Professional Documents

Culture Documents

Positive Displacement Pump Parts and Function Explained

Uploaded by

mister pogiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Positive Displacement Pump Parts and Function Explained

Uploaded by

mister pogiCopyright:

Available Formats

LESSON

4

LECTURE

POSITIVE DISPLACEMENT PUMPS PARTS

LIST & FUNCTION

SUB OBJECTIVE

At the end of this lesson the t!inee "ill #e !#le to$

%& De'onst!te !n (ndest!ndin) of Positi*e Dis+l!,e'ent P('+s- P!ts List !nd

F(n,tion&

%&. DISPLACEMENT PUMP

As defined in the lesson "l", that a displacement pump in which energy is periodically

added by application of force. To one or more movable boundaries, of any desired

number of enclosed fluid containing volumes resulting in a direct increase in pressure

up to the value required to more the fluid through valves or parts into the discharge

line. See Fig. 5!" for classification of displacement pumps.

/&. RECIPROCATIN0 PUMP

A reciprocating is a positive displacement pump which at constant speed, deliver

essentially the same capacity at any pressure within the capability of the driver and

the strength of the pump. Thus reciprocating pump is most useful in the field of high

pressure and low capacity. #n some application the constant delivery at varying

pressure is a definite advantage and act as a metering device.

/&% CLASSIFICATION

A reciprocating pump may be defined as a pump that operates using a bac$ and forth

straightline motion and frequently they driven by an air or steam reciprocation piston.

%otary driven reciprocating pumps are usually powered by electric motor and or by

internal combustion engines.

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* "

Fi)& 41/& C(t!"!2 sho"in) the inten!l +!ts of e,i+o,!tin) +iston +('+s&

Fi)& 413& On the to+ is ! t2+e of +l(n)e +('+ to+ to #otto' is the ,onst(,tion

of ! +l(n)e +('+&

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* 3 0,-0 -A#(T*(A()*

-ost of the pump bodies and plungers are made of stainless steel or other

corrosionresistant alloys. ,sually, the clearance between the plunger and the pump

body is very small. #n many cases the plunger and the pump body are /A00*&

4ground or polished as a set or pair5 to form a closetolerance fit. This close fit

eliminates lea$age within the pump and helps to meter the fluid discharge more

accurately.

The plunger in this pumps is prevented from lea$ing fluid by several sets of

).*'%+( 4' shaped crosssection5 pac$ing. The pac$ing materials may be rubber,

neoprene, nylon Teflon, or other materials depending on the fluid being pumped.

(ormally ad6usting the length of the stro$e, through a calibrated connecting rod

ad6ustment controls the amount of fluid discharge.

3&. DIAP4RA0M PUMP

The reciprocating pumps used in the power and desal plants, are diaphragm pumps.

They are use for chemicals dosing in the systems.

STRUCTURE FUNCTION AND MATERIALS OF DIAP4RA0M PUMP

Fig. 11 is a simplified section drawing of diaphragm pump, one of the chemical

dosing pumps.

". An electric motor

3. A pair of couplings

!. 7orm which is connected to couplings

1. 7orm wheel assembly. This is shown in main cross section drawing

5. )am assembly. *8plained later

9. ()ran$ shaft

:. )ross head &iaphragm

;. )am 0iston )onnecting rod.

<. Function is same as e8plained in !." .3

"=. 2land pac$ing

"". 0lunger

"3. 0late

"!. .andle assembly

"1. 2land pac$ing

"5. )am .ead

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* !

0ower is transmitted by an electric motor 4"5, which connects worm 4!5 to pair of

couplings 435.

7hen an electric motor is used to drive the pump, the worm transmits the power to

the worm wheel 415 and the ( cran$ shaft, via a slotted $ey way and $ey. The

(cran$ is attached eccentrically to the center of the shaft. )am 455 provide eccentric

motion to the connecting rod 4:5 plunger connected with connecting rod, provided

reciprocating motion and which pushed the oil lowered the diaphragm 4;5. +n the

other side of the diaphragm fluid pushed out through the discharge valve.

Fi)& 414& 5!6& Se,tion D!"in) of Di!+h!)'&

5#6& Vie" A1A&

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* 1 0,-0 -A#(T*(A()*

4&. STRO7E ADJUSTMENT T4ROU04 T4E N 1CRAN7

The principle of stepless stro$e ad6ustment 4from => to "==>5, with the pump

operating or idle, depends upon the upward and downward movement of the )ran$.

This movement changes the total value of the eccentricity of the cam and the )ran$

from => to "==>.

Figure 15 4a5 7hen the stro$e is =>, the ()ran$ is at the bottom.

4b5 7hen the stro$e is "==>, the ()ran$ is at the top.

Fi)& 418& Pin,i+le of the N1C!n9 !nd sto9e !d:(st'ent

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* 5

8&. FUNCTION OF REPLENIS4MENT C4AMBER

A replenishing chamber consists of an oil relief valve 43=5 and an Fig. 19 oil

compensating valve 4";5.

Fi)& 41;& Oil Flo" Di!)!' in the Di!+h!)' +('+

The oil relief valve actuates when the pressure in the displacement chamber is higher

than the specified value. 7hen the oil volume in the displacement chamber is greater, the

diaphragm touches the plate 4"15 prior to the completion of discharge stro$e, resulting in

an e8cessive pressure rise in the chamber.

An oil compensating valve actuates to provide the oil to the displacement chamber. 7hen

the plunger 4"!5 is on a suction stro$e, if the oll volume in the displacement chamber is

lower, the diaphragm touches the plate 4"15 prior to the completion of the suction stro$e,

producing a lower discharge flow rate and decreasing the pressure in the displacement

chamber. The negative pressure induces the entry of the oil in the oil compensating valve

to the displacement chamber, by the spring force created by the negative pressure.

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* 9 0,-0 -A#(T*(A()*

;&. MATERIAL

Following table shows the materials used in the main parts of the diaphragm pump.

T!#le 41%& M!tei!ls of '!in +!ts of ! di!+h!)' +('+&

<&. ROTAR= PUMPS

%otary pumps are positive displacement pumps in which the main pumping action is

caused by relative movement between the rotating and stationary elements of the

pumps distinguishes them from reciprocating positive displacement pumps. The

positive displacement nature of the pumping action of rotary pumps distinguishes

them from the general class of centrifugal pumps.

%otary pumps are useful in handling both fluids and liquids, where fluid is a general

term that includes, gases, vapors, and mi8tures thereof, and sometimes solids in

suspension, and where liquid is a more specific term that is limited to true liquids

which are relatively incompressible and relatively free of gases, vapors, and solids.

See Fig. 1: for various type of rotary pump.

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* :

Fi)& 41< so'e +ositi*e dis+l!,e'ent +('+s

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* ; 0,-0 -A#(T*(A()*

<&/ S4AFT AND COUPLIN0

-ost rotary pumps have drive shaft which accept drive torque from a power source.

The ma6ority of rotary pumps are mechanically coupled to the driving power source

with couplings of various type.

>&. ROTAR= E?TERNAL 0EAR PUMP

.eavyduty geartype pumps are able to withstand rugged operating conditions, are

simple in construction, and are economical in cost and maintenance 4Fig. 1;5. .igh

volumetric efficiency of gear type pumps depends on maintaining complete sealing of

all gear tooth contact surfaces. All gear surfaces are precision finished, and each pair

is matched carefully.

2eartype pumps are made with fewer wor$ing parts than many other types of

pumps. )astings are made of a special alloy iron, are precision machined, and are

capable of resisting bursting under severe shoc$ loading.

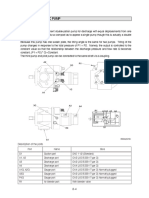

Fi)& 41> C(t!"!2 *ie" sho"in) +!ts of ! sin)le fl(id1+o"e +('+

*nd covers for fluid power pumps are usually specified and coded. These details are

important in specifying and ordering parts. The shaftend cover may be furnished in

either flange or pad mounting, and the portend cover may be provided either with no

porting or with end porting arrangements.

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* <

The drive shafts are also specified and ordered by code number. They may be either

splined or straight$eyed shafts.

A bearing carrier is used on tandem pumps and motors. #t is positioned between

ad6acent pumps or motors. The bearing carrier is also available with tapered thread,

SA* thread and straightthread fittings, and either with no porting or with left and?or

right hand side porting.

Some rotary geartype pumps for generalpurpose applications use a pac$ed bo8 for

the shaft seal. The pac$ing gland should be ad6usted to permit slight seepage for

best performance. A mechanical uses less power than the pac$ed bo8, has longer

service life under proper conditions, and does not require ad6ustment. Special

mechanical seals, such as 'iton 41===F5, and Teflon 45==+F and corrosion

resistant5, can be supplied for special conditions.

#n the rotary pump, a steam chest located between the casing and the outboard

bearing effectively transfers heat to both the pump and the pac$ing. #t can be used

with hot water, steam, and heat transfer oil@ or it can be used as a cooling chamber.

The steam chest is ideal for transferring thic$, viscous liquids, such as asphalt mi8es,

creosote, refined sugars, corn starch, etc.

An ad6ustable relief valve 1< in the pump faceplate eliminates outside piping and

protects the pump from e8cessive outlet line pressure@ it also permits the operator to

close the discharge line without stopping the pump, under standard operating

conditions. 'arious spring siAes are available to provide ad6ustments over the full

operating range of the pump from != to "== psi.

As aforementioned, the rotary geartype pumps are more simple in design, and they

have fewer wor$ing parts than the rotary vanetype and pistontype pumps. The

names of the various parts of a typical geartype pump can be learned from the

diagram and parts list in Fig. 1"=.

Fig. 1<. An ad6ustable relief valve protects the rotary geartype pump from e8cessive

outlet line pressure

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* "= 0,-0 -A#(T*(A()*

Fi)& 41%. E@ten!l & inten!l )e! +('+

Fi)& 41%%& Di!)!' !nd +!ts list fo ! )e! t2+e +('+

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* ""

A&. SCREB PUMPS

Screw pumps are a special type of rotary positive displacement pump in which the flow

through the pumping elements is truly a8ial. The liquid is carried between screw threads on

one or more rotors and is displaced a8ially as the screws rotate and mesh. #n all other rotary

pumps the liquid is forced to travel circumferentially, thus giving the screw pump with its

unique a8ial flow pattern and low internal velocities a number of advantages in many

applications where liquid agitation or churning is ob6ectionable.

Fi) 41%/& 1 Di!)!'s of s,e" !nd )e! ele'ents- sho"in) 5!6 !@i!l !nd 5#6

,i,('feenti!l

Fi)& 41%3& Sin)le1oto

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* "3 0,-0 -A#(T*(A()*

%.&. CONSTRUCTION

Basic types as indicated in the introduction, there are three ma6or types of screw

pumpsC

". Singlerotor

3. -ultiplerotor timed

!. -ultiplerotor untimed

The second and third types are available in two basic arrangements singleend and

doubleend. The doubleend construction is probably the best$nown version as it

was by far the most widely used f or many years because of its relative simplicity and

compactness of design.

Fi) 41%4 T2+es of s,e" +('+s

A&'A()*& )+,%S* -*).A(#)A/ -A#(T*(A()* )+,%S*

0,-0 -A#(T*(A()* /*SS+( 1 0A2* "!

%%&. ADVANTA0ES & DISADVANTA0ES OF A SCREB PUMP

ADVANTA0ES

7ide range of flows and pressures

7ide range of liquids and viscosities

.igh speed capability, allowing freedom of driver selection

/ow internal velocities

Selfpriming, with good suction characteristics

.igh tolerance for entrained air and other gases

-inimum churning of foaming

/ow mechanical vibration, pulsationfreeflow, and quiet operation

%ugged, compact design easy to install and maintain.

.igh tolerance to contamination in comparison with other rotary pumps

DISADVANTA0ES

%elatively high cost because of close tolerances and running clearances

0erformance characteristics sensitive to viscosity change

.igh pressure capability requires long pumping elements

-*).A(#)A/ -A#(T*(A()* )+,%S* A&'A()*& )+,%S*

/*SS+( 1 0A2* "1 0,-0 -A#(T*(A()*

You might also like

- Valve Timing Diagram 1.1 AIMDocument11 pagesValve Timing Diagram 1.1 AIMswiserd_cars1199No ratings yet

- Summer ReportDocument22 pagesSummer ReportAnchalGuptaNo ratings yet

- PUMPING TERMS LESSON DECODEDDocument17 pagesPUMPING TERMS LESSON DECODEDmister pogiNo ratings yet

- TECHNICAL Layne Engineering ManualDocument34 pagesTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNo ratings yet

- Apuntes Bombas (Inglés)Document19 pagesApuntes Bombas (Inglés)Amanita Roja BlancaNo ratings yet

- Centrifugal Pumps - Basic Concepts of Operation, Maintenance, and Troubleshooting - CheengineeringDocument40 pagesCentrifugal Pumps - Basic Concepts of Operation, Maintenance, and Troubleshooting - CheengineeringSayed KassarNo ratings yet

- John Pump CharacheristicDocument20 pagesJohn Pump CharacheristicjohnNo ratings yet

- Rotating EquipmentDocument235 pagesRotating EquipmentpraSHANT2331100% (5)

- LT3 00032 2 A - P24 P30SDocument67 pagesLT3 00032 2 A - P24 P30Sedgar_retuerto78No ratings yet

- Pumps - Compressors-Rev1Document8 pagesPumps - Compressors-Rev1nikitaNo ratings yet

- Water Pumps: Types, Components, and OperationDocument6 pagesWater Pumps: Types, Components, and OperationaadhanNo ratings yet

- Vertical Turbine Pump InformationDocument10 pagesVertical Turbine Pump Informationraghu_mn100% (1)

- lt3 00032 2 A p24 p30sDocument67 pageslt3 00032 2 A p24 p30sBruno SamaeianNo ratings yet

- Lesson Piston Valves: Sub-ObjectiveDocument4 pagesLesson Piston Valves: Sub-Objectivemister pogiNo ratings yet

- Lesson Centrifugal PumpDocument14 pagesLesson Centrifugal Pumpmister pogiNo ratings yet

- Lesson Main Stop Valve & Servomotor, Governing Valves and ServomotorDocument41 pagesLesson Main Stop Valve & Servomotor, Governing Valves and Servomotormister pogiNo ratings yet

- Section I-Balance of Plant - Introduction & Coverage 1.0Document20 pagesSection I-Balance of Plant - Introduction & Coverage 1.0fkghkNo ratings yet

- Air or Gas Driven Injectors: Description ApplicationsDocument8 pagesAir or Gas Driven Injectors: Description ApplicationsEyo Etim0% (1)

- Phase II Steering Gear Q&ADocument11 pagesPhase II Steering Gear Q&ANithin Varghese100% (2)

- Lesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet ValvesDocument15 pagesLesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet Valvesmister pogiNo ratings yet

- Module 4Document40 pagesModule 4Himanshu ChaudhariNo ratings yet

- Home-Made Hydraulic Ram Pump: Click Here To See A Picture of An Assembled Ram PumpDocument54 pagesHome-Made Hydraulic Ram Pump: Click Here To See A Picture of An Assembled Ram PumpbracioNo ratings yet

- PVV 540 PumpDocument14 pagesPVV 540 PumpMONANo ratings yet

- Maintaining Centrifugal PumpsDocument4 pagesMaintaining Centrifugal Pumpsaserf251No ratings yet

- Reciprocating compressor guide covering types, parts, and constructionDocument59 pagesReciprocating compressor guide covering types, parts, and constructionAhmad Aloudah100% (3)

- IFP - Perrin Denis - Well Completions and Servicing (1) - 190-238 (2) - 20-30Document11 pagesIFP - Perrin Denis - Well Completions and Servicing (1) - 190-238 (2) - 20-30Yves Emmanuel KouadioNo ratings yet

- Thermal Engineering Lab ManualDocument52 pagesThermal Engineering Lab ManualBharath ReddyNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Abs VmoaDocument7 pagesAbs VmoaTxavitoNo ratings yet

- 17-Oil Centrifuge PDFDocument89 pages17-Oil Centrifuge PDFUmangtarangNo ratings yet

- 4 PumpsDocument26 pages4 PumpsdhasdjNo ratings yet

- 2300 Series ManualDocument24 pages2300 Series ManualJuprayNo ratings yet

- Performance Characteristic of Centrifugal PumpDocument30 pagesPerformance Characteristic of Centrifugal PumpthongpvgasNo ratings yet

- Gear PumpDocument58 pagesGear Pumpsgupta_615796100% (5)

- Model F470 External Resetting Multimatic Deluge ValvesDocument16 pagesModel F470 External Resetting Multimatic Deluge ValveseduardoNo ratings yet

- Sucker Rod PumpDocument57 pagesSucker Rod PumpashrafsaberNo ratings yet

- Carburetor Setting Handbook: Complete Guide to Adjusting Dell'Orto CarburetorsDocument11 pagesCarburetor Setting Handbook: Complete Guide to Adjusting Dell'Orto Carburetorsdanijel22100% (1)

- Single-Stage, Double Suction Vertical PumpsDocument20 pagesSingle-Stage, Double Suction Vertical Pumpsسامح الجاسمNo ratings yet

- Farval Dr45 & Dr460a Reversing ValvesDocument8 pagesFarval Dr45 & Dr460a Reversing ValvesRobinson MarinNo ratings yet

- Farval Dr45 & Dr460a Reversing ValvesDocument8 pagesFarval Dr45 & Dr460a Reversing ValvesanwarmughalNo ratings yet

- Haskel Liquid Pump SpecsDocument30 pagesHaskel Liquid Pump SpecsMarcos Rodrigues Dos SantosNo ratings yet

- Industrial Training Report: (Diesel Shed Tughalakabad)Document23 pagesIndustrial Training Report: (Diesel Shed Tughalakabad)Vikas DhuliNo ratings yet

- 2400 Series IORPMDocument24 pages2400 Series IORPMab5951No ratings yet

- Book LayoutDocument8 pagesBook LayoutaamenaNo ratings yet

- Modeling 6.1 Development of Non-Linear Model: Tuning of Injection Molding MachineDocument19 pagesModeling 6.1 Development of Non-Linear Model: Tuning of Injection Molding Machinegoldy243usNo ratings yet

- Bombas de Tinta - 1Document3 pagesBombas de Tinta - 1leandrouniaNo ratings yet

- Engineering Encyclopedia: Centrifugal PumpsDocument70 pagesEngineering Encyclopedia: Centrifugal PumpsMajdi Belguith67% (3)

- 325 Lanzhou 3NB1300C Instruction Manual PDFDocument21 pages325 Lanzhou 3NB1300C Instruction Manual PDFOilGasManNo ratings yet

- Home-Made Hydraulic Ram Pump1Document9 pagesHome-Made Hydraulic Ram Pump1ainozamaNo ratings yet

- 1995 Ford Escort 1Document11 pages1995 Ford Escort 1Francisco SanchezNo ratings yet

- 3306 Industrial Engine 64Z05381-UP (SEBP1989 - 33) - Sistemas y ComponentesDocument15 pages3306 Industrial Engine 64Z05381-UP (SEBP1989 - 33) - Sistemas y ComponentesLynda Carroll100% (2)

- Turbine OverhaulsDocument33 pagesTurbine OverhaulsArjun Saoji100% (1)

- PT-104 Pumping Trap Installation and MaintenanceDocument12 pagesPT-104 Pumping Trap Installation and MaintenancevkumaranNo ratings yet

- Copt ManualDocument79 pagesCopt ManualPradeep Shukla94% (17)

- Group 2 Hydraulic Pump: 1. GeneralDocument8 pagesGroup 2 Hydraulic Pump: 1. GeneralJet AcostaNo ratings yet

- Bomba Haskel..Document24 pagesBomba Haskel..Luis Cervantes BarradasNo ratings yet

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineFrom EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineNo ratings yet

- Growing Catfish in The PhilippinesDocument4 pagesGrowing Catfish in The Philippinesmister pogiNo ratings yet

- 20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZDocument12 pages20 Piping Supervisor Interview Questions Answers - InterviewQuestionsAZmister pogi100% (1)

- How To Acclimate Strawberry Plants - Stark Bro'sDocument5 pagesHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNo ratings yet

- SWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and SystemsDocument8 pagesSWCC Training Center Al-Jubail Advanced Operations Training Course MSF Desalination Plants Technology and Systemsmister pogiNo ratings yet

- Manual For Welding InspectorDocument308 pagesManual For Welding Inspectormister pogi100% (1)

- Atty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC ProceedingsDocument15 pagesAtty. Manuel J. Laserna Jr. - Labor Cases FAQs - NLRC Proceedingsmister pogiNo ratings yet

- How To Acclimate Strawberry Plants - Stark Bro'sDocument5 pagesHow To Acclimate Strawberry Plants - Stark Bro'smister pogiNo ratings yet

- Stub End LengthDocument1 pageStub End Lengthmister pogi100% (1)

- 4air Con04Document24 pages4air Con04mister pogiNo ratings yet

- Air Con 01overDocument19 pagesAir Con 01overmister pogiNo ratings yet

- Air Con 03 OverDocument30 pagesAir Con 03 Overmister pogiNo ratings yet

- 4air Con05Document6 pages4air Con05mister pogiNo ratings yet

- Air Con 02 OverDocument50 pagesAir Con 02 Overmister pogiNo ratings yet

- Msfpt2 LesDocument9 pagesMsfpt2 Lesmister pogiNo ratings yet

- 4air Con02Document9 pages4air Con02mister pogiNo ratings yet

- Lesson Introduction To CompressorsDocument12 pagesLesson Introduction To Compressorsmister pogiNo ratings yet

- Lesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet ValvesDocument15 pagesLesson Turbine Throttle, Control & Non-Return Valves: 1.0 Main Steam Inlet Valvesmister pogiNo ratings yet

- Turbine 2Document32 pagesTurbine 2mister pogiNo ratings yet

- 3air Con02Document12 pages3air Con02mister pogiNo ratings yet

- Lesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration SystemsDocument4 pagesLesson Introduction To Refrigeration: Air Conditioning & Refrigeration Lesson 1 Page 1 Basic Refrigeration Systemsmister pogiNo ratings yet

- Lesson Basic RiggingDocument15 pagesLesson Basic Riggingmister pogiNo ratings yet

- 10air Con04Document7 pages10air Con04mister pogiNo ratings yet

- 10air Con03Document10 pages10air Con03mister pogiNo ratings yet

- 3air Con03Document10 pages3air Con03mister pogiNo ratings yet

- Lesson Heat Pumps and Complete Air Conditioning SystemDocument14 pagesLesson Heat Pumps and Complete Air Conditioning Systemmister pogiNo ratings yet

- Lesson Basic Air Conditioner SystemsDocument7 pagesLesson Basic Air Conditioner Systemsmister pogiNo ratings yet

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDocument26 pagesLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNo ratings yet

- Lesson Rigging SafetyDocument14 pagesLesson Rigging Safetymister pogiNo ratings yet

- Lesson Heating and CoolingDocument8 pagesLesson Heating and Coolingmister pogiNo ratings yet

- Turbine 3Document11 pagesTurbine 3mister pogiNo ratings yet

- Autocarro - Astra hd9 - E3 - 8x8 - GBDocument4 pagesAutocarro - Astra hd9 - E3 - 8x8 - GBMaurizio De LucaNo ratings yet

- KX-21 Parts List Part Code Number Order: KX-21 S/M A-4-1 Revised May 2001Document6 pagesKX-21 Parts List Part Code Number Order: KX-21 S/M A-4-1 Revised May 2001Phong DoNo ratings yet

- How To Wire Up A 1uzfe 2uzfe and 3uzfe Including Diagrams PDFDocument87 pagesHow To Wire Up A 1uzfe 2uzfe and 3uzfe Including Diagrams PDFEdson Jalla100% (1)

- Tohatsu Outboard Internal Engine PartsDocument1 pageTohatsu Outboard Internal Engine PartsMarine Parts ChinaNo ratings yet

- Cat Blade 6a 6S Ser 15C 16C 85CDocument71 pagesCat Blade 6a 6S Ser 15C 16C 85Cwiluxaju100% (1)

- 0 200 EngeineDocument6 pages0 200 EngeineVipin ChahalNo ratings yet

- Introduction About CI EngineDocument2 pagesIntroduction About CI Enginevijayakumar100% (1)

- 00 Truck Crane Inspection FormDocument10 pages00 Truck Crane Inspection FormRiza DSNo ratings yet

- Fits and Clearances - Contents: Propeller Maintenance Manual 132ADocument8 pagesFits and Clearances - Contents: Propeller Maintenance Manual 132AAlexis KidemaNo ratings yet

- 37 Drillable Cementing BushingDocument1 page37 Drillable Cementing BushingGhinet Teodor-ioanNo ratings yet

- Service and Maintenance Manual: ModelDocument116 pagesService and Maintenance Manual: ModelAdriano Alves SilvaNo ratings yet

- 6.75in Ultra XL - DuraMaxDocument2 pages6.75in Ultra XL - DuraMaxNuring Tyas Wicaksono0% (1)

- Ampacity of Copper Conductors Including Wire in RacewayDocument2 pagesAmpacity of Copper Conductors Including Wire in RacewayTenda Kyojin0% (1)

- Design and Fabrication of Angular DrillingDocument8 pagesDesign and Fabrication of Angular DrillingvasanthNo ratings yet

- Manual Bombas Series 300Document24 pagesManual Bombas Series 300Marco GuachunNo ratings yet

- Additional Works BOQ-EDITEDDocument39 pagesAdditional Works BOQ-EDITEDLoralie SanggaNo ratings yet

- 02 - Sistema MotorDocument86 pages02 - Sistema Motorludimila.dinizNo ratings yet

- Installation and Operating Manual: Tri TR Turbo Coupling With Constant Fill and PulleyDocument128 pagesInstallation and Operating Manual: Tri TR Turbo Coupling With Constant Fill and PulleyChintan GorasiaNo ratings yet

- Hydraulics Basic LevelDocument14 pagesHydraulics Basic LevelIndhusekaran NatarajanNo ratings yet

- L1350Document4 pagesL1350RodrigoAndrésMondacaArriazaNo ratings yet

- Candy Go128-86sDocument34 pagesCandy Go128-86sΙΩΑΝΝΗΣ ΣΑΜΑΡΙΚΑΣNo ratings yet

- Spare Parts Catalogue: (Export)Document75 pagesSpare Parts Catalogue: (Export)visugue_26No ratings yet

- Renegade Sport S 300 Epa 2017 Parts Catalogue 2016 09 05Document33 pagesRenegade Sport S 300 Epa 2017 Parts Catalogue 2016 09 05JeovannyAlexanderMatamorosSanchezNo ratings yet

- Dealer Code Dealer Name Quo No Quo Date Cust Code Cust Name Mac No Item No Part NoDocument6 pagesDealer Code Dealer Name Quo No Quo Date Cust Code Cust Name Mac No Item No Part NoJonathan KaleNo ratings yet

- Closed Cooling Water System (Sample)Document37 pagesClosed Cooling Water System (Sample)shahidaNo ratings yet

- Revisions List: W4 Series High Pressure Breathing Air Compressor User ManualDocument65 pagesRevisions List: W4 Series High Pressure Breathing Air Compressor User ManualjaimeherzNo ratings yet

- Ctc-211 Engine SystemsDocument333 pagesCtc-211 Engine SystemsDorival VenâncioNo ratings yet

- 4 Common Engine Misfire CausesDocument11 pages4 Common Engine Misfire Causesaemo.ai90No ratings yet

- Lab Report 12Document8 pagesLab Report 12mamoona noreenNo ratings yet

- ReferenceDocument190 pagesReferencekhairalla mohamedNo ratings yet