Professional Documents

Culture Documents

Welding The First ERW X80 Grade Pipeline

Uploaded by

mailmaverick81670 ratings0% found this document useful (0 votes)

47 views12 pagesWelding the First ERW X80 Grade Pipeline.pdf

Original Title

Welding the First ERW X80 Grade Pipeline

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWelding the First ERW X80 Grade Pipeline.pdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views12 pagesWelding The First ERW X80 Grade Pipeline

Uploaded by

mailmaverick8167Welding the First ERW X80 Grade Pipeline.pdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 1

WELDING THE FIRST ERW X80 GRADE PIPELINE

Barbaro F J, Bowie G F and Holmes W

ABSTRACT

Pipeline materials and construction costs are the most signicant components of

major transmission pipelines. In Australia these costs have been contained over

the past two decades by the utilisation of high strength thin walled pipe. API 5L

X70 grade pipe is common place and 13km of X80 grade pipe has been installed

in a looping section of the Roma - Brisbane pipeline. The aim of the Roma -

Brisbane looping project was to fully evaluate the economic benets associated

with the use of 8.8mm thick, 406mm diameter X80 grade pipe. The evaluation

involved development of weld procedures using both the conventional cellulosic

manual metal arc (MMA) process and a mechanised gas metal arc welding

(GMAW) system to determine the inuence of weld metal strength on allowable

girth weld defect tolerance.

Although currently available cellulosic consumables have been shown

to undermatch the strength of X80 pipe, the full section pipe tension test

demonstrated tolerance to both Tier 1 and Tier 2 girth weld defect allowances.

These results support recent research which has shown that the tolerable level of

weld metal strength undermatching is related to the pipe wall thickness and the

defect depth assumption

Weld metal strength matching with an appropriate level of toughness was shown

using engineering critical assessment procedures to provide increased defect

tolerance. Defect tolerance under axial yield stress loading is more accurately

determined using destructive test methods.

KEYWORDS

Pipelines, X80, GMAW, Cellulosic, Full section pipe tension test, Defect

acceptance, ECA, Destructive test.

AUTHOR DETAILS

Frank J Barbaro, Chief Development Ofcer and Graham F Bowie, Senior

Development Ofcer, BHP Steel Flat Products, Port Kembla Steelworks, New

South Wales and William Holmes, Technology Manager Pipeline & Coatings,

Agility Team Build, Fyshwick Canberra, ACT

First published in the proceedings of the Welding Technology Institute of

Australia International Conference on Pipeline Construction Technolog, 4-5

March 2002, Novotel North Beach, Wollongong, Australia.

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 2

The signicant cost of pipeline materials and construction in

conjunction with competition with other energy sources has

driven the development of high strength linepipe for transmission

of natural gas. The cost savings associated with high strength

pipe arise from a reduction in pipe wall thickness which reduces

both required steel tonnage and also welding cost. In comparison

with X70 grade pipe, X80 grade pipe represents approximately

12% reduction in total steel weight and up to 25% less deposited

weld metal. These benets however are balanced by any increase

in the pipe / weld consumable costs and require that eld welding

productivity is not compromised.

In Australia, where thin walled small diameter pipe is

commonplace, maximum economic benets have been obtained

by the use of high strength linepipe up to and including X70

grade pipe [1]. The continued use of conventional manual metal

arc (MMA)welding using cellulosic consumables for such pipe

designs has enabled eld construction rates which have been as

high as 8kms per day.

The strength of X80 however, challenges the continued use of

cellulosic welding consumables because of their limit in strength

and also high inherent hydrogen content. The main issues in

the welding of high strength linepipe are resistance to hydrogen

assisted cold cracking (HACC) and sufcient weld metal strength

to match the pipe [2, 3]. Extensive investigations have shown

that under normal eld construction practices HACC can be

avoided [4, 5]. The limited strength of cellulosic consumables is

a more serious concern and has been shown to undermatch the

yield strength of X80 grade pipe [6] and even X70 grade pipe at

the upper end of the normal strength range [7, 8]. It is pertinent

to point out however, that it is not simply the weld metal yield

strength that is the governing factor but rather the level of defect

tolerance relative to the pipe design. From an economic viewpoint

adequate weld metal strength matching is required to ensure

sufcient tolerance to the typical weld defects which occur during

pipeline construction in order to avoid unnecessary repairs.

There is an important difference between weld metal yield

strength matching and weld metal strength matching. The latter is

directly related to weld defect tolerance, which not only depends

on the actual yield strength of the weld metal and the pipe, but

also the specied defect limits (particularly depth) and pipe wall

thickness. Yield strength matching will provide maximum defect

tolerance but is difcult to determine [7], particularly where

different yielding phenomena can occur in different suppliers of

high strength pipe grades.

To address these issues of weld metal requirements and eld

welding productivity, AGL Pipelines undertook to construct a

section of the Roma to Brisbane Looping line using 8.8mm

thick, 406mm diameter API 5L X80 grade pipe. This particular

looping project was selected because the pipe dimensions

closely represented a number of proposed pipelines which could

also benet economically by the use of X80 grade pipe. The

justication for the use of X80 grade pipe involved evaluation

of different welding processes with particular emphasis on

the assessment of defect tolerance. Cellulosic MMA and two

commercial automatic GMAW processes were evaluated by full

section pipe tension (FSPT) [9] tests to determine limits in girth

weld defect tolerance. Further evaluation was undertaken using

approved fracture mechanics methods to support the FSPT tests.

This paper details the results of the investigation and some eld

welding experience using automatic GMAW.

01 INTRODUCTION

02 PROCEDURE

2.1. Pipe material

The pipe used in this program was 406mm diameter, 8.8mm thick

seam welded using the electrical resistance welding (ERW) process.

The chemical composition of the pipe (Table 1) is characterised by a

low carbon content and controlled additions of microalloys required

for advanced thermomechanical rolling to optimise the level of

strength and toughness as well as control of weldability.

2.2. Mechanical properties

Tensile tests were performed in both the longitudinal and transverse

direction of the pipe. Pipe body Charpy impact tests were carried

out over a range of temperatures. Girth weld Charpy impact tests

were carried out at the minimum design operating temperature

which was dened as 0C

2.2.1. Welding procedure

Pipe girth welding trials involved conventional MMA welding using

cellulosic consumables and two different commercially available

automatic GMAW processes.

The cellulosic welding procedure, C1, employed the standard

pipe mill prepared end bevel, which consisted of a 60 included

angle with a 1.5mm root face. Root opening varied between 1 and

1.5mm.

The rst GMAW process, which will be referred to as G1, utilised

the standard pipe mill bevel but was ground just prior to welding

to remove the root face. The pipe ends were aligned without a

gap and relied on the welding procedure to ensure full penetration.

Internal segmented copper shoes were employed to prevent

excessive internal weld reinforcement and/or burnthrough.

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 3

The second GMAW process, which will be referred to as G2,

utilised a narrow gap J type preparation machined on site

just prior to welding. This welding process employed a newly

developed mode of metal transfer, the surface tension transfer

(STT) technique, to deposit the root pass which avoided the

need to use internal copper shoes. Detailed welding conditions

are presented in (Table 2.).

2.3. Defect tolerance determination.

Defect tolerance was determined using a FSPT test, which was

developed by the Cooperative Research Centre for Welded

Structures. The test basically involves loading a complete

section of pipe, containing a girth weld and the dened

defect, in uniaxial tension up to the point of fracture. Defects

were produced in the root pass on the inside surface of the

pipe using electro discharged machining to a depth of 3mm

which is the assumed maximum depth of a girth weld defect.

Assessment of the complete pipe diameter eliminates the

conservatism associated with other smaller scale tests such

as the well-known wide plate test. The test rig used in this

investigation is described elsewhere [6, 7, 9].

The aim of the test is to demonstrate that gross section

yielding (GSY), and not net section yielding (NSY), occurs

before fracture. The GSY criteria, which is dened below, is

designed to ensure that the weld metal containing the defect

has sufcient strength to transfer strain to the adjacent pipe

and so ensure a reasonable level of overall elongation of the

pipe before failure. NSY occurs when the strain is concentrated

in the weld metal and fails at low levels of elongation. It is

important to state that the GSY criteria is not designed to

prevent catastrophic failure but to ensure a dened level of

defect tolerance.

The GSY criteria was originally dened by the European

Pipeline Research Group (EPRG) [10] and requires that the girth

weld, containing the maximum allowable defect, under load in

uniaxial tension achieve a:

maximum test stress >= the parent pipe yield stress,

total elongation >= 0.8%, and,

remote or parent pipe strain >= 0.5%

In the FSPT test the maximum load is determined using a

calibrated load cell. Total elongation was measured with a

linear displacement transducer attached along the length of the

welded test pipes. Remote or parent pipe strain was measured

using strain gauges. Recorded strain levels are veried by

subtracting the weld strain, measured by a clip gauge opening

across the weld defect, ie crack mouth opening displacement,

on the inside of the pipe, from the total elongation.

The crack mouth opening displacement (CMOD) not only

provides a check on strain levels but also uniquely denes the

onset of strain transfer to the pipe body. At the point of strain

distribution to the parent plate (or yielding of the pipe) the

CMOD is interrupted as the uniaxial load increases.

03 RESULTS AND DISCUSSION

The Australian Pipeline Standard AS2885.2 has a 3 tier approach

to assessment of girth weld defects, which is designed to improve

economics in pipeline construction. An increased level of weld

imperfections is permitted provided the girth weld possesses a

minimum level of strength matching and toughness. Tier 1 is a

workmanship level which, in general, permits 25mm long surface

breaking defects and 50mm long embedded defects. Tier 2

defect limits however, are a function of pipe diameter and wall

thickness and for the 406mm diameter 8.8mm wall thickness pipe

in the present investigation, the maximum defect length is 84mm,

irrespective of its position through the wall thickness.

The following results detail the pertinent characteristics of girth

welds produced in API 5L X80 grade pipe using different welding

procedures and its ability to meet the above mentioned defect

limits.

3.1. Radiography of welds

All welds fabricated as part of this investigation were examined

by conventional radiographic techniques and complied with

the requirements of AS2885.2. It was however noted that

radiographs of welds produced by the GMAW, G1 process

contained marks which corresponded with artefacts produced

on the surface of the root pass by the segmented copper shoes.

In general this did not interfere with the inspection process.

3.2. Chemical composition and microstructure

of welds

The chemical composition of nal cap weld deposits is given in

(Table 3). It will be noted that the carbon equivalent of the GMAW

consumables were markedly different. The carbon equivalent of

G1 was the highest of all assessed and is related to the addition

of Ni along with the Cr and Mo levels. The carbon equivalent of

G2 was extremely low and is reected in mechanical properties.

The MMA weld C1 also had a high carbon equivalent which

predominantly relied upon a relatively high carbon content and

additions of Mo and V for strengthening.

The relative level of deposited weld metal strength however

depends upon welding conditions and it is evident from the

macrophotographs presented in (Figure 1), that both GMAW

welds were welded at low heat inputs as evidenced by the

narrow width of visible weld HAZ. It is apparent from (Figure 1.)

that the MMA weld was carried out at weld heat inputs greater

than both GMA welds, refer (Table 2.).

The microstructure of weld C1 primarily consisted of ferrite

and pearlite throughout the entire weld thickness. This as

mentioned above is related to the weld heat input and also the

alloy design. A high weld heat input produces a low cooling

rate which promotes the formation of coarse equilibrium

microstructures and also increases the extent of recrystallisation

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 4

of previously deposited underlying weld runs. The level of

heat input employed in weld C1 was evident by the complete

recrystallisation of the root pass (Figure 2a.) which was up to

4mm of the girth weld thickness.

Both GMA welds were characterised by distinct columnar

structures which persisted throughout the weld thickness.

The low weld heat input employed limited the extent of

recrystallisation of underlying weld runs. As a result both welds

contained relatively ne grained acicular ferrite and martensite

microstructures outlined by columnar grain boundary ferrite

(Figure 2b and c). The difference between welds G1 and G2

can be related to the consumable alloy design. Weld G1 with

a carbon equivalent some 16 points higher than G2 contained

signicantly higher levels of martensite. This was most

prominent in the root pass of weld G1 where rapid cooling

over the copper shoes employed during root pass welding

further enhanced martensite formation. This observation was

supported by the hardness results presented later.

3.3 Mechanical properties

The results of tensile tests carried out on the parent pipe in both

the transverse and longitudinal directions are presented in Table

4. Recorded yield strengths in the transverse direction were

within a tight range with the maximum less than 70 MPa above

the minimum specication.

Conventional cross weld tensile tests demonstrated that all

weld procedures satised traditional workmanship requirements

with a tensile strength greater than that of the specied

minimum of the pipe (Table 5.). It should be noted however, that

both welds C1 and G2, with the weld reinforcement removed,

failed in the weld metal at a strength less than that of the pipe.

Assessment of weld metal strength matching as determined

by the notched tensile test, although acknowledged as difcult

to interpret, revealed signicant differences in weld metal yield

strength (Table 6.). Clearly the MMA weld C1 undermatched the

yield strength of the pipe by approximately 17% while the high

carbon equivalent of weld G1 provided a considerable level of

overmatching, approximately 8%. It is interesting to note that

the low carbon equivalent GMAW weld G2, that indicated slight

tensile strength undermatching in the standard cross weld

tensile test, in fact demonstrated yield strength matching in the

notched tensile test.

Clearly the recorded weld metal strength is directly related to

the alloy design and the welding conditions as evidenced by

the weld metal microstructures detailed above. The results

also highlight that the level of weld metal yield strength

undermatching may go unnoticed in the standard cross weld

tensile test. It is however important to emphasise that, as

mentioned in the introduction, strength matching is not the

only characteristic of a girth weld that inuences weld defect

tolerance.

3.4. Hardness

Through thickness hardness (HV5) proles were conducted

on all weld deposits, refer (Table 7). As expected the higher

strength GMA weld, G1, recorded the highest hardness with

values in the root pass up to 50 points higher than the pipe.

Both welds C1 and G2 recorded hardness values which were

below that of the pipe which supports the cross weld tensile

tests discussed previously. The level of hardness of weld C1

could again be attributed to weld microstructure.

It is important to note that the level of hardness recorded in

the root pass of weld G1 could not be solely attributed to the

carbon equivalent or weld conditions. The root pass of this

weld was carried out with the use of internal copper shoes

which has increased the cooling rate to produce the high levels

of martensite in the microstructure.

3.5. Toughness

Girth weld toughness was evaluated using the Charpy test at

0C and results are presented in Table 8. All welds satised

the minimum requirement of 22J minimum individual and 30J

minimum average specied in AS2885.2 which is required to

ensure that in the event of girth weld failure, fracture would

occur by plastic collapse and not in a brittle manner.

It is however evident that weld G2 clearly possessed a superior

level of toughness compared to both welds C1 and G1. The

low carbon equivalent of weld G2 along with the controlled low

heat input welding appear to have combined to provide a ne

grained microstructure. The outcome is an optimum balance

of toughness and, as shown later, adequate strength for the

welding of X80 grade pipe. Although a similar ne grained

ferritic microstructure was produced in weld G1, the higher

carbon equivalent and weld cooling rate has increased the level

of martensite to the detriment of toughness. The toughness

of the conventional MMA weld C1 can be explained by the

relatively coarse ferritic microstructure.

CTOD fracture toughness values for both weld C1 and G1 are

consistent with the measured Charpy impact test results Table

8. Unfortunately weld G2 was not tested, but based on Charpy

toughness, a CTOD signicantly exceeding that achieved with

C1 and G2 would be expected.

3.6. Full section pipe tension (FSPT) tests

Limited girth weld samples prevented a complete assessment

of all weld procedures. Four tests covering defect lengths

of 75-150mm were carried out on weld C1. Unfortunately

only two tests were carried out on weld G2 while insufcient

material prevented any tests on weld G1. The articial defects

produced were accurately controlled around the maximum

assumed depth of 3mm and provided a thorough assessment

of tolerance as dened by Australian Standard AS2885.2.

It is apparent from Table 9. that GSY was satisfactorily

demonstrated in weld C1 with a defect length up to 100mm.

The 125mm defect, which did not meet the gross stress

requirement by just 2 MPa could also be considered

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 5

satisfactory if the slight increase in defect depth of this test

is taken into consideration. Despite this however, the results

clearly demonstrate that the maximum dened limit of the less

conservative Tier 2, i.e. 84mm, was quite easily achieved.

The defect lengths selected for GMAW procedure G2 was

based on the level of weld metal yield strength and previous

experience and unfortunately for the two tests carried out,

neither completely satised the GSY criteria. Interpolation of

the data however, in the form of a plot of the maximum stress

versus defect area (Figure 3.) strongly suggests that the defect

limit to be a length approximately 170mm which is signicantly

greater than AS2885.2 Tier 2 limit of 84mm.

3.7. Field welding

The production sequence consisted of the normal pipe

stringing and alignment with an internal compressed air clamp.

The welding technique employed was identical to that of weld

procedure G1 above including pipe end preparation and the

use of internal segmented copper shoes. Only one welding

station was employed however.

The welding system consisted of two welding bugs each with

twin heads, which travelled around a metal band attached to

the pipe. Welding commenced by deposition of the root and hot

pass using one welding bug down one side of the pipe from the

12 oclock position to the 6 oclock position. Before completion

of this rst run the weld start position was ground in preparation

for a similar run down the other side of the pipe, which

commenced as soon as possible but generally on completion

of the rst side. As the root / hot pass on the second side of

the pipe was being deposited, preparation for the ll and cap

was underway in a similar sequence to the root / hot passes.

Unfortunately however, severe arc blow was experienced

during welding of the root / hot pass run on the second side of

the pipe. Efforts to eliminate the effect indicated that the root

cause may originate from induced magnetic effects from the

twin welding heads. As a result of these issues the majority of

the X80 section was successfully welded with MMA cellulosic

consumables in accordance with procedure C1.

3.8. Engineering critical assessment of girth

weld defect limits

The determination of critical defect dimensions in a girth

weld using fracture mechanics is not only dependent on the

mechanical properties of the weld metal and pipe but also the

assumed operating stresses. For a gas transmission pipeline

the stress imposed, which could be considered normal,

includes the eld hydrostatic test and the maximum allowable

operating pressure. These are dened levels of stress for

which a defect limit can be estimated. More recent attention

however, has focussed on the capacity of girth welds,

containing defects, to withstand displacement controlled

loading, i.e. axial yield stress loads, which could occur in areas

of unstable ground.

An engineering critical assessment (ECA) was carried out

on the current pipe design using The Welding Institute

software program CRACKWISE 3 which is based on British

Standard BS7910 - 1999 Guide on methods for assessing the

acceptability of aws in metallic structures, Level 2 analysis.

(Table 10.) presents the calculated critical length of 3mm deep

defects for the above three stress conditions as a function of

fracture toughness and enables a direct comparison with the

current experimental FSPT test results.

Evident from Table 10. is a signicant difference in the ECA

calculated critical defect length and the measured FSPT test

value under yield stress loading conditions. It is also apparent

that with the ECA under this loading condition (600MPa),

fracture toughness does not effectively inuence defect

tolerance since predicted tolerance is very low (length <6mm).

Clearly the ECA approach employed for this particular pipe

design has grossly underestimated defect tolerance and would

appear to be related to an assumption that failure occurs by a

brittle or tearing mechanism, whereas EPRG has found that if

fracture toughness exceeds a CTOD value of 0.1mm minimum,

0.15mm average, fracture would occur by plastic collapse.

For the MMA weld C1 with a fracture toughness of 0.156mm,

the calculated critical defect length increases to 239mm under

hydrotest conditions (1.4 x 0.72 x 0.3 x SMYS (552) = 167MPa)

and 465mm for maximum allowable operating conditions (0.3 x

0.72 x SMYS = 119MPa). Clearly under these stress conditions

defect tolerance is inuenced by fracture toughness and would

be considered reasonable predictions based on the current

destructive tests.

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 6

04 CONCLUSIONS

The results of this investigation have demonstrated that the

8.8mm thick API 5L X80 grade pipe can be welded with both

the conventional MMA cellulosic process and mechanised

GMAW systems. The mechanical strength of the girth welds

varied signicantly but, for the pipe design assessed, did not

compromise the structural integrity of the pipeline and meets

the accepted requirements of GSY for currently specied defect

limits in both Tiers 1 and 2 of Australian Standard AS2885.2.

MMA cellulosic weld, C1, provided adequate toughness and

defect tolerance despite a degree of weld metal yield strength

undermatching. In fact, the measured defect limit is some

15mm greater in length than currently specied in Tier 2 of

AS2885.2. GMAW processes offer a greater range of weld

metal strengths and increased defect tolerance.

Engineering critical assessments provide a reasonable

assessment of defect tolerance under normal operating

conditions. Under axial yield stress loads destructive tests

would provide a more accurate estimate however.

05 ACKNOWLEDGEMENTS

The authors would like to thank colleagues at Agility and BHP

Steel for their many contributions.

06 REFERENCES

Venton P October 1995. Pipeline construction costs in 1.

Australia. Paper 21. WTIA/APIA Research Panel 7 Seminar,

Wollongong, Australia.

Barbaro F J, Bilston K, Fletcher L, Kimber M and Venton 2.

P July 1999. Research shows that X80 pipe can be

economically and safely welded by conventional methods,

Australian Pipeliner 22-23.

Barbaro F J March 1999. Types of hydrogen cracking in 3.

pipeline girth welds. WTIA/APIA/CRC-WS International

Conference on Weld metal cracking in pipeline girth welds,

Wollongong, Australia.

Barbaro F J, Meta A, Williams J G and Fletcher L September 4.

1995. Weldability of high strength ERW X80 grade pipe.

Pipeline Technology Conference II, Ostend, Belgium.

Alam N, Dunne D P and Barbaro F J March 1999. Weld metal 5.

crack testing for high strength cellulosic electrodes. WTIA/

APIA/CRC-WS International Conference on Weld metal

cracking in pipeline girth welds. Wollongong, Australia.

Barbaro F J and Bowie G F October 2000. Assessment 6.

of workmanship defect acceptance levels in high strength

5mm wall thickness pipeline girth welds. IIW Asian Pacic

International Congress, Melbourne, Australia.

Bowie G F and Barbaro F J July 2000. Defect acceptance 7.

levels and fracture risk in pipeline girth welds. CRC-WS

nal report 98-62.

Barbaro F J, Bowie G F, Stathers P A and Williams J G 8.

November 1997. Factors controlling defect acceptance

levels in 5mm thick high strength pipeline girth welds. Intl

Welding and Joining Research Conference and WTIA 45

th

Annual Conference, Melbourne, Australia.

Bowie G F and Barbaro F J July 1998. Defect acceptance 9.

levels in 5mm thick high strength pipeline girth welds. CRC-

WS nal report 96-31.

Hopkins P and Denys R May 1993. The background to the 10.

proposed European pipeline research groups girth weld

defect limits for transmission pipelines. Joint EPRG/PRC

Conference.

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 7

The chemical composition of X80 pipe-steel

C P Mn Si S Ni Cr Mo Cu Al V Nb Ti Ceq IIW

X80 pipe .065 .014 1.55 .31 .002 .023 .027 .28 .019 .026 .002 .068 .018 .39

TABLE 01

Reported conditions for each welding process

Weld Process Weld Pass Consumable Amps Volts

Travel Speed

mm/min

Heat Input kJ/

mm

Cellulosic C1 root E8010 120 25 400 0.45

hot E9010 180 28 390 0.77

ll E9010 165 27 210 1.27

cap E9010 140 27 195 1.16

GMAW G1 **

one consumable

root 0.9mm 230 22 ) )

hot austmig 250 22 ) ~ 950 ) ~ 0.35

ll NiCrMo 240 21 ) )

cap 80/20Ar/CO2 235 20 ) ~ 400 ) ~ 0.70

GMAW G2

one consumable

root 0.9mm 205 16 380 0.51

hot Hobart / 215 23 508 0.56

ll Thyssen 215 23 508 0.56

cap ER70S-6 80/20Ar/CO2 150 20 330 0.56

** Weld G1 employed internal copper shoes to avoid blow through during root pass welding

TABLE 02

The chemical composition of weld capping deposits

C P Mn Si S Ni Cr Mo Cu Al V Nb Ti Ceq IIW

C1 .155 .009 0.70 0.13 .007 0.47 0.39 0.33 .047 <.003 .049 .003 .007 0.46

G1 .065 .007 1.36 0.37 .009 1.15 0.24 0.23 0.11 .007 .070 .017 .005 0.48

G2 0.07 .008 1.35 0.59 .009 .025 .031 .064 .098 .008 <.003 .014 .028 0.32

Tensile properties of X80 pipe

Transverse Longitudinal

0.5% TEYS (MPa) Tensile Strength (MPa) Y / T ratio (%) 0.5% TEYS (MPa) Tensile Strength (MPa) Y / T ratio (%)

572 - 622 712 - 764 73 - 84 585 - 600 703 - 717 83 - 84

TABLE 03

TABLE 04

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 8

Cross weld tensile properties of girth welds

Weld Code Weld Consumable UTS (MPa) Fracture Location Weld Reinforcement

C1 E8010/ E9010 650 weld removed

709 weld/HAZ reinforced

G1 NiCrMo 727 pipe removed

724 pipe reinforced

G2 ER70S-6 692 weld removed

725 pipe reinforced

TABLE 05

Notched tensile properties of X80 pipe and deposited weld metal

X80 parent pipe Weld metal (notched tensile test)

0.5% TEYS

(MPa)

TS (MPa) Y/T ratio (%) YS (MPa) TS (MPa) Y/T ratio (%) YS matching ratio

C1 E8010/ E9010 585 703 83 483 629 77 0.83

G1 NiCrMo 600 714 84 649 741 88 1.08

G2 ER70S-6 591 717 83 590 692 85 1.00

Through thickness hardness prole of each Weld Procedure,

Vickers HV5

Root pass Hot Pass Fill Pass Cap Pass Parent Pipe

Cellulosic C1 185 207 199 191 228

GMAW G1 287 252 245 244 233

GMAW G2 228 226 196 203 232

Weld Metal Charpy V-notch Test Results, test temperature 0C

Weld Specimen Size (mm) Min Value (J) Average (J)

AS2885.2 reqts

min Indiv min Average

CTOD (mm)

Cellulosic C1 10 X 7.5 34 43 22 30 0.156

GMAW G1 10 X 7.5 54 72 22 30 0.113

GMAW G2 10 X 7.5 108 117 22 30 not tested

TABLE 06

TABLE 07

TABLE 08

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 9

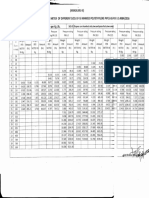

Full Section Pipe Tensile Test Results

Defect Results

Weld Length (mm) Depth (mm) Area (mm2) Overall Elong (%) Parent Strain (%) Max Stress (MPa) Yielding Mode

C1 75 2.9 177 1.02 1.5, 1.4, 0.55, 0.5 587 GSY

100 2.9 236 0.74 0.5, 0.63, 0.48, 0.38 599 GSY

125 3.1 295 0.87 1.5, 0.53, 0.80, 0.51 583 GSY/NSY

150 2.9 353 0.75 1.7, 0.83, 0.54, 0.46 575 NSY

Tier 2 Reqt 84 3.0 >0.6 0.5 585 GSY

G1 not tested

G2 200 3.0 471 0.53 0.71, 0.55, 0.41, 0.26 573 NSY

250 3.0 589 0.52 0.42, 0.46, 0.60, 0.32 586 NSY

Tier 2 Reqt 84 3.0 >0.6 0.5 591 GSY

Calculated critical length of 3mm deep surface breaking defects in

API 5L X80 grade pipeline girth welds for 3 different stress conditions

and limits experimentally determined using the FSPT test

Fracture toughness c,

mm

Yield stress loading-

600MPa

Hydro test loading

167MPa

MAOP Loading 119Mpa

FSPT test, yield stress

loading, 600MPa

0.05 <6 11 14

0.06 <6 15 19

0.075 <6 22 30

0.1 <6 45 73

0.113 <6 67 113

0.156 <6 239 465 125

0.2 <6 629 919

0.22 <6 849 1069 (170)

0.25 <6 1041 1241

TABLE 09

TABLE 10

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 10

Macrographs of girth welds. a) Weld C1 b) Weld G1 c) Weld G2

FIGURE 01

a)

b)

c)

STEEL FOR PIPELINES

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 11

Fi

Photomicrographs showing the characteristic microstructure of each weld

a) Weld C1 b) Weld G1 c) Weld G2.

FIGURE 02

0.10 mm

0.10 mm

0.10 mm 0.10 mm

0.10 mm

0.10 mm

STEEL FOR PIPELINES

2010 BlueScope Steel is a registered trademark of BlueScope Steel Limited. ABN 16 000 011 058.

You can rely on Australias experts in steel

Page 12

Fi

Full section pipe tension test results of Weld G2. Maximum stress plotted against defect area in

conjunction with measure parent strain enables estimation of the maximum defect area to meet the

GSY criteria

FIGURE 03

Defect Area mm

2

S

t

r

e

s

s

(

M

P

a

)

You might also like

- Surge Analysis and The Wave Plan MethodDocument126 pagesSurge Analysis and The Wave Plan Methodmailmaverick8167No ratings yet

- Hdpe Rates Pe100Document1 pageHdpe Rates Pe100mailmaverick8167No ratings yet

- Hdpe Rates Pe80Document1 pageHdpe Rates Pe80mailmaverick8167No ratings yet

- Modeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsDocument22 pagesModeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsmailmaverick8167No ratings yet

- Joint Efficiency Factors For Seam-Welded Factory-Made Pipeline BendsDocument18 pagesJoint Efficiency Factors For Seam-Welded Factory-Made Pipeline Bendsmailmaverick8167No ratings yet

- Properly Sizing Pumps and Pipes for Variable Viscosity Non-Newtonian FluidsDocument3 pagesProperly Sizing Pumps and Pipes for Variable Viscosity Non-Newtonian Fluidsmailmaverick8167No ratings yet

- Hydraulic Design of Storm Sewers With Excel CourseDocument41 pagesHydraulic Design of Storm Sewers With Excel CourseRonal Salvatierra100% (1)

- Centrifugal Pump SelectionDocument25 pagesCentrifugal Pump SelectionAbhay Sisodia100% (1)

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 pagesDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167No ratings yet

- The Secrets of Breakpoint ChlorinationDocument26 pagesThe Secrets of Breakpoint Chlorinationmailmaverick8167No ratings yet

- Modeling pump startup and shutdown transients in the same simulationDocument5 pagesModeling pump startup and shutdown transients in the same simulationmailmaverick8167No ratings yet

- HDPE Pipe InformationDocument24 pagesHDPE Pipe InformationTylerNo ratings yet

- Air Valve Orifice SizeDocument1 pageAir Valve Orifice Sizemailmaverick8167No ratings yet

- By Dr. A Jon Kimerling, Professor Emeritus, Oregon State UniversityDocument3 pagesBy Dr. A Jon Kimerling, Professor Emeritus, Oregon State Universitymailmaverick8167No ratings yet

- Enhancement of Efficiency of Biogas Dige PDFDocument6 pagesEnhancement of Efficiency of Biogas Dige PDFmailmaverick8167No ratings yet

- Effect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration SystemDocument11 pagesEffect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration Systemmailmaverick8167No ratings yet

- Is 9523 Ductile Iron FittingsDocument32 pagesIs 9523 Ductile Iron FittingsKathiravan Manimegalai100% (2)

- 12 Shibly RahmanDocument34 pages12 Shibly Rahmanmailmaverick8167No ratings yet

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 pagesDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167No ratings yet

- Flow Control ValvesDocument6 pagesFlow Control Valvesmailmaverick8167100% (1)

- PG 67 IS 456Document1 pagePG 67 IS 456mailmaverick8167No ratings yet

- Flow Control ValvesDocument24 pagesFlow Control Valvesmk_chandru100% (1)

- Siewtanyimboh Warm 2012 Epanet PDXDocument23 pagesSiewtanyimboh Warm 2012 Epanet PDXmailmaverick8167No ratings yet

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 pagesDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167No ratings yet

- Flow Control ValvesDocument6 pagesFlow Control Valvesmailmaverick8167100% (1)

- CHP Old Projects Pump DimensionsDocument2 pagesCHP Old Projects Pump Dimensionsmailmaverick8167No ratings yet

- Surge Tank Design Considerations ForDocument14 pagesSurge Tank Design Considerations ForPatricio Muñoz Proboste100% (1)

- Computation of Afflux With Particular Reference To Widening of Bridges On A RoadwayDocument8 pagesComputation of Afflux With Particular Reference To Widening of Bridges On A Roadwaymailmaverick8167No ratings yet

- 5822Document16 pages5822rambinodNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wet H2S Service - Total's RequirementsDocument7 pagesWet H2S Service - Total's Requirementsm5416100% (2)

- Welding Hardox and Weldox PDFDocument4 pagesWelding Hardox and Weldox PDFEnoc AndradeNo ratings yet

- Multi Choice Question Paper (MSR - WI - 3)Document6 pagesMulti Choice Question Paper (MSR - WI - 3)BudimanNo ratings yet

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Document31 pagesStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaNo ratings yet

- 4 - ASME IX Exam (61 Q&A)Document10 pages4 - ASME IX Exam (61 Q&A)Dada KhalandarNo ratings yet

- STEEL INDUSTRY EMBRACES A992Document6 pagesSTEEL INDUSTRY EMBRACES A992Jagadeesh Nandam100% (1)

- Chunky GraphiteDocument16 pagesChunky GraphitesachinguptachdNo ratings yet

- FLBOEA Course Notes Welding MEM05026B-Sections 13-18Document111 pagesFLBOEA Course Notes Welding MEM05026B-Sections 13-18stanleyNo ratings yet

- Welding Consumables-Mild Steel BocDocument43 pagesWelding Consumables-Mild Steel Bocargentino_ar01No ratings yet

- Construction Standard for Steel Reinforcing BarsDocument52 pagesConstruction Standard for Steel Reinforcing Barsmath0506hk8561No ratings yet

- Irc SP 104 2015Document89 pagesIrc SP 104 2015Pathankot MandiNo ratings yet

- Wem300 Welding PracticesDocument71 pagesWem300 Welding PracticesjudicejrNo ratings yet

- Translated A 5523Document20 pagesTranslated A 5523Pd ProxyNo ratings yet

- Dillinger Dillimax Dillidur BrochureDocument12 pagesDillinger Dillimax Dillidur BrochureVictorNo ratings yet

- Carbon Equivalent (Ce) Composition Parameter (PCM)Document9 pagesCarbon Equivalent (Ce) Composition Parameter (PCM)Arif Budi JatmikoNo ratings yet

- FAQ - What Is The Difference Between The Various Carbon Equivalent Formulae Used in Relation To Hydrogen CrackingDocument3 pagesFAQ - What Is The Difference Between The Various Carbon Equivalent Formulae Used in Relation To Hydrogen CrackingahmedNo ratings yet

- Paper No: 2002 OMAE - Volume 111, Materials EngineeringDocument6 pagesPaper No: 2002 OMAE - Volume 111, Materials EngineeringAnonymous 9PIxHy13No ratings yet

- Effect of Heat Treatment On The Mechanical Properties and Microstructure of Welded Abrasion Resistant Steel Ar200 PDFDocument119 pagesEffect of Heat Treatment On The Mechanical Properties and Microstructure of Welded Abrasion Resistant Steel Ar200 PDFBurag HamparyanNo ratings yet

- Linepipe Specification SummaryDocument36 pagesLinepipe Specification SummaryRokan PipelineNo ratings yet

- Pipe FabricationDocument42 pagesPipe FabricationJanani M Janani67% (6)

- Chart Method To Calculate PreheatDocument11 pagesChart Method To Calculate Preheatrent63No ratings yet

- Industeel Tableau Nuances Special Carbon and Low AlloyDocument1 pageIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeNo ratings yet

- BS en 10025-3Document28 pagesBS en 10025-3yasser awadallhNo ratings yet

- Corus Jumbo Sections 2004Document20 pagesCorus Jumbo Sections 2004Collin NguNo ratings yet

- Astm A992Document2 pagesAstm A992MUHAMEDNo ratings yet

- AFS Thermal Analysis of CupsDocument10 pagesAFS Thermal Analysis of Cupsyash_ganatraNo ratings yet

- Steel Construction in The New Millennium: December 2003Document41 pagesSteel Construction in The New Millennium: December 2003CIVILNo ratings yet

- Amendment No. 1 November 2012 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument4 pagesAmendment No. 1 November 2012 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationThetarun100% (1)

- Turbine RepairDocument67 pagesTurbine RepairFrancisco Novoa Rodriguez50% (2)

- Great Minds of Carbon Equivalent CompleteDocument14 pagesGreat Minds of Carbon Equivalent CompleteColonelprivate100% (1)