Professional Documents

Culture Documents

HTF Super™: Flat Tempering

Uploaded by

Costel Marian MantaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HTF Super™: Flat Tempering

Uploaded by

Costel Marian MantaCopyright:

Available Formats

HTF Super

Flat Tempering

Glaston is your glass processing technology One-Stop-Partner providing

Albat + Wirsam, Bavelloni and Tamglass products and services.

Tamglass is known as the reliable brand for safety glass ma-

chinery for the architectural, appliance and automotive glass

industries. Tamglass has delivered over 2,000 safety glass pro-

duction lines to more than 70 countries during its over 36 years

of operation.

Tamglass is a trademark of Glaston Corporation. Glaston is the

leading supplier of high-quality glass processing technology. Its

customer service network is the largest in the glass processing

industry, with over 30 local units around the world.

Glaston Corporation is a solid, growth-oriented technology

company listed in the Helsinki Exchanges.

Comprehensive expertise

in safety glass processing

Page 02 Tamglass

Glaston is your One-Stop-Partner

for glass processing technology

offering wide range of machines

and services under brand names

Albat+Wirsam, Bavelloni and

Tamglass. Whether the request is

for a single machine, production

line or complete factory with

production control, completed with

the best service network and pre-

processing tools, we have the right

solutions for you to choose from.

Glastons One-Stop-

Partner solutions

Software solutions

Float glass End products Pre-processing Heat treatment

Insulated

glass

processing

Service solutions

Improved productivity

Improved productivity

The HTF Super has estab-

lished itself as a global leader

with over 500 satisfied custom-

ers worldwide. It is ideal for

mixed production; the unique

optimized heating system of

HTF Super with temperature

profiles and convection allows

high quality tempering of all

glass types and thicknesses

including LOW-E. Due to a high

uptime of the equipment a solid

cash flow from the start-up is

ensured.

Reduced operation

costs

Reduced operation

costs

The revolutionary HTF Super

production efficiency is pow-

ered by a number of patented

innovations along the line. The

most important of these are

individual heating element

control, individual operation

of the furnace modules and a

high-efficiency quench system.

The HTF Super minimizes

glass processing costs and

ensures a fast pay back for your

investment.

Secured customer

deliveries

Secured customer

deliveries

HTF Super is built to temper

high quality glass load after

load, 24 hours a day, seven days

a week, year after year. The

HTF Super delivery is much

more than a machine delivery. It

includes a solid of accumulated

know-how with inbuilt options

for retrofits and technology

upgrades in our all-out support

for customers businesses.

Proven Tamglass technology

means high availability and

guaranteed glass deliveries.

Page 03 Tamglass

We are at your service

Glaston seeks to establish long-

term business relationships

through highly professional

services prior to, during and

following delivery. Our After Sales

Services has established itself

in several locations around the

world in order to serve customers

locally with a variety of services and

products.

Temperature profle

Top convection

pressure

P

T

HTF Super - Premium class

processing exibility

Page 04 Tamglass

HTF Super advantages at a glance

The unique HTF Super heating

system utilizes optimized

wavelength of radiation together

with temperature profiles for heat

transfer. This technology results

an excellent glass heating

uniformity and avoids thermal

shocks for thick glass.

01

In addition HTF Super enables

real savings in operating cost

due to its low peak power, small

transformer size and flexible

layout with small footprint. With

HTF Super you ensure technical

leadership, reliability and future

upgrading with new built-in

features that fulfill changing

market requirements.

Page 05 Tamglass

02 03 04 05

Image 01

OPTIMIZED HEATING SYSTEM

HTF Super unique heating technology with low

surface temperature heaters and convection

system results high optical glass quality for all

glass types and thicknesses including Low-E.

Image 02

AUTOMATIC HEATING CONTROL

Fast processing of different glasses loaded

(e.g. multiple pieces, coated glasses, different

shapes)

Image 03

UNIQUE BLOWER SYSTEM

High production efficiency with unique blower

system according to the customers product mix

Image 05

HIGH PROCESS AND

EQUIPMENT RELIABILITY

The HTF Super all major components that

require servicing are located outside the furnace

for easy access. Moving parts are well protected

from dust and heat, but easily accessible.

Image 04

HIGH EFFICIENCY QUENCH

Capability to temper and heat strengthen all

glass types and sizes including Low-E.

Minimized foot print is required.

HTF Super versatile and

user-friendly tempering solutions

Page 06 Tamglass

Main components

Loading and unloading conveyors

(with lifting tables for HTF

Super-2xxx models)

Complete heating furnace

system with optimized heating

technology OHS and top

convection system ECG

Integrated high efficiency Low-E

quenching/cooling section

Unique blower system and duct

work for quenching/cooling

Complete and independent drive

system

Emergency cooling and battery

backup system with DC drive

Tamglass RTOS control system

with user-friendly HMI graphical

interface

Electrical cabins with internal

wiring

Complete set of manuals for

operation and maintenance

Installation supervision with

operation and maintenance

training

Layout design for customers

factory

Utilities supplied

by the buyer

Electric power supply for

heating, drives and blowers; 4

wire system (3 phases and earth)

Compressed air 7 bar (700 kPa)

Succeed

in glass processing

Our after sales services support your

maintenance and help you improve your

performance. For maintaining machines

we offer you good availability of parts

through comprehensive stocks and reliable

deliveries. In addition, we guarantee the

availability of services and support with

our comprehensive 24h telephone facility

supported by the remote-on-line system.

The ROLS

TM

connects customers machines

or subsystems directly to our service centre

and we can be at the scene of the action

immediately. Improve your performance

with our long-term experience in the glass

business through consultation and training

services. Benet from the support of the

original machine supplier.

Page 07 Tamglass

Optional features (indicator in parenthesis)

Boost unit for tempering of thin

glass sheets down to 3.0 mm

thickness according to ANSI Z

97.1 and BS 6206, down to 3.2 mm

thickness according to EN 12150-

1 and ECE R 43 (BC)

Readiness for the boost unit (B)

Low-E tempering system acc. to

EN 12150-1, obtaining ECE R 43

by blowers (20)

Energy efcient frequency

converter controlled blower

system for 4-19 mm thickness (S)

Thick glass tempering facility up

to 19 mm by axial blower system

with frequency converter (TA)

Heat strengthening system up

to 10 mm glass acc. to EN 1863

(HS10)

Peak power limitation system

(PPL)

Energy saving option for 3mm

and/or 4mm (ES)

Noise reduction cabin around the

quench/cooling section for max.

noise pressure level of LpA = 85

dB or LpA = 82 dB (A) (N85), (N82)

Cullet conveyor system under

quenching section (VC)

Motorized integrated pyrometer

system, measurement on top

(MR)

Integrated glass quality

measurement system (SCA)

External PC terminal for

monitoring, printing and backup

the process data (PC)

Extended top convection system

ECG+ for Low-E (ECG+)

Quality monitoring system

QMS for ISO 9001 / ISO 9002

(QMS)

Maintenance consultation

contract MCC with remote on-

line service ROLS (MCC)

Tamglass Reactor on-line

process monitoring system

(REACTOR)

Main dimensions

NOTE:

Dimensions of blower room are indicative of and subject to the factory layout. Dimensions for multi chamber furnaces will be given separately.

Location of the blower room according to the factory layout.

With noise reduction cabin total height is 3,1 m / LpA =85 dB (A).

3,6 m / LpA =82 dB (A).

Capacity (ANSI Z97.1-1984 for architectural glass)

NOTE:

Capacities are based on 100 % utilisation of the loading area with clear oat glass. Installed power for blowers and boost unit at special conditions

(temperature, humidity and altitude) will be specied separately.

* Single sheets longer than 300 mm can be tempered with reduced production rate.

** 3,8mm tempering acc. to ANSI Z97.1 with max. 65% loading efficiency, S-option

TAMGLASS

HTF Super

total length

[m]

total width

[m]

total height

[m]

Working height

[m]

Blower room dimensions

LxWxH [m]

Blower room dimensions

with thin glass option

(boost unit)

LxWxH [m]

HTF Super-2136 18.5 4.9 3.1 0.9 8,5 x 5,5 x 4,0 12,0 x 6,5 x 5,3

HTF Super-2142 20.9 4.9 3.1 0.9 9,1 x 6,0 x 4,0 13,5 x 6,5 x 5,3

HTF Super-2436 18.5 5.3 3.1 0.9 9,1 x 6,0 x 4,0 13,5 x 6,5 x 5,3

HTF Super-2442 20.9 5.3 3.1 0.9 9,1 x 6,0 x 4,0 13,5 x 6,5 x 5,3

HTF Super-2448 23.3 5.3 3.1 0.9 9,7 x 6,5 x 4,0 14,0 x 7,0 x 5,3

Capacity (m

2

/h)/ glass thickness [mm]

(ANSI Z97.1 for architectural purposes;

max. glass size: 865 x 1930 mm)

Installed power at sea level

[kW]

Required

transformer

capacity

[kVA]**

TAMGLASS

HTF Super

Loading area

= maximum sheet

size

W x L [mm]*

Minimum

glass size

W x L

[mm]

3.0 mm

(ANSI)

3.8 mm

(ANSI)

6 mm

(ANSI)

8 mm

(ANSI)

12 mm

(ANSI)

19 mm

(ANSI)

Heating

and

drives

Quench Total Added

power

for boost

unit

HTF Super-2136 2100 x 3600 (3900) 100 x 250 180 177 120 91 61 35 486 320 806 132 475

HTF Super-2142 2100 x 4200 (4500) 100 x 250 213 207 141 106 71 41 567 370 937 132 540

HTF Super-2436 2440 x 3600 (3900) 100 x 250 209 206 140 106 70 41 567 370 937 160 545

HTF Super-2442 2440 x 4200 (4500) 100 x 250 247 240 163 124 82 48 662 400 1062 160 615

HTF Super-2448 2440 x 4800 (5100) 100 x 250 285 275 187 141 94 55 790 500 1290 200 720

www.glaston.net

HEADQUARTERS

Glaston Corporation

Vehmaistenkatu 5

33730 Tampere

Finland

Tel. +358 10 500 500

Fax +358 10 500 6190

info@glaston.net

Glaston Italy Spa

Italy

Tel. +39 031 72 83 11

info.italy@glaston.net

Glaston Mexico SA de CV

Mexico

Tel. +52 333 1452045 / 1451404

Glaston is your glass processing

technology One-Stop-Partner

providing Bavelloni and Tamglass

products and services

ENVIROMENT-FRIENDLY

GLASS PROCESSING TECHNOLOGY

Glaston takes into account the whole lifecycle of

its machines. One key issue is designing and

manufacturing constructions to tolerate the heavy use

imposed on Glaston machines. Special attention has

been paid to the recyclability of materials, particularly to

wearing components that have to be replaced during the

regular maintenance programme.

PRODUCTI ON / ASSEMBLY UNI TS:

Glaston Finland Oy

Finland

Tel. +358 3 372 3111

info@glaston.net

Glaston Tianjin Co. Ltd

China

Tel. +86 22 8219 1100

Glaston USA, Inc.

USA

Tel. +1 856 786 1200

Glaston South America Ltda.

Brazil

Tel. +55 11 4066 2506

SALES AND SERVI CE OFFI CES:

Glaston Italy Spa

Italy

Tel. +39 031 72 83 11

info.italy@glaston.net

Glaston Services Ltd. Oy

Tamglass After Sales services

in Italy

Italy

Tel. +39 055 50 01 931

Glaston North America (USA), Inc.

Greensboro, USA

Tel. +1 336 299 8300

usa@glaston.net

Glaston America, Inc.

Pittsburgh, USA

Tel. +1 412 787 7020

usa@glaston.net

Glaston America, Inc.

After Sales services

Las Vegas, USA

Tel. +1-702-433 4003

Glaston America, Inc.

After Sales services

Cinnaminson, USA

Tel. +1 856 786 1200

Glaston Germany GmbH

Germany

Tel. +49 911 61 50 05

germany@glaston.net

Glaston Germany GmbH

Tamglass After Sales services

in Poland

Poland

Tel. +48 22 646 0483

Glaston UK Ltd.

UK

Tel. +44 1773 545850

uk@glaston.net

Glaston Netherlands BV

Netherlands

Tel. +31 46 4570 970

netherlands@glaston.net

Glaston France S.A.R.L.

France

Tel. +33 478 902667

france@glaston.net

Glaston France S.A.R.L.

Tamglass After Sales services

in Spain

Spain

Tel. +34 956 888051

Glaston Russia OOO

Russia

Tel. +7 495 1315101 / 1315103

russia@glaston.net

Glaston Estonia O

Estonia

Tel. +372 626 3110

estonia@glaston.net

Glaston Services Ltd. Oy

- Middle East

Dubai, UAE

Tel. +971 4 8838 268

middle.east@glaston.net

Glaston Singapore Pte. Ltd.

Singapore

Tel: +65 6299 0842

singapore@glaston.net

Glaston Shanghai Machinery

Trading Co. Ltd

China

Tel. +86 21 5840 9778

shanghai@glaston.net

Glaston Shanghai Machinery

Trading Co. Ltd

After Sales Services

Shenzhen, China

Tel. +86 755 251 82459

Glaston Japan, Inc.

Japan

Tel. +81-3-5447-6023

japan@glaston.net

Glaston Japan, Inc.

Republic of Korea

Tel. +82 2 3472 3147

Glaston Australia PTY, Ltd

Australia

Tel. +61 7 5514 0631

australia@glaston.net

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chp1 - Measurements of Length and TimeDocument26 pagesChp1 - Measurements of Length and Timejonathan tungalNo ratings yet

- ESP32-WiFi & Bluetooth Getting Started GuideDocument12 pagesESP32-WiFi & Bluetooth Getting Started Guidehandsontec100% (8)

- Challenges and Opportunities in Internationalizing Student Learning in IndonesiaDocument25 pagesChallenges and Opportunities in Internationalizing Student Learning in IndonesiaAndrea K. IskandarNo ratings yet

- SBI PO Prelims Memory Based Paper (Held On 22 Nov 2021 Shift 1)Document30 pagesSBI PO Prelims Memory Based Paper (Held On 22 Nov 2021 Shift 1)dragondevilgod999No ratings yet

- Khaled Galal, Tamer El-Sawy - Effect of Retrofit Strategies On Mitigatins Progressive Collapse of Steel Frame StructuresDocument12 pagesKhaled Galal, Tamer El-Sawy - Effect of Retrofit Strategies On Mitigatins Progressive Collapse of Steel Frame StructuresAndreea CrisanNo ratings yet

- 8 FallaciesDocument2 pages8 FallaciesZain MehmoodNo ratings yet

- Measures of Central Tendency & RangeDocument1 pageMeasures of Central Tendency & RangeAmit KumarNo ratings yet

- Nizam CSE College BrochureDocument3 pagesNizam CSE College BrochureWajathNo ratings yet

- Young's Double Slit InterferenceDocument11 pagesYoung's Double Slit InterferenceHanin ThariqueNo ratings yet

- Batch Programming Basics Part-1Document34 pagesBatch Programming Basics Part-1Shantanu VishwanadhaNo ratings yet

- Semiotic Subversion and Popular ResistanceDocument4 pagesSemiotic Subversion and Popular ResistanceBra CaNo ratings yet

- HDL-BUS Pro UDP Protocal and Device Type (Eng) PDFDocument12 pagesHDL-BUS Pro UDP Protocal and Device Type (Eng) PDFAnonymous of8mnvHNo ratings yet

- The Art of Writing / Argumentative Essay Grading Rubric: ST NDDocument2 pagesThe Art of Writing / Argumentative Essay Grading Rubric: ST NDNicole BooteNo ratings yet

- TOEFL Vocabulary Review (Exercises 2)Document3 pagesTOEFL Vocabulary Review (Exercises 2)Jenny A. JamesNo ratings yet

- Maxwell's Equations Guide Modern TechDocument8 pagesMaxwell's Equations Guide Modern Techpaulsub63No ratings yet

- 01 Fundamentals Sets and SequencesDocument26 pages01 Fundamentals Sets and SequencesE-syam'zGreenheartNo ratings yet

- Designing Specialized Shipping ContainersDocument165 pagesDesigning Specialized Shipping ContainersGeorgeKKonsolasNo ratings yet

- Alway 8 - ReflectionDocument1 pageAlway 8 - ReflectionVergel Pico AquitNo ratings yet

- Prepare Small Business with BCP ChecklistDocument1 pagePrepare Small Business with BCP ChecklistjefftroyNo ratings yet

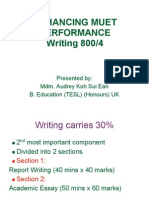

- Guidelines For Muet WritingDocument35 pagesGuidelines For Muet Writingkumutha93% (28)

- Communicate Effectively in English For Customer ServiceDocument16 pagesCommunicate Effectively in English For Customer ServiceIvy Macairan - RodriguezNo ratings yet

- Performance by Design - Computer Capacity Planning by ExampleDocument272 pagesPerformance by Design - Computer Capacity Planning by ExampleAdrian Mihăilă100% (1)

- Simon Speck PDFDocument45 pagesSimon Speck PDFjaysethNo ratings yet

- Unit 9 Daily AgendaDocument51 pagesUnit 9 Daily Agendaapi-309578782No ratings yet

- Curtis Hays Whitson NTH PHD ThesisDocument360 pagesCurtis Hays Whitson NTH PHD ThesisLuis Alberto Izarra100% (1)

- Lab 5 Flow Over Weir ExampleDocument19 pagesLab 5 Flow Over Weir ExampleAmy FarhanaNo ratings yet

- Grain/Seed Counter (Economy Model)Document1 pageGrain/Seed Counter (Economy Model)BalRam DhimanNo ratings yet

- Section Views Tutorial in AutoCAD With VideoDocument24 pagesSection Views Tutorial in AutoCAD With VideoRohit Chandrakant SalveNo ratings yet

- White Et Al-2017-Corporate Social Responsibility and Environmental ManagementDocument14 pagesWhite Et Al-2017-Corporate Social Responsibility and Environmental ManagementNiro AmadorNo ratings yet

- NDCC - The EnvironmentDocument54 pagesNDCC - The EnvironmentPaul Dan OctavianNo ratings yet