Professional Documents

Culture Documents

KilnLine Operation

Uploaded by

breakthrough198889%(9)89% found this document useful (9 votes)

1K views32 pageshay

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthay

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

89%(9)89% found this document useful (9 votes)

1K views32 pagesKilnLine Operation

Uploaded by

breakthrough1988hay

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 32

Page 1 Training THALOFA

Operation of the kiln line

Training

Klaus Grittner

Polysius Services

Polysius Headquarters / Germany

19. May 13. June 2008

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 2

Heating Up

Starting Sequence

Start Up

Increasing Performance

Normal Operation

Optimisation

Main Control Loops

Normal Shut Down

Emergency Power Consumers

Operation of the Kiln Line

Page 3 Training THALOFA

Rotary kiln

Clinker cooler

P

r

e

h

e

a

t

e

r

C

a

l

c

i

n

e

r

Tertiary Air Duct

1400 C

Clinker Production Line Clinker Production Line

1700 C 280 C; to EP

900 C

340 C; to raw mill

and / or EP

80 C

fuel

55 60 %

fuel

40 45 %

860 C

80 - 100 C

Ambient air temp.

350 C

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 4

Heating up the kiln line

The fuel burns with the smallest possible amount of combustion air.

There is no CO, or only slightly formation of CO at the kiln inlet

Most of the heat remains in the clinkering zone

The flame is short and compact.

for the new kiln heating up takes approx.

-- 48 hrs. (with new brick lining)

-- 30 36 hrs. (after normal maintenance shut down)

Page 5 Training THALOFA

Example for 1st heating up the kiln line

Continuous turning

or heavy fuel oil

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 6

Tilting and turning the kiln

During the heating up the kiln should be continuously inched and turned,

the guide values for a new kiln are :

0 12 h: 1/3 revolution with auxiliary drive every 30 minutes

12- 24 h: 1/3 revolution with auxiliary drive every 20 minutes

24 36 h: 1/3 revolution with auxiliary drive every 15 minutes

36 46 h: 1/3 revolution with auxiliary drive every 10 minutes

46 - 46 h: continuous rotation with auxiliary drive 0,1 rpm

from 48 h: turn kiln with main drive app. 0,6 rpm

and start feed

Page 7 Training THALOFA

Starting-up Sequence of the Kiln Line

Filter dust transport

De-dusting plant

De-dusting filter fan

Kiln waste gas fan (ID-fan)

Remarks:

Control air compressors,

cooling water system.

Auxiliaries of the kiln line

with closed damper

with closed damper

rapping system

Page 8 Training THALOFA

Starting-up Sequence of the Kiln Line

Remarks:

Clinker transport

Cooler waste air filter dust transport

Bull Nose cooling fan

Fuel supply (fuel oil or coal)

CO < min.

- analyser behind cyclone 2

- analyser before bag house

Primary air fan for MB

With damper closed

cooler roof protection

Page 9 Training THALOFA

Starting-up Sequence of the Kiln Line

Cooling for roller crusher

Remarks:

Cooler exhaust air fan

Cooler de-dusting filter

Roller crusher

Cooling air fans for

recuperation zone

With damper closed

With damper closed

Page 10 Training THALOFA

Starting-up Sequence of the Kiln Line

Remarks:

Cooler grates

Kiln main drive

Cooling fans for kiln outlet

Cooling fans for kiln shell

Main burner many preconditions (CO, T.)

slow speed 0.6 rpm

only if main drive is running

Page 11 Training THALOFA

Starting-up Sequence of the Kiln Line

Kiln feed

Remarks:

Pre-heater cleaning systems

Open tertiary air dampers

Calciner burners

Cooling tower

app. 20 %

Fuel MIN

Page 12 Training THALOFA

Start of the Kiln Line / Kiln Feed

For kiln feed start sufficient personnel has to be in the

pre-heater to watch the function of the pendulum flaps

and material flow!!!

1. Cooler Grates: ~ 3 - 5 stroke/min, (minimum speed)

2. Kiln main drive : 0,6 0,8 rpm

3. Cooler Fans : ~ 30% of the nominal quantity

kiln hood pressure: -1 to -2 mm WG (Automatic control)

4. Main burner fuel: Heavy oil: ~1.000 Nm/h

Coal / Pet coke: ~ 6.000 kg/h

5. Start Kiln Feed : ~30 to 35% of nominal feed rate (new kiln, no coating)

att.: there is a time delay between kiln feed group start

and real kiln feed.

6. Adjust draft after : - 12 to -15 mbar by ID-fan/ dampers exhaust gas duct.

cyclone pre-heater

!

Page 13 Training THALOFA

Start of the Kiln Line / Kiln Feed

7. Main burner : Increasing of the fuel quantity to specific

heat consumption 1300 ...1500 kcal/kg clinker

Att. ! : Its only a guide value!!!

8. Start PC-burner : Sufficient Oxygen - after cyclone stage 2: > 2,5 %

- after DOPOL: > 4,0 %

Fuel distribution: MB ~70-75%, PC ~25-30%.

Kiln inlet : ~ 1050 C,

After stage I: ~ 860 C,

Hot meal 1: ~ 840 C

9. Adjustment of according to kiln feed ( ~ 2,0 Nm/kg clinker)!!!

cooling air:

10. Observing clinker visual check, kiln camera, pyrometer,

formation: observe the power consumption of the kiln drive.

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 14

Gas analyser / Alarm set points

Gas analyser behind kiln

-- CO (max 0,8 %, Alarm)

-- O

2

(min 1,0 %, Alarm)

Gas analyser behind Calciner

-- CO (max-max. 0,8 %; calciner burner)

-- O

2

normal value app. 2,5 %

Gas analyser before bag house

-- CO (max-max 1,1 %; main burner)

-- O

2

normal value app. 4,0 %

CO > 0.6 % alarm

CO > 0.8 % shut off the calciner burners

CO > 1,1 % stop the main burner

Page 15 Training THALOFA

Increasing the kiln performance

Precondition: granulated clinker in the sintering zone and in the clinker cooler

1. Increasing the gas flow through via damper or speed of ID-fan- / filter-fan

the cyclone pre-heater Oxygen content behind cyclone

stage 5 > 4,0 % before increasing fuel.

After ID-fan: keep -50 mm WG (by EP-fan)

2. Stepwise opening of the (Oxygen at kiln inlet adjust to ~2 3 %)

tertiary flaps

3. Increasing of clinker keep kiln hood pressure -1 to -2 mm WG.

cooler air quantity (control loop)

Page 16 Training THALOFA

Increasing performance

4. increase of kiln feed and fuel target of fuel distribution:

-- MB ~ 45%,

-- PC ~ 55%

5. increase of kiln speed according to the kiln feed

6. close fresh air flap (if open) depends on temp. after the pre-heater

7. operate clinker cooler with -- until a clinker bed dept ~ 500 mm

slow speed -- pressure in aeration chamber 1 ~ 40 mbar)

Same above mentioned steps for further increasing of the kiln feed!

Page 17 Training THALOFA

Increasing performance

Cooler grate velocity (watch the pressure!!!) and cooling air

quantities have to be adapted

(1,8 2 Nm/kg Clinker)!

Att.: Secondary air and tertiary air temperatures will rise! The specific heat

consumption will reduce!!! Prevent overheating the sintering zone!!!

Take attention to: the kiln inlet temperature (max. 1150C),

the hot meal temperature (max 870C),

the temperature after pre-heater

(normal 340C, max. 450C):

Page 18 Training THALOFA

Normal Operation

Preconditions of trouble-free operation:

- most homogeneous raw meal (LSF, SR, AR)

- constant kiln feed (variation < 1 % / minute)

- constant fuel rates (variation < 1 % / minute)

- constant gas flows, cooling air flows

Page 19 Training THALOFA

Optimisation of the plant

-- Process parameters

-- Typical operating parameters

-- Burner-/ Flame adjustments

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 20

Process Parameters

1. kiln feed rate tons / h

2. Specific heat consumption, kcal / kg (calculated)

3. Total fuel rate , tons / h

4. Proportion of fuel to pre calciner / riser, %

5. Secondary air temperature , degree C

6. ID fan draft , mbar

7. Pre-heater exhaust gas temperature, degree C

8. Kiln inlet gas analyser O

2

%, CO %, NOx mg

9. Cyclone stage II gas analyser O

2

%, CO %, NOx mg

10. After ID.-fan gas analyser O

2

%, CO %, NOx mg

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 21

11. Water into the cooling tower l / h

12. Kiln feed material (meal chute 1) SO

3

%, LoI. %, (Lab. results)

13. Kiln drive power , kW, Amps

14. Primary air pressure mbar

15. Clinker cooler ventilators, air volume Nm

3

/ h

16. (Primary air, Nm

3

/ h)

17. Pre-heater profile (Temp. Pressure) C; mbar;

18. Specific Calculations kcal/kg clinker

-- Specific kiln volume loading, tons / mday

-- Gas velocity in burning zone, m / sec

-- Specific heat loading of burning zone, Mcal / h per m

2

Process Parameters

Page 22 Training THALOFA

Typical Operation Parameters

Temp.: -- gas duct 1: 860.... 880 C

-- meal chute 1: 840.... 860 C

-- tertiary air: 850.... 950 C

-- after pre heater: 320.... 340 C

Press.: -- Kiln Hood: - 0,1- 0,3 mbar

-- Kiln Inlet: - 4. .- 6 mbar

-- Gas Duct 1: -14.- 16 mbar

-- after Pre heater: - 50.- 60 mbar

Clinker cooler: -- Chamber 1 pressure 50... 60 mbar

-- Secondary air temp. 900.... 1000 C

-- Cooler exhaust air temp. 250.... 300 C

-- Clinker temperature 80... 100 C

Page 23 Training THALOFA

-- to burn a good clinker quality, but prevent damages in the refractory.

-- to build and to keep good coating formation.

as protection of kiln bricks and reduced kiln shell temperature,

but also to avoid coatings rings etc.

-- good heat transfer to the material by radiation and convection.

Burner- / Flame Adjustment

Page 24 Training THALOFA

Burner- / Flame Adjustment

Main Burner Fuel: - Temperature of sintering zone

- Kiln inlet temperature

- Kiln main drive power (A or kW)

- Free lime (CaO) in the clinker

Total Fuel: - Specific heat consumption (kcal/kg clinker)

- Temperatures of meal and gas in the pre-heater

Fuel Calcinator: - Hot meal temperature

- Degree of calcination (92...95%)

Attention: Orientation only! Parameters/Results may overlap!!!

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 25

Page 26 Training THALOFA

Gas conditions: CO ---> to be prevented!!!

min. of Oxygen is required!

Oxygen after pre-heater: ~ 4 % by damper or fan speed

Oxygen after stage II ~ 2 3 % by damper or fan speed

Kiln inlet: ~ 1,5 - 2 % by Tertiary Air Flaps

-- more open:

Oxygen stage II up / kiln inlet down!!!

-- more closed:

Oxygen stage II down / kiln inlet up!!!

Optimal Operation:

SilzR 13 Jun 2008 S:\Team\Training\THALOFA\CD-for-Customer\05-04-KilnLine-Operation.ppt Page 27

Kiln hood pressure Target: -0.1 mbar

Actuator: Cooler exhaust fan speed or damper

Under grate press. Target: constant at set point

(chamber 1 or 2) Actuator hydraulic drive for grates

Cooler air flow Target: constant at set point

Actuator: Cooler fan speed or damper position

Press. after kiln ID fan Target: - 5 mbar

Actuator: EP-fan speed or damper position

Temp. after Target: 160-190 C

Cooling tower Actuator: Water valve at the return line

Main control loops of a kiln plant

Page 28 Training THALOFA

Normal shut-down of the kiln plant

Generally

-- reducing of the kiln feed in steps of app. 5%

-- minimal kiln feed is about 4050%

-- an empty kiln can be easier heated-up and re-started!

Stop of PC-Burners and kiln feed

Reduce fuel at the main burner

Reduce pre-heater draft

Close the Tertiary air sliders / flaps

Stop of main burner

primary fans to be kept in operation (for cooling!!!)

Close the DOPOL-flaps to 10-15%

Page 29 Training THALOFA

Normal shut-down of the kiln plant

DOPOL-fan: dampers to be closed

Clinker cooler fans: dampers to be closed

Cooler exhaust air fan: controlled by kiln hood pressure measurement,

or set to minimum value

Kiln to be tilted! - during cooling down

- if raining continuously with auxiliary drive

- 1st and 2nd hour each 10 min 120

- 3rd hour each 15 min 120

- 4th hour each 20 min 120

- 5th till 8th hour each 25 min 120

- then... each 30 min 120

...till a kiln shell temperature (sintering zone) of about 100C is reached

cooler track units: to be operated in intervals

Page 30 Training THALOFA

Emergency power consumers

-- Emergency lighting

-- Communication systems

-- UPS unit for computer and process automation equipment

-- Control voltage for the total kiln plant

-- Cooling water supply system

-- Dampers in DOPOL exhaust gas duct

-- Kiln auxiliary drive including lubrication)

-- Oil pumps for circulation lubrication system for roller bearings

-- Primary air fans for all burners including actuators

-- Protective air fan for sintering zone pyrometer

-- Actuators for damper in tertiary air duct

-- Fan for kiln outlet cooling

-- Cooling air fans for roller crusher

-- Cooling air fans for recuperation section

Page 31 Training THALOFA

Stop

Timer

Filter dust transport

CLINKER Transport

5 min

Stop Timer

15 min

failure of 2 or

more air fans

failure of one fan

CALCINER

BURNER

Stop Timer

0,5 hour

FILTER FAN

KILN ID-FAN

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

STOP

MAIN DRIVE

KILN FEED

MAIN BURNER

PRIMARY AIR FAN

CO

Stage 2 > Max Max

Temperature

Preheater > Max Max

CO

Preheater > Max Max

Temperature

Preheater > Max Max

Grate 1

CLINKER

COOLER

CLINKER

COOLER

CLINKER

COOLER

Exhaust air

fan

STOP

STOP

Stop

Timer

5 min

M

a

i

n

P

l

a

n

t

I

n

t

e

r

l

o

c

k

Rotary Kiln

Grate 2

Page 32 Training THALOFA

You might also like

- Start Up Procedures PDFDocument18 pagesStart Up Procedures PDFbulentbulut100% (1)

- Burner - Standard Requirements: Technical Development Program For Process Performance EngineersDocument64 pagesBurner - Standard Requirements: Technical Development Program For Process Performance Engineersvikubhardwaj922486% (7)

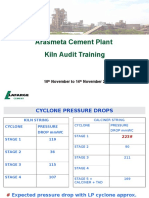

- Kiln Audit Training IntroductionDocument15 pagesKiln Audit Training IntroductionTamer Fathy100% (1)

- PREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTDocument19 pagesPREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTali100% (2)

- 081 - TSP HUA400 20080305 Kiln Audit Dec07Document30 pages081 - TSP HUA400 20080305 Kiln Audit Dec07mkpq100% (2)

- Clinker FormationDocument120 pagesClinker FormationDragos PlaesuNo ratings yet

- Clinker CoolersDocument76 pagesClinker CoolersShariq Khan100% (6)

- Mod 6Document49 pagesMod 6mkpq100% (1)

- Alk-SO3-Cl Balance - v2.1Document4 pagesAlk-SO3-Cl Balance - v2.1shani5573100% (4)

- The Effects of Oxygen Enrichment On ClinkerDocument9 pagesThe Effects of Oxygen Enrichment On ClinkerNael100% (1)

- Duoflex Burner CoalDocument30 pagesDuoflex Burner CoalChay Nag100% (4)

- How To Measure False AirDocument3 pagesHow To Measure False AirTamer Fathy100% (3)

- Thermal Expansion Effects and Mechanical Issues for Kiln PatrollersDocument30 pagesThermal Expansion Effects and Mechanical Issues for Kiln Patrollersbulentbulut100% (3)

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pages117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBmkpqNo ratings yet

- Clinker Kiln TheoryDocument37 pagesClinker Kiln TheoryMehmet C100% (1)

- Alkali Khaled PDFDocument21 pagesAlkali Khaled PDFbulentbulut100% (1)

- By Pass SystemDocument56 pagesBy Pass SystemIrshad Hussain100% (2)

- V4 Process Technology 2Document724 pagesV4 Process Technology 2RRHH100% (4)

- Flame MomentumDocument30 pagesFlame MomentumSanth Raul100% (7)

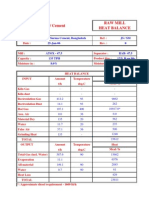

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- CoolersDocument297 pagesCoolersMUNNALURU UMAKANTHA RAONo ratings yet

- Coal Mill SafetyDocument17 pagesCoal Mill SafetyJoko Dewoto100% (4)

- SO3 Build Up and ControlDocument6 pagesSO3 Build Up and ControlM. Ali Parvez100% (1)

- Circulation Phenomena in the Clinkerization ProcessDocument58 pagesCirculation Phenomena in the Clinkerization ProcessZein Khalifa100% (2)

- ROTAFLAM Burner AdjustmentDocument5 pagesROTAFLAM Burner AdjustmentMuhammad Zaghloul100% (2)

- Blaine Vs OutputDocument2 pagesBlaine Vs OutputAaron HortonNo ratings yet

- Cement Kilns-Chlorine Impact On ProcessDocument27 pagesCement Kilns-Chlorine Impact On Processmuhaisen2009100% (4)

- Combustion Engineering: Technical Development Program For Process Performance EngineersDocument36 pagesCombustion Engineering: Technical Development Program For Process Performance Engineersvikubhardwaj9224100% (1)

- How To Line The Burner Pipe PDFDocument19 pagesHow To Line The Burner Pipe PDFMustafa Ramadan100% (2)

- Blaine Vs ResiduesDocument3 pagesBlaine Vs ResiduesVisnu Sankar100% (2)

- Multifuel Rotary Kiln Burner: Presented At: "1 Burner Day" 18 February 2004"Document38 pagesMultifuel Rotary Kiln Burner: Presented At: "1 Burner Day" 18 February 2004"mustafNo ratings yet

- Kiln Emergency YSDocument50 pagesKiln Emergency YSShadi Al Habbal100% (3)

- Burning DashboardDocument3 pagesBurning DashboardMehmet C100% (1)

- Kiln Cooler Heat Mass BalanceDocument84 pagesKiln Cooler Heat Mass BalancePrabhakar Reddy PeramNo ratings yet

- Ask DR. CLARK - OdtDocument50 pagesAsk DR. CLARK - Odtmauryaraj200750% (2)

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Coating kiln refractory liningsDocument8 pagesCoating kiln refractory liningsAnonymous NxpnI6jC100% (1)

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- Mechanism of Clinker Coating Formation & FlameDocument39 pagesMechanism of Clinker Coating Formation & FlameNael93% (14)

- K.F To Cl. FactorDocument1 pageK.F To Cl. FactorvvijaybhanNo ratings yet

- Kiln Operator Emergency GuideDocument12 pagesKiln Operator Emergency GuideLe HoangNo ratings yet

- Process Problem Trouble ShootingDocument13 pagesProcess Problem Trouble ShootingMin Zayar100% (2)

- What Is A Process ControlDocument17 pagesWhat Is A Process ControlpashaNo ratings yet

- Report On Cement MillDocument9 pagesReport On Cement MillYounas Khan100% (1)

- Pyro Process Equipment PDFDocument114 pagesPyro Process Equipment PDFMohamedNo ratings yet

- Cyclone DPDocument2 pagesCyclone DPTamer Fathy0% (1)

- Cooler Design and Operation CriteriaDocument19 pagesCooler Design and Operation Criteriatricky777100% (1)

- Course 3 - Clinker Production: 3.4 CalcinerDocument28 pagesCourse 3 - Clinker Production: 3.4 CalcinerAndreea Ștefura100% (1)

- Measurement DDocument37 pagesMeasurement Dgvrr1954100% (2)

- Optimize Vertical Roller Mills OperationsDocument4 pagesOptimize Vertical Roller Mills OperationsSai Sricharan Reddy83% (6)

- A Better Kiln CoatingDocument2 pagesA Better Kiln Coatingamir100% (4)

- IEE Handout 2Document2 pagesIEE Handout 2Sunil DeshmukhNo ratings yet

- Kiln Control and Operation - Infinity For Cement EquipmentDocument74 pagesKiln Control and Operation - Infinity For Cement EquipmentRizwanKhanNo ratings yet

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Operation of The Kiln Line: TrainingDocument32 pagesOperation of The Kiln Line: TraininglafecapoNo ratings yet

- Auxiliary BoilerDocument56 pagesAuxiliary BoilerNirdosh AnanthNo ratings yet

- Interview Q and Ans FOR THARMAL POWER PLANTDocument15 pagesInterview Q and Ans FOR THARMAL POWER PLANTRajkumar Prasad100% (2)

- Ref CompDocument36 pagesRef Compwahyudi0906No ratings yet

- ITK-233-6 - Power Production & RefrigerationDocument30 pagesITK-233-6 - Power Production & RefrigerationAndy Noven KrisdiantoNo ratings yet

- Mid-Term Training EvaluationDocument26 pagesMid-Term Training EvaluationVishalSharmaNo ratings yet

- Apache LicenseDocument5 pagesApache Licenseapi-286574869No ratings yet

- 3ee-Cement Mill Dosing SystemDocument25 pages3ee-Cement Mill Dosing Systembreakthrough1988No ratings yet

- Dry Process KilnDocument20 pagesDry Process KilnISLAM I. Fekry100% (8)

- 3ee-Cement Mill Dosing SystemDocument25 pages3ee-Cement Mill Dosing Systembreakthrough1988No ratings yet

- 3e9-Cement Packing and DispatchingDocument30 pages3e9-Cement Packing and Dispatchingbreakthrough1988No ratings yet

- 3ee-Cement Mill Dosing SystemDocument25 pages3ee-Cement Mill Dosing Systembreakthrough1988No ratings yet

- 3e2-Limestone and Clay PreblendingDocument15 pages3e2-Limestone and Clay Preblendingbreakthrough1988No ratings yet

- 3ee-Cement Mill Dosing SystemDocument25 pages3ee-Cement Mill Dosing Systembreakthrough1988No ratings yet

- Optimizing Kiln System OperationDocument98 pagesOptimizing Kiln System OperationMarvin Garcia Catungal83% (24)

- Check Your English Vocabulary For TOEICDocument81 pagesCheck Your English Vocabulary For TOEICRobby100% (27)

- Optimizing Kiln System OperationDocument98 pagesOptimizing Kiln System OperationMarvin Garcia Catungal83% (24)

- Kiln System Operations - by Gerald L Young and F. M.millerDocument44 pagesKiln System Operations - by Gerald L Young and F. M.millersadatjafari100% (2)

- Optimizing Kiln System OperationDocument98 pagesOptimizing Kiln System OperationMarvin Garcia Catungal83% (24)

- Kiln System Operations - by Gerald L Young and F. M.millerDocument44 pagesKiln System Operations - by Gerald L Young and F. M.millersadatjafari100% (2)

- Kiln System Operations - by Gerald L Young and F. M.millerDocument44 pagesKiln System Operations - by Gerald L Young and F. M.millersadatjafari100% (2)

- 3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetDocument2 pages3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetSergioNo ratings yet

- GA 33 KV VCB HT Panel - Siddharth Nagar Project. UPDocument17 pagesGA 33 KV VCB HT Panel - Siddharth Nagar Project. UPaayushNo ratings yet

- English 9 - Q2 - M5Document16 pagesEnglish 9 - Q2 - M5myraNo ratings yet

- CED-2021 EnergyTransition ReportDocument75 pagesCED-2021 EnergyTransition ReportCityNewsTorontoNo ratings yet

- ISSAQ: An Integrated Sensing Systems For Real-Time Indoor Air Quality MonitoringDocument15 pagesISSAQ: An Integrated Sensing Systems For Real-Time Indoor Air Quality MonitoringKemHuyềnNo ratings yet

- TCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructionDocument30 pagesTCXD 46-1984 / Lightning Protection For Buildings - Standard For Design and ConstructiontrungjindoNo ratings yet

- SCHEMACSC520Document3 pagesSCHEMACSC520fazaseikoNo ratings yet

- Quote: Quotation Prepared By: Sloan SellersDocument2 pagesQuote: Quotation Prepared By: Sloan SellersRubén CastañoNo ratings yet

- Valve Type Trim Type CF XTDocument1 pageValve Type Trim Type CF XTAye KyweNo ratings yet

- Radiation Safety Officers Handbook A PDFDocument100 pagesRadiation Safety Officers Handbook A PDFAlejandro Zubiate100% (1)

- Basic Engineering & Site DataDocument13 pagesBasic Engineering & Site DataBalasubramanianNo ratings yet

- Control Charts For Lognormal DataDocument7 pagesControl Charts For Lognormal Dataanjo0225No ratings yet

- Chapter Six: Capital Allocation To Risky AssetsDocument26 pagesChapter Six: Capital Allocation To Risky AssetsjimmmmNo ratings yet

- Alenar R.J (Stem 11 - Heliotrope)Document3 pagesAlenar R.J (Stem 11 - Heliotrope)REN ALEÑARNo ratings yet

- 12 New Trends in ManagementDocument18 pages12 New Trends in ManagementSaqib IqbalNo ratings yet

- 7 Barriers To Implementing and Maintaining An Effective HRM FunctionDocument13 pages7 Barriers To Implementing and Maintaining An Effective HRM FunctionPaing Hein KyawNo ratings yet

- ECO Report 03Document96 pagesECO Report 03ahmedshah512No ratings yet

- Risk Culture Assessment QuestionnaireDocument3 pagesRisk Culture Assessment QuestionnairemohamedNo ratings yet

- Screen 2014 Nettleton 5 28 PDFDocument24 pagesScreen 2014 Nettleton 5 28 PDFtaroefNo ratings yet

- Bing WorksheetDocument3 pagesBing WorksheetFrutti MataniNo ratings yet

- Shs Core Subjects MelcsDocument63 pagesShs Core Subjects MelcsRoldan Merjudio100% (1)

- 330 Computer Reset AddendumDocument75 pages330 Computer Reset AddendumA WongNo ratings yet

- SAP MM Purchase Info Record GuideDocument3 pagesSAP MM Purchase Info Record GuidevikneshNo ratings yet

- Ms Word McqsDocument12 pagesMs Word McqsUraiBa AnsaRi0% (1)

- Engine Retrofit Guide v8Document70 pagesEngine Retrofit Guide v8Romulo AlvarezNo ratings yet

- Despiece Des40330 Fagor Sr-23Document45 pagesDespiece Des40330 Fagor Sr-23Nữa Đi EmNo ratings yet

- Laptop Chip Level CourseDocument2 pagesLaptop Chip Level CourselghmshariNo ratings yet

- Department of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADDocument2 pagesDepartment of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADAbdul MalikNo ratings yet

- Axle, Front Drive - Housing, Swivel PDFDocument2 pagesAxle, Front Drive - Housing, Swivel PDFLeo VegaNo ratings yet

- Significant Ships 1993Document101 pagesSignificant Ships 1993Joe TahirNo ratings yet