Professional Documents

Culture Documents

ch13 SCM

Uploaded by

Arghya Mukherjee0 ratings0% found this document useful (0 votes)

15 views15 pagespdf

Original Title

ch13_SCM

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views15 pagesch13 SCM

Uploaded by

Arghya Mukherjeepdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

Page 1 of 15

Chapter-13 Supply Chain Management

Certificate in Retail Management

Confidentiality statement

This document should not be carried outside the physical and virtual boundaries of TCS and

its client work locations. Sharing this document with any person other than a TCS associate

would tantamount to violation of confidentiality agreement signed by you while joining

TCS.

Notice

The information given in this course material is merely for reference. Certain third party

terminologies or matter that may be appearing in the course are used only for contextual

identification and explanation, without an intention to infringe.

Contents

Chapter 13 Supply Chain Management .................................................................................... 4

13.1 Supply Chain Management ............................................................................................. 5

13.2 Concept of Supply Chain Management ........................................................................... 5

13.3 Need for Supply Chain Management ............................................................................... 6

13.4 Evolution of Supply Chain Management .......................................................................... 7

13.5 Issues Involved in Developing the Supply Chain Framework ........................................... 8

13.6 Supply Chain Integration ................................................................................................ 9

13.6.1 Retail Market Characteristics: ................................................................................... 9

13.6.2 The Lead Time Gap ................................................................................................. 11

13.7 Innovation in Supply Chain Management ....................................................................... 11

13.7.1 Cross Docking .......................................................................................................... 11

13. 7.2 Collaborative Planning, Forecasting and Replenishment (CPFR) ............................ 11

13.8 Retail Logistics ............................................................................................................... 12

13.9 Reverse Logistics An Emerging Trend ......................................................................... 13

Summary: ............................................................................................................................. 14

Certificate in Retail Management TCS Business Domain Academy

Page 4 of 15

Chapter 13 Supply Chain Management

Introduction

This chapter will help associates to understand the importance of the supply chain in retail. It

also tells about the new developments in supply chain and helps associates to come with

innovative ways to serve the client.

Learning Objectives

After reading this chapter you will know:

Why supply chain is important

New methods to improve the chain

Different methods in supply chain

Certificate in Retail Management TCS Business Domain Academy

Page 5 of 15

13.1 Supply Chain Management

The business of retail has been defined as one that makes goods available to the consumer,

when and where he/she wants them. In order to be able to service the customers

requirements, the retailer needs to understand their preferences, to identify the right products

and their manufacturers, to locate the wholesale or retail stock points, as the case may be, and

to make arrangements for the right quantity to be available.

While this appears to be simple, it is one of the most complex aspects of retailing. We can easily

see the degree of complexity by taking the example of a local department store. A typical

department store has a number of departments, such as apparel, gifts, cosmetics, kitchenware,

appliances and electronics. Take one such department, such as apparel; this will have sections

for men, women and children. Each of these sections will have sub- sections for casual wear;

formal clothes, accessories, etc. Further each category in each sub section will have different

designs, colours and sizes. We now see that put together it represents a very large number of

items. This is further complicated by the involvement of merchandisers, buyers, stores, finance

and other functionaries in the department store.

The department store, in all probability, has at least a hundred suppliers. Some of these could

be manufacturers, some of them agents and other distributors. The challenge of managing a

continuous supply of goods from all these different entities is managing the supply chain.

We start this chapter by understanding the need of supply chain management for a retailer.

This is followed by a brief discussion on the evolution of the concept and innovations in this

field. The concept of retail logistics and reverse logistics are then examined.

13.2 Concept of Supply Chain Management

A supply chain is a network of facilities and distribution options that performs the following

functions:

Procurement of materials

Transformation of these materials into intermediate and finished products,

Distribution of these products to the customers.

Supply chain management ensures smooth and efficient flow, from raw material to finished

goods in to the hand of the consumers. It is a concept which has increasingly replaced the

traditional fragmented management approaches to buying, storing and moving goods. Supply

chains exist in both service and manufacturing organizations, although the complexity of the

chain may vary greatly from industry to industry and from firm to firm. It aims to integrate

activities across the entire merchandise flow, to achieve quick response in supplying products

Certificate in Retail Management TCS Business Domain Academy

Page 6 of 15

and services to the customers who need them. By doing this the production time can be set

close to selling period, achieving better prediction of selling targets.

It is difficult to put down the value of the supply chain industry. However it is estimated that the

global market size of the supply chain and logistics industry, is US$ 3 trillion, which is significant

chunk of global domestic gross product.

The estimated market size for supply chains globally includes aspects like trucking,

warehousing, inventory costs, transaction costs and administration costs for these key

elements. The importance of supply chain management in India can be gauged from fact that

logistics cost constitutes 10 12 percent of our GDP. It is estimated that over Rs1, 00,000 crore

of the total capital, is tied up in inventories in the industrial sector. This is close to 22 percent of

the aggregate industry sales.

13.3 Need for Supply Chain Management

Not long ago, retail stores existed to cater to the needs of the local markets. When one needed

bread and eggs, one visited grocery stores. To buy the garments, one simply, either bought

fabric and had it tailored or bought what was available in the market. Buying for the retail

organization was a much simpler task then. It meant dealing with a few products and a limited

number of suppliers. What existed at that time was a simple supply chain, as illustrated below.

Managing this was fairly simple and easy for the retailer.

However, as markets expanded and retailers business grew, the number of products offered by

the retailer, also increased. While the number of suppliers increased, there was also an

increased pressure on margins. Retailers needed to think of ways of cutting costs. In order to be

able to cut down on costs, it was necessary to integrate the complete supply chain.

Supply chain management today, links demand management, resource management, and

supply management and hence plays an important role in retailing.

Today retailers operate in a dynamic world. Customers buying habits are constantly changing

and competitors are continually adding and improving their product offerings. Demand

changes mean a shorter life cycle for the companys products and inventory. The cost of

holding inventory may restrict the company from providing a reasonably priced product, as

funds are tied up in inventory. The number of suppliers of an organization may vary from a few

hundreds to thousands, depending on the range of products offered to the consumer. Sourcing,

vendor management and logistics play a major role in getting the right products to the right

place, at the right time and the right condition. The second reason partially, is the increased

national and international competition. Customers have multiple sources to choose from, to

satisfy their demands: locating the product throughout the distribution channel for maximum

Certificate in Retail Management TCS Business Domain Academy

Page 7 of 15

customer accessibility, at a minimum cost, becomes crucial. The third reason is the increasing

pressure on the profit margins earned. Companies are becoming aware that they need to look

at the whole picture and not at the functional excellence of individual departments alone.

Lastly, it is a technology driven world. Advances in technology enable companies to get sales,

inventory and production data, across various locations not only within the country, but also

internationally. Information is the key enabler of supply chain management.

13.4 Evolution of Supply Chain Management

In the 70s and the early 80s, as the cost pressures started building up, most organizations

started to take a look in their operations, to see where they could cut costs. Initially, the focus

was on optimizing the levels of raw material, work- in progress and finished goods stored.

Depending on the industry characteristics, different organizations started focusing on

achieving efficiencies in different areas, such as procurement, logistics, manufacturing,

operations, etc.

Out of these initiatives emerged various models for production and operations control and

management, such as Just In Time (JIT) inventory management model, the total quality

management (TQM) model, etc.

JIT is an inventory strategy that strives to improve a businesss return on investment by

reducing in-process inventory and associated carrying costs. To meet JIT objectives, the

process relies on signals of Kanban between different points in the process, which tell

production when to make the next part. Kanban are usually tickets but can be simple visual

signals, such as the presence or absence of a part on a shelf.

TQM is a management philosophy that seeks to integrate all organizational functions

(marketing, finance, design, engineering, and production, customer service, etc.) to focus on

meeting customer needs and other organizational objectives.

These models focused on various components of the supply chain, in isolation. Each one of

them was oriented towards optimization of a sub part of the system. However, soon,

organizations realized the need for taking an integrated look at the entire chain. From this

emerged the discipline now commonly referred to as supply chain management.

Early beginners of the supply chain management initiative can be traced to the apparel industry

in USA. The textile industry in the USA faced intense competition in the 1980s. The industry

leaders came together and formed the crafted with pride in the USA council, in 1984. They

commissioned a study on the supply chain analysis. This study found that the delivery time for

apparel supply chain, from raw material, to the final consumer, was 66 week long, 40 weeks of

which were spent in warehouses or transit. The long supply chain had resulted in major losses

Certificate in Retail Management TCS Business Domain Academy

Page 8 of 15

to the industry, due to the need for financing the inventory and the lack of the right product in

the right place, at the right time.

In order to overcome the problem, the strategy of Quick Response (QR) was developed. The

basic premise of quick response is to share information. Retailers and suppliers work together

to respond more quickly to the consumer needs, by sharing information. The installation of the

Point of Sale (POS) scanning systems and sharing of data through Electronic Data Interchange

(EDI) became the new standard of the industry. The industry also adopted the Universal

Product Code (UPC). QR incorporates marketing information on promotions planned, discounts

and forecasts into the manufacturing and distribution plan. It increases the product availability

and lowers inventory investments. It also helps in reducing logistics expenses. With QR

systems, retailers can negotiate a direct store delivery system, in which the vendors supply

floor ready merchandise to each store, rather than to the distribution centre (DC). The cost of

the DC and transportation thus is eliminated.

The success of QR initiative prompted a group of grocery industry leaders in the USA, to create

a joint industry task force, called Efficient Consumer Response (ECR) working groups. This

group primarily, worked on identifying opportunities to make the supply chain more

competitive in grocery retailing. Studies commissioned by this group revealed that by

expediting the quick and accurate flow of information up the supply chain, ECR enabled

distributors and suppliers to anticipate future demand far more accurately than the current

system. A little change in the technology was required to improve the performance, besides

further development of the EDI and POS systems.

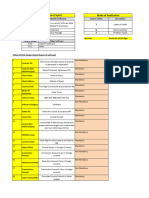

13.5 Issues Involved in Developing the Supply Chain Framework

A useful framework for analyzing the issues involved in developing a supply chain can be

represented as a pyramid. This framework is depicted below.

At the strategic level, the retailer can focus on service level required to support unique value

proposition that the retailer has developed. The retailer can then evolve appropriate channels

and networks, to achieve the uniqueness desired.

The next, structural level, allows the retailer to identify the suppliers and stock points and to

develop an appropriate transportation model. The extent of outsourcing is also determined at

this level.

At the functional level, the operational details are worked out. This includes developing policies

and procedures around the facilities and the equipment to be deployed, implementing

information systems to support the operations and ensuring the right organizational and

Certificate in Retail Management TCS Business Domain Academy

Page 9 of 15

training inputs. The constructs developed using any framework, must be successful

implementation usually requires a programmed approach to ensure that the implementation is

effective and the goals are achieved.

13.6 Supply Chain Integration

As stated earlier, supply chain management links, demand management, resource

management and supply management. Let us understand this in terms of retail organization. In

a typical retail organization, the marketing team or department would be the one looking at the

sales data, working on targets and looking at the ways to meet these targets. The

merchandising and design team would work on getting the best price for the materials required

for manufacturing the product so as to fulfil the customers needs, while the purchase

department would work on getting the best price for the materials required to manufacture the

product. The aim of each department would be different and while they may individually excel,

the organization as a whole, would benefit only when they share a common approach and the

information is shared between departments, suppliers and vendors.

The nature of the industry that the retail organization operates in also influences the supply

chain and logistics decisions. Nowhere is this more apparent in the apparel and grocery

industries.

13.6.1 Retail Market Characteristics:

Retail markets in these industries typically exhibit the following characteristics:

1. Short Life Cycles: Many products in these sectors have a short life cycle. In many cases,

the product may have been created to capture the mood of the moment; consequently,

the time period in which it is saleable is likely to be short and seasonal. Similarly due to

the perishable nature of the products in the grocery business the shelf life is short.

2. High Volatility: Demand for these products is rarely stable or linear. It may be influenced

by the vagaries of weather, movies, TV shows or indirectly, by advertising.

3. Low Predictability: Due to the volatility of demand it is extremely difficult to forecast,

with any accuracy.

4. High Impulse Purchase: Many buying decisions for these products are based on impulse

and occur at the point of purchase.

5. Conventional wisdom holds that the way to cope with uncertainty is to improve the

quality of forecasts. However, as this may not always be possible, ways must be found

to reduce the reliance on forecasts and focus on lead time reduction. Shorter lead

time mean, by definition, that the forecasting horizon is shorter hence the risk of error

Certificate in Retail Management TCS Business Domain Academy

Page 10 of 15

is lower. There are three critical lead times that must be managed by organizations that

seek to compete successfully in the retail business.

6. Time To Market: The time that it takes the business to recognize a market

opportunity, translate this into a product or service and to bring it to the market.

7. Time TO Serve: The time that it takes to capture a customers order and to deliver

the product to the retail customers satisfaction.

8. Time To React: The time that it takes to adjust the output of the business, in

response to the volatile demand.

Some of these concepts are explained in detail below:

Time To Market

In the shorter life cycle markets, being able to spot trends quickly and to translate them into

products in the shop, has become a pre requisite for success. Companies that are slow to

market, miss out on a sale opportunity that may not be repeated. An example of this would be a

style of clothing that may become popular. If the retailer is fast to spot the trend and procure

the goods for the store, it would definitely be beneficial for the organization. On the other

hand, trends can be spotted by looking at the changing consumer habits, like the need for pre

cooked meals has prompted a few Indian companies to enter this field and retail ready to

eat meals.

Time TO Serve

Traditionally, in retail, orders from the retailers had to be placed on the suppliers many months

in advance. This may give rise to the risk of obsolescence and high stock outs, as well as an

increased cost of inventory. The lead time was long, not necessarily due to the process of

manufacturing, shipping and transit, but due to the excessive documentation required at each

stage.

Time To React

Ideally, in any market, a company would want to meet a customers requirements at the time

and place that the customer needs them. The challenge for any business in the fashion market

is the ability to perceive real demand. Real demand is what the customers are buying or

requesting for. Because most supply chains are driven by orders, which themselves are driven

by forecasts and inventory replenishments, individual parties in that chain will have no real

visibility of the final market place. Inventory hides the demand.

Certificate in Retail Management TCS Business Domain Academy

Page 11 of 15

13.6.2 The Lead Time Gap

The fundamental problem that faces many companies is, that the time that it takes to source

the materials, convert them into products and move them into the marketplace is invariably

longer than the time the customer is prepared to wait. This difference between what might be

called the logistics pipeline and the customers order cycle is termed the lead time gap. The

challenge for logistics management is to find ways to reduce, if not close the gap.

Successful companies in retail, seem not only to be able to capture the imagination of the

consumer with their products, but are also often, characterized by their agility. Many

organizations have found that it is possible to make significant improvements by adopting a

twin strategy of simultaneously reducing the logistics lead time and capturing information

sooner, on actual customer demand.

13.7 Innovation in Supply Chain Management

13.7.1 Cross Docking

Cross Docking is a function of the warehouse or distribution centres (DC), which was introduced

by Wal-Mart. Cross Docking is a system in which the vendors ship merchandise to a distribution

centre, pre-packed in quantities required by each store. The merchandise is delivered to one

side of the DC, for delivery to the shipping dock, thus, the expression cross docking. The DCs

are equipped with miles faster guided conveyor belts that read the UPCs on the incoming cases

and direct them to the right truck for their onward journey. These DCs are less costly than the

traditional DCs because there is little or no storage required and the processing is minimal.

13. 7.2 Collaborative Planning, Forecasting and Replenishment (CPFR)

Collaborative Planning, Forecasting and Replenishment (CPFR), is one of the hottest buzzwords

in the chain context. By aligning the forecasts of a retailer and the vendor, CPFR offers the

opportunity to increase in-stock positions, gross margins and sales, while reducing inventory

investments and stock-outs.

CPFR is business practice that reduces inventory costs, while improving product availability

across the supply chain. The process begins with an agreement between the trading partners,

to share information with each other and to collaborate on planning, with the ultimate goal of

delivering products based on true market demand. The business partners share forecasts,

results and data over the internet. CPFR technology analyzes the data, and if the forecasts do

not match, it notifies the planners at both the companies. The two then work together to

resolve these exceptions. The final plan is agreed to by both, describes whats going to be sold

and how it will be merchandised and promoted.

Certificate in Retail Management TCS Business Domain Academy

Page 12 of 15

The function of supply chain management is perhaps the most important function of a retail

organization. Indian retail organizations still lack supply chain sophistication. However with

organized retailing set to grow in India, and the increase in competition in each sector, efficient

management of the supply chain is bound to become a necessity.

13.8 Retail Logistics

An integral part of supply chain management is Logistics Management. The main objective of

logistics management is to reduce inventory- holding costs and improve profits.

The word logistics is derived from the French word loger which means to quarter and supply

troops. In the last decade, there have been several well-published logistics exercises,

internationally. The Gulf War of 1991 was on e of the largest, since World War II.

Many international retailers have built their success on logistical prowess. Speedy restocking of

goods, elimination of poor sellers and promotion of successes, also contribute to a clear sales

advantage. Logistics entail more than mere trucking and distribution of goods. For without

good information about sales and insight into customer needs, the finest distribution centre

and transport capabilities are likely to send the wrong products, at the wrong place, at the

wrong time. Effective logistics therefore, needs an efficient information system, as well as good

transport, distribution centre and store handling capabilities.

A single recipe for success does not exist. A logistics system has to be built to suit the needs to

the organization, keeping in mind the kind of products that the company retails and the

competition prevailing. Fashion retailer may need to focus on speed, discount retailers on cost.

The needs of each are different.

Retail logistics is the organized process of managing the flow of merchandise, from the source

of supply to the customer. Thus, it incorporates the following functions:

Physically, moving the goods from one place to another, where the location may be a

distribution centre, warehouse, store or manufacturer.

Stocking the goods at locations needed, in the quantities needed.

13.8.1 The Management of the Entire Process

Good logistics cut costs, speed, and work and improves customer service. A logistics strategy

can either be a pull strategy or a push strategy. A pull logistics strategy has orders for

merchandise being generated, at the store level, on the basis of the demand data captured by

the POS terminals. A push logistics strategy has the merchandise allocated to stores, based on

the historical demand and the inventory position of the store and the warehouse.

Certificate in Retail Management TCS Business Domain Academy

Page 13 of 15

As retail operations become more complex and the flow of information within the organization

is established, more retailers are now moving towards the pull strategy. At the heart of the

logistics is the Distribution Centre (DC). It serves several functions, from coordinating the

inbound transportation, receiving, checking, storing and cross docking to coordinating the

outbound transportation.

The method used for handling logistics largely depends on the nature of the industry and the

number of outlets that the organization has in each city, state or region. Food World, a grocery

retail chain in India, works on hub and spoke system.

Figure 1: Hub and Spoke model (Source: http://ostpxweb.dot.gov)

The hub is the distribution centre, which it develops in each city. The hub services all shops in

that particular city.

On the other hand a department store, like the Shoppers Stop, may find that it is not feasible

to develop and maintain a distribution centre in each city, as it would have one or at the most

two shops in every city. In such a case, a regional distribution centre may be developed. Some

retail organizations in India, like Globus, have outsourced their needs for logistics and

distribution.

13.9 Reverse Logistics An Emerging Trend

At the simplest level, the disposition of returned goods consists of junking them or giving them

away. But with more sophisticated systems and processes, returned goods can be put back into

the inventory, sold at liquidation centres, or broken service. How companies handle product

returns can also be a competitive differentiator. It is a new area to exploit for increased

efficiencies.

However, handling reverse logistics is not easy. Specifically, designed software is needed for

this purpose. Many third party service providers, such as Federal Express Worldwide Logistics,

GenCorp Distribution System, and UPS Worldwide Logistics, use customized systems to usher

Certificate in Retail Management TCS Business Domain Academy

Page 14 of 15

customers returned products to a central recovery centre, where they are stored for parts,

reconditioned or junked.

Summary:

Supply chain management ensures smooth and efficient flow, from raw material to

finished goods in to the hand of the consumers.

In India can be gauged from fact that logistics cost constitutes 10 12 percent of our

GDP.

Logistics play a major role in getting the right products to the right place, at the right

time and the right condition.

Retail markets in these industries typically exhibit the following characteristics

Short Life Cycles, High Volatility, Low Predictability, High Impulse Purchase

There are three critical lead times that must be managed by organizations

Time To Market, Time TO Serve, Time To React

The difference between what might be called the logistics pipeline and the

customers order cycle, is termed the lead time gap

Cross Docking was introduced by Wal-Mart

Collaborative Planning, Forecasting and Replenishment (CPFR) offers the opportunity

to increase in-stock positions, gross margins and sales, while reducing inventory

investments and stock-outs.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Togaf 9 1 Cheat Sheet v0 2Document13 pagesTogaf 9 1 Cheat Sheet v0 2Arghya Mukherjee67% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Digital TransformationDocument26 pagesDigital TransformationArghya Mukherjee100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Employment Application: (Newgen Software Technologies LTD, D-162 Okhla Phase I, New Delhi - 110020) PersonalDocument5 pagesEmployment Application: (Newgen Software Technologies LTD, D-162 Okhla Phase I, New Delhi - 110020) PersonalArghya MukherjeeNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- SAP For Managers: An Overview: Friday, February 27, 2015 1Document58 pagesSAP For Managers: An Overview: Friday, February 27, 2015 1Arghya MukherjeeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- E-Readiness QuestionnaireDocument6 pagesE-Readiness QuestionnaireArghya MukherjeeNo ratings yet

- Case Study SevenDocument3 pagesCase Study SevenArghya MukherjeeNo ratings yet

- Quality Management - QMTG14-4: Session 08 Inspection (Continued) + VSM (Continued)Document8 pagesQuality Management - QMTG14-4: Session 08 Inspection (Continued) + VSM (Continued)Arghya MukherjeeNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Chapter-6 Customer Centric Assortment Planning: Certificate in Strategic Retail ManagementDocument15 pagesChapter-6 Customer Centric Assortment Planning: Certificate in Strategic Retail ManagementArghya MukherjeeNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Chapter-8 Rationalization of SKU: Certificate in Strategic Retail ManagementDocument12 pagesChapter-8 Rationalization of SKU: Certificate in Strategic Retail ManagementArghya MukherjeeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- TCO Analysis Addresses : One-Time Acquisition Costs Process CostsDocument3 pagesTCO Analysis Addresses : One-Time Acquisition Costs Process CostsArghya MukherjeeNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Village Report - SEEDSDocument8 pagesVillage Report - SEEDSArghya MukherjeeNo ratings yet

- United Nations Literacy Decade: Effective PracticeDocument3 pagesUnited Nations Literacy Decade: Effective PracticeArghya MukherjeeNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Subrata Sarkar ECLDocument3 pagesSubrata Sarkar ECLRick RoyNo ratings yet

- Lozada - NVIDIA SWOT AnalysisDocument2 pagesLozada - NVIDIA SWOT AnalysisKyrelle Mae LozadaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Needs and Expectations, Turtle ChartDocument1 pageNeeds and Expectations, Turtle ChartChiheb GNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Resume - Jatin Kumar NagarDocument1 pageResume - Jatin Kumar NagarVinayNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Od 330390050476522100Document3 pagesOd 330390050476522100rjvNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Business Intelligence ArticleDocument22 pagesBusiness Intelligence ArticlesumahithaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Afm Module 3 - IDocument26 pagesAfm Module 3 - IABOOBAKKERNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Taxation On Real Estate Transactions: A - B S. MDocument37 pagesTaxation On Real Estate Transactions: A - B S. MMcke YapNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Buying Merchandise 1.1 Related TermsDocument5 pagesBuying Merchandise 1.1 Related TermsAryanNo ratings yet

- SoftexcodesDocument12 pagesSoftexcodesGuru MoorthiNo ratings yet

- MGP ApplicationDocument6 pagesMGP Application21f1006509No ratings yet

- R3 PT Canggu International-1 PDFDocument2 pagesR3 PT Canggu International-1 PDFkarina MEPNo ratings yet

- Case 2 Group 2 BUS 520 MDS Section1Document6 pagesCase 2 Group 2 BUS 520 MDS Section1Saief AhmadNo ratings yet

- SSS CCL Aka PDFDocument18 pagesSSS CCL Aka PDFVikram VickyNo ratings yet

- Billing Error Notice TemplateDocument4 pagesBilling Error Notice TemplateRoberto Monterrosa92% (25)

- Chapter 1 Test BankDocument10 pagesChapter 1 Test Bankمحمود احمدNo ratings yet

- Training Module For SHG Book Keepers: SHG Books of Records Duration: 3 DaysDocument32 pagesTraining Module For SHG Book Keepers: SHG Books of Records Duration: 3 DaysONYANGO JohnnyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Production Logistics and Human-Computer Interaction - State-Of-The-Art, Challenges and Requirements For The FutureDocument19 pagesProduction Logistics and Human-Computer Interaction - State-Of-The-Art, Challenges and Requirements For The FutureBladimir MendezNo ratings yet

- Onopoly: Presented By: Submitted ToDocument21 pagesOnopoly: Presented By: Submitted ToSimran VermaNo ratings yet

- Banking OmbudsmanDocument66 pagesBanking Ombudsmanmrchavan143No ratings yet

- 10 Golden Rules of Pricing ConversationsDocument3 pages10 Golden Rules of Pricing ConversationsPete Majkowski100% (1)

- Muhammad Shahid Bhatti S/O Abdul Ghafoor H No 8 ST No 50 Nadeem Shaheed RDDocument1 pageMuhammad Shahid Bhatti S/O Abdul Ghafoor H No 8 ST No 50 Nadeem Shaheed RDkhawar mukhtarNo ratings yet

- Wording CGLDocument16 pagesWording CGLabielcahyaNo ratings yet

- 1.5.6 Resultados Del Test de Estilo de EmprendedorDocument5 pages1.5.6 Resultados Del Test de Estilo de EmprendedorGFranco BlancasNo ratings yet

- How To Test Banking Domain Applications: A Complete BFSI Testing GuideDocument52 pagesHow To Test Banking Domain Applications: A Complete BFSI Testing GuideMamatha K NNo ratings yet

- Cel2106 SCL Worksheet Week 4Document3 pagesCel2106 SCL Worksheet Week 4raed nasrallahNo ratings yet

- Let's Create Local and Global Ads: Activity 2: Home Business! Lead inDocument3 pagesLet's Create Local and Global Ads: Activity 2: Home Business! Lead inwendy barillasNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Antoine Touzé: Profile SummaryDocument1 pageAntoine Touzé: Profile SummaryAnonymous g9jqvalhGNo ratings yet

- Atos SyntelDocument2 pagesAtos SyntelSharad MoreNo ratings yet

- Limits, Alternatives, and Choices: Mcgraw-Hill/IrwinDocument30 pagesLimits, Alternatives, and Choices: Mcgraw-Hill/IrwinWafaFarrukhNo ratings yet