Professional Documents

Culture Documents

How Gas Turbine Power Plants Work

Uploaded by

chella2705Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How Gas Turbine Power Plants Work

Uploaded by

chella2705Copyright:

Available Formats

HOW GAS TURBINE POWER PLANTS WORK

The combustion (gas) turbines being installed in many of today's natural-gas-fueled power

plants are complex machines, but they basically involve three main sections:

The compressor, which draws air into the engine, pressurizes it, and feeds it to the

combustion chamber at speeds of hundreds of miles per hour.

The combustion system, typically made up of a ring of fuel injectors that inject a steady

stream of fuel into combustion chambers where it mixes with the air. The mixture is

burned at temperatures of more than 2000 degrees F. The combustion produces a high

temperature, high pressure gas stream that enters and expands through the turbine

section.

The turbine is an intricate array of alternate stationary and rotating aerofoil-section

blades. As hot combustion gas expands through the turbine, it spins the rotating blades.

The rotating blades perform a dual function: they drive the compressor to draw more

pressurized air into the combustion section, and they spin a generator to produce

electricity.

Land based gas turbines are of two types: (1) heavy frame engines and (2) aeroderivative

engines. Heavy frame engines are characterized by lower pressure ratios (typically below

20) and tend to be physically large. Pressure ratio is the ratio of the compressor discharge

pressure and the inlet air pressure. Aeroderivative engines are derived from jet engines, as

the name implies, and operate at very high compression ratios (typically in excess of 30).

Aeroderivative engines tend to be very compact and are useful where smaller power

outputs are needed. As large frame turbines have higher power outputs, they can produce

larger amounts of emissions, and must be designed to achieve low emissions of pollutants,

such as NOx.

One key to a turbine's fuel-to-power efficiency is the temperature at which it operates.

Higher temperatures generally mean higher efficiencies, which in turn, can lead to more

economical operation. Gas flowing through a typical power plant turbine can be as hot as

2300 degrees F, but some of the critical metals in the turbine can withstand temperatures

only as hot as 1500 to 1700 degrees F. Therefore, air from the compressor might be used

for cooling key turbine components, reducing ultimate thermal efficiency.

One of the major achievements of the Department of Energy's advanced turbine program

was to break through previous limitations on turbine temperatures, using a combination of

innovative cooling technologies and advanced materials. The advanced turbines that

emerged from the Department's research program were able to boost turbine inlet

temperatures to as high as 2600 degrees F - nearly 300 degrees hotter than in previous

turbines, and achieve efficiencies as high as 60 percent.

Another way to boost efficiency is to install a recuperator or heat recovery steam generator

(HRSG) to recover energy from the turbine's exhaust. A recuperator captures waste heat in

the turbine exhaust system to preheat the compressor discharge air before it enters the

combustion chamber. A HRSG generates steam by capturing heat from the turbine exhaust.

These boilers are also known as heat recovery steam generators. High-pressure steam from

these boilers can be used to generate additional electric power with steam turbines, a

configuration called a combined cycle.

A simple cycle gas turbine can achieve energy conversion efficiencies ranging between 20

and 35 percent. With the higher temperatures achieved in the Department of Energy's

turbine program, future hydrogen and syngas fired gas turbine combined cycle plants are

likely to achieve efficiencies of 60 percent or more. When waste heat is captured from these

systems for heating or industrial purposes, the overall energy cycle efficiency could

approach 80 percent.

Gas Turbine Working Principle

Gas turbine engines derive their power from burning fuel in a combustion chamber and using the fast flowing

combustion gases to drive a turbine in much the same way as the high pressure steam drives a steam turbine.

One major difference however is that the gas turbine has a second turbine acting as an air compressor mounted on

the same shaft. The air turbine (compressor) draws in air, compresses it and feeds it at high pressure into the

combustion chamber increasing the intensity of the burning flame.

It is a positive feedback mechanism. As the gas turbine speeds up, it also causes the compressor to speed up forcing

more air through the combustion chamber which in turn increases the burn rate of the fuel sending more high

pressure hot gases into the gas turbine increasing its speed even more. Uncontrolled runaway is prevented by

controls on the fuel supply line which limit the amount of fuel fed to the turbine thus limiting its speed.

The thermodynamic process used by the gas turbine is known as the Brayton cycle. Analogous to the Carnot cycle in

which the efficiency is maximised by increasing the temperature difference of the working fluid between the input and

output of the machine, the Brayton cycle efficiency is maximised by increasing the pressure difference across the

machine. The gas turbine is comprised of three main components: a compressor, a combustor, and a turbine. The

working fluid, air, is compressed in the compressor (adiabatic compression - no heat gain or loss), then mixed with

fuel and burned by the combustor under constant pressure conditions in the combustion chamber (constant pressure

heat addition). The resulting hot gas expands through the turbine to perform work (adiabatic expansion). Much of the

power produced in the turbine is used to run the compressor and the rest is available to run auxiliary equipment and

do useful work. The system is an open system because the air is not reused so that the fourth step in the cycle,

cooling the working fluid, is omitted.

Gas Turbine Aero Engine (Deutches Museum)

Gas turbines have a very high power to weight ratio and are lighter and smaller than internal combustion engines of

the same power. Though they are mechanically simpler than reciprocating engines, their characteristics of high speed

and high temperature operation require high precision components and exotic materials making them more

expensive to manufacture.

History

Electrical Power Generation

In electricity generating applications the turbine is used to drive a synchronous generator which provides the electrical

power output but because the turbine normally operates at very high rotational speeds of 12,000 r.p.m or more it

must be connected to the generator through a high ratio reduction gear since the generators run at speeds of 1,000

or 1,200 r.p.m. depending on the AC frequency of the electricity grid.

Turbine Configurations

Gas turbine power generators are used in two basic configurations

Simple Systems consisting of the gas turbine driving an electrical power generator.

Combined Cycle Systems which are designed for maximum efficiency in which the hot exhaust gases from the

gas turbine are used to raise steam to power a steam turbine with both turbines being connected to electricity

generators.

Turbine Performance

Turbine Power Output

To minimise the size and weight of the turbine for a given output power, the output per pound of airflow should

be maximised. This is obtained by maximising the air flow through the turbine which in turn depends on

maximising the pressure ratio between the air inlet and exhaust outlet. The main factor governing this is the

pressure ratio across the compressor which can be as high as 40:1 in modern gas turbines. In simple cycle

applications, pressure ratio increases translate into efficiency gains at a given firing temperature, but there is a

limit since increasing the pressure ratio means that more energy will be consumed by the compressor.

System Efficiency

Thermal efficiency is important because it directly affects the fuel consumption and operating costs.

Simple Cycle Turbines

A gas turbine consumes considerable amounts of power just to drive its compressor. As with all cyclic heat

engines, a higher maximum working temperature in the machine means greater efficiency (Carnot's Law),

but in a turbine it also means that more energy is lost as waste heat through the hot exhaust gases whose

temperatures are typically well over 1,000C . Consequently simple cycle turbine efficiencies are quite low.

For heavy plant, design efficiencies range between 30% and 40%. (The efficiencies of aero engines are in

the range 38% and 42% while low power microturbines (<100kW) achieve only 18% to 22%). Although

increasing the firing temperature increases the output power at a given pressure ratio, there is also a

sacrifice of efficiency due to the increase in losses due to the cooling air required to maintain the turbine

components at reasonable working temperatures.

Combined Cycle Turbines

It is however possible to recover energy from the waste heat of simple cycle systems by using the exhaust

gases in a hybrid system to raise steam to drive a steam turbine electricity generating set . In such cases

the exhaust temperature may be reduced to as low as 140C enabling efficiencies of up to 60% to be

achieved in combined cycle systems.

In combined-cycle applications, pressure ratio increases have a less pronounced effect on the efficiency

since most of the improvement comes from increases in the Carnot thermal efficiency resulting from

increases in the firing temperature.

Thus simple cycle efficiency is achieved with high pressure ratios. Combined cycle efficiency is obtained

with more modest pressure ratios and greater firing temperatures.

See also Heat Engines

Fuels

One further advantage of gas turbines is their fuel flexibility. They can be adapted to use almost any flammable gas

or light distillate petroleum products such as gasoline (petrol), diesel and kerosene (paraffin) which happen to be

available locally, though natural gas is the most commonly used fuel. Crude and other heavy oils and can also be

used to fuel gas turbines if they are first heated to reduce their viscosity to a level suitable for burning in the turbine

combustion chambers.

Applications

Gas turbines can be used for large scale power generation. Examples are applications delivering 600 MW or more

from a 400 MW gas turbine coupled to a 200 MW steam turbine in a co-generating installation. Such installations are

not normally used for base load electricity generation, but for bringing power to remote sites such as oil and gas

fields. They do however find use in the major electricity grids in peak shaving applications to provide emergency peak

power.

Low power gas turbine generating sets with capacities up to 5 MW can be accommodated in transportation

containers to provide mobile emergency electricity supplies which can delivered by truck to the point of need.

You might also like

- Gas Turbine Power PlantsDocument8 pagesGas Turbine Power Plantssakibsultan_308No ratings yet

- Gas Turbine DescriptionDocument8 pagesGas Turbine DescriptionSIVAPATHASEKARANNo ratings yet

- Rankine ReheatDocument2 pagesRankine ReheatManik SinghNo ratings yet

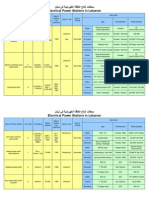

- نﺎﻨﺒﻟ ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻗﺎﻄﻟا جﺎﺘﻧإ تﺎﻄﺤﻣ Electrical Power Stations in LebanonDocument2 pagesنﺎﻨﺒﻟ ﻲﻓ ﺔﻴﺋﺎﺑﺮﻬﻜﻟا ﺔﻗﺎﻄﻟا جﺎﺘﻧإ تﺎﻄﺤﻣ Electrical Power Stations in LebanonRichard YazbeckNo ratings yet

- Internal Combustion Engines GuideDocument16 pagesInternal Combustion Engines GuideAshton SelokaNo ratings yet

- COMBUSTION2222222222222222222Document47 pagesCOMBUSTION2222222222222222222Habtamu Tkubet EbuyNo ratings yet

- TPDocument2 pagesTPRonit VelariNo ratings yet

- The Concept of Exergy and Energy Quality - Truls GundersenDocument26 pagesThe Concept of Exergy and Energy Quality - Truls Gundersenuser_account100% (1)

- Thermal power plant economiser guideDocument7 pagesThermal power plant economiser guideSteve M D'souzaNo ratings yet

- Combined Heat and PowerDocument8 pagesCombined Heat and Powerawhk2006No ratings yet

- Biomass Power PlantDocument5 pagesBiomass Power Plantmikko intalNo ratings yet

- Lecture Note - Steam CycleDocument37 pagesLecture Note - Steam CycleSuchi Suchi SuchiNo ratings yet

- Otto Diesel Dual Ideal Cycle - PPT (Compatibility Mode)Document16 pagesOtto Diesel Dual Ideal Cycle - PPT (Compatibility Mode)Danang Wahdiat Aulia Ishaq0% (1)

- Power PlantDocument14 pagesPower PlantKanna B CoolNo ratings yet

- Combustion Modeling of Dual-Fuel Engines - 2Document2 pagesCombustion Modeling of Dual-Fuel Engines - 2helenNo ratings yet

- Simulatingcombinedcyclegasturbinepowerplantsin Aspen HYSYSDocument14 pagesSimulatingcombinedcyclegasturbinepowerplantsin Aspen HYSYSJessica Del Carmen Parra MercadoNo ratings yet

- Gas Turbine Thermal Power PlantDocument7 pagesGas Turbine Thermal Power PlantAkshay ManzaNo ratings yet

- THM Gas Turbines for Power GenerationDocument8 pagesTHM Gas Turbines for Power GenerationMSD65352300No ratings yet

- Gas Turbine Power PlantDocument48 pagesGas Turbine Power PlantArif Ahmed100% (1)

- Assignment - 2 (Waste Heat Recovery)Document4 pagesAssignment - 2 (Waste Heat Recovery)Akmal Hafeez Muhammad HafeezNo ratings yet

- Slides of All TurboDocument383 pagesSlides of All TurboDeivid William TorresNo ratings yet

- Ideal Rankine Cycle ExplainedDocument12 pagesIdeal Rankine Cycle ExplainedAarvin GeorgeNo ratings yet

- 413 Topic IV-3 (Fossil Fuels and Boiler Efficiency)Document60 pages413 Topic IV-3 (Fossil Fuels and Boiler Efficiency)Sabina Suljic100% (1)

- Powr PlantDocument10 pagesPowr PlantSajjad Ibraheem100% (1)

- Training Ebsilon EnglDocument49 pagesTraining Ebsilon EnglUsama Jawaid100% (1)

- Ic Engines: Four Stroke Cycle Diesel EnginesDocument11 pagesIc Engines: Four Stroke Cycle Diesel Enginesmechjobs4meNo ratings yet

- Extending the Range of Single-Shaft Combined Cycle Power PlantsDocument12 pagesExtending the Range of Single-Shaft Combined Cycle Power PlantsSrinivasa Rao PallelaNo ratings yet

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Document5 pagesA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungNo ratings yet

- Rankine CycleDocument13 pagesRankine CycleAtul100% (5)

- Boiler Turbine Dynamics in Power Plant ControlDocument12 pagesBoiler Turbine Dynamics in Power Plant ControlAmanjit SinghNo ratings yet

- Basic of Gas TurbinesDocument48 pagesBasic of Gas Turbinessrexpower100% (1)

- Gas Turbine Power Plant: By: Ms. Monika DeshwalDocument19 pagesGas Turbine Power Plant: By: Ms. Monika DeshwalKeshantSharma100% (1)

- Steam Boiler Systems From Bosch: Highly Efficient and Reliable Process HeatDocument19 pagesSteam Boiler Systems From Bosch: Highly Efficient and Reliable Process Heatnemi90No ratings yet

- Chapter 3 - Reacting Mixtures and CombustionDocument54 pagesChapter 3 - Reacting Mixtures and CombustionrrhoshackNo ratings yet

- Boiler Efficiency Calculation SimplifiedDocument4 pagesBoiler Efficiency Calculation SimplifiedSean Thomas100% (1)

- Dry Flue Gas Loss (LDG) : LDG (24 X DG X (FGT - CAT) ) ÷ HHV, WhereDocument1 pageDry Flue Gas Loss (LDG) : LDG (24 X DG X (FGT - CAT) ) ÷ HHV, WhereParmasamy SubramaniNo ratings yet

- Group-D Presentation (CCPP)Document31 pagesGroup-D Presentation (CCPP)Anik FaisalNo ratings yet

- Waste heat recovery technologies and applications overviewDocument17 pagesWaste heat recovery technologies and applications overviewSazid ZamanNo ratings yet

- MA2007 Summary Cycles Processes Part 2 FormulasDocument15 pagesMA2007 Summary Cycles Processes Part 2 FormulasYap Gee ShiuanNo ratings yet

- Combustion ChemistryDocument17 pagesCombustion Chemistryrajeev50588No ratings yet

- Auxiliary BoilerDocument56 pagesAuxiliary BoilerNirdosh AnanthNo ratings yet

- Chapter 3 - Fuels and CombustionDocument21 pagesChapter 3 - Fuels and CombustionRobertNo ratings yet

- Isentropic Efficiencies of Turbines, Compressors and NozzlesDocument24 pagesIsentropic Efficiencies of Turbines, Compressors and NozzlesgrandecaciqueNo ratings yet

- What Is CogenerationDocument3 pagesWhat Is CogenerationmuthuNo ratings yet

- Internal Combustion Engine TypesDocument35 pagesInternal Combustion Engine TypesMuhammad FaizNo ratings yet

- Lec 3 BoilerDocument20 pagesLec 3 BoilerRajiv SharmaNo ratings yet

- Designing of Center CrankshaftDocument24 pagesDesigning of Center CrankshaftAshvathSharma0% (1)

- Cogeneration Class PDFDocument66 pagesCogeneration Class PDFeselcosacNo ratings yet

- ReportDocument20 pagesReportMoaaz KhanNo ratings yet

- Commercial & Technical Proposal For 10MW - 11 KV MWM DEUTZ Gas Engine Power PlantDocument15 pagesCommercial & Technical Proposal For 10MW - 11 KV MWM DEUTZ Gas Engine Power PlantSojib hossain100% (1)

- HRSG Design Tutorial - Heat BalanceDocument3 pagesHRSG Design Tutorial - Heat BalanceRavi KasaudhanNo ratings yet

- Feedwater Heater - Regeneration Analysis - HandbookDocument19 pagesFeedwater Heater - Regeneration Analysis - HandbookAnonymous wIPMQ5rhNo ratings yet

- Components of a Simple Vapour Power PlantDocument7 pagesComponents of a Simple Vapour Power Plantdipta sahaNo ratings yet

- T 9109Document9 pagesT 9109Ayush Singh BeruvarNo ratings yet

- GALGALLA - Working Assignment 3 - Gas TurbineDocument5 pagesGALGALLA - Working Assignment 3 - Gas TurbineGodfrey Jr Jr.No ratings yet

- How Gas Turbine Power Plants WorkDocument12 pagesHow Gas Turbine Power Plants WorkLa Vien Rose100% (1)

- Gas Turbines FundamentalsDocument2 pagesGas Turbines FundamentalsMohamedNo ratings yet

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- FBC Boilers: Syllabus FBC Boilers: Introduction, Mechanism of Fluidized Bed Combustion, AdvantagesDocument12 pagesFBC Boilers: Syllabus FBC Boilers: Introduction, Mechanism of Fluidized Bed Combustion, AdvantagesTejas T S TejasNo ratings yet

- Hydro To NuclearDocument10 pagesHydro To Nuclearchella2705No ratings yet

- Main Parts of A Thermal Power Plant. WorkingDocument8 pagesMain Parts of A Thermal Power Plant. WorkingprateekjenaNo ratings yet

- MAGNETOHYDRODYNAMICDocument5 pagesMAGNETOHYDRODYNAMICchella2705No ratings yet

- Combined Cycle Power PlantDocument7 pagesCombined Cycle Power Plantchella2705100% (1)

- Project Biomass Wood BrazilDocument34 pagesProject Biomass Wood Brazilmar4478100% (2)

- SERIGAS-SPARSE technology overviewDocument25 pagesSERIGAS-SPARSE technology overviewRajahVKNo ratings yet

- Geo 2010 Tech Progr DetailsDocument20 pagesGeo 2010 Tech Progr DetailsMani BansalNo ratings yet

- Oil & Gas Exploration Drilling ProcessDocument19 pagesOil & Gas Exploration Drilling ProcessCindy Andromeda VincentNo ratings yet

- 01.Cv Musmulyadi Rigger - Scaffolding and Roustabout Word EmailDocument40 pages01.Cv Musmulyadi Rigger - Scaffolding and Roustabout Word EmailIfan TaufanNo ratings yet

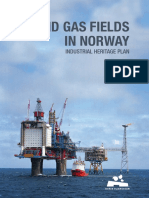

- Oil and Gas Fields in NorwayDocument9 pagesOil and Gas Fields in NorwaySATRIA PUTRA SAMUDRANo ratings yet

- Scheda Gas Turbine Ae94 2Document4 pagesScheda Gas Turbine Ae94 2Josemar LopesNo ratings yet

- EVS Questions and Answers - 2 MarksDocument20 pagesEVS Questions and Answers - 2 MarksPawan Reddy100% (2)

- Installation and Servicing Instructions For 24cdi RSF Discontinued 07Document42 pagesInstallation and Servicing Instructions For 24cdi RSF Discontinued 07mcanaliNo ratings yet

- The Big Picture 2023-MTSC S&P Global ReportDocument15 pagesThe Big Picture 2023-MTSC S&P Global ReportpillaiwarmNo ratings yet

- Plastic & Resin Manufacturing in The US Industry Report PDFDocument35 pagesPlastic & Resin Manufacturing in The US Industry Report PDFAnonymous rMvQNxcPDCNo ratings yet

- Valero Refinery Fire Caused by Unprotected Dead-Leg PipingDocument65 pagesValero Refinery Fire Caused by Unprotected Dead-Leg PipingAndrew WilliamsonNo ratings yet

- Carbon Emissions From Base Metal Mine Sites PDFDocument5 pagesCarbon Emissions From Base Metal Mine Sites PDFSt_LairNo ratings yet

- Week 8Document6 pagesWeek 8shmye100% (1)

- 2010 Trinidad y TobagoDocument22 pages2010 Trinidad y TobagorubenpeNo ratings yet

- EHS Guidelines Offshore Oil and Gas June2015Document42 pagesEHS Guidelines Offshore Oil and Gas June2015IFC Sustainability100% (3)

- CNG Industry in Indonesia Are They Ready For The Shift (GLG Webcast)Document36 pagesCNG Industry in Indonesia Are They Ready For The Shift (GLG Webcast)Ramius HamdaniNo ratings yet

- Lebw4977-04.gaseous Fuels - Application & Installation Guide A&i Guide PDFDocument48 pagesLebw4977-04.gaseous Fuels - Application & Installation Guide A&i Guide PDFvoivod6No ratings yet

- Simulation of Liquefied Petroleum Gas LPG ProductiDocument7 pagesSimulation of Liquefied Petroleum Gas LPG ProductiThinh Tran HungNo ratings yet

- Turboexpander-Generators: GE Oil & GasDocument5 pagesTurboexpander-Generators: GE Oil & GaslubangjarumNo ratings yet

- Trane Make Up Air UnitDocument44 pagesTrane Make Up Air UnitgutmontNo ratings yet

- Chapter 2 explores energy types and sourcesDocument45 pagesChapter 2 explores energy types and sourcesjohn kayhnNo ratings yet

- Internship Report - Shivani Kumbhare PDFDocument22 pagesInternship Report - Shivani Kumbhare PDFpiyush solankiNo ratings yet

- Gas Pooling ReportDocument73 pagesGas Pooling ReportP VinayakamNo ratings yet

- Overall Performance Evaluation of Small Scale LNGDocument23 pagesOverall Performance Evaluation of Small Scale LNGEbrahim AbdelrahmanNo ratings yet

- Flare Modeling ParametersDocument26 pagesFlare Modeling Parametersromdhan88No ratings yet

- ESI-Case-Study-Enagas-PLM-Pipeline TrainerDocument5 pagesESI-Case-Study-Enagas-PLM-Pipeline TrainerMuhammad ImranNo ratings yet

- Biogas To BioCNG-Solutions For Waste-To-Green-Fuel Projects An Experience Sharing-Ashish NawadeDocument26 pagesBiogas To BioCNG-Solutions For Waste-To-Green-Fuel Projects An Experience Sharing-Ashish NawadeFurqan AliNo ratings yet

- Biogas Mass Balance PDFDocument9 pagesBiogas Mass Balance PDFHafizhun SoekiswoNo ratings yet