Professional Documents

Culture Documents

Rub Co Industry

Uploaded by

Anonymous XZUyueN0 ratings0% found this document useful (0 votes)

148 views13 pagesindustry profile

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentindustry profile

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

148 views13 pagesRub Co Industry

Uploaded by

Anonymous XZUyueNindustry profile

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 13

CHAPTER 2

INDUSTRY PROFILE AND COMPANY PROFILE

INDUSTRY PROFILE

Rubber is an important plant for world economic strategies and for human kind .

The more the social development ,the more requirement of product made of products .

Natural latex is the one of the important raw materials used for production in heavy industries

, kitchenware ,houseware etc .

India is one of the largest natural rubber producers in the world .Now it occupies the

fourth postion with Thailand , Indonesia and Malaysia occupying the first , second , third

postions respectively . The rubber plantation sector in India is dominated by small holdings

that account for 85% of the productions .Kerala is the leading state in India having

5,74,274.64 acres of rubber plantation and a production of 7,83,000 M .Tonnes a year which

is 92% of total Indian production . Kottayam is the largest rubber producing district in Kerala

. In India 72.2% of the production is processed as Ribbed Smoked Sheet ( RSS ) .

The rubber plantation sector employs about 4 lakh persons directly with a good number of

them being women . Commercial cultivation of rubber in India was started in 1902

Various grades of the Natural Rubber :

Ribbed Smoked Sheet (RSS) 1

Ribbed Smoked Sheet (RSS) 2

Ribbed Smoked Sheet (RSS) - 3

Ribbed Smoked Sheet (RSS) - 4

Ribbed Smoked Sheet (RSS) 5

Indian Rubber Board was established in April 1947 to look after the rubber plantation industry in

the country . Its functions were defined under the Rubber Act ,1947 and included the development of

the natural rubber industry by devising suitable promotional measures , undertaking scientific

technology and economic research .The quality of above grades of natural rubber is certified by the

Indian Rubber Board before it is shipped .India has been supplying natural rubber to Turkey ,

SriLanka , Malaysai , Peru , China , Pakistan , Taiwan , Kenya , Poland , south Africa etc .

There are two type of industries in rubber sector . One is the processing industry with rubber wood

Other is the manufacturing industry based on latex or dry rubber . Under the manufacturing industries

about 35,000 products are there. There are two types ,based on the type of raw material used. Some

use latex which incudes products like gloves ,balloons , rubber band , others are based on dry rubber

sheets and the products include tyre and tubes ,automobile parts , erasers and mould goods .

The Indian Rubber industry today produces all varieties of rubber goods using the most

sophisticated technologies . We now have a gathering of entrepreneurial talent as well as technology

talent to ensure that india will be the World Wide Leader in the industry .

MATTRESS INDUSTRY

As the world economy is developing fast in the past 10 years , the mattress markets have

opened up . The world mattress market value grew by an average of 9% yearly between 2002

to 2014 reaching a value of more than 20 billion .Indian mattress industry accounts for about

half of worlds mattress industry . The production value of this industry in this area is around

$60 billion .Considered to be a labour intensive industry, it provides employment for around

1million people .According to the study by the Coir Board , the organized mattress industry is

expected to grow by 10 percent a year in India .

The availability of Coir boosted the growth of mattress industry in India . The excellent designs

,models , rich ,solid and deluxe trends and high quality have given stylishness to Indian mattress

segment . The fast emerging concept of normal life style , sense of comfort and health issues like back

pain have given mattress industy an ever growing platform .Globization and media are stong factors

.The turnover of Indian mattress industry is approximately Rs 3500 crore annually .The major states

manufacturing the rubberised coir mattress in India are Kerala ,Tamil Nadu , Orissa and Karnataka.

The major customers for mattress in India are Automobile industry ,especially car manufacturers and

state transport corporations for seat & truck cushion requirements , air conditioner manufactures for

air filters and public utilities like hospitals ,hotels ,auditoriums and theatres. Railways and defence

require Rubberised Coir products in large quantity .So there is a huge potential for Rubberised

mattress in India .

RUBCO RUBBERISED COIR MATTRESS DIVISION

Caption : Sound technology for sound sleep

RUBCOs Rubberised coir mattress factory is established in 2001 and it is located at Poothakuzhy

near Pampady ,Kottayam district , Kerala . RUBCOs rubberised coir mattress division is realized

with an investment of 2.6 million , The manufacturing plant employs advanced Australian machinery ,

sourced from DOA , Austria , a leader in Rubberised mattress . The plant has an annual installed

capacity of 4.8 million units ,consisting of mattress and other rubberised coir products, cushions and

furnitures upholstery.

.A unique feature of the main sheeting plant is that it facilitates vertical fiber orientation , a

process that results in a deeper penetration of latex into the sheet making it very elastic . This provides

the mattress with uniform density throughout and an extra cushioning effect .It is scientifically

designed to provide proper back support without compromising on comfort .By virtue of their

ingenious design and unique 3-D technology, Rubco mattress is firm without being hard,it is very

comfortable and ensures a healthy and restful sleep .It is crafted from the finest materials and finished

to perfection in manufacturing plants.There are mattresses that prevent dust mites which can cause

respiratory diseases.Other benefits are heat and moisture resistance,insulation,flame retardant etc.

PRODUCT PROFILE OF RUBCO RCM DIVISION

Rubco manufactures a wide range of mattresses catering to diverse segments to the market .

The range consists of :

HEAVEN

A premium model that provides unmatched sleeping comfort

,available in 3 inch and 4 inch thickness . Also available in

customized dimensions and thickness for large quantities .

HEAVEN PLUS

A Luxury model that is elegant as well as comfortable

which is available in 5 inch thickness .

HI TECH

A hi end model with an accent on finish and luxury, available in 5 inch thickness .

DOSTH

An economy model that offers true value for money is available in 2 and 3 inches .

SAFAL

A regular mattress that combines comfort and durability is available in 3 and 4 inches .

YATHRI

An elegant mattress meant for hotels,hospitals,tourist resorts etc.It combines superior sleeping

comforts with perfect back support,enabling relaxed healthy sleep.Layer upon layer of rubberised coir

and latex enhance the comfort while soft and elegant quilting adds a luxurious feel,available in 3 and

4 inch thickness.

HEAL

Aquality product suitable for use in hospitals.available in 3 and 4 inch thickness.

RELIEF

A special mattress scientifically designed for orthopaedic

patients,available in 5 inch thickness.

COMPANY PROFILE

The Kerala state Rubber co-operative Limited , popularly known as RUBCO is a well

diversified industrial conglomerate with a strong presence in the rubber industrial segment .

RUBCO was formed with the prime objective of has successfully introduced a wide range of

fast moving rubber based products achieving a turnover of Rs 100 crores . The Divisions

operating under RUBCO group are involved in a wide range of business such as footwear ,

furniture , rubberised coir matterss and natural rubber . Many new initiatives are on the anvil

in line with RUBCOs vision of turning into a multi-faceted ,globally competitive

organisations .

RUBCO came into being on 9

th

June 1997 , with a view to augment the commercial

utilisation of natural rubber and to ensure a reasonable price to rubber growers and to share

value addition with them .RUBCO is the largest exporter of natural rubber in the country .

Even in the domestic market, RUBCO is the major supplier of natural rubber to all leading

tyre business in India . RUBCO is also a Govt .intervention agency towards market

stabilization and has been concerned about the farming community directly and indirectly to

get reasonable price . Arresting drastic fall in price during the peak production

period,RUBCOs policy in natural rubber trading has been a harmonious blend of social

obligation and commercial practice.

RUBCO stands for :

R : RELIABLE

U: UNIQUE

B: BENEFICIAL

C: CREDIT WORTHY

O: ORIGINAL

Rubco ensures efficient service , economical price and eco- friendly products while

marketing its products.

HEAD OFFICE

The Head office of Kerala state Rubber Co-operative Ltd is located in Kannur at RUBCO

House . RUBCO HOUSE is centrally air conditioned and well furnished co-operative office

.It is a seven storey building of 43,145 sq feet area showroom along with a functioning

insurance office and auditorium .

BOARD OF DIRECTORS

The Managing Director and Chairman share the top most authority followed by the General

Manager. Members are headed by Chairman Mr . E Narayanan and Managing Director Mr

.Jacob Mathew . The administration and management of the company rest in the hands of

managing directors consisting of 15 members as follows :

Nine directors elected by A class share holders among them

Two directors elected by B class share holders

Three ex office directors elected by Registrar of co-opertive societies Kerala

President Kerala state Co-operative Bank

OWNERSHIP PATTERN

The authorised share capital of RUBCO as per the byelaws is 300 crore made up of class

A,B,C and D shareholders.Class A shares are open to primary co-operative rural banks and

rubber marketing societies functioning in the area of operation of Rubco.B class shares are

open to Kerala State Co-operative bank and other state-level co-operative federations.C

class shares are open only to the Central and State govt. And rubber board,D class shares

are open to individuals having business associations with Rubco.

VISION AND MISSION

To become global leader in rubber industry .

To give enchanced satisfaction to customers and to strive for excellence.

Optimum utilisation of resources .

Setting innovative trends

To make every employee of RUBCO feel proud of his organisation .

OBJECTIVES

General Objectives :

Manufacturing and sales of rubber wood based products .

Trading business of natural rubber latex and dry form of natural rubber .

Social Objectives :

To ensure a study market with remunerative price to rubber growers for their natural

rubber

Welfare of rubber growers particularly of small and marginal segment.

Commercial Objectivies :

To promote establish maintain and manage business related to anufacture and sales of

tyres for heavy vehicles ,cars and other 4 wheelers,for 3-wheelers and 2-wheelers

Purchase and sale of rubber in any form.

MARKETING STRATEGY

To create new customers and wide choice of goods to customers

To motivate the sales team

To make profit through customer satisfaction

To develop a pricing strategy

To ensure the growth of organisation

Marketing department

The department consists of Senior General Manager,Marketing Manager,Sales

Manager,Assistant Manager, Senior Sales Officers Junior Sales Officers and Sales

executives.

RUBCO MILESTONES

1997

9

th

June:RUBCO registered,started commercial operation in the same year

Commercial procurement of natural rubber,directly from farmers

1998

Foundation stone laid for footwear manufacturing unit and Tread rubber

manufacturing unit at Valiyavelicham industrial centre,Koothuparamba

Exported rubber to Singapore and Nepal

Took over the reins of Sreekandapuram Latex Ltd.

1999

Foundation stone laid for cycle tyre manufacturing unit

Foundation stone laid for rubberised coir mattress factory at Pampady,Kottayam

2000

Foundation stone laid for casual shoes project

2001

RUBCO HUAT wood processing and furniture factory commenced commercial

operations

Inaugaration of RUBCO Tyre India Pvt.Ltd

2002

Started activities of coconut complex for the production of virgin coconut oil and

ancillary products

Expression of interest submitted to Govt.of Kerala to set up a unit for production of

rubber components for automobiles and railways.

2008

RUBCO HOUSE started

2009

Compound mixing plant started

PROMOTERS OF RUBCO

Govt.of Kerala alongwith Indian Rubber Board and some district and primary co-

operative banks in Kerala are the promoters.Govt.of Kerala holds the majority of

shares.

TOP TEN SHAREHOLDERS

Govt.of Kerala

Rubber Board,Kottayam district Co-operative bank

Palakkad district Co-operative bank

Ernakulam district Co-operative bank

Thrissur district Co-operative bank

Kozhikode district Co-operative bank

Thiruvananthapuram district Co-operative bank

Kollam district Co-operative bank

Indian Rubber Board

ACHIEVEMENT/ AWARD

ISI-IS 8291, Licence No Cm/L-6336770. BIS certification marks for Rubberised coir

sheets

INDIA organic

USDA organic United State Development Of Agriculture

DNV-NABCBQMS 001

ISO certified star export houses

RUBCO UNDERTAKINGS

RUBCO HUAT WOODS PVT LTD

Set up in 2000 in collaboration with world major in rubber processing,Huat Berhad of

Malaysia.

State-of-the art machinery for manufacturing modern furniture under the brand name

rub-wood.

Location:Thalassery,Kannur

Products:Edge-glued panels,door and window frame,dining table,computer

table,office furniture,kitchen cabinets,Rubco home series.

RUBCO HAWAI CHAPPAL FACTORY

Manufactures both conventional and ultra light weight models .

Location : Industrial growth centre , Valiyavelichan ,Kannur

Products : Hawai , Rain Bow Eva weight, Power Grip .

RUBCO RUBBERISED COIR MATTRESS FACTORY

Realised with an investment of Rs 280 millions

Annual installed capacity of 4.8 million units ,comprising of mattress pillows and

cushions .

Strict quality control observed at every stage of the production to ensure that RUBCO

rubberised coir mattress always measure up to highest standards.

LOCATION : Pampady near Kottayam Kerala

RUBCO VIRGIN COCONUT OIL PROJECT

Produces lush massage oil,hair oil,baby oil and Nutrico cooking oil

Health benefits and medical properties of natural coconut oil.

LOCATION:Kolanchery,Ernakulam

RUBCO RUBBER COMPOUND MIXING PLANT

Three-storeyed plant has a total area of 60,000 sq.feet with storage facilities for:

Natural synthetic rubber-1000 tons

Carbon blacks

Process oil

Chemicals/white fillers

Master batches

RUBCO TREAD RUBBER FACTORY

Capacity of 12 to 330 MT of pre-cured tread rubber per year

Has production capacity of strip rubber,bombing gum and vulcanising solution

RUBCO FARMERS ALLIANCE STRATEGY

Technology-oriented farmer based market plan to directly interact with farmers and to

promote their welfare.

You might also like

- Charater Letter To JudgeDocument9 pagesCharater Letter To Judgechong seng fooNo ratings yet

- Palm Oil Market and Sustainability in IndiaDocument28 pagesPalm Oil Market and Sustainability in IndiaNachiketa Das100% (1)

- Petition For The Issuance of A New Owner's Duplicate TCTDocument4 pagesPetition For The Issuance of A New Owner's Duplicate TCTNikel TanNo ratings yet

- Indian Specialty Chemicals Growth CatalystsDocument98 pagesIndian Specialty Chemicals Growth CatalystsbrijsingNo ratings yet

- A Project Report: Tata Iron & Steel CompanyDocument37 pagesA Project Report: Tata Iron & Steel CompanyPranjal_Ashok__1825No ratings yet

- Barbed Wire Manufacturing Unit Project ProfileDocument6 pagesBarbed Wire Manufacturing Unit Project ProfilemichelbgggNo ratings yet

- Forex Risk ManagementDocument114 pagesForex Risk ManagementManish Mandola100% (1)

- Sree Sakthi Paper MillsDocument68 pagesSree Sakthi Paper MillsMohammed AnamNo ratings yet

- Project On Oil Palm India KottayamDocument62 pagesProject On Oil Palm India KottayamAkhilAS82% (11)

- Tfr-Upvc Windows and Doors Fab. UnitDocument31 pagesTfr-Upvc Windows and Doors Fab. UnittechnopreneurvizagNo ratings yet

- Latex GlovesDocument22 pagesLatex GlovesThang Cao75% (4)

- Industry AnalysisDocument13 pagesIndustry AnalysisVanaja SureshkumarNo ratings yet

- Project On Retail or Hyper MarketDocument22 pagesProject On Retail or Hyper Marketakhileshh100% (3)

- Project Report On Latex Gloves Manufacturing UnitDocument7 pagesProject Report On Latex Gloves Manufacturing UnitEIRI Board of Consultants and PublishersNo ratings yet

- Furniture Quality Standards ManualDocument21 pagesFurniture Quality Standards ManualHabibie Akbar100% (1)

- LP DLL Entrep W1Q1 2022 AujeroDocument5 pagesLP DLL Entrep W1Q1 2022 AujeroDENNIS AUJERO100% (1)

- BALA Footwear Cost AnalysisDocument20 pagesBALA Footwear Cost AnalysisMuhammad SaadNo ratings yet

- Project Report On Discontinuous Puf Panels Using Cyclopentane As A Blowing AgentDocument6 pagesProject Report On Discontinuous Puf Panels Using Cyclopentane As A Blowing AgentEIRI Board of Consultants and PublishersNo ratings yet

- Thoosan Wheat Plate ProjectDocument56 pagesThoosan Wheat Plate ProjectApple Computers100% (2)

- SWOT Analysis of India Rubber IndustryDocument6 pagesSWOT Analysis of India Rubber IndustryKeshav Gupta33% (3)

- Rubber Products Innovation Draft-SEENDocument20 pagesRubber Products Innovation Draft-SEENZi Lin HeNo ratings yet

- OSK Rubber Glove Industry in Malaysia ReportDocument8 pagesOSK Rubber Glove Industry in Malaysia ReportChoh Shee TeohNo ratings yet

- Report Cera SanitarywareDocument10 pagesReport Cera SanitarywareShiva SinghNo ratings yet

- India's Pulses and Spices MarketingDocument8 pagesIndia's Pulses and Spices MarketingPrakash KcNo ratings yet

- Field Manual For Propagation of Bamboo in North-East IndiaDocument18 pagesField Manual For Propagation of Bamboo in North-East IndiamobyelectraNo ratings yet

- Furniture and Fixtures in A Garment Manufacturing UnitDocument32 pagesFurniture and Fixtures in A Garment Manufacturing Unitishan_k87No ratings yet

- Indian Steel Industry EconomyDocument18 pagesIndian Steel Industry Economydj gangster0% (2)

- SGX SICOM Rubber Factsheet 201801-English PDFDocument6 pagesSGX SICOM Rubber Factsheet 201801-English PDFKien TrungNo ratings yet

- Project Report On Production of Condom Manufacturing From LatexDocument7 pagesProject Report On Production of Condom Manufacturing From LatexEIRI Board of Consultants and PublishersNo ratings yet

- Report Commodity Derivative Markets 042018Document333 pagesReport Commodity Derivative Markets 042018AmeerHamsaNo ratings yet

- INTERSHIP REPORT SharooqDocument24 pagesINTERSHIP REPORT SharooqSagar K SNo ratings yet

- List of Tables: Data From Financial Websites 67,71,75,79,83 Data From Factsheets 67,71,75,79,83 Riskometer 57Document93 pagesList of Tables: Data From Financial Websites 67,71,75,79,83 Data From Factsheets 67,71,75,79,83 Riskometer 57VijayGogulaNo ratings yet

- Unit 8 Role of Monitoring and StagingDocument15 pagesUnit 8 Role of Monitoring and Stagingsaranya pugazhenthiNo ratings yet

- Accenture ATIOS Publication Natural Rubber Trading MarketsDocument36 pagesAccenture ATIOS Publication Natural Rubber Trading MarketsLuis Carrillo100% (1)

- Adult Diaper Market in India AnalysisDocument3 pagesAdult Diaper Market in India AnalysisVaibhav Baheti100% (1)

- ICT in AgricultureDocument6 pagesICT in AgricultureEnoch CyrilNo ratings yet

- By K.Anbazhagan M0208004 Magnus School of Business Bangalore Faculty Guide Prof. Brindha VenkateshDocument15 pagesBy K.Anbazhagan M0208004 Magnus School of Business Bangalore Faculty Guide Prof. Brindha VenkateshanbubalrajNo ratings yet

- Consumer Behavior On Iron and Steel IndustryDocument8 pagesConsumer Behavior On Iron and Steel IndustryPadmaKhanalNo ratings yet

- ExportDocument42 pagesExportAzharuddinShaikhNo ratings yet

- Task 19Document3 pagesTask 19Medha SinghNo ratings yet

- Introduction of PulsesDocument48 pagesIntroduction of PulsesAnjali Sinha0% (1)

- Steel Industry: Backbone of Global DevelopmentDocument64 pagesSteel Industry: Backbone of Global DevelopmentSyaape100% (1)

- Itc Intership ReportDocument49 pagesItc Intership ReportPani Bhushan RaodevalaNo ratings yet

- Maize Demand and Value Chains Inasia PDFDocument44 pagesMaize Demand and Value Chains Inasia PDFKrishna VeniNo ratings yet

- Food Packaging IndustryDocument7 pagesFood Packaging IndustrySanjay Kumar ShahiNo ratings yet

- Economy of CoimbatoreDocument9 pagesEconomy of CoimbatoreRangaraju PalanisamyNo ratings yet

- Rural Marketing Research PaperDocument8 pagesRural Marketing Research PaperShazia JamalNo ratings yet

- Analysis of commodity and capital marketsDocument70 pagesAnalysis of commodity and capital marketsChandrashekar AkkiyavarNo ratings yet

- Indian Gems and Jewellery Industry AnalysisDocument27 pagesIndian Gems and Jewellery Industry AnalysisAkash MehtaNo ratings yet

- Paint IndustryDocument13 pagesPaint IndustryKartikeyaDwivediNo ratings yet

- Apparel and Non Apparel Manufacturing in Asia PacificDocument35 pagesApparel and Non Apparel Manufacturing in Asia PacificAnurag DixitNo ratings yet

- On RK MarblesDocument15 pagesOn RK Marbles21nannu100% (1)

- Etop AnalysisDocument3 pagesEtop Analysislaxmi01ranganavarNo ratings yet

- Natraj Oil Mills Private Limited Tamilnadu IndiaDocument10 pagesNatraj Oil Mills Private Limited Tamilnadu IndiaNatraj Oil Mills Private LimitedNo ratings yet

- Executive SummaryDocument18 pagesExecutive SummaryAshutosh MangalNo ratings yet

- Agrochemicals: By-Akanksha Gupta (06) Isha Sharma (27) MBA (Oil & Gas), Upes Batch: - 2012-2014Document32 pagesAgrochemicals: By-Akanksha Gupta (06) Isha Sharma (27) MBA (Oil & Gas), Upes Batch: - 2012-2014Akanksha Gupta100% (2)

- Financial Management PDFDocument11 pagesFinancial Management PDFஒப்பிலியப்பன்No ratings yet

- 2 Letter of TransmittalDocument6 pages2 Letter of TransmittalAsif Rajian Khan AponNo ratings yet

- Black Book ProjectDocument33 pagesBlack Book ProjectPRIYANKA ADAKNo ratings yet

- Knowledge Paper Specialty ChemicalsDocument86 pagesKnowledge Paper Specialty Chemicalsvineet_bmNo ratings yet

- Water Purifier BusinessDocument15 pagesWater Purifier BusinessSantosh SrikarNo ratings yet

- Novonous - Gold Loan Market in India 2016 - 2020 - 2016-06-03Document9 pagesNovonous - Gold Loan Market in India 2016 - 2020 - 2016-06-03Niraj Bajaj0% (1)

- Rubco PROFIL1Document18 pagesRubco PROFIL1SebinpallickalNo ratings yet

- Ok 1Document38 pagesOk 1vipinsrevalsam7015No ratings yet

- A Two-Element Parasitic Antenna Approaching The Minimum Q-Factor at A Given DirectivityDocument11 pagesA Two-Element Parasitic Antenna Approaching The Minimum Q-Factor at A Given DirectivityAnonymous XZUyueNNo ratings yet

- Analysis of Hydrogen Permeation Effects on Infrared Absorption in Optical FibresDocument3 pagesAnalysis of Hydrogen Permeation Effects on Infrared Absorption in Optical FibresAnonymous XZUyueNNo ratings yet

- Fourth PaperDocument4 pagesFourth PaperAnonymous XZUyueNNo ratings yet

- Mosfet EbdDocument9 pagesMosfet EbdSrikanth PudhariNo ratings yet

- Data Transmission Over Bandlimited Channels: ELEX 3525: Data Communications 2015 Winter SessionDocument5 pagesData Transmission Over Bandlimited Channels: ELEX 3525: Data Communications 2015 Winter SessionAnonymous XZUyueNNo ratings yet

- ThoughtsDocument10 pagesThoughtsAnonymous XZUyueNNo ratings yet

- Effect of Dielectric Constant On The Design of Rectangular Microstrip AntennaDocument9 pagesEffect of Dielectric Constant On The Design of Rectangular Microstrip AntennaAnonymous XZUyueNNo ratings yet

- Leaky-Wave Theory, Techniques, and ApplicationsDocument29 pagesLeaky-Wave Theory, Techniques, and ApplicationsAnonymous XZUyueNNo ratings yet

- Millimeter-wave antenna measurement: Scattering parameters and radiation patternDocument5 pagesMillimeter-wave antenna measurement: Scattering parameters and radiation patternAnonymous XZUyueNNo ratings yet

- Planar Dipole Antenna Design at 1800MHz Band Using Different Feeding Methods For GSM Application PDFDocument5 pagesPlanar Dipole Antenna Design at 1800MHz Band Using Different Feeding Methods For GSM Application PDFsebastian diazNo ratings yet

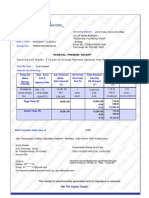

- Account Statement As of 31-03-2021 20:00:43 GMT +0530Document2 pagesAccount Statement As of 31-03-2021 20:00:43 GMT +0530Anonymous XZUyueNNo ratings yet

- Electronics and Communications in Japan, Part 1: Numerical Analysis of Microstrip Printed DipolesDocument10 pagesElectronics and Communications in Japan, Part 1: Numerical Analysis of Microstrip Printed DipolesAnonymous XZUyueNNo ratings yet

- Received With Thanks ' 10,320.42 Through Payment Gateway Over The Internet FromDocument1 pageReceived With Thanks ' 10,320.42 Through Payment Gateway Over The Internet FromAnonymous XZUyueNNo ratings yet

- On The Properties of Pseudo Noise Sequences With A Simple Proposal of Randomness TestDocument6 pagesOn The Properties of Pseudo Noise Sequences With A Simple Proposal of Randomness TestAnonymous XZUyueNNo ratings yet

- Ms Square PatchDocument3 pagesMs Square PatchIrsan PaneNo ratings yet

- Experiment 1 Op-Amps and Basics of Signal ConditioningDocument6 pagesExperiment 1 Op-Amps and Basics of Signal ConditioningAnonymous XZUyueNNo ratings yet

- Effects of Substrate Thickness On The Properties of RectangularDocument4 pagesEffects of Substrate Thickness On The Properties of RectangularAnonymous XZUyueNNo ratings yet

- Design & Analysis of Square Microstrip Patch AntennaDocument4 pagesDesign & Analysis of Square Microstrip Patch AntennaAnonymous XZUyueNNo ratings yet

- Account Statement As of 31-03-2021 20:00:43 GMT +0530Document2 pagesAccount Statement As of 31-03-2021 20:00:43 GMT +0530Anonymous XZUyueNNo ratings yet

- MICROSTRIP DIPOLE ANTENNA FOR WLAN APPLICATIONDocument4 pagesMICROSTRIP DIPOLE ANTENNA FOR WLAN APPLICATIONAnonymous XZUyueNNo ratings yet

- Compact Folded Dipole Microstrip Antenna For 2.4 GHZ Wlan ApplicationDocument2 pagesCompact Folded Dipole Microstrip Antenna For 2.4 GHZ Wlan ApplicationAnonymous XZUyueNNo ratings yet

- Microstrip Dipole Antenna For Wlan ApplicationDocument4 pagesMicrostrip Dipole Antenna For Wlan ApplicationAnonymous XZUyueNNo ratings yet

- Microstrip Dipole Antenna For Wlan ApplicationDocument4 pagesMicrostrip Dipole Antenna For Wlan ApplicationAnonymous XZUyueNNo ratings yet

- Effects of Slots On Resonant Frequencies of A Microstrip Patch AntennaDocument5 pagesEffects of Slots On Resonant Frequencies of A Microstrip Patch AntennaAnonymous XZUyueNNo ratings yet

- Main List: Kerala Public Service CommissionDocument4 pagesMain List: Kerala Public Service CommissionAnonymous XZUyueNNo ratings yet

- Millimeter-wave antenna measurement: Scattering parameters and radiation patternDocument5 pagesMillimeter-wave antenna measurement: Scattering parameters and radiation patternAnonymous XZUyueNNo ratings yet

- Tlam Design Guide 2 0111Document21 pagesTlam Design Guide 2 0111Anonymous XZUyueNNo ratings yet

- 8-Design of MicrostripDocument3 pages8-Design of MicrostripAnonymous XZUyueNNo ratings yet

- Dr. Swapna P. Antony: Phone: E-MailDocument11 pagesDr. Swapna P. Antony: Phone: E-MailAnonymous XZUyueNNo ratings yet

- Module 2: MOSFET Lecture 4: MOS Capacitor: ObjectivesDocument4 pagesModule 2: MOSFET Lecture 4: MOS Capacitor: ObjectivesAruna ManiNo ratings yet

- Castells Information AgeDocument6 pagesCastells Information Agemaswing@yahoo.comNo ratings yet

- Macroeconomics: Ninth Canadian EditionDocument48 pagesMacroeconomics: Ninth Canadian EditionUzma KhanNo ratings yet

- Early Registration FormDocument2 pagesEarly Registration FormMylene PilongoNo ratings yet

- Nathaly - Work Shop 3Document3 pagesNathaly - Work Shop 3Laurita Artunduaga OtavoNo ratings yet

- Specific Gravity of FluidDocument17 pagesSpecific Gravity of FluidPriyanathan ThayalanNo ratings yet

- New Venture Creation IdeasDocument6 pagesNew Venture Creation IdeasDaoud HamadnehNo ratings yet

- University Student Council: University of The Philippines Los BañosDocument10 pagesUniversity Student Council: University of The Philippines Los BañosSherwin CambaNo ratings yet

- Receivable Financing Pledge Assignment ADocument34 pagesReceivable Financing Pledge Assignment AJoy UyNo ratings yet

- Financial Reporting Quality and Investment Efficiency - Evidence F PDFDocument12 pagesFinancial Reporting Quality and Investment Efficiency - Evidence F PDFRenjani Lulu SafitriNo ratings yet

- Expedite Unclaimed Cargo AuctionsDocument4 pagesExpedite Unclaimed Cargo AuctionsDinesh ChakravartyNo ratings yet

- List of Solar Energy Operating Applications 2020-03-31Document1 pageList of Solar Energy Operating Applications 2020-03-31Romen RealNo ratings yet

- AIDA Model in AdvertisingDocument3 pagesAIDA Model in AdvertisingHằng PhạmNo ratings yet

- 2015 Scholarship ApplicationDocument3 pages2015 Scholarship Applicationapi-280767644No ratings yet

- A Reply - Lee Epstein, Gary KingDocument19 pagesA Reply - Lee Epstein, Gary KingAdam PeaseNo ratings yet

- LG Overnight Trader Q3 2019 EST PDFDocument11 pagesLG Overnight Trader Q3 2019 EST PDFjim6116No ratings yet

- Pak Steel Product Price ListDocument6 pagesPak Steel Product Price ListHamid NaveedNo ratings yet

- Investment Evaluation MethodDocument13 pagesInvestment Evaluation MethodBAo TrAmNo ratings yet

- Survey QuestionnairesDocument4 pagesSurvey QuestionnairesSashaNo ratings yet

- FM AssignmentDocument10 pagesFM AssignmentPrashant KumarNo ratings yet

- Resume for College Professor PositionDocument3 pagesResume for College Professor PositionYours PharmacyNo ratings yet

- InvoiceDocument1 pageInvoiceDp PandeyNo ratings yet

- Satyam PPT FinalDocument16 pagesSatyam PPT FinalBhumika ThakkarNo ratings yet

- Questions of ValueDocument2 pagesQuestions of ValueRockyNo ratings yet

- Late Birth Registration Form for KenyaDocument2 pagesLate Birth Registration Form for KenyaSarati80% (5)

- Fondazione Prada - January 2019Document6 pagesFondazione Prada - January 2019ArtdataNo ratings yet

- Tso C139Document5 pagesTso C139Russell GouldenNo ratings yet