Professional Documents

Culture Documents

JMS 316 GS-N.L: Technical Specification

Uploaded by

Martin Kratky0 ratings0% found this document useful (0 votes)

293 views4 pagesThis document provides the technical specifications for a Jenbacher JMS 316 GS-N.L natural gas engine module that produces 834kW of electricity. The module includes the gas engine, alternator, heat exchangers, and control equipment mounted on a base frame. The specifications include dimensions, weights, electrical and thermal outputs, emissions levels, and connection details.

Original Description:

Jenbacher

Original Title

J316V05_en

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides the technical specifications for a Jenbacher JMS 316 GS-N.L natural gas engine module that produces 834kW of electricity. The module includes the gas engine, alternator, heat exchangers, and control equipment mounted on a base frame. The specifications include dimensions, weights, electrical and thermal outputs, emissions levels, and connection details.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

293 views4 pagesJMS 316 GS-N.L: Technical Specification

Uploaded by

Martin KratkyThis document provides the technical specifications for a Jenbacher JMS 316 GS-N.L natural gas engine module that produces 834kW of electricity. The module includes the gas engine, alternator, heat exchangers, and control equipment mounted on a base frame. The specifications include dimensions, weights, electrical and thermal outputs, emissions levels, and connection details.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

GE Jenbacher GmbH & Co OHG

A-6200 Jenbach, Austria

JMS 316 GS-N.L

Natural gas 834kW el.

http://information.jenbacher.com

jenbacher.info@ge.com

Tel. +43 5244 600-0

Fax +43 5244 63255

Jenbacher gas engines

Technical Specification

JMS 316 GS-N.L

Natural gas 834kW el.

CO-GEN Module data: Additional information:

Electrical output kW el. 834 Sound pressure level (engine, average value 1m) dB(A) 96

Recoverable thermal output (120 C) kW 988 Sound pressure level exhaust gas (1m, 30 off engin dB(A) 116

Energy input kW 2.091 Exhaust gas mass flow rate, wet kg/h 4.477

Fuel Consumption based on a LHV of Exhaust gas volume, wet Nm/h 3.541

9,5 kWh/Nm Nm/h 220 Max.admissible exhaust back pressure after engine mbar 60

Electrical efficiency % 39,9% Exhaust gas temperature at full load C [8] 485

Thermal efficiency % 47,3% Combustion air mass flow rate kg/h 4.327

Total efficiency % 87,2% Combustion air volume Nm/h 3.347

Heat to be dissipated (LT-Circuit) kW 43 Max. inlet cooling water temp. (intercooler) C 40

Emission values: Max. pressure drop in front of intake-air filter mbar 10

NOx < 500 mg/Nm (5% O2) Return temperature C 70

Forward temperature C 90

Hot water flow rate m/h 42,4

Engine data: Alternator:

Engine type J 316 GS-C05 Manufacturer STAMFORD

Configuration V 70 Type PE 734 B2

No. of cylinders 16 Type rating kVA 1.400

Bore mm 135

Stroke mm 170

Piston displacement lit 38,93 Efficiency at p.f. = 1,0 % 96,9%

Nominal speed rpm 1.500 Efficiency at p.f. = 0,8 % 95,8%

Mean piston speed m/s 8,5 Ratings at p.f. = 1,0 kW 834

Mean effe. press. at stand. power and nom. spe bar 17,70 Ratings at p.f. = 0,8 kW 825

Compression ratio Epsilon 11,8 Frequency Hz 50

ISO standard fuel stop power ICFN kW 861 Voltage V 400

Spec. fuel consumption of engine kWh/kWh 2,43 Protection Class IP 23

Specific lube oil consumption g/kWh 0,30 Insulation class H

Weight dry kg 4.000 Speed rpm 1.500

Filling capacity lube oil lit 300 Mass kg 2.710

Based on methane number MZ 70

Technical parameters:

Applicable standards: Based on DIN-ISO 3046

Based on VDE 0530 REM with specified tolerance

Standard conditions: Air pressure: 1000 mbar or 100 m above sea level

Air temperature: 25C or 298 K

Relative Humidity: 30%

Engine output derating:

Gas quality: according to TA 1000-0300

Gas flow pressure: 80 - 200 mbar

(Lower gas pressures upon inquiry)

Max. variation in gas pressure: 10%

All data are based on engine full load at specified media temperatures and are subject to change.

The technical Instruction TA 1100-0110 "PARAMETER FOR GE Jenbacher GAS ENGINES" must be strictly observed.

for plants installed at > 500m above see level and/or intake temperature > 30C, the reduction of engine power is

determined for each project.

Jenbacher gas engines

Technical Specification

Basic engine equipment: Module equipment:

*Exhaust gas turbocharger, Intercooler *Base frame for gas engine,

*Motorized carburator for LEANOX control alternator and heat exchangers

*Electronic contactless high performance ignition system *Internal pole alternator with excitation alternator and

*Lubricating oil pump (gear driven) with automatic voltage regulator; p.f. 0,8 lagging to 1,0

*Lubricating oil filters in main circuit *Flexible coupling, bell housing

*Lubricating oil sump; Lubricating oil heat exchanger *Anti-vibration mounts

*Jacket water pump *Air filter

*Fuel-, lubricating oil and jacket water pipe work on engine *Automatic lube oil replenishing with level control

*Flywheel for alternator operation; Exhaust gas manifold *Wiring of components to module interface panel

*Viscous damper *Crankcase breather

*Knock sensors *Jacket water electric preheating

Engine accessories:

*Electric starter motor

*Electronic speed governor

*Electronic speed monitoring device including starting and Module control panel:

overspeed control *Totally enclosed , single door cubicle, wired to terminals and

*Transducers and switches for oil pressure, jacket water temp., ready to operate, protection IP 41 outside,

jacket water pressure, charge pressure and mixture temperature IP 10 inside, according to VDE-standards

*One thermocouple per cylinder Control equipment:

*Engine-Management-System dia.ne (Dialog Network)

Supplied loose: **Visualisation (industry PC-10'' color graphics display): Operation data,

Gas train according to DIN-DVGW consisting of: controller display,Exh. gas temp.,Generator electr. connection,etc.

*Manual stop valve, fuel gas filter, two solenoid valves, **Central engine- and module control: Speed-, Power output-,

Leakage control device, gas pressure regulator LEANOX-Control and knock control, etc.

*Multi-transducer

Documentation: *Lockable operation mode selector switch

*Operating and maintenance manual Positions: "OFF", "MANUAL", "AUTOMATIC"

*Spare parts manual *Demand switch

*Drawings

Assembly, painting, testing in Jenbach/Austria

Identical to Genset except that heat recovery is included.

*jacket water heat exchanger mounted on module frame

*exhaust gas heat exchanger mounted on module frame;

*all heat exchangers with complete pipework

*Heat exchangers and all inherent auxiliaries

*Identical to module/genset but installed in 40' ISO container (65 dB(A) @ 10m); complete with all pipework and fittings

*Twin circuit radation cooler for dissipation of intercooler jacket water and lube oil thermal output; ventilation equipment

*Gas & smoke detectors; exhaust silencer; lube oil equipment; starting system; flexible connections

*Seperate control room complete with generator switchgear and all internal power and monitoring cables

Scope of Supply & Design Subject to Local Regulations and product development

>>> Scope of supply container - JG(M)C 316 GS-N.L

>>> Scope of supply genset - JGS 316 GS-N.L

>>> Scope of supply module - JMS 316 GS-N.L

Jenbacher gas engines

Technical Specification

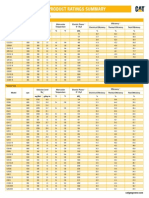

Genset

Main dimensions and weights (approximate value) Connections (at genset)

Length L mm 5.200 Jacket water inlet and outlet DN/PN 80/10

Width B mm 1.800 Exhaust gas outlet DN/PN 250/10

Height H mm 2.300 Fuel gas (at gas train) DN/PN 80/16

Weight empty kg 9.000 Intercooler water connection:

Weight filled kg 9.600 Low Temperature Circuit DN/PN 65/10

Module

Main dimensions and weights (approximate value) Connections (at module)

Length L mm 5.300 Hot water inlet and outlet DN/PN 80/10

Width B mm 2.300 Exhaust gas outlet DN/PN 250/10

Height H mm 2.300 Fuel gas (at gas train) DN/PN 80/16

Weight empty kg 10.100 Intercooler water connection:

Weight filled kg 10.700 Intercooler water-Inlet/Outlet 2nd stage DN/PN 65/10

Container

Main dimensions and weights (approximate value) Connections (container)

Length L mm 12.200

Width B mm 2.500 Jacket water inlet and outlet DN/PN 80/10

Height H mm 2.600 Exhaust gas outlet DN/PN 250/10

Container weight (dry) kg 23.400 Fuel gas connection (container) mm 80/16

Container weight (filled) kg 24.700 Fresh oil connection G 28x2''

GE Jenbacher GmbH & Co OHG Tel. +43 5244 600-0

A-6200 Jenbach, Austria Fax +43 5244 63255

0

4

.

J

u

l

2

0

0

6

http://information.jenbacher.com

jenbacher.info@ge.com

Jenbacher gas engines

Technical Specification

You might also like

- J320V21 enDocument4 pagesJ320V21 enMartin KratkyNo ratings yet

- J612V22 enDocument4 pagesJ612V22 enMartin Kratky100% (1)

- Gcu-Dg4 User Manual PDFDocument29 pagesGcu-Dg4 User Manual PDFnhocti007No ratings yet

- JMS 616 GS-N.L: Technical SpecificationDocument4 pagesJMS 616 GS-N.L: Technical SpecificationMohammad SarjoghiNo ratings yet

- Tedom Handbook For Designers 2008Document57 pagesTedom Handbook For Designers 2008ManretyNo ratings yet

- Datasheet S16RDocument4 pagesDatasheet S16RFandi HikaruNo ratings yet

- Technical Specs LHD Models 2WD 4WD Diesel GasolineDocument2 pagesTechnical Specs LHD Models 2WD 4WD Diesel GasolineGuntaraNo ratings yet

- 1100 Buggy Service ManualDocument54 pages1100 Buggy Service Manualferran_alfonsoNo ratings yet

- 2011 Gsx1300r HayabusaDocument128 pages2011 Gsx1300r Hayabusajaspal59No ratings yet

- Onan Parts ManualDocument71 pagesOnan Parts ManualRon Schmitt100% (2)

- Operator'S Manual: For Models: L6140A, L6140AL2, M6140AL, & M6140AL2Document35 pagesOperator'S Manual: For Models: L6140A, L6140AL2, M6140AL, & M6140AL2DominicNo ratings yet

- 95 Egge KatlogDocument196 pages95 Egge KatlogMartin J.No ratings yet

- Ficha Tecnica CAT CG 132B-16Document1 pageFicha Tecnica CAT CG 132B-16MarioAndrésRamirezC.No ratings yet

- Knock SensorDocument1 pageKnock SensorTommy TribbianiNo ratings yet

- Schedle Maintenance JenbacherDocument3 pagesSchedle Maintenance JenbacherEnrique Garcia0% (1)

- 3004 kW 16V 4000 P83 Engine SpecsDocument1 page3004 kW 16V 4000 P83 Engine SpecsAmir Asyraf SuhailiNo ratings yet

- ID FLX Lite 1 3 OperatorGuide ComapDocument19 pagesID FLX Lite 1 3 OperatorGuide ComapMahesh MirajkarNo ratings yet

- Engine Performance Optimization - GT PowerDocument2 pagesEngine Performance Optimization - GT Powermanoj262400/2No ratings yet

- 981-0240B Onan DKD (Spec A-E) AUX RV Genset Parts Manual (11-1999)Document76 pages981-0240B Onan DKD (Spec A-E) AUX RV Genset Parts Manual (11-1999)Peter CardonaNo ratings yet

- Service Info Technology: Old EnginesDocument6 pagesService Info Technology: Old EnginesJavier CardonaNo ratings yet

- Cylinder Head: Maintenance InstructionDocument12 pagesCylinder Head: Maintenance InstructionReny NapitupuluNo ratings yet

- Naca TR 189Document19 pagesNaca TR 189SrinathReddyNo ratings yet

- Cummins 6B Series Engine 1000 Hour Maintenance ListDocument1 pageCummins 6B Series Engine 1000 Hour Maintenance ListghostshotNo ratings yet

- vnx.su transit 1976-1986 Часть2 PDFDocument543 pagesvnx.su transit 1976-1986 Часть2 PDFscodavnxNo ratings yet

- Engine DiscriptionDocument4 pagesEngine DiscriptionramidalfNo ratings yet

- SUNNEN BilgiDocument29 pagesSUNNEN BilgiSerkan TopcuNo ratings yet

- Fiat 128 MotoriDocument13 pagesFiat 128 MotoriZastava 101 KlubNo ratings yet

- Installation Instructions: WarningDocument35 pagesInstallation Instructions: WarningwcuevasmNo ratings yet

- Porsche Manual - The 912 Engine - Introduction PDFDocument7 pagesPorsche Manual - The 912 Engine - Introduction PDFMarcinNo ratings yet

- 1 X Jgs 420-Bl-BopDocument25 pages1 X Jgs 420-Bl-Bophaji atinNo ratings yet

- Darton SleevesDocument56 pagesDarton SleevesBzidroglioNo ratings yet

- EPA Tier 4 Certified Diesel Engines for 2-3t Forklift TrucksDocument6 pagesEPA Tier 4 Certified Diesel Engines for 2-3t Forklift TrucksTien NguyenNo ratings yet

- GW Wingle (All) SpecsDocument5 pagesGW Wingle (All) SpecsNorberto PattNo ratings yet

- Diesel Forklift Truck - Linde Forklifts Offer Germany Quality & PerformanceDocument6 pagesDiesel Forklift Truck - Linde Forklifts Offer Germany Quality & Performancemurshed audatallaNo ratings yet

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- 24L FourDocument28 pages24L FourIqbal NugrohoNo ratings yet

- MKV EngineDocument59 pagesMKV EngineiolinNo ratings yet

- Aracer Smart - 20190816 PDFDocument17 pagesAracer Smart - 20190816 PDFLưuTrầnNo ratings yet

- Performance ParametersDocument19 pagesPerformance Parametersahmed50% (2)

- DB S60 1DS GB 3231171 112010 PDFDocument2 pagesDB S60 1DS GB 3231171 112010 PDFjhonmarcNo ratings yet

- Effect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsDocument9 pagesEffect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsNgocTinhPhamNo ratings yet

- JGS 420 GS-S.L: Low Methane - Coal Mine MethaneDocument34 pagesJGS 420 GS-S.L: Low Methane - Coal Mine MethaneDexterous EngineeringNo ratings yet

- G3306Document4 pagesG3306carlucido247970100% (1)

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimNo ratings yet

- ENGINE MECHANICAL SECTIONDocument32 pagesENGINE MECHANICAL SECTIONStelian CrisanNo ratings yet

- Tad730ge 111797s01Document8 pagesTad730ge 111797s01roozbehxoxNo ratings yet

- Toyota Nico PDFDocument33 pagesToyota Nico PDFDaniel GarciaNo ratings yet

- Jenbacher: 1. Power Shift Diagrams Type 6 Engines in Compliance With ISO 8528, Part 5: - 2Document4 pagesJenbacher: 1. Power Shift Diagrams Type 6 Engines in Compliance With ISO 8528, Part 5: - 2ArîfNo ratings yet

- Gas Generator Set of MTU Engine Tech JBG1000Document7 pagesGas Generator Set of MTU Engine Tech JBG1000Pankaj KambleNo ratings yet

- QSK19G PerformanceDocument5 pagesQSK19G PerformancetroyNo ratings yet

- Subaru WRX (STi) 07 Lubrication FSMDocument22 pagesSubaru WRX (STi) 07 Lubrication FSMGustavo RivasNo ratings yet

- DC MOTOR GUIDE FOR 15W, 25W, 40W, 60W, 90W, AND 120W MODELSDocument17 pagesDC MOTOR GUIDE FOR 15W, 25W, 40W, 60W, 90W, AND 120W MODELSccarbajal_3No ratings yet

- QSK60 G6 PDFDocument2 pagesQSK60 G6 PDFShahzad Ali100% (2)

- 16 L200 LHD +GCC-E SpecDocument2 pages16 L200 LHD +GCC-E Specafraz_xecNo ratings yet

- Stand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsDocument1 pageStand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsKamieshiNo ratings yet

- YDP20MH Portable Diesel Fire Pump 4.7HP Yanmar EngineDocument1 pageYDP20MH Portable Diesel Fire Pump 4.7HP Yanmar EngineTaufiq Omar HasanNo ratings yet

- 4008TAG2 Electro Unit PN2199Document2 pages4008TAG2 Electro Unit PN2199RioNo ratings yet

- Chassis Dynamometer Testing: Addressing the Challenges of New Global LegislationFrom EverandChassis Dynamometer Testing: Addressing the Challenges of New Global LegislationNo ratings yet

- GE Jenbacher JMS 316 GS-B.L Biogas Engine SpecsDocument4 pagesGE Jenbacher JMS 316 GS-B.L Biogas Engine SpecsMartin KratkyNo ratings yet

- HIMSEN Catalog 2011Document100 pagesHIMSEN Catalog 2011airtupasNo ratings yet

- High-Efficiency Diesel EngineDocument4 pagesHigh-Efficiency Diesel EngineMartin KratkyNo ratings yet

- INNIO Jenbacher Type 2 - 2019 - enDocument2 pagesINNIO Jenbacher Type 2 - 2019 - enMartin KratkyNo ratings yet

- HIMSEN Catalog 2010 PDFDocument46 pagesHIMSEN Catalog 2010 PDFGabriela SanchezNo ratings yet

- Book PDFDocument24 pagesBook PDFJon SnowNo ratings yet

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Daihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformanceDocument8 pagesDaihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformancePrince ChaudharyNo ratings yet

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Himsen Engines: Hyundai Heavy Industries Annual Report 2012Document2 pagesHimsen Engines: Hyundai Heavy Industries Annual Report 2012Martin KratkyNo ratings yet

- Lexe0422 04Document2 pagesLexe0422 04Connor SailorNo ratings yet

- Daihatsu de SeriesDocument32 pagesDaihatsu de Seriesfernando_cassol100% (1)

- Baudouin Company ProfileDocument16 pagesBaudouin Company ProfileMartin KratkyNo ratings yet

- Rolls-Royce Allen 5000 Engine For Liquid FuelDocument2 pagesRolls-Royce Allen 5000 Engine For Liquid FuelMartin KratkyNo ratings yet

- Nordwest Service Manual PDFDocument136 pagesNordwest Service Manual PDFMartin KratkyNo ratings yet

- Nordwest Service Manual PDFDocument136 pagesNordwest Service Manual PDFMartin KratkyNo ratings yet

- Kohler Sdmo Kd2250-EDocument6 pagesKohler Sdmo Kd2250-EMartin KratkyNo ratings yet

- Lexe0422 04Document2 pagesLexe0422 04Connor SailorNo ratings yet

- Rolls-Royce Allen 5000 Engine For Liquid FuelDocument2 pagesRolls-Royce Allen 5000 Engine For Liquid FuelMartin KratkyNo ratings yet

- Synchronous Generator ManualDocument56 pagesSynchronous Generator ManualMartin Kratky100% (3)

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Power: SolutionsDocument12 pagesPower: Solutionsmargarita margaNo ratings yet

- Wartsila W32 Brochure 2016Document2 pagesWartsila W32 Brochure 2016Martin KratkyNo ratings yet

- EMD 645 Marine Emissions Kits A4Document2 pagesEMD 645 Marine Emissions Kits A4Martin KratkyNo ratings yet

- Flexicycle Power Plants 2015 PDFDocument6 pagesFlexicycle Power Plants 2015 PDFVictor Macedo AchancarayNo ratings yet

- The New Prechamber Improves Efficiency of W34SGDocument1 pageThe New Prechamber Improves Efficiency of W34SGMartin KratkyNo ratings yet

- FME OP BrochureDocument2 pagesFME OP BrochureMartin KratkyNo ratings yet

- Fairbanks MorseDocument32 pagesFairbanks MorseMartin Kratky100% (1)

- Wartsila 'Combined Heat and Power' LeafletDocument16 pagesWartsila 'Combined Heat and Power' LeafletMartin Kratky100% (1)

- MTU 4000 PPU1500NG 50 HZ ENDocument15 pagesMTU 4000 PPU1500NG 50 HZ ENMartin KratkyNo ratings yet

- GE's New L250 Inline Diesel Engine Offers Compact Power and Emissions ComplianceDocument6 pagesGE's New L250 Inline Diesel Engine Offers Compact Power and Emissions ComplianceMartin KratkyNo ratings yet

- 16V2000G65 3B Consumption AC EnglishDocument9 pages16V2000G65 3B Consumption AC Englishepicenterrulez100% (1)

- Refrigeration Cycles and Systems: A Review: ArticleDocument18 pagesRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaNo ratings yet

- WabtecLocomotiveProductCatalog PDFDocument68 pagesWabtecLocomotiveProductCatalog PDFMargoth C NovoaNo ratings yet

- Shaft SinkingDocument10 pagesShaft SinkingAnonymous 340A7vnwV1No ratings yet

- Instruction Manual for High Pressure Breathing Air CompressorsDocument46 pagesInstruction Manual for High Pressure Breathing Air CompressorserssNo ratings yet

- TESSLibs17 General Descriptions PDFDocument79 pagesTESSLibs17 General Descriptions PDFhoangpalestineNo ratings yet

- Man L21-31 Marine Hfo Engine Generating Set-Ettes Power PDFDocument8 pagesMan L21-31 Marine Hfo Engine Generating Set-Ettes Power PDFKumaran MohanNo ratings yet

- Twd1031ve Volvo PDFDocument37 pagesTwd1031ve Volvo PDFANH LÊ100% (2)

- C700 - Basic Frame DescriptionDocument13 pagesC700 - Basic Frame Descriptionidigiti100% (1)

- Compressed Air Installation GuideDocument24 pagesCompressed Air Installation Guidesauro100% (1)

- Cooling System Guidelines For Waukesha PDFDocument4 pagesCooling System Guidelines For Waukesha PDFFaisal NaeemNo ratings yet

- 3012-26TA4 3000 Series: Diesel Engine - Industrial Open Power UnitDocument2 pages3012-26TA4 3000 Series: Diesel Engine - Industrial Open Power UnitNaleen Chand100% (1)

- TAD740GE: Volvo Penta Genset EngineDocument2 pagesTAD740GE: Volvo Penta Genset Engineجمال ابو الفضلNo ratings yet

- Mitsubishi Marine Gas SolutionsDocument2 pagesMitsubishi Marine Gas SolutionsAlbertoNo ratings yet

- N67 ENT 175kW Diesel EngineDocument4 pagesN67 ENT 175kW Diesel EngineTruong NguyenNo ratings yet

- Grindale Hme Maintenance 2022Document126 pagesGrindale Hme Maintenance 2022HughoNo ratings yet

- TD610V Manual PDFDocument184 pagesTD610V Manual PDFrburtonshaw100% (7)

- Application & Installation Guide G3500 Gas Engines: LEBW5339-07Document35 pagesApplication & Installation Guide G3500 Gas Engines: LEBW5339-07Djebali Mourad100% (1)

- ZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413Document24 pagesZH355-900 Plus ZH630-1600 Plus ZH1000-3150 EN Antwerp 2935063413karun agrawalNo ratings yet

- Second Law Analysis If IC EnginesDocument16 pagesSecond Law Analysis If IC Enginesdjermounimohamed100% (1)

- MaK M20 - Инстр. по экспл.ГТН R4-3Document104 pagesMaK M20 - Инстр. по экспл.ГТН R4-3Serhii100% (1)

- Perkins Tier 2 Diesel Engine Electronic Troubleshooting GuideDocument154 pagesPerkins Tier 2 Diesel Engine Electronic Troubleshooting GuideJAVIER NAVA100% (1)

- Sensores 3500B EUIDocument32 pagesSensores 3500B EUICesar Ego-Aguirre Calderon100% (3)

- D-Line: Operation ManualDocument134 pagesD-Line: Operation Manualabduallah muhammadNo ratings yet

- Ecu Remap and Why DRD DIESEL TUTORIALDocument13 pagesEcu Remap and Why DRD DIESEL TUTORIALPetrus Van Schalkwyk100% (1)

- MSG TURBO-AIR 3000 Brochure A4Document6 pagesMSG TURBO-AIR 3000 Brochure A4Juan CruzNo ratings yet

- 2marks U4 Power PlantDocument5 pages2marks U4 Power PlantAnonymous MLC7TDLXO9No ratings yet

- Referencia Aire ComprimidoDocument9 pagesReferencia Aire ComprimidoChristian Paul Salazar SanchezNo ratings yet

- FMIC Amp InstallationDocument9 pagesFMIC Amp InstallationLucas SabineNo ratings yet

- DAF PR Solaris Motori PDFDocument4 pagesDAF PR Solaris Motori PDFmicakojicNo ratings yet