Professional Documents

Culture Documents

Flowmeter Measurement Apparatus

Uploaded by

Syafiq IzzuddinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flowmeter Measurement Apparatus

Uploaded by

Syafiq IzzuddinCopyright:

Available Formats

EXPERIMENTAL MANUAL

MODEL: FM 101

SOLUTION ENGINEERING SDN. BHD.

NO.3, JALAN TPK 2/4, TAMAN PERINDUSTRIAN KINRARA,

47100 PUCHONG, SELANGOR DARUL EHSAN, MALAYSIA.

TEL: 603-80758000 FAX: 603-80755784

E-MAIL: solution@solution.com.my

WEBSITE: www.solution.com.my

423-1210-FM

SOLTEQ

EQUIPMENT FOR ENGINEERING EDUCATION

FLOWMETER

MEASUREMENT

APPARATUS

FLOWMETER

MEASUREMENT

APPARATUS

Table of Contents

Page

List of Figures................................................................................................................................... i

1.0 INTRODUCTION.. .... 1

2.0 GENERAL DESCRIPTION

2.1 Sketch of apparatus and devices .............................................................................. 2

2.2 Parts Identification ..................................................................................................... 3

2.3 Specification of dimensions ....................................................................................... 4

2.4 General Requirements .............................................................................................. 4

3.0 SUMMARY OF THEORY

3.1 Rotameter ................................................................................................................. 5

3.2 Venturi Meter ............ 5

3.3 Orifice Meter .............................................................................................................. 7

3.4 90

o

elbow .............................................................................................................. 8

4.0 EXPERIMENTAL PROCEDURE

4.1 General Start-up Procedures .................................................................................... 11

4.2 Demonstration of the operation and characteristic of three different basic types of

flowmeter ................................................................................................................... 13

4.3 Determination of the loss coefficient when fluid flows through a 90 degree elbow .... 14

4.4 General Shut-down Procedures ................................................................................ 15

5.0 MAINTENANCE AND SAFETY PRECAUTIONS ............................................................... 16

6.0 REFERENCES.................................................................................................................... 17

APPENDIX A Experimental Data Sheet

APPENDIX B Typical Experimental Results

i

List of Figures

Page

Figure 1 Sketch of apparatus and devices 2

Figure 2 Parts identification diagram 3

Figure 3 Specification of the venturi meter 4

Figure 4 Specification of the orifice plate 4

Figure 5 The rotameter 5

Figure 6 Venturi Meter 5

Figure 7 Orifice Meter 7

Figure 8 Piezometric head along a pipeline 8

Figure 9 90

o

Elbow 10

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

1

1.0 INTRODUCTION

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM101) apparatus is

designed to operate together with a basic hydraulic bench or any water supply. It is to

familiarize the students with typical methods of flow measurement of an incompressible

fluid.

The apparatus is able to demonstrate the flow measurement comparison by using a venturi

device, orifice device and rotameter. The flow comparison can be further be used to

compare against the flow measurement of the hydraulics bench which can be either by

Gravimeteric or Volumetric Method, depending on the type of hydraulics bench in use.

Other features of the flow apparatus include a 90 degree elbow with pressure tappings

before and after this elbow. The purpose of these features is to provide an added function

to this apparatus to allow students to calculate the total head loss and loss coefficient when

fluid flows through these devices.

In short, the apparatus allows following range of experiment to be carried out:

a) Direct comparison of flow measurement using venturi, orifice, rotameter and bench.

b) Determination of total head loss and loss coefficient of fluid flow through a 90 degree

elbow.

c) Comparison of pressure drop against each device.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

2

2.0 GENERAL DESCRIPTION

2.1 Sketch of apparatus and devices

Figure 1: Sketch of apparatus and devices

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

3

2.2 Part Identification

Figure 2: Part Identification Diagram

1. Manometer Tubes 6. Rotameter

2. Discharge Valve 7. 90 Elbow

3. Water Outlet 8. Orifice

4. Water Supply 9. Venturi

5. Staddle Valve

4

3

2

1

5

6

7

8

9

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

4

2.3 Specification of dimensions

i) Venturi meter

Figure 3: Specification of the Venturi Meter

Tapping A = 26 mm

Tapping B = 21.6 mm

Tapping C = 16 mm

Tapping D = 20 mm

Tapping E = 22 mm

Tapping F = 26 mm

ii) Orifice

Figure 4: Specification of the Orifice Plate

Orifice upstream diameter (G) = 26 mm

Orifice diameter (H) = 16 mm

2.4 General Requirements

SOLTEQ

Hydraulic Bench (Model: FM110)

C

A

D

E F B

G H

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

5

3.0 SUMMARY OF THEORY

3.1 Rotameter

The rotameter is a flow meter in which a rotating free float is the indicating element.

Basically, a rotameter consists of a transparent tapered vertical tube through which

fluid flow upward. Within the tube is placed a freely suspended float of pump-bob

shape. When there is no flow, the float rests on a stop at the bottom end. As flow

commences, the float rises until upward and buoyancy forces on it are balanced by

its weight. The float rises only a short distance if the rate of flow is small, and vice

versa. The points of equilibrium can be noted as a function of flow rate. With a

well-calibrated marked glass tube, the level of the float becomes a direct measure

of flow rate.

Figure 5: The Rotameter

3.2 Venturi Meter

The venturi meter consists of a venturi tube and a suitable differential pressure

gauge. The venturi tube has a converging portion, a throat and a diverging portion

as shown in the figure below. The function of the converging portion is to increase

the velocity of the fluid and lower its static pressure. A pressure difference

between inlet and throat is thus developed, which pressure difference is correlated

with the rate of discharge. The diverging cone serves to change the area of the

stream back to the entrance area and convert velocity head into pressure head.

Figure 6: Venturi Meter

Tapered tube

Flow

Scale

1

2

Inlet

Throat

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

6

Assume incompressible flow and no frictional losses, from Bernoullis Equation

2

2

2 2

1

2

1 1

2 2

Z

g

v p

Z

g

v p

+ + = + +

....(1)

Use of the continuity Equation Q = A1V1 = A2V2, equation (1) becomes

(

(

|

|

\

|

= +

2

1

2

2

2

2 1

1

2

2 1

A

A

g

V

Z Z

p p

....(2)

Ideal

2 1

2 1

2 1

2

1

2

2 2 2

2 1

2 1

/

/

(

(

|

|

\

|

+

(

(

|

|

\

|

= =

Z Z

p p

g

A

A

A V A Q

...(3)

However, in the case of real fluid flow, the flow rate will be expected to be less

than that given by equation (2) because of frictional effects and consequent head

loss between inlet and throat. In metering practice, this non-ideality is accounted

by insertion of an experimentally determined coefficient, Cd that is termed as the

coefficient of discharge. With Z1 = Z2 in this apparatus, equation (3) becomes

Actual

2 1

2 1

2

1

2

2

2 1

2 1

(

|

|

\

|

(

(

|

|

\

|

=

p p

g

A

A

A Cd Q ... (4)

Hence,

( ) [ ]

2 1

2 1

2 1

2

/ 2 1 P P g

A

At

At Cd q

(

(

\

|

=

..... (5)

Where,

Cd = Coefficient of discharge (0.98)

D2 = Throat diameter = 16 mm

D1 = Inlet diameter = 26 mm

At = Throat area = 2.011 x 10

-4

m

2

A = Inlet area = 5.309 x 10

-4

m

2

g = 9.81 m/s

2

= Density of water = 1000 kg/m

3

P1 = Inlet pressure (Pa)

P2 = Throat pressure (Pa)

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

7

3.3 Orifice Meter

The orifice for use as a metering device in a pipeline consists of a concentric

square-edged circular hole in a thin plate, which is clamped between the flanges of

the pipe as shown in the figure below.

Figure 7: Orifice Meter

Pressure connections for attaching separate pressure gauges are made at holes in

the pipe walls on both side of the orifice plate. The downstream pressure tap is

placed at the minimum pressure position, which is assumed to be at the vena

contracta. The centre of the inlet pressure tap is located between one-half and two

pipe diameters from the upstream side of the orifice plate, usually a distance of

one pipe diameter is employed. Equation (4) for the venturi meter can also be

applied to the orifice meter where

Actual

2 1

2 1

2 1

2

1

2

2

2 1

(

|

|

\

|

(

(

|

|

\

|

=

p p

g

A

A

A Cd Q . (6)

The coefficient of discharge, Cd in the case of the orifice meter will be different

from that for the case of a venturi meter.

( ) [ ]

2 1

8 7

2 1

2

2 1 h h g

A

At

At Cd Q

(

(

\

|

=

.(7)

Where,

Cd = Coefficient of discharge (0.63)

D7 = Orifice diameter = 16 mm

D8 = Orifice upstream diameter = 26 mm

At = Orifice area = 2.011 x 10

-4

m

2

A = Orifice upstream area = 5.309 x 10

-4

m

2

(h7 h8) = Pressure difference across orifice (m)

A

1

A

2

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

8

3.4 90

o

elbow

Figure below shows fluid flowing in a pipeline where there is some pipe fitting such

as bend or valve, and change in pipe diameter. Included in the figure is the

variation of piezometric head along the pipe run, as would be shown by numerous

pressure tappings at the pipe wall.

Figure 8: Piezometric head along a pipeline

If the upstream and downstream lines of linear friction gradient are extrapolated to

the plane of fitting, a loss of piezometric head, h, due to the fitting is found. By

introducing the velocity heads in the upstream and downstream runs of pipe, total

head loss, H can be determined in which

g

V

g

V

h H

2 2

2

2

2

1

+ = (8)

Energy losses are proportional to the velocity head of the fluid as it flows around

an elbow, through an enlargement or contraction of the flow section, or through a

valve. Experimental values for energy losses are usually expressed in terms of a

dimensionless loss coefficient K, where

g V

H

or

g V

H

K

2 2

2

2

2

1

/ /

= ..(9)

depending on the context.

V

2

2

/ 2g

V

1

2

/ 2g

H

h

V

2 V

1

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

9

For results of better accuracy, long sections of straight pipe are required to

establish with certainty the relative positions of the linear sections of the

piezometric lines. However, in a compact apparatus as described in this manual,

only two piezometers are used, one placed upstream and the other downstream of

the fitting, at sufficient distances as to avoid severe disturbances. These

piezometers measure the piezometric head loss, h between the tapping. Thus

f

h h h = ' ..(10)

Where

|

|

\

|

|

\

|

=

g

V

D

L

f h

f

2

4

2

hf = friction head loss which would be incurred in fully developed flow

along the run of pipe between the piezometer tappings

f = friction factor

L = distance between the piezometer, measured along the pipe center line

D = pipe diameter

V = average velocity of fluid flow in pipe

The friction head loss is estimated by choosing a suitable value of friction factor, f

for fully developed flow along a smooth pipe. The method used in this manual to

determine the friction factor is the prandtl equation

( ) 4 0 4

1

. Re log = f

f

(11)

Typical values derived from this equation are tabulated in the table below:

Re, x 10

4

0.5 1.0 1.5 2.0 2.5 3.0 3.5

F, x 10

-3

9.27 7.73 6.96 6.48 6.14 5.88 5.67

In determination of the fraction factor, f, it is sufficient to establish the value of f at

just one typical flow rate, as about the middle of the range of measurement due to

the fact that f varies only slowly with Re, and the friction loss is generally fairly

small in relation to the measured value of h.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

10

Characteristic of flow through elbow and at changes in diameter

90

o

Elbow

Figure below shows flow round a 90

o

elbow which has a constant circular cross

section.

Figure 9: 90

o

Elbow

The value of loss coefficient K is dependent on the ratio of the bend radius, R to

the pipe inside diameter D. As this ratio increase, the value of K will fall and vice

versa.

g V K H 2 /

2

= ..(12)

Where,

K = Coefficient of losses

V = Velocity of flow

g = 9.81 m/s

2

D V

R

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

11

4.0 EXPERIMENTAL PROCEDURES

4.1 General Start-up Procedures

The Flowmeter Measurement Apparatus (Model: FM 101) is supplied ready for use

and only requires connection to the Hydraulic Bench (Model: FM 110) as follows:

a) Place the apparatus on top of a suitable hydraulic bench.

b) Level the apparatus on the bench top.

c) Connect the hydraulic coupling to the outlet supply of the hydraulic bench.

d) Connect the discharge connect of the flow apparatus hose to the collection

tank of the hydraulic bench.

e) You are now ready to start the apparatus.

Starting up the Apparatus:

1. Fully close the flow control valve of hydraulic bench and fully open the

discharge valve.

2. Ensure that discharge hose is properly directed to volumetric tank of

fibreglass before starting up system. Also ensure that volumetric tank

drain valve is left OPEN to allow flow discharge back into sump tank.

3. Once step (b) is confirmed start up the pump supply from hydraulic bench.

Open the bench valve slowly. At this point, you will see water flowing from

hydraulic bench through to the flow apparatus and discharge through into

the volumetric tank of hydraulic bench and then drained back into sump

tank of hydraulic bench.

4. Proceed to fully open the flow control valve. When the flow in the pipe is

steady and there is no trapped bubble, start to close the bench valve to

reduce the flow to the maximum measurable flow rate.

5. You will see that water level in the manometer board will begin to display

different level of water heights. (If the water level in the manometer board

is too high where it is out of visible point, adjust the water level by using

the staddle valve. With the maximum measurable flow rate, retain

maximum readings on manometer).

6. At this point, slowly reduce the flow by controlling the flow discharge valve

of apparatus; you may close this discharge valve totally.

7. You will begin to see that the water level in the manometer board will

begin to level into a straight level. This level maybe at the lower or maybe

at the higher end of the manometer board range. (Take note that the pump

from the hydraulic bench is at this time, still supplying water at a certain

pressure in the system).

8. Also be on the lookout for Trapped Bubbles in the glass tube or plastic

transfer tube. You would want to remove them from the system for better

accuracy. To do this, you can either slowly press the plastic tube to push

the bubbles up or lightly tab the glass tube to release the bubbles

upwards.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

12

Note:

If above methods fail, then you will now have to flush the system by bleeding to

air out.

All that is required is the use of a small object such as pen or screw driver, to

depress the staddle valve, found at the top right side of manometer board.

Depress staddle valve lightly to allow fluid and trapped air to escape out. (Take

care or you will wet yourself or the premise).

Allow sufficient time for bleeding until all bubbles escape.

Once all bubbles have been bleed, start to reduce the water supply now by

manipulating BOTH control valves, reducing first the flow apparatus discharge

valve and then the hydraulic bench valve in alternate motion, bringing down the

DATUM level of the water in the manometer board.

(i) At this point you may start the experiment proper.

(j) You are ONLY interested in the data obtained from tubes:

Probe A and C for venturi calculation

Probe G and H for orifice calculation

Probe I and J for 90 degree elbow calculation

All other probe readings are for viewing of pressure curve ONLY.

(k) With above guide, record water level of each probe at a certain flow. With the

height difference (h), use formula provided to calculate. Verify the results

obtained against rotameter and hydraulic bench for experiment of flow

measurement comparison.

(l) Complete experiment with other flow rates.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

13

4.2 Demonstration of the operation and characteristic of three different basic

types of flowmeter

Objective:

To obtain the flow rate measurement by utilizing three basic types of flow

measuring techniques; rotameter, venturi meter and orifice meter.

Procedures:

1. Place apparatus on bench, connect inlet pipe to bench supply and outlet pipe

into volumetric tank.

2. With the bench valve fully closed and the discharge valve fully opened, start

up the pump supply from hydraulic bench.

3. Slowly open the bench valve until it is fully opened.

4. When the flow in the pipe is steady and there is no trapped bubble, start to

close the bench valve to reduce the flow to the maximum measurable flow rate.

5. By using the air bleed screw, adjust water level in the manometer board.

Retain maximum readings on manometers with the maximum measurable flow

rate.

6. Note readings on manometers (A - J), rotameter and measured flow rate.

7. Step 6 is repeated for different flow rates. The flow rates can be adjusted by

utilizing both bench valve and discharge valve.

8. To demonstrate similar flow rates at different system static pressures, adjust

bench and flow control valve together. Adjusting manometer levels as required.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

14

4.3 Determination of the loss coefficient when fluid flows through a 90 degree

elbow

Objective:

To investigate the loss coefficient of fluid through 90 degree elbow.

Procedures:

1. Place apparatus on bench, connect inlet pipe to bench supply and outlet pipe

into volumetric tank.

2. With the bench valve fully closed and the discharge valve fully opened, start

up the pump supply from hydraulic bench.

3. Slowly open the bench valve until it is fully opened.

4. When the flow in the pipe is steady and there is no trapped bubble, start to

close the bench valve to reduce the flow to the maximum measurable flow rate.

5. By using the air bleed screw, adjust the water level in the manometer board.

Retain maximum readings on manometers with the maximum measurable flow

rate.

6. Note readings on manometers (I and J) and measured flow rate.

7. Step 6 is repeated for different flow rates. The flow rates can be adjusted by

utilizing both bench valve and discharge valve.

8. Complete the tables below.

9. Plot graph H against

g

V

s

2

2

for 90 degree elbow to determine the coefficient of

losses.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

15

4.4 General Shut-down Procedures

1. Close water supply valve and venturi discharge valve.

2. Turn off the water supply pump.

3. Drain off water from the unit when not in use.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

16

5.0 MAINTENANCE AND SAFETY PRECAUTIONS

1. It is important to drain all water from the apparatus when not in use. The apparatus

should be stored properly to prevent damage.

2. Any manometer tube, which does not fill with water or slow fill, indicates that tapping

or connection of the manometer is blocked. To remove the obstacle, disconnect the

flexible connection tube and blow through.

3. The apparatus should not be exposed to any shock and stresses.

4. Always wear protective clothing, shoes, helmet and goggles throughout the

laboratory session.

5. Always run the experiment after fully understand the unit and procedures.

SOLTEQ

Flowmeter Measurement Apparatus (Model: FM 101)

17

6.0 REFERENCES

Applied Fluid Mechanics 5th Edition, Robert L. Mott, Prentice-Hall

Elementary Fluid Mechanics 7

th

Edition, Robert L. Street, Gary Z. Watters, John K.

Vennard, John Wiley & Sons Inc.

Fluid Mechanics 4th Edition, Reynold C. Binder

Fluid Mechanics with applications, Anthony Esposito, Prentice-Hall International Inc.

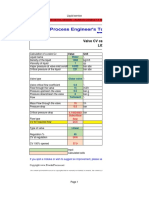

Appendix A

Experimental Data Sheets

Demonstration of the operation and characteristic of three different basic types of flowmeter

Manometer reading (mm) Rotameter

(l/min)

Vol

(l)

Time

(min)

Flowrate,

Q

(l/min)

Flowrate calculated using

the Bernoulli's Equation

(l/min)

A B C D E F G H I J Venturi Orifice

Determination of the loss coefficient when fluid flows through a 90 degree elbow

Volume

(L)

Time

(sec)

Flowrate,Q

(l/min)

Differential Piezometer Head, h'

(mm)

V V

2

/2g

(m/s) (mm)

Elbow (hI-hJ)

Appendix B

Typical Experimental Results

Demonstration of the operation and characteristic of three different basic types of flowmeter

Manometer reading (mm) Rotameter

(l/min)

Vol

(l)

Time

(min)

Flowrate,

Q

(l/min)

Flowrate calculated using

the Bernoulli's Equation

(l/min)

A B C D E F G H I J Venturi Orifice

324 309 305 304 306 309 317 279 290 289 7 3 0.41 7.35 7.80 7.09

334 329 303 319 323 325 329 265 290 288 10 3 0.28 10.86 9.96 9.20

358 347 295 326 336 380 345 190 250 243 15 3 0.19 15.72 14.20 14.32

418 394 294 356 374 400 390 110 219 210 20 3 0.15 20.13 19.93 19.25

436 415 288 370 390 410 410 65 198 186 22 3 0.13 22.73 21.77 21.37

Sample Calculation

For rotameter flow rate = 22 l/min

Venturi flow rate,

( ) [ ]

2 1

2 1

2

1

2 1

C A

h h g

A

At

At Cd q

(

(

|

|

\

|

=

( )( ) ( )( ) [ ] s m q / 288 . 0 436 . 0 81 . 9 2

10 309 . 5

10 011 . 2

1 10 011 . 2 98 . 0

3 2 1

2 1

2

4

4

4

(

(

|

|

\

|

( )( ) ( )( ) [ ]

min

60

1

1000

288 . 0 436 . 0 81 . 9 2

10 309 . 5

10 011 . 2

1 10 011 . 2 98 . 0

2 1

2 1

2

4

4

4

l

q

(

(

|

|

\

|

min / 77 . 21 l q =

Orifice flow rate,

( ) [ ]

2 1

2 1

2

7

2 1

H G

h h g

A

At

At Cd Q

(

(

|

|

\

|

=

( )( ) ( )( ) [ ] s m Q / 065 . 0 410 . 0 81 . 9 2

10 309 . 5

10 011 . 2

1 10 011 . 2 63 . 0

3 2 1

2 1

2

4

4

4

(

(

|

|

\

|

( )( ) ( )( ) [ ]

min

60

1

1000

065 . 0 410 . 0 81 . 9 2

10 309 . 5

10 011 . 2

1 10 011 . 2 63 . 0

2 1

2 1

2

4

4

4

l

Q

(

(

|

|

\

|

min / 37 . 21 l Q =

Determination of the loss coefficient when fluid flows through a 90 degree elbow

g v

H

K

2 /

2

=

Slope = K=0.370

Volume

(L)

Time

(min)

Flowrate,Q

(l/min)

Differential Piezometer Head, h'

(mm)

V V

2

/2g

(m/s) (mm)

Elbow (hI-hJ)

3 0.55 5.43 1 0.17 1.48

3 0.30 10.07 2 0.32 5.09

3 0.23 13.29 3 0.42 8.88

3 0.16 18.42 6 0.58 17.05

3 0.13 22.87 10 0.72 26.27

Sample calculations

Choose the min flow rate, Q = 5.43l/min = 9.05 X 10

-5

m

3

/s

Velocity of flow in the pipe (Diameter = 26 mm)

( )

2

3

5

10 26

4

10 05 . 9

V

= 0.17 m/s

mm

g

V

48 . 1

81 . 9 2

17 . 0

2

2

2

=

You might also like

- Ve - Occupational Disease Statistics 2005-2014Document1 pageVe - Occupational Disease Statistics 2005-2014Syafiq IzzuddinNo ratings yet

- Chapter 3 Colloid and Fine Particle EH2206D PDFDocument10 pagesChapter 3 Colloid and Fine Particle EH2206D PDFSyafiq IzzuddinNo ratings yet

- Pro - Asniza Hamimi Abdul Tharim A 12Document7 pagesPro - Asniza Hamimi Abdul Tharim A 12Syafiq IzzuddinNo ratings yet

- Topic 4 - Design of Ideal Reactors For Single ReactionDocument23 pagesTopic 4 - Design of Ideal Reactors For Single ReactionSyafiq Izzuddin50% (2)

- Statistic AccidentDocument1 pageStatistic AccidentSyafiq IzzuddinNo ratings yet

- Chapter 2 Particle Size CharacterizationDocument45 pagesChapter 2 Particle Size Characterizationfatthul hadiNo ratings yet

- Cover Letter .Document2 pagesCover Letter .Syafiq IzzuddinNo ratings yet

- Chapter 1 Introduction To Bulk SolidDocument14 pagesChapter 1 Introduction To Bulk SolidSyafiq IzzuddinNo ratings yet

- Chapter 10 - Profitability AnalysisDocument41 pagesChapter 10 - Profitability AnalysisSyafiq IzzuddinNo ratings yet

- Lab 3 SimulationDocument11 pagesLab 3 SimulationSyafiq IzzuddinNo ratings yet

- Apb 2014 Elc 500 2nd Edition Suggested AnswersDocument24 pagesApb 2014 Elc 500 2nd Edition Suggested AnswersSyafiq IzzuddinNo ratings yet

- Chapter 9 - Engineering EconomicsDocument45 pagesChapter 9 - Engineering EconomicsSyafiq IzzuddinNo ratings yet

- Chapter 15 - Heat Exchanger Networks - IDocument49 pagesChapter 15 - Heat Exchanger Networks - ISyafiq IzzuddinNo ratings yet

- FM112 Liquid Mixing Experiments GuideDocument17 pagesFM112 Liquid Mixing Experiments GuideSyafiq IzzuddinNo ratings yet

- CPE613 Propylene Glycol Production ProjectDocument1 pageCPE613 Propylene Glycol Production ProjectSyafiq IzzuddinNo ratings yet

- Chapter 7 - Capital Cost EstimationDocument35 pagesChapter 7 - Capital Cost EstimationSyafiq IzzuddinNo ratings yet

- LLE Experiment 2Document10 pagesLLE Experiment 2Syafiq IzzuddinNo ratings yet

- Ciu ResultDocument1 pageCiu ResultSyafiq IzzuddinNo ratings yet

- Ciu ResultDocument1 pageCiu ResultSyafiq IzzuddinNo ratings yet

- ELC500 Sample Test 2Document10 pagesELC500 Sample Test 2Syafiq IzzuddinNo ratings yet

- Study of A Supercritical CO2 Power Cycle ApplicationDocument12 pagesStudy of A Supercritical CO2 Power Cycle ApplicationSyafiq IzzuddinNo ratings yet

- FM11 ManualDocument11 pagesFM11 ManualSyafiq IzzuddinNo ratings yet

- Study of A Supercritical CO2 Power Cycle ApplicationDocument12 pagesStudy of A Supercritical CO2 Power Cycle ApplicationSyafiq IzzuddinNo ratings yet

- FM11 Complete ManualDocument12 pagesFM11 Complete ManualSyafiq Izzuddin100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ncrit Thesis - Implementation of A New Transition Prediction Method in XfoilDocument168 pagesNcrit Thesis - Implementation of A New Transition Prediction Method in XfoilDavid Jiménez MenaNo ratings yet

- ReviewDocument31 pagesReviewkarlobrondialNo ratings yet

- EmulsionDocument27 pagesEmulsionSharanya SrinivasanNo ratings yet

- Introduction to MHD and Applications to Thermofluids of Fusion BlanketsDocument38 pagesIntroduction to MHD and Applications to Thermofluids of Fusion BlanketsKathyNo ratings yet

- ProblemsetDocument6 pagesProblemsetMaryll TapiaNo ratings yet

- MIT Introduction to Aerodynamics CourseDocument307 pagesMIT Introduction to Aerodynamics CourseAnonymous PJp7tvGNo ratings yet

- Free Water Knockout Design & OperationDocument4 pagesFree Water Knockout Design & Operationحمامة السلامNo ratings yet

- Vent Line Pressure Drop CalculationDocument4 pagesVent Line Pressure Drop CalculationRubensBoerngenNo ratings yet

- Amtecol Marine Lubricants Tabele EchivalenteDocument5 pagesAmtecol Marine Lubricants Tabele EchivalenteCorina StanculescuNo ratings yet

- Part 02 Question (528 - 541)Document16 pagesPart 02 Question (528 - 541)rudrakshengg.No ratings yet

- 74. Natural ConvectionDocument39 pages74. Natural Convectionraghu.entrepreneurNo ratings yet

- Investigation of Wind Tunnel Design and ConstructionDocument5 pagesInvestigation of Wind Tunnel Design and ConstructionsalmanNo ratings yet

- Accumulator Volume Capacity Calculation (API RP53 and IRP 1)Document2 pagesAccumulator Volume Capacity Calculation (API RP53 and IRP 1)aqawaqawNo ratings yet

- Electro CoalescenciaDocument7 pagesElectro CoalescenciaiqubaldoNo ratings yet

- Flow and CV Calculation ToolDocument3 pagesFlow and CV Calculation Toolmohan babuNo ratings yet

- C5 HH223 Fluid Mechanics IDocument2 pagesC5 HH223 Fluid Mechanics IArturo AnticonaNo ratings yet

- Gels PDFDocument31 pagesGels PDFShumaila QadirNo ratings yet

- Advanced Reservoir Simulation & Rock Typing PDFDocument46 pagesAdvanced Reservoir Simulation & Rock Typing PDFFiktoriusKevinNo ratings yet

- Conservation Equations Fluid DynamicsDocument8 pagesConservation Equations Fluid DynamicsRaman ChawlaNo ratings yet

- Register For Exam: Osiris: Capillary RiseDocument24 pagesRegister For Exam: Osiris: Capillary RiseShwet KumarNo ratings yet

- Chapter 11: Steady Waves in Compressible FlowDocument22 pagesChapter 11: Steady Waves in Compressible FlowDeez34PNo ratings yet

- Aga 3 - 2000 RevisionDocument57 pagesAga 3 - 2000 RevisionAnonymous XV4AlTzUNo ratings yet

- Lesson VII Emulsion Preparation Equipment and StabilityDocument26 pagesLesson VII Emulsion Preparation Equipment and StabilityEleanor100% (2)

- DiscussionDocument3 pagesDiscussionmayhem65No ratings yet

- 5ChED Thurs-Group1 Packed ColumnDocument15 pages5ChED Thurs-Group1 Packed ColumnRaniella Bianca Yim Coronado100% (1)

- Bernoulli'sDocument7 pagesBernoulli'sabdallh55No ratings yet

- Nukiyama & Tanasawa Correlation: Liquid Mean Droplet Size or Sauter Mean DiameterDocument2 pagesNukiyama & Tanasawa Correlation: Liquid Mean Droplet Size or Sauter Mean Diametersreekanth reddyNo ratings yet

- Bernoulli's Theorem ProofDocument2 pagesBernoulli's Theorem ProofSourav Das50% (4)

- NPSH Calculating ItDocument6 pagesNPSH Calculating ItJerry MateoNo ratings yet

- Flow Past Semicircular CylinderDocument8 pagesFlow Past Semicircular CylinderMohamad FaruqNo ratings yet