

- Effect of Ribs and Stringer Spacings On The Weight of Composite StructuresDocument7 pagesEffect of Ribs and Stringer Spacings On The Weight of Composite StructuresVesa RäisänenNo ratings yet

- 4 BangsDocument1 page4 BangsIvandelist XNo ratings yet

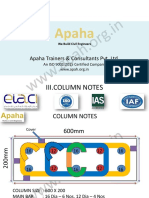

- RCC-Column-Notes - Apaha-Trainers-and-Consultants-Punjisksjd JSJDJSJJSJD Isisjjdd JSJSJDJD JsjsjeDocument17 pagesRCC-Column-Notes - Apaha-Trainers-and-Consultants-Punjisksjd JSJDJSJJSJD Isisjjdd JSJSJDJD Jsjsjepranjal soniNo ratings yet

- Mortars and Plasters: Building Construction MaterialsDocument70 pagesMortars and Plasters: Building Construction MaterialschinmayihyNo ratings yet

- GCW-'UltraTech PPC' Issue Date:14.11.2011Document1 pageGCW-'UltraTech PPC' Issue Date:14.11.2011nanda kishopreNo ratings yet

- Bubble Deck Slab REPORTDocument29 pagesBubble Deck Slab REPORTMangesh ShindeNo ratings yet

- Investigation of Linear Dynamic Analysis and Duc-Tile Design of High Rise Structure As Per Revised Indian CodeDocument12 pagesInvestigation of Linear Dynamic Analysis and Duc-Tile Design of High Rise Structure As Per Revised Indian CodeIJRASETPublicationsNo ratings yet

- Damp-proofing methods to prevent moisture damageDocument68 pagesDamp-proofing methods to prevent moisture damageMARUFNo ratings yet

- Tilt Wall Analysis ACI 318-14Document1 pageTilt Wall Analysis ACI 318-14Dan SmithNo ratings yet

- Tinpiple, Lamjung Project Name: Construction of Rainas Aaudhogikgram Contract ID: Rainas/NCB/W/02/076-077 Location: Rainas-7 Comparitive ChartDocument6 pagesTinpiple, Lamjung Project Name: Construction of Rainas Aaudhogikgram Contract ID: Rainas/NCB/W/02/076-077 Location: Rainas-7 Comparitive ChartBhim DahalNo ratings yet

- Exposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementDocument8 pagesExposure Effect of Mgso4 and HCL On Strength Properties of Ceramic Waste Powder by Partial Replacement With CementIJIRSTNo ratings yet

- Uninterrupted Height of Masonry Cladding To Light Steel FramingDocument4 pagesUninterrupted Height of Masonry Cladding To Light Steel FramingmgmccarthyNo ratings yet

- Prequalified Seismic Moment ConnectionsDocument2 pagesPrequalified Seismic Moment Connectionssymon ellimacNo ratings yet

- Reinforced Cement Concrete Multiple Choice QuestionDocument4 pagesReinforced Cement Concrete Multiple Choice QuestionPrashanth Sunagar100% (1)

- Beams, Steel I Beams, Structural Beams, Wide FlangeDocument4 pagesBeams, Steel I Beams, Structural Beams, Wide Flangeanon_795652448No ratings yet