Professional Documents

Culture Documents

StateoftheArtTechnologies Wray

Uploaded by

M Refaat FathOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

StateoftheArtTechnologies Wray

Uploaded by

M Refaat FathCopyright:

Available Formats

Simplified Base

Isolation Design

Procedure

Gordon Wray, P.E.

SEAONC Protective Systems

Subcommittee Objectives

> Current Unique Code Requirements

More sophisticated engineering analysis

Geotechnical need site specific study

Peer review is required by the code and needs

to be done concurrently with the design.

> Why Simplify the Process?

Base isolated structure is a structural system

that is closest to SDOF

Only structure in US codes that often requires

non-linear time history analysis

> SEAONC PSSC believes that the design and

analysis process must be simplified for more

widespread use of the technology

Breaking Down the Process

> Input Parameters

V

y

: Nominal (Target) system yield

strength as a fraction of total building

weight

T

2

: Nominal (Target) second slope

system period

Displacement

Force

V

y

Displacement

Force

g K

W

T

2

2

2 =

K

2

V

y

= 0.9*Dp

2

K

2

= G

r

A

r

/h

V

y

= Friction

Coefficient

R

K

2

= W/R

Lead Rubber Bearing

Friction Pendulum Bearing

High Damping Rubber V

y

based on rubber properties

> Consider Property Variation

Upper Bound Properties Increase Base Shear

Accounts for aging, contamination, first

cycle effects, specification tolerance

1.33 for LRB, FPS

1.50 for HDR

Lower Bound Properties Increase Maximum Displacement

Accounts for specification tolerance

0.85 for all systems

> Displacement due to Accidental Torsion

D

TM

includes 1.2 amplification factor on D

M

Breaking Down the Process

D

M

D

TM

Sample Result

T2 = 3 seconds

0

0.05

0.1

0.15

0.2

0.25

0.3

0 5 10 15 20 25

Di spl acement (i n)

B

a

s

e

S

h

e

a

r

(

g

)

U

p

p

e

r

B

o

u

n

d

(

x

1

.

3

3

)

L

o

w

e

r

B

o

u

n

d

(

x

0

.

8

5

)

N

o

m

i

n

a

l

V

max

D

M

D

TM

Breaking Down the Process

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

Design Response Spectra

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

0.0 1.0 2.0 3.0 4.0

Period (sec)

S

p

e

c

t

r

a

l

A

c

c

e

l

e

r

a

t

i

o

n

(

g

)

S

M1

= 0.80g

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

Determine V

y

T2 SM1 Max Vy

12 18 24 30 36 42

0.4 0.027 0.065

0.5 0.048 0.023 0.08

3.0 0.6 0.078 0.037 0.021 0.08

0.7 0.117 0.056 0.031 0.08

0.8 0.166 0.079 0.045 0.028 0.08

0.9 0.108 0.061 0.038 0.08

DTM

T2 SM1 Max Vy

12 18 24 30 36 42

0.4 0.030 0.035

0.5 0.054 0.029 0.06

4.0 0.6 0.087 0.046 0.028 0.075

0.7 0.130 0.069 0.041 0.027 0.08

0.8 0.098 0.059 0.038 0.08

0.9 0.134 0.080 0.052 0.036 0.08

DTM

T2 SM1 Max Vy

12 18 24 30 36 42

0.4 -

0.5 0.062 0.034 0.021 0.035

5.0 0.6 0.098 0.054 0.033 0.022 0.06

0.7 0.079 0.049 0.032 0.07

0.8 0.110 0.068 0.045 0.032 0.08

0.9 0.091 0.061 0.043 0.031 0.08

DTM

If S

m1

>=0.7 then minimum

V

y

>=0.04, otherwise

minimum V

y

>=0.03

Gray area not permitted, values

included for interpolation only

Notes applicable on all tables

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

Determine V

max

Unreduced Isol ati on System Base Shear, Vm versus S1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 1.1

S1 (g)

V

m

(

V

/

W

t

)

T2 =2 sec

T2 =2.5 sec

T2 =3 sec

T2 =4 sec

T2 =5 sec

T2 =6 sec

Vm = 0.6 x Sm1 - 0.035

Vm = 0.45 x Sm1 - 0.020

Vm = Sm1 / 3 + 0.002

Vm = Sm1 / T2

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

> Select Structural System

Determine R

i

(typically 2)

Concrete Shear Wall, R

i

= 2.0

Ordinary Braced Frame, R

i

= 1.6

> Calculate Design Base Shear

V

s

= V

max

/R

i

Vs = 0.17g in example (0.27/1.6)

Vs = 0.21g for fixed base OCBF, type B soil

> Check Minimum Base Shear Requirements

Vs > 1.5* Vy

Vs > Wind Load

Vs > Base Shear for a fixed base structure with Period T

D

Design Base Shear

Simplified Modeling

Procedure

Horizontally Rigid Isolator Elements (pins)

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

Vertical Distribution

Low Strength, V

y

< 0.04W

High Displacement

High Strength, V

y

> 0.06W

Low Displacement

>Current code distribution approximates

dynamic response of high strength system

>Low Strength, High Displacement results in

better performance

Overturning Moments Comparison

Moment Frame, T

2

= 3 seconds

0

10

20

30

40

50

60

70

0 2 4 6 8 10

Overturning Moment (k-ft/W)

H

e

i

g

h

t

(

f

t

)

V

y

= 0.03 Dynamic

Overturning Moments Comparison

Moment Frame, T

2

= 3 seconds

0

10

20

30

40

50

60

70

0 2 4 6 8 10

Overturning Moment (k-ft/W)

H

e

i

g

h

t

(

f

t

)

V

y

= 0.03 Dynamic

V

y

= 0.03 Code

Overturning Moments Comparison

Moment Frame, T

2

= 3 seconds

0

10

20

30

40

50

60

70

0 2 4 6 8 10

Overturning Moment (k-ft/W)

H

e

i

g

h

t

(

f

t

)

V

y

= 0.08 Dynamic

V

y

= 0.03 Dynamic

Overturning Moments Comparison

Moment Frame, T

2

= 3 seconds

0

10

20

30

40

50

60

70

0 2 4 6 8 10

Overturning Moment (k-ft/W)

H

e

i

g

h

t

(

f

t

)

V

y

= 0.08 Dynamic

V

y

= 0.08 Code

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

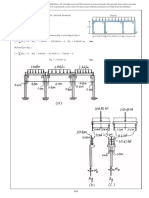

Check Isolator Tension/Uplift

0.8D 0.8D 0.8D 0.8D

Fm3

Fm2

Fm1

Tension

>Check with Manufacturer for Isolator Tension

Capacity Sliding isolators cannot resist uplift

100 psi

Check Isolator Tension/Uplift

0.8D 0.8D 0.8D

Fm3

Fm2

Fm1

>Check strength/stability after progressively

removing isolator elements.

0.8D

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

Design Structure

1.2D+L 1.2D+L 1.2D+L

Fm3

Fm2

Fm1

1.2D+L

P

P

= D

TM

P/2

P/2

>Design framing above isolators for Vs

Determine S

M1

Choose T

2

& D

TM

Choose T

2

& V

y

or

Use Table to determine

minimum V

y

Use Table to

determine D

TM

Use Chart to Determine V

max

Determine Design Shear, V

s

Distribute Forces Vertically

Check Isolator Tension/Uplift

Design Structure

Isolator System Layout

Design Process

Isolator System Layout

> Use Spreadsheet to Layout Isolators

Arrange Sizes, Types, Lead Core Locations

Friction Isolator

> Vy: Friction Coefficient a function of bearing

stress

> T2: Function of Weight/Radius

Lead Rubber Isolator

> Vy: Function of Lead Core

> T2: Function of Rubber Area and Height

Confirm Properties with Manufacturer for

varying axial loads

Sum properties and confirm system meets V

y

and T

2

requirements

Isolator System Layout

> Locate Center of Stiffness/Center of Mass

Design for Least Amount of Accidental Torsion

D

TM

/D

M

assumption uses 1.2 factor as limit

for torsionally regular buildings

Arrange isolators to align center of stiffness

(K

2

) and center of strength (V

y

) to center of

mass.

Committee working on recommendations for

maximum allowed eccentricity from center of

mass.

Isolator System Layout

-20

0

20

40

60

80

100

120

140

160

180

-20 0 20 40 60 80 100 120 140

X Location (ft)

Y

L

o

c

a

t

i

o

n

(

f

t

)

Isolator Type A Isolator Type B Center of Mass

Center of K2 Center of Vy

Summary

> Isolator System Properties

Site dictates S

M1

or C

v

Engineer chooses T

2

, D

TM

Easily determine V

max

, V

y

Useful preliminary design tool

> Alternative Modeling

Choose structural system

Build static model with horizontally rigid

isolators

Apply static loads, including P load case

Layout isolators and confirm properties

with manufacturer

> Work in Progress

Modification to vertical distribution

Confirmation of allowed center of K

2

,

center of V

y

eccentricity

Questions

K2 Qd K2 Qd K2 Qd

Contamination - - 1.0 1.1 - -

Aging 1.1 1 1 1.1 1.2 1.2

Scragging 1 1.2 1 1.1 1.2 1.2

Upper Bound Factor from

Nominal Properties

1.10 1.20 1.00 1.33 1.44 1.44

System Property Modification

Factor

Maximum Upper Bound

Factor from Nominal

Properties

Adjusted Upper Bound

Factor

System Upper Bound

Specification Tolerance

System Lower Bound

Specification Tolerance

Final Upper Bound Factor

From Nominal Properties

Final Lower Bound Factor

From Nominal Properties

1.10 1.10

0.85 0.85 0.85

0.85 0.85 0.85

1.25 1.34 1.42

1.10

1.44

0.66 0.66 0.66

Property Modification Factor Table

1.13 1.22 1.29

LRB FPS HDR

1.20 1.33

You might also like

- Check SauceDocument2 pagesCheck Saucebig boss90% (10)

- 2007 Analyses of Underground Structures Crossing An Active Fault in CoronadoDocument6 pages2007 Analyses of Underground Structures Crossing An Active Fault in Coronadoryan rakhmat setiadiNo ratings yet

- Fluid Viscous Dampers & Lock-Up Devices Clevis - Clevis ConfigurationDocument1 pageFluid Viscous Dampers & Lock-Up Devices Clevis - Clevis ConfigurationcrvishnuramNo ratings yet

- 䕔䵁吠䕂 - 14M CURVED POLE FATIGUE CHECKDocument38 pages䕔䵁吠䕂 - 14M CURVED POLE FATIGUE CHECKanammominNo ratings yet

- Questionnaire Exercise: Deals Desk Analyst Please Answer Below Questions and Email Your Responses Before First Technical Round of InterviewDocument2 pagesQuestionnaire Exercise: Deals Desk Analyst Please Answer Below Questions and Email Your Responses Before First Technical Round of InterviewAbhinav SahaniNo ratings yet

- Marketing For Hospitality & TourismDocument5 pagesMarketing For Hospitality & Tourismislahu56No ratings yet

- Brand Plan - SingulairDocument11 pagesBrand Plan - Singulairshashank100% (2)

- Problemas Del Capitulo 7Document26 pagesProblemas Del Capitulo 7dic vilNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Tunneling Introduction To TPKBDocument55 pagesTunneling Introduction To TPKBHansen ChouNo ratings yet

- Or Tan Teng - Cost Reduction Through Base IsolationDocument20 pagesOr Tan Teng - Cost Reduction Through Base IsolationmandorNo ratings yet

- Seaony Ramon Gilsanz StructuralDocument100 pagesSeaony Ramon Gilsanz StructuralPrakash SinghNo ratings yet

- Bracci, ThesisDocument176 pagesBracci, Thesisprisciliano1No ratings yet

- 2010 MSK - Volume 3Document489 pages2010 MSK - Volume 3Amanda MathisNo ratings yet

- PARAS 0014.BlastMitigationStrategies - FinalguidebookDocument193 pagesPARAS 0014.BlastMitigationStrategies - FinalguidebookRey Eduard Q. UmelNo ratings yet

- 6000 StructuresDocument79 pages6000 Structuresahong100No ratings yet

- Reduce Earthquake Effects On Buildings Project ReportDocument133 pagesReduce Earthquake Effects On Buildings Project ReportNisanth ThulasidasNo ratings yet

- 21 - Ahmadi - HDNR Seismic Isolators Performance and Historical DevelopmentDocument45 pages21 - Ahmadi - HDNR Seismic Isolators Performance and Historical DevelopmentHasrina Mohd RamaziNo ratings yet

- Belete Highway II-1Document674 pagesBelete Highway II-1Nathan KebedeNo ratings yet

- ASCE 7-10 GuidelinesDocument55 pagesASCE 7-10 GuidelinesMe MeNo ratings yet

- Comparative Response Assessment of Steel Frames With Different Bracing PDFDocument14 pagesComparative Response Assessment of Steel Frames With Different Bracing PDFaxl_calin82No ratings yet

- 10001-A30-22-Rev-B - Technical Report - Asera Rahabangga - LRBDocument15 pages10001-A30-22-Rev-B - Technical Report - Asera Rahabangga - LRBandhika maulana100% (1)

- Lecture 4Document28 pagesLecture 4Mong100% (1)

- ASCE Intermediate Diaphragms SC.1943-5576.0000272Document10 pagesASCE Intermediate Diaphragms SC.1943-5576.0000272jrhst36100% (1)

- ICGE 15 KN 04 Endicott PDFDocument10 pagesICGE 15 KN 04 Endicott PDFDiego SerónNo ratings yet

- Learning Lessons From Design Case Studies 29mar17Document25 pagesLearning Lessons From Design Case Studies 29mar17Arjun RajaNo ratings yet

- A23b - Chalenges For Underwater Concrete Repair in Deep WaterDocument12 pagesA23b - Chalenges For Underwater Concrete Repair in Deep WaterJoão Carlos Protz ProtzNo ratings yet

- CE5710 Assignment IDocument1 pageCE5710 Assignment INani RujaNo ratings yet

- Testing Protocols For Seismic Isolation PDFDocument10 pagesTesting Protocols For Seismic Isolation PDFFrancisco GoFlesNo ratings yet

- Energy Dissipators: South Dakota Drainage ManualDocument24 pagesEnergy Dissipators: South Dakota Drainage ManualRiya Sree100% (1)

- Davy Sukamta - Up-Down ConstructionDocument6 pagesDavy Sukamta - Up-Down Constructionyudi hidayatNo ratings yet

- Herrenknecht - Suez Canal Road Tunnels Meeting 08.09.2016 Ismailia/EgyptDocument36 pagesHerrenknecht - Suez Canal Road Tunnels Meeting 08.09.2016 Ismailia/EgyptMohamed Abd El-HalimNo ratings yet

- Materi Hari 2 Davy Sukamta PDFDocument20 pagesMateri Hari 2 Davy Sukamta PDFLaode AliyaNo ratings yet

- Seismic Design Bridge AbutmentsDocument4 pagesSeismic Design Bridge Abutmentsclam2014No ratings yet

- Volume - 4Document85 pagesVolume - 4DEBASIS BARMANNo ratings yet

- Special Considerations and Challenges in Seismic Design of Tall BuildingsDocument55 pagesSpecial Considerations and Challenges in Seismic Design of Tall Buildingsf430_boyNo ratings yet

- Analysis Anda Design Pre Stressd SleepersDocument25 pagesAnalysis Anda Design Pre Stressd SleeperspoezpietaNo ratings yet

- General Principles of Bridge DesignDocument3 pagesGeneral Principles of Bridge DesignJason GuzmanNo ratings yet

- Soil Dynamics and Earthquake Engineering: Ngoc-Anh Do, Daniel Dias, Pierpaolo Oreste, Irini Djeran-MaigreDocument11 pagesSoil Dynamics and Earthquake Engineering: Ngoc-Anh Do, Daniel Dias, Pierpaolo Oreste, Irini Djeran-MaigrePaloma CortizoNo ratings yet

- CIGRE b2-305Document8 pagesCIGRE b2-305Jorge Pinto RochaNo ratings yet

- Calculation Report Peninggian Cleaning Area Sulzer r.03Document224 pagesCalculation Report Peninggian Cleaning Area Sulzer r.03Lukman SitanggangNo ratings yet

- VSL CCT Pot BearingsDocument8 pagesVSL CCT Pot BearingsalsvsuryaNo ratings yet

- Relating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaDocument13 pagesRelating Seismic Design Level and Seismic Performance: Fragility-Based Investigation of RC Moment-Resisting Frame Buildings in ChinaAniket DubeNo ratings yet

- Shilpa PPT FinalDocument51 pagesShilpa PPT FinalDrakeNo ratings yet

- Concrete DesignDocument106 pagesConcrete DesignBoy AlfredoNo ratings yet

- CEE 241 Notes IIIDocument58 pagesCEE 241 Notes IIINguyen DuyNo ratings yet

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanNo ratings yet

- Wind Induced Vibration WhitePaper FinalDocument5 pagesWind Induced Vibration WhitePaper FinalHussain AliNo ratings yet

- 14 0005Document562 pages14 0005aenima696No ratings yet

- Use of Headed Reinforcement in Beam - Column JointsDocument24 pagesUse of Headed Reinforcement in Beam - Column JointsHabibi MehediNo ratings yet

- Comparison Between Conventional Steel Structures and Tubular PDFDocument5 pagesComparison Between Conventional Steel Structures and Tubular PDFa duttaNo ratings yet

- Presentation Basar Arioglu Yapi Merkezi InsaatDocument29 pagesPresentation Basar Arioglu Yapi Merkezi InsaatALIYA FATHIMA BNo ratings yet

- (NATO ASI Series 215) Jozsef Bodig (Auth.), Jozsef Bodig (Eds.) - Reliability-Based Design of Engineered Wood Structures-Springer Netherlands (1992)Document198 pages(NATO ASI Series 215) Jozsef Bodig (Auth.), Jozsef Bodig (Eds.) - Reliability-Based Design of Engineered Wood Structures-Springer Netherlands (1992)Fatlum100% (1)

- WA209 01F02 (Rev0) BB ReportDocument92 pagesWA209 01F02 (Rev0) BB ReportnilangNo ratings yet

- UCASE Incremental DesignDocument76 pagesUCASE Incremental DesignctrleNo ratings yet

- ASCE Paper PDFDocument8 pagesASCE Paper PDFLeandroNo ratings yet

- Limit On Strength of Normal Weight Concrete ACIDocument6 pagesLimit On Strength of Normal Weight Concrete ACIBengkulu BetonNo ratings yet

- Scrra Resident Engineers ManualDocument61 pagesScrra Resident Engineers Manualahong100No ratings yet

- History of Nonlinear Seismic Analysis PDFDocument18 pagesHistory of Nonlinear Seismic Analysis PDFDr RajeevNo ratings yet

- C StrucDesign Morgan Jun151 PDFDocument3 pagesC StrucDesign Morgan Jun151 PDFkyleNo ratings yet

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDocument18 pagesJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321No ratings yet

- Guideline On Design of Railings PDFDocument4 pagesGuideline On Design of Railings PDFDanny LamNo ratings yet

- ETCulvert V2 Brochure Web PDFDocument2 pagesETCulvert V2 Brochure Web PDFjorgesalinasengNo ratings yet

- Calculation of The Plastic Section Modulus Using The ComputerDocument4 pagesCalculation of The Plastic Section Modulus Using The ComputerAnonymous 7MdZQn1No ratings yet

- ANZSCO List of OccupationsDocument854 pagesANZSCO List of OccupationsAmber PattersonNo ratings yet

- Numerical Analysis of A 36 M Deep Diaphragm Wall - Parametric StudyDocument6 pagesNumerical Analysis of A 36 M Deep Diaphragm Wall - Parametric StudyM Refaat FathNo ratings yet

- Proceedings - 25EYGEC Circuklar ShaftDocument444 pagesProceedings - 25EYGEC Circuklar ShaftM Refaat Fath0% (1)

- Tobctj 8 104Document18 pagesTobctj 8 104M Refaat FathNo ratings yet

- RAPT User ManualDocument738 pagesRAPT User ManualrakhbirNo ratings yet

- Steel Design 1232Document21 pagesSteel Design 1232Mike JamesNo ratings yet

- b18355353 IrDocument362 pagesb18355353 IrM Refaat FathNo ratings yet

- Ufc 4-211-01n Aircraft Maintenance Hangars - Type I, Type II and Type Iii, With Change 3 (16 December 2009)Document155 pagesUfc 4-211-01n Aircraft Maintenance Hangars - Type I, Type II and Type Iii, With Change 3 (16 December 2009)Bob VinesNo ratings yet

- Biaxial Hollow Slab With Innovative Types of Voids: Journal HomepageDocument19 pagesBiaxial Hollow Slab With Innovative Types of Voids: Journal HomepagerohithNo ratings yet

- Clep Us History 3Document10 pagesClep Us History 3M Refaat FathNo ratings yet

- 01 Taylor Slurry WallDocument30 pages01 Taylor Slurry WallAlfredo A LopezNo ratings yet

- Concrete EC2Document186 pagesConcrete EC2Ivan Grad100% (1)

- Precast Concrete Systems PDFDocument275 pagesPrecast Concrete Systems PDFAlex RodriguesNo ratings yet

- Pile Foundation Design and Construction - What Can Go Wrong PDFDocument6 pagesPile Foundation Design and Construction - What Can Go Wrong PDFpabulumzeng100% (1)

- Deloitte GlobalHumanCapitalTrends 2016 3 PDFDocument124 pagesDeloitte GlobalHumanCapitalTrends 2016 3 PDFAcuy Sang Pemimpi100% (1)

- 1 SsssDocument14 pages1 SsssM Refaat FathNo ratings yet

- Vol1SDG BridgeDocument332 pagesVol1SDG BridgeM Refaat FathNo ratings yet

- Structure Design Manual 032016Document255 pagesStructure Design Manual 032016M Refaat FathNo ratings yet

- Ufc 3 201 01Document42 pagesUfc 3 201 01M Refaat FathNo ratings yet

- Wind Load CalculationDocument105 pagesWind Load CalculationMadusha Galappaththi100% (2)

- EarthqakeDocument256 pagesEarthqakeEugene AfableNo ratings yet

- Ufc 3 220 01Document35 pagesUfc 3 220 01M Refaat FathNo ratings yet

- 12Document60 pages12M Refaat FathNo ratings yet

- Fema 303 Seismic DesignDocument366 pagesFema 303 Seismic DesignM Refaat Fath100% (1)

- 1997v05 Hangar DesignDocument60 pages1997v05 Hangar DesignM Refaat FathNo ratings yet

- Performance Based Evaluation of Shear Walled RCC Building by Pushover AnalysisDocument4 pagesPerformance Based Evaluation of Shear Walled RCC Building by Pushover AnalysisIJMERNo ratings yet

- Hangar DesignDocument5 pagesHangar DesignZoran100% (1)

- 14 04Document8 pages14 04M Refaat FathNo ratings yet

- American Society of Heating - OCRDocument30 pagesAmerican Society of Heating - OCRM Refaat FathNo ratings yet

- Novozymes IPRDocument19 pagesNovozymes IPRthereisaneedNo ratings yet

- Star - 6 ManualDocument100 pagesStar - 6 ManualOskarNo ratings yet

- Attachment I - Instructions To Bidders - EEPNL EEPN (OE) L QA QC PDFDocument24 pagesAttachment I - Instructions To Bidders - EEPNL EEPN (OE) L QA QC PDFMathias OnosemuodeNo ratings yet

- Assignment3 (Clarito, Glezeri BSIT-3A)Document9 pagesAssignment3 (Clarito, Glezeri BSIT-3A)Jermyn G EvangelistaNo ratings yet

- OTP Protocol PharmacistsDocument14 pagesOTP Protocol PharmacistsericNo ratings yet

- Openness and The Market Friendly ApproachDocument27 pagesOpenness and The Market Friendly Approachmirzatouseefahmed100% (2)

- Book LoRa LoRaWAN and Internet of ThingsDocument140 pagesBook LoRa LoRaWAN and Internet of ThingsNguyễn Hữu HạnhNo ratings yet

- Lampiran Surat 739Document1 pageLampiran Surat 739Rap IndoNo ratings yet

- Manual TP5000Document206 pagesManual TP5000u177427100% (4)

- IDS701Document26 pagesIDS701Juan Hidalgo100% (2)

- Dilip - SFDC CPQ Architect14 GCDocument5 pagesDilip - SFDC CPQ Architect14 GCmariareddy17100% (1)

- 48 - 1997 SummerDocument42 pages48 - 1997 SummerLinda ZwaneNo ratings yet

- C TKP3 SMQDocument11 pagesC TKP3 SMQDavid Tovar cruzNo ratings yet

- C28x WorkshopDocument400 pagesC28x WorkshopMarcio De Andrade VogtNo ratings yet

- Common Metallurgical Defects in Grey Cast IronDocument9 pagesCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- Status Of: Philippine ForestsDocument11 pagesStatus Of: Philippine ForestsAivy Rose VillarbaNo ratings yet

- Group Terms&ConditionsDocument5 pagesGroup Terms&Conditionsbelen rodriguezNo ratings yet

- PlayAGS, Inc.Document309 pagesPlayAGS, Inc.vicr100No ratings yet

- I. Characteristics of WastewaterDocument59 pagesI. Characteristics of WastewaterEljay VinsonNo ratings yet

- Feasibility Report, Modhumoti, Rev. - April-.2015-1Document19 pagesFeasibility Report, Modhumoti, Rev. - April-.2015-1Jahangir RaselNo ratings yet

- Fadm Project 5 ReportDocument4 pagesFadm Project 5 ReportVimal AgrawalNo ratings yet

- Standards For Pipes and FittingsDocument11 pagesStandards For Pipes and FittingsMohammed sabatinNo ratings yet

- SMB Marketing PlaybookDocument18 pagesSMB Marketing PlaybookpramodharithNo ratings yet

- Super Duty - Build & PriceDocument8 pagesSuper Duty - Build & PriceTyler DanceNo ratings yet

- DL5/DL6 With CBD6S: User ManualDocument32 pagesDL5/DL6 With CBD6S: User ManualMeOminGNo ratings yet