Professional Documents

Culture Documents

Escalator safety, design, and passenger behavior

Uploaded by

Guha ArnabOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Escalator safety, design, and passenger behavior

Uploaded by

Guha ArnabCopyright:

Available Formats

Categories: Issue 6/2006

Date: Nov 2, 2006

Title: Escalator Human Factors: Passenger Behaviour, Accidents and Design

Dr. Lutfi Al-Sharif 1)

A general overview is given of passenger safety and accidents on escalators, and how they relate

to engineering design, passenger behaviour and overall management (including operation,

maintenance, inspection and education). The proposed passenger accident triangular model is

presented. It comprises Design, Passenger Behaviour and Management. The interaction between

these three elements is discussed as well as the prevention of accidents by manipulating them. Any

accident is caused by one or more of the factors above, and understanding this is crucial to

eliminating accidents.

Risky passenger behaviour on escalators is discussed in relation to contributing to passenger

accidents. This is based on historical data gathered from observation of passenger behaviour. The

most important hazards on escalators are: Falls on escalators, falls from escalators, entrapments

and crushing inside escalators. These are discussed with examples given on each type of hazard.

Design features that prevent/mitigate each hazard are also discussed.

Escalator management of passenger accidents is crucial to preventing them. The lifecycle of such

a management process is discussed in detail considering each stage in the cycle.

1. Introduction

Passenger accidents on escalators are one of the highest sources of minor injuries today.

Preventing the passenger accidents involves understanding their causes and eliminating or

mitigating such causes.

This paper identifies the causes of passenger accidents and suggests way of eliminating their

contribution.

2. Passenger Accident Escalator Model

The passenger accidents on the escalator are affected by three areas:

The escalator design: Design is used here in its widest sense. It covers the engineering

electrical and mechanical design of the escalator, the environment in which the escalator is

situated (e.g., lighting, exposure to the elements) and its location (e.g., small circulation

landing, limited headroom above).

1.

The escalator maintenance, inspection and operation: The maintenance aspect covers

engineering areas such as the periodic preventative maintenance and remedial works as well

as items such as cleaning (cleaning prevents accumulation of dust and dirt that can lead to

escalator fires). Inspection is necessary (preferable by third parties) to ensure the escalator is

maintained in a safe condition, that all the safety devices are operational and that the

structural integrity of the escalator components are maintained (e.g., nondestructive testing

of steps). It is important to emphasise that operation is an important part of this item,

comprising decisions such as keeping an escalator in service, withdrawing it from service or

running it as a fixed staircase

2.

Passenger behaviour: The way in which a passenger behaves has a significant contribution

to passenger accidents. Passenger behaviour is driven by passenger awareness (short term)

and passenger education (long term).

3.

Each accident when analysed can be related back to any one of the factors above, a combination of

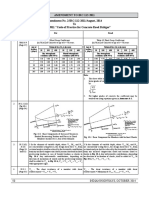

two of them or all three. This is shown in a Venn type of diagram in Figure 1.

Page 1 of 11

Based on the Venn diagram, seven categories of accidents can be identified:

Accidents caused solely by poor design (including location and environment). 1.

Accidents caused solely by poor maintenance, lack of inspection or bad operation. 2.

Accidents caused solely by passenger behaviour. 3.

Accidents caused by the combination of poor design and poor maintenance/

inspection/operation.

4.

Accidents caused by the combination of poor design and passenger behaviour. 5.

Accidents caused by the combination of poor maintenance/inspection/operation and

passenger behaviour.

6.

Accidents caused by a combination of all three factors. 7.

Some examples of these are given below:

Accidents caused by poor maintenance: If for example the over-speed detection/protection

device in an escalator is not maintained or tested properly, this would lead to an overspeed

situation and consequential passenger falls and injuries (regardless of the escalator design or

passenger behaviour).

1.

Accidents caused by poor design and bad passenger behaviour: Some escalators in shopping

centre are located in an atrium with a gap between the two escalators. Teenagers are

sometimes tempted to try to jump from one escalator to the adjacent one. In one case this

has lead to a teenager falling in the gap between the two escalators when trying to jump

from one to the other. Leaving such a gap between the two escalators is an example of poor

design (location in this case), whereby the teenager trying to jump from one escalator to the

next is an example of bad passenger behaviour.

2.

Accidents caused by poor escalator design: The design of the braking system of the

escalator is a compromise between stopping within a specified distance and stopping in a

smooth manner. If this is not designed correctly, harsh stopping of the escalator would lead

to passenger falls (and in some cases to avalanche falls). This is despite the fact that the

escalator might be maintained properly within the design parameters.

3.

What this model emphasises is the fact that preventing passenger accidents involves

addressing all three areas and not just one. There is a limit to what the escalator design can

achieve on its own, and there is a need to address all three areas in order to successfully

reduce or even eliminate accidents.

4.

It is worth noting that passenger behaviour is composed of and it is influenced by two items:

Passenger awareness (immediate): This is the short term awareness of the passenger during

the journey. It is influenced by items such as audible announcements (e.g., hold onto the

handrail) or signs (e.g., fold the baby pushchair). On the other hand passenger concentration

can be distracted by commercial advertising. Thus signage can have a positive as well as a

negative impact on passenger awareness.

1.

Passenger education (long term): this aspect is a long tem aspect and it involves educating

the passenger into the hazards on the escalators and the correct behaviour. An example of

this is an education program that has been running for more than 10 years in the USA,

whereby school children are educated into the correct behaviour on lifts and escalators (The

safe-T rider programme).

2.

Page 2 of 11

As an example of accident prevention models a model for reducing passenger falls on escalators

and mitigating the post fall effects is shown in Figure 2. It shows what can be done to prevent the

fall in the first place and what can then be done to mitigate the post fall injury.

Examples of the design elements that would reduce the risk of falling are reducing the angle of

incline (e.g., 30 degrees is preferable to 35 degrees) and reducing the speed (0.5 m/s is preferable

to 0.75 m/s).

One of the most important items in reducing the probability of passenger falls is ensuring the

escalator stops in a smooth manner (e.g., using intelligent braking systems). This is discussed in

detail in [3].

3. Risky Passenger Behaviour

A study by Human Reliability Associates was carried out for London Underground in May 1993.

The study used a video camera to record passenger behaviour on the escalators. Analysis of the

recordings was used to record passenger risky behaviour [4, 5, 6 and 7].

One of the main findings of the study was to identify main types of risky passenger behaviour, as

shown in Table 1 below.

The types of behaviour above can lead to passenger accidents. For example, reading on an

escalator implies that the passenger is distracted and is not holding onto the handrail, thus

increasing the risk of passenger falls.

4. Hazards on Escalators

The types of injuries on escalators are covered by different scenarios.

Entrapments: These fall into the following categories: entrapment between two consecutive

steps; between the step and the skirt; between the step and the comb; under the handrail or

at the handrail entry point.

Falls (falls from escalator; falls on escalator): Falls could then lead to cuts and bruises,

entrapments or both.

Page 3 of 11

Crushing/shearing by/inside the escalator step-band (e.g., falling inside the machine due to a

step collapse).

Crushing under other passengers.

Fire on escalator.

Electrocution from escalator.

It is worth noting that the condition of over-speed is not considered a risk in itself as it will lead to

one of the above risks.

Some of those risks are discussed in more detail next.

4.1 Escalator Falls

Falls are the highest source of minor injuries on escalators, and of particular importance are the so

-called cascade/ avalanche falls.

In order to reduce the effect on passengers, measures can be taken to:

Prevent the fall in the first place, or

Mitigate the post-fall injury.

It has been shown that 2.5 % of all stops on London Underground escalators lead to a passenger

fall. It has also been recorded that three fatalities in the last 50 years on London Underground

were caused by cascade falls (two of which were football crowd related).

4.1.1 Falls on escalators (including runaway escalators)

Falls on escalator are a major source of injuries for passengers. Passengers fall on escalator for a

number of reasons, such as:

Tripping while walking up or down. 1.

Falling due to the escalator stopping suddenly. 2.

The escalator getting into a runaway situation and over-speeding. As a consequence

passengers fall on each other and end up in a pile at the lower landing of the escalator.

3.

Falling due to the handrail suddenly stopping on an up moving escalator (a passenger

holding onto the handrail would be pulled backwards). In these situations passenger

sometimes get confused and report that the handrail reversed direction.

4.

A piece of luggage falling and hitting a passenger causing him/her to fall. 5.

Misuse of wheelchairs on escalators (a wheelchair user trying to ride the escalator in his/her

wheelchair by holding onto both handrails, and then losing grip causing the wheelchair to

fall and knock off other passengers).

6.

Falling due to the wallpaper illusion: It has been proposed that the visual impact of the step

cleats on passengers coupled with the brightness of the Aluminium3) could lead to the so-

called wallpaper illusion that causes passenger to get disorientated and lose balance [1].

7.

Falls are also dangerous because they can lead to entrapments (a passenger falling on a step tries

to cushion his/her fall by using his/her hands, whereby a finger gets entrapped between the step

and the skirting), as the following example shows:

A five-year-old girl was injured when she fell on a department store escalator in Chubbuck,

Idaho, U.S.A. in late December. She apparently fell backward and caught her hand between the

steps and skirt, losing two fingers. The escalator was dismantled and the fingers were retrieved

and reattached by doctors (Source elenet, 13/1/2005).

Number of flat steps

It is believed that the number of fl at steps at the upper and lower landings has an effect on the risk

of falls. They provide the passenger with time to adjust his/her stance prior to the steps forming.

The European escalator standard, EN 115, requires two fl at steps at each landing (three steps

where the rise is more than 6 m). Public service escalators are specified with five steps at the

upper landing and four steps at the lower landing.

Page 4 of 11

Angle of incline

It is also believed, based on circumstantial evidence4), that increasing the angle of incline increase

the probability of passenger falls.

Mitigating the post fall injury

A number of measures can be taken to mitigate the post fall injury, as follows:

Softer treads would reduce the severity of cuts and bruises. These are usually made of a

certain type of polymer. Polymer treads have been considered on London Underground, but

currently do not meet the fi re code requirements (fl ammability test, smoke and fumes).

The smart-step from Thyssenkrupp addresses this problem (a fi bre glass reinforced polymer

step).

Intermediate landings (wave escalator): The wave escalator is an escalator that has one

intermediate landing formed by a series of fl at moving steps. It is given the name wave

due to its shape.

Avalanche Falls

Avalanche falls are a particularly dangerous example of falls. They take place when one passenger

loses balance and falls, causing a second passenger to fall causing a third passenger to fall and so

on, leading to a human pile at the lower landing of the escalator. Avalanche falls can sometime be

initiated by falling luggage.

Runaway Situations

Runaway situations are one main source of falls on escalators. A runaway situation takes place

when a heavily loaded escalator accelerates downwards exceeding its rated speed and causing a

passenger pile at the lower landing. An example of a runaway situation was the accident at the CN

Tower in Toronto that took place in 1988. The following is an excerpt from the news item in the

press (shown from Elevator World December 1988 below):

Nine children were taken to the hospital after being in a human pile-up on an escalator at the base

of Torontos CN Tower, but were quickly released.

Staff-Sergeant Doug Ecklund of the Metro Police said witnesses reported that the escalator

seemed to accelerate before halting after the emergency stop button was pushed. He said an adult

pushed the button after becoming concerned about congestion at the base of the escalator.

Runaway situations take place when the braking system of the escalator is not properly adjusted

and cannot bring the loaded escalator to rest. When the escalator stops unloaded or lightly loaded,

the friction in the escalator is sufficient to stop it. However, when the escalator is heavily loaded

with passengers (as is the case during rush hours or following major events such as football

matches or concerts) the braking system is unable to stop the loaded escalator when the stop

button is pressed. Passengers are reported as saying: I pressed the stop switch a number of times

but the escalator did not stop! Tests carried out after the accident do not reveal the problem, as

the escalator is stopped with no load on it, and friction is sufficient to bring it to rest.

What happens during a runaway situation is outlined here. A down-moving heavily loaded

escalator is given a command to stop (either by someone pressing the stop switch or by a spurious

safety device trip). The motor is then disconnected from the source of supply by the tripping of the

main contactors. By taking the power away from the motor, the escalator is left to move freely

under gravity. As the braking system is ineffective the escalator and its load start accelerating

downwards. Attempts by passengers to stop it by pressing the stop switch are futile, as the

escalator is already electrically stopped; and is in fact mechanically under gravity. The escalator

accelerates to dangerously high speeds (speeds as high as 2 m/s have been reported). Passengers

get to the lower landing falling on each other and forming a human pile. Once a significant

number of passengers have been thrown off the escalator, the escalator starts slowing down until

it stops under friction.

Page 5 of 11

In cases where the heavily loaded escalator is moving upwards, the escalator slows down to a

standstill and then reverses direction and accelerates downwards in the same sequence of events

discussed above for the case of the down moving escalator.

In certain cases the cause of the runaway is not a defective braking system, but a mechanical

shearing of the top shaft of the escalator. The sequence of events however is similar.

If the problem is not detected by operational staff, what happens sometimes is that the escalator is

left in service (in a stationary condition) following he accident. New passengers arriving find the

escalator stationary and think that it is in service as a fixed staircase. Once enough passengers

board the stationary defective escalator is starts moving downwards under gravity, repeating the

sequence of events above.

The following are examples of runaway incidents:

Toronto CN Tower, December 1988 (down)

MARTA (Metropolitan Atlanta, Rapid Transit Authority), Atlanta, Georgia, U.S.A.

Escalators locked off to prevent free-wheeling during crowded conditions (Elevator World

1997).

London Underground, London, United Kingdom, Oxford Circus Station, Escalator number

4, August 1999 (sheared top shaft).

18th January 2000, Nashville International Airport, U.S.A.

Newcastle, England, United Kingdom, Metro escalator, May 1st, 2001 (up).

Newcastle, England, United Kingdom. Metro escalator, February 9th 2002 (down).

London Underground, London, United Kingdom, Waterloo Station, 2002.

Anaheim, California, baseball fans May 7th 2002, 15 passengers with minor injuries

(down).

Coors Field Stadium (Denver, Colorado, U.S.A.) 9/7/2003, 20 injured.

Raffles City Shopping Centre, Singapore, May 2003, (up), 1 person hospitalised.

Escalator reversed direction, Xinzhuang Station, Shanghai, China, number one subway line

(38 people injure) (up).

Handrail initiated falls

The handrail plays in important role in passenger balance and safety. When a handrail slips or

stops it can become a cause of passenger falls, and hence the design of the handrail drive system

must ensure high reliability. The following is an example of a fall caused by a malfunctioning

handrail drive system.

Moorgate Escalator number 2 (London Underground, United Kingdom), 24/9/ 1995: A male

passenger suffered a cut over his left eye and his partner sustained a bruised left ankle when they

fell after the handrail started to move in the opposite direction whilst travelling in the up

direction. Two other passengers fell over but they were not injured.

One protection measure that has been proposed is to detect the speed of the handrail and stop the

escalator in case of handrail slippage or stoppage. A study conducted by London Underground

into handrail caused accidents concluded that it is more effective to improve the traction system

(V-grooved handrail5) than install under-speed handrail detection systems [8]. The study found

that no accidents were recorded on the escalators that were fitted with V-groove profiled handrail.

On escalators fitted with a standard profile handrail one in every three handrail slippages resulted

in a passenger accident (i.e., fall). In this case prevention is definitely better than cure.

4.1.2 Falls from escalators

Another type of fall is falling from escalators. These mainly take place due to the escalator being

located in a void (as is the case in most shopping centres). Due to the height of the fall, the injuries

are usually very severe (death in some cases). Some examples are given below.

A 2-year-old boy playing on the belt of an escalator located in a shopping complex in

Nishinomiya, Hyogo Prefecture, Japan, fell 10 meters from the fourth to the second floor and died

(June 2004).

Page 6 of 11

A child was caught on video at a Marks & Spencer Store in Belfast/Northern Ireland riding onto

the handrail and then falling into the void.

A nine-year-old boy with a developmental disorder died as a result of a fall from an escalator on

21st September 2002. The incident occurred in a Brooklyn, New York mall.

The handrail on an escalator at a shopping center in the St. Louis suburb of Belleville allegedly

caught a seven-year-old girls clothing as she stood on a second-story balcony. The girl fell at

least 18 feet, sustaining a broken arm and other injuries. The girl was reportedly standing near the

escalator when she leaned over the balcony rail (source: elenet, January 2005).

It is interesting to note that the Norway Technical Regulations under the Planning and Building

Act 1997 has a requirement related to the open spaces next to escalators [9]:

When an escalator is located in an open transit area such that the height of fall may be large, the

possibility of falling from the escalators balustrade shall be prevented.

4.3 Entrapments

By definition an escalator has a moving platform next to stationary components and this gives rise

to the risk of entrapment. Entrapment can affect human limbs, footwear, personal articles, pets

paws and loose clothing. In extreme cases, entrapments can result in amputations.

Entrapments can be prevented by:

Close control of the gaps (step to step, step to skirt, step to comb).

Use of deflector devices (brush-guards, side step insert): These generally discourage

passengers from standing too near to the skirting.

Yellow lines on steps: These also aim to discourage passengers from standing near the step

edge.

Low friction on skirting (this is a code requirement in the U.S.A.): The low friction helps

reduce the probability of entrapment.

Eliminating the step to skirt interface (as in the Otis new-step escalator design).

A Human Reliability Associates study in 1993 for London Underground concluded that the brush

-guard (deflector device) reduced the number of passengers that kept their feet within 2 cm of the

balustrade by 90 %.

4.3 Crushing/shearing inside escalator

One of the extreme accidents that could take place on an escalator is a passenger falling into the

escalator step band due to a missing step or a step collapse. These accidents are rare but have

drastic consequences when they take place. It is thus extremely important that the maintenance

regime regularly checks the structural integrity of the step-band and especially the steps. The

following are some examples of these accidents. Most of them appear to be the result of poor

maintenance and inspection.

Tuesday 7th October 1986 a step collapsed on escalator number 4 at Euston London Underground

Station. The lady standing on that step suffered injuries to her ankle and bruises to her leg and foot

when her leg fell into the escalator as the step collapsed.

A 35-year-old woman was killed at the Brooklyn offi ce building where she worked when an

escalator step collapsed and she was pulled into its machinery. After the stairs had climbed a short

distance, the step on which she stood collapsed, creating a sheer drop. She fell feet first inside the

machinery and was pulled by a conveyor belt inside the machine before it came to a halt. The

same escalator was the site of another accident in 1982 when it suddenly reversed direction as 80

employees on it were returning from a fire drill. Dozens received minor injuries.

The following is an example of an accident caused by poor asset maintenance. It has been reported

that the actual cause of the incident was that one of the travolator pallets (i.e., steps) was removed

from the travolator and the gap hidden under the travolator overnight. Due to a faulty braking

Page 7 of 11

system, the travolator started moving under passenger load and the gap reemerged on the

passenger side.

A British woman died as a result of in juries sustained when the escalator (travolator) on which

she was riding collapsed. The incident occurred at the Tiburtina railway station in Rome. Several

others were injured.

The following example shows how important step structural integrity is to passenger safety. The

other important point in this accident is the lack of knowledge on the passenger side of where the

stop switch was (and probably the bad location and signage of the stop switch by the designer).

In December 1999 Jyotsna, an eight-year-old girl, got crushed to death while descending an

escalator at Indira Gandhi International Airport. The strap of a descending passengers hand

baggage got stuck at the far end of the escalator in the arrival hall. As the passenger tried to pull

the strap out, others kept climbing down. Some of them crowded around to help pull the bag out.

When Jyotsna reached the end of the escalator where the commotion was going on, she tumbled

and fell headlong. Within seconds she was sucked between the plates of the escalator which had

by then been prised open to yank the bag out. The little girl remained stuck up there between the

last step and the floorboard till the machine was shut down, which took about 30 to 35 minutes as

nobody knew how to bring the moving steps to a halt. When she was pulled out, the body was

mutilated beyond recognition.

5. Escalator Management

Escalator management (especially incident management) comprises five stages:

Alarm raised. 1.

Operational decision taken (short term). 2.

Necessary inspection and analysis (short term). 3.

Adjustment to maintenance regime (medium term). 4.

Component modification and re-design (long term). 5.

These stages are discussed in more detail here.

a) Alarm raised.

The first stage is when an alarm is raised. This can take the shape of any of the following:

Accident

Near miss.

Failed component found in service (the component might fail in service without leading to

an accident).

Failed component found during inspections or maintenance.

Management becoming aware of new information.

Sharing of safety critical information between operators (e.g., aviation, railway).

b) Operational decision taken (short term).

Once the asset management team becomes aware of a cause for concern, they need to take swift

action to mitigate against any risk to the public. This can take the form of:

In the most extreme of cases, the asset can be withdrawn from service. This is normally only

taken if a serious risk of injury is present such as step collapse or over-speeding.

They can restrict the operation (e.g., restricting the hours of operation; restricting the

direction of travel especially if the hazard identified is more prominent in one direction of

travel).

High level of staff supervision can be put in place (e.g., operational staff in attendance

around the asset to ensure correct usage).

Passenger awareness measures can be taken, to ensure that passengers follow a certain

behaviour pattern or are aware of the hazard identified. This can be done via signs or

audible announcement (e.g., encouraging passengers to hold onto the handrail).

Page 8 of 11

c) Necessary inspections and analysis (short term). Once the immediate decision has been taken to

mitigate any risks to the public, inspection and analysis are necessary to inform the management

as to the following:

How widespread is the problem within the fleet of assets?

How advanced is the problem where it does exist?

How much time is available for remedial works before a dangerous situation takes place?

Regular inspections will be necessary if the problem is found to be widespread within the fleet.

The frequency of such inspection needs to be tailored to the criticality of the failure, ease of

detection and time taken to failure (e.g., in case of a crack: time between initiation of crack until

full failure). The first pass of inspection will give an idea of the size of the problem. The

frequency of inspections will start to drop as more information becomes available and more

permanent measures are put in place.

Technical analysis of the failure will run in parallel with the inspections. The results from the

analysis can be used to enhance/ adjust the nature/frequency of the inspections as necessary.

d) Adjustment to the maintenance regime (medium term). It is important that the maintenance

regime be adjusted in accordance with the findings of the investigation. This could include

recommendations of extra inspections and checks during routine maintenance. It is also possible

that adjustments to the incident reporting forms/procedures are needed.

e) Component modifications and re-design (long term). The lessons learnt from the incident and

the resulting investigations should then be fed back into component modifications on existing

escalators or revision of the complete design for new escalators.

The issue of public service escalator management and long term planning is discussed in more

detail in [2].

5.1 Balancing the risk of decisions

The five steps outlined above for managing incidents/accidents could apply to any asset/facility

used by the public (e.g., lift, building, railway station, fairground ride).

Risk assessment and common sense has to be used in taking the various decisions and it is

important to always balance the risk resulting from the decision against the risk from the

unsatisfactory asset. For example, withdrawing an asset(s) from service could present more risk to

the public than the perceived risk of a failed component.

It is always important to act swiftly. Once regulatory authorities get involved, things can get very

complicated.

6. Conclusions

Escalator Passenger accidents can be caused by three factors: Escalator design; escalator

maintenance, inspection and operation; and passenger behaviour. The passenger accident model is

based on understanding the effect of three parameters on passenger accidents and addressing them

to reduce/eliminate passenger accidents. Every accident can be attributed to one or a combination

of more than one of these three factors. Merely addressing escalator design is insufficient to

address passenger accidents.

An overview of the main examples of risky passenger behaviour has been discussed, such as

reading while traveling, facing the wrong direction of travel and standing on the wrong side.

The main hazards on escalators are: falls on escalators, falls from escalators, entrapments,

crushing/shearing inside escalator, fire on escalator and electrocution on escalator. The first four

of these have been discussed in detail and examples given.

An escalator accident management model has been presented and comprises five stages: Alarm

raised; operational decision taken; inspection and analysis; adjustment to maintenance and

Page 9 of 11

inspection; and component and general design modifycation. It is important to follow these steps

in dealing with any accident in order to reduce or eliminate accidents.

I strongly believe that there is no such a thing as a freak accident . only an accident waiting to

happen or be prevented!

Acknowledgement

The contents of this paper were first delivered in a lecture to the Lift Technology M.Sc. students at

the University of Northampton during a residential weekend on Friday 28th January 2005.

References and Bibliography

[1] Wallpaper illusion: Cause of disorientation and falls on escalators, Theodore E. Cohn, David

J. Lasley, U.C. Transportation Centre, Perception 1990, Vol. 19, page 573580.

[2] Asset Management of Public Service Escalators, Dr. Lutfi Al-Sharif, Elevator Technology 9

1996.

[3] Intelligent Braking Systems for Public Service Escalators, Dr. Lutfi Al-Sharif, Proceedings

of the 1st International Conference Building Electrical Technology Professional Network

(BETNET) Conference, BETNET 2004, October 2004, Hong Kong, China.

[4] Investigation into the causes of passenger accidents on escalators R93/06 Human Reliability

Associates, May 1993.

[5] Investigation into the causes of passenger accidents on escalators R93/06, Human Reliability

Associates, May 1993: Technical Report number 1: Analysis of Accident data.

[6] Investigation into the causes of passenger accidents on escalators R93/06, Human Reliability

Associates, May 1993: Technical Report number 2: Ergonomic Analysis

[7] Investigation into the causes of passenger accidents on escalators R93/06, Human Reliability

Associates, May 1993: Technical Report number 3: Behavioural Analysis.

[8] Escalator handrail related passenger incidents, Author: Colin Greatrex, LE-RP-5033 A2,

July 1999, London Underground Ltd.

[9] Norway Technical Regulations under the Planning and Building Act 1997, 22 January 1997

No. 33: Regulations concerning requirements for construction works and products for construction

works ( 963:4).

Lutfi Al-Sharif received his B.Sc. in Electrical Engineering from the Jordan University in 1987,

his M.Sc. in Automatic Control in 1990 and his Ph.D. in Automatic Control in 1992 from UMIST

(Manchester, United Kingdom).

After working for 17 years in the areas of manufacturing, transport and consultancy he formed the

London based vertical transportation consultancy Al-Sharif VTC Ltd (www.al-sharif.co.uk) in

2002. Dr. Al-Sharif is also currently Assistant Professor in the Department of Mechatronics

Engineering in the Jordan University, Amman, Jordan.

He is a Corporate Member of the IET, Chartered Electrical Engineer, Co-Author of the CIBSE

Guide D 2005, Vice Chairman of the CIBSE Lift Group, Member of the Executive Team of the

IETs Building Electrical Technology Professional Network and Member of the BSI Sub-

committee MHE 4/3/2. He has more than 30 published papers in the area of vertical transportation

systems.

1) Director, Al-Sharif VTC Limited, London, United Kingdom

2) The standard practice on London Underground is for passengers to stand on the right hand side

and walk on the left hand side.

3) Most escalator steps are of the one piece die cast Aluminium type.

Page 10 of 11

4) It is believed that this was shown to be the case in a Marks & Spence store in Southend-on-Sea

that contains two escalators: one inclined at 35 degrees and the other at 30 degrees. The staff

noticed that there were more falls on the 35 degree escalator. However, no documented evidence

has been found to corroborate this.

5) The V-profile refers to the profile of the handrail and its track, as opposed to plain handrails,

sometimes referred to as C (in reference to eth shape of the handrail.

Page 11 of 11

You might also like

- ElevatorDocument10 pagesElevatorfatemeh100% (1)

- Report North Point IncidentDocument29 pagesReport North Point Incidentsimoncarter313No ratings yet

- Fundamental HSE Management TrainingDocument8 pagesFundamental HSE Management TrainingIGede SumantraNo ratings yet

- Near Miss Report Form DetailsDocument1 pageNear Miss Report Form Detailskkalvi100% (1)

- Ergonomic Awareness CourseDocument46 pagesErgonomic Awareness CourseEvert W. VanderBerg100% (1)

- CHT 4331 - Chap 3 - Risk ManagementDocument12 pagesCHT 4331 - Chap 3 - Risk ManagementKatleho MohonoNo ratings yet

- Heat StressDocument10 pagesHeat StressMirza Ibrahim Ali BaigNo ratings yet

- Health Safety and Welfare For Construction ManagementDocument23 pagesHealth Safety and Welfare For Construction ManagementOchini Chandrasena100% (1)

- FMA RegsDocument361 pagesFMA RegsJiong SoonNo ratings yet

- HirarcDocument21 pagesHirarcSaravanan SukumaranNo ratings yet

- Ra Tools (11dec)Document71 pagesRa Tools (11dec)safety departmentNo ratings yet

- Visitor Safety BriefingDocument1 pageVisitor Safety Briefingshahrul azhar100% (1)

- Health, Safety and Environment (HSE) Monthly Report: Please Refer Calculation of LTI in Safety StatisticDocument4 pagesHealth, Safety and Environment (HSE) Monthly Report: Please Refer Calculation of LTI in Safety StatisticNethiyaaNo ratings yet

- Safety in MaintenanceDocument5 pagesSafety in MaintenanceKavindra MishraNo ratings yet

- Eng. Nouh, ASP - CSP Videos LinksDocument2 pagesEng. Nouh, ASP - CSP Videos LinksAhmed AbdulfatahNo ratings yet

- Theory of Accident Causes - JDPDocument32 pagesTheory of Accident Causes - JDPNeggaz D MapeleNo ratings yet

- Critical Factors For Implementation of Occupational Safety and Health Management System in Malaysian Petrochemical Based Manufacturing CompaniesDocument6 pagesCritical Factors For Implementation of Occupational Safety and Health Management System in Malaysian Petrochemical Based Manufacturing CompaniesDR. MOHD FAUZI ISMAILNo ratings yet

- Ergonomics and Anthropometry DefinitionsDocument14 pagesErgonomics and Anthropometry DefinitionsWNAMALI0% (1)

- Location Risk Assessment Form-Part A: Basic Information & Hazard ListDocument3 pagesLocation Risk Assessment Form-Part A: Basic Information & Hazard Listapi-330049796No ratings yet

- Health & Safety AssignmentDocument10 pagesHealth & Safety AssignmentLeo SerasingheNo ratings yet

- 4 August 2021 ExamDocument5 pages4 August 2021 ExamRafa'eel BickooNo ratings yet

- Safety Circuit Design PrinciplesDocument63 pagesSafety Circuit Design PrinciplesMansoor KhaderNo ratings yet

- HSE InductionDocument20 pagesHSE InductionShailendraNo ratings yet

- Mechanical Hazards PDFDocument43 pagesMechanical Hazards PDFAlvin DeliroNo ratings yet

- Miem M.ADocument33 pagesMiem M.AMuhamad sairul azhar bin yaNo ratings yet

- Arc Welder Risk MG T FormDocument9 pagesArc Welder Risk MG T FormMohd FikryNo ratings yet

- Manual Handling of MaterialsDocument51 pagesManual Handling of MaterialsakubestlahNo ratings yet

- OSH-MS Guide to Malaysian Standard 1722Document6 pagesOSH-MS Guide to Malaysian Standard 1722Emiliana BrendaNo ratings yet

- Assignment On TE 4225: TopicsDocument27 pagesAssignment On TE 4225: TopicsNaimul HasanNo ratings yet

- Industrial Safety and Health AssignmentDocument21 pagesIndustrial Safety and Health AssignmentJustin AldrinNo ratings yet

- HSE Alert 105-21 Welder Finger InjuryDocument2 pagesHSE Alert 105-21 Welder Finger InjuryAlecs NedeaNo ratings yet

- NEBOSH Ncc1 Exam RPT Dec 09Document5 pagesNEBOSH Ncc1 Exam RPT Dec 09Yan MusevNo ratings yet

- Introduction To Ohs Management System Standards: Presenter: Zaikhasra Zainuddin 17 JULY 2009Document40 pagesIntroduction To Ohs Management System Standards: Presenter: Zaikhasra Zainuddin 17 JULY 2009Chandral VaradanNo ratings yet

- Inspection Trade UnionsDocument35 pagesInspection Trade UnionsVenky Chowdary VankayalapatiNo ratings yet

- ROSA - Instructions 2011-2012 PDFDocument24 pagesROSA - Instructions 2011-2012 PDFMlv Riesgos LopcymatNo ratings yet

- Guide Lines For NSC HSE PlanDocument52 pagesGuide Lines For NSC HSE Planജിനാദ് അബ്ദുസ്സലാംNo ratings yet

- Health Risks From Hand-Arm VibrationDocument19 pagesHealth Risks From Hand-Arm VibrationadammzjinNo ratings yet

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- Air Powered Tools SafetyDocument6 pagesAir Powered Tools SafetyHafidzManafNo ratings yet

- UNMH Elevator ProceduresDocument3 pagesUNMH Elevator ProceduresBudi YunantoNo ratings yet

- FUSHAN TECH SAFETY PROCEDUREDocument11 pagesFUSHAN TECH SAFETY PROCEDUREhoangmtbNo ratings yet

- Standard For Old Age PDFDocument65 pagesStandard For Old Age PDFRendani VeleNo ratings yet

- CPE615-Lecture 3 Theories of Accident CausationDocument44 pagesCPE615-Lecture 3 Theories of Accident CausationNaufal Rafif LupikoNo ratings yet

- Exposure to hand-arm and whole-body vibration from road drill useDocument3 pagesExposure to hand-arm and whole-body vibration from road drill usehogoshNo ratings yet

- Safety Standard-Portable Pneumatic and Hand Operated Hand Tools-Aug09Document3 pagesSafety Standard-Portable Pneumatic and Hand Operated Hand Tools-Aug09madhulikaNo ratings yet

- hsg245 PDFDocument88 pageshsg245 PDFYousef OlabiNo ratings yet

- Principles of Accident PreventionDocument72 pagesPrinciples of Accident PreventionShaikh IbrahimNo ratings yet

- DR Azrul Rozaiman Dato HJ Abdullah - An-Nur Specialist HospitalDocument22 pagesDR Azrul Rozaiman Dato HJ Abdullah - An-Nur Specialist Hospitalakubestlah100% (1)

- Bloodborne and Airborne Pathogens: (Universal Precautions)Document2 pagesBloodborne and Airborne Pathogens: (Universal Precautions)roberto_00643557No ratings yet

- Noise & Vibration Learning OutcomesDocument45 pagesNoise & Vibration Learning OutcomesRoshan RajasNo ratings yet

- Of Ergonomics Ergonomics (Or Human Factors) Is The ScientificDocument27 pagesOf Ergonomics Ergonomics (Or Human Factors) Is The ScientificMaricarl AuroNo ratings yet

- HAZARDS AND RISKS EXPLAINEDDocument20 pagesHAZARDS AND RISKS EXPLAINEDJhunrey ObnialaNo ratings yet

- Excavation Safety Standard Operating Procedures SummaryDocument33 pagesExcavation Safety Standard Operating Procedures SummaryPriyanka JNo ratings yet

- Exam Paper Occupational 2 PDFDocument8 pagesExam Paper Occupational 2 PDFHema0% (1)

- Human Machine InterfaceDocument46 pagesHuman Machine InterfaceAbhishek Kumar100% (1)

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanNo ratings yet

- OSH MGMT SystemDocument22 pagesOSH MGMT Systemzaleiha100% (1)

- Safety Data Sheet: 1. Product and Company IdentificationDocument20 pagesSafety Data Sheet: 1. Product and Company IdentificationPubcrawlNo ratings yet

- BBS JBE IntroDocument246 pagesBBS JBE IntroInfrastructure Development ServiceNo ratings yet

- The Two Modes of Failure of Escalator Braking Systems: Lutfi Al-SharifDocument10 pagesThe Two Modes of Failure of Escalator Braking Systems: Lutfi Al-Sharifgeorge_zouridisNo ratings yet

- Detect seismic events and protect elevators with the DRK-S701-ROHS EMD seismic detectorDocument1 pageDetect seismic events and protect elevators with the DRK-S701-ROHS EMD seismic detectorGuha ArnabNo ratings yet

- AG05 (Temperature Rise)Document2 pagesAG05 (Temperature Rise)aries26marchNo ratings yet

- Procedure For Metro Certification 08.12.2015Document52 pagesProcedure For Metro Certification 08.12.2015Guha ArnabNo ratings yet

- InsulationDocument2 pagesInsulationpppppppppppppppsssssNo ratings yet

- Motor Winding Temperature ClassDocument2 pagesMotor Winding Temperature ClassExecutive Engineer I & C, Ashuganj SouthNo ratings yet

- Report On International Efficiency Efficiency Classes For Low Voltage AC MotorsDocument38 pagesReport On International Efficiency Efficiency Classes For Low Voltage AC MotorsGuha ArnabNo ratings yet

- Report On International Efficiency Efficiency Classes For Low Voltage AC MotorsDocument13 pagesReport On International Efficiency Efficiency Classes For Low Voltage AC MotorsmersiumNo ratings yet

- 9AKK107319 EN 05-2018 - 20848 - ABB - Technical - Note - IEC - 60034 - 30 - 1Document2 pages9AKK107319 EN 05-2018 - 20848 - ABB - Technical - Note - IEC - 60034 - 30 - 1Guha ArnabNo ratings yet

- 61ph III DMRC ModelDocument1 page61ph III DMRC ModelGuha ArnabNo ratings yet

- 263Document9 pages263Edward Elric2No ratings yet

- IndustrialmotorscatalogueDocument86 pagesIndustrialmotorscataloguenavneetNo ratings yet

- Sketch 1 of 8Document1 pageSketch 1 of 8Guha ArnabNo ratings yet

- Recharge Details: Mobile Number DateDocument1 pageRecharge Details: Mobile Number DateGuha ArnabNo ratings yet

- Chapter - 6 - Railway Track DesignDocument48 pagesChapter - 6 - Railway Track Designzaher201275% (16)

- Ipl 2017Document4 pagesIpl 2017Guha ArnabNo ratings yet

- Irc 112-2011-2Document2 pagesIrc 112-2011-2Anonymous HJ7hmihhNo ratings yet

- KMRCL - Calendar 2018Document1 pageKMRCL - Calendar 2018Guha ArnabNo ratings yet

- 11 PDFDocument1 page11 PDFGuha ArnabNo ratings yet

- Go No 46Document5 pagesGo No 46Guha ArnabNo ratings yet

- DIGITAL FIRE ALARM SYSTEMDocument32 pagesDIGITAL FIRE ALARM SYSTEMGuha ArnabNo ratings yet

- Is 4759 1996 PDFDocument12 pagesIs 4759 1996 PDFSandeep SundriyalNo ratings yet

- Rail stress calculation methodology document summaryDocument13 pagesRail stress calculation methodology document summaryGuha ArnabNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To InformationGanesh EshwarNo ratings yet

- ASTM G62 87 Reapproved 1998 PDFDocument5 pagesASTM G62 87 Reapproved 1998 PDFGuha ArnabNo ratings yet

- FGA ModelDocument1 pageFGA ModelGuha ArnabNo ratings yet

- Guideline To Prepare Fire Safety ReportDocument2 pagesGuideline To Prepare Fire Safety ReportGuha ArnabNo ratings yet

- APC Battery Management SystemDocument2 pagesAPC Battery Management SystemGuha ArnabNo ratings yet

- AG05 (Temperature Rise)Document2 pagesAG05 (Temperature Rise)aries26marchNo ratings yet

- BikesDocument2 pagesBikesGuha ArnabNo ratings yet

- Circumstances Which Led To The Creation of Pakistan:: Pakistan and The Modern World by Liaqat Ali KhanDocument14 pagesCircumstances Which Led To The Creation of Pakistan:: Pakistan and The Modern World by Liaqat Ali KhanHafiz Mehroz Khan0% (1)

- Managing Multiple Trauma InjuriesDocument9 pagesManaging Multiple Trauma InjuriesMia MusNo ratings yet

- Poster PresentationDocument1 pagePoster PresentationFenny Adelaide KennesyNo ratings yet

- Gerund or InfinitiveDocument4 pagesGerund or InfinitivenayamillNo ratings yet

- NCLEX Review QuestionsDocument14 pagesNCLEX Review QuestionsMariel EstoniloNo ratings yet

- List of British-English Common HomophonesDocument4 pagesList of British-English Common HomophonesPep EscondiolaNo ratings yet

- Fitness Fitness: TabataDocument19 pagesFitness Fitness: TabataRonaldLCasto100% (2)

- Synth EsDocument36 pagesSynth EsFrank QuitianNo ratings yet

- FG ChartsDocument8 pagesFG Chartsalucardd20No ratings yet

- DR - VP Singh - Medrecon (FINAL)Document45 pagesDR - VP Singh - Medrecon (FINAL)Virendar Pal SinghNo ratings yet

- M01 00101-15 LPDocument34 pagesM01 00101-15 LPMacelevi Darevi100% (3)

- Arm Anatomy Dissection PicturesDocument71 pagesArm Anatomy Dissection PicturesShivamNo ratings yet

- Exam 2019 Answer OAPA: Criminal Law (University of London)Document5 pagesExam 2019 Answer OAPA: Criminal Law (University of London)Md. Yousuf RifatNo ratings yet

- AnnMaxillofacSurg72250-4171566 113515Document6 pagesAnnMaxillofacSurg72250-4171566 113515Arlanda Diane MahendraNo ratings yet

- Prelegere Osteoarticular enDocument93 pagesPrelegere Osteoarticular enViorelVelenciucNo ratings yet

- Reading Assignment 4Document17 pagesReading Assignment 4John Chris LuminangNo ratings yet

- Office of Highway Safety Bridge InspectionsDocument25 pagesOffice of Highway Safety Bridge Inspectionsdiarto trisnoyuwonoNo ratings yet

- bc-5800 Operator's Manual v5.0 - en PDFDocument416 pagesbc-5800 Operator's Manual v5.0 - en PDFBruno Swanggs Kanaalo100% (1)

- PeléDocument1 pagePeléSholikhudin ArifNo ratings yet

- The Effect of WarDocument16 pagesThe Effect of Warapi-251665102No ratings yet

- Autumn Dawn Spark 01 No Words AloneDocument124 pagesAutumn Dawn Spark 01 No Words AloneUma Raj100% (1)

- Refleks & Arcus RefleksDocument23 pagesRefleks & Arcus Reflekswandry octaNo ratings yet

- Us Squash 1Document52 pagesUs Squash 1Shayla LarsonNo ratings yet

- Handball RulesDocument2 pagesHandball RulesleowongmusicNo ratings yet

- OSTEOMYELITISDocument14 pagesOSTEOMYELITISKristine Alejandro0% (1)

- CARE OF PATIENTS IN TRACTIONDocument105 pagesCARE OF PATIENTS IN TRACTIONFelipe Quidayan67% (3)

- CCEB Exam Content July 2013Document24 pagesCCEB Exam Content July 2013StarLink1No ratings yet

- Elbow Wrist StretchesDocument3 pagesElbow Wrist StretchesPratik KadamNo ratings yet

- Anatomy (Ayurveda Library) FDocument22 pagesAnatomy (Ayurveda Library) FAnkit BhardwajNo ratings yet

- Knee Replacement TotalDocument16 pagesKnee Replacement Totalamoon12100% (2)