Professional Documents

Culture Documents

Solutions For Recycling Elmwood Park

Uploaded by

recycletechno0 ratings0% found this document useful (0 votes)

79 views6 pagesRecycleTech Corporation is an innovation-driven company utilizing the latest technology to provide solutions for recycling and waste reduction. Founded in 2004 as specialized recycler of EPS - Expanded Polystyrene, commonly known as Styrofoam™ - scrap material, RecycleTech Corp. has set up its first processing facility in Lakeland, Florida in 2005. In a partnership with the Solid Waste Division of Polk County, some 4,000 lbs of material is processed daily from the post-industrial "loose foam" scrap received from the local organizations.

Original Title

Solutions for Recycling Elmwood Park

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRecycleTech Corporation is an innovation-driven company utilizing the latest technology to provide solutions for recycling and waste reduction. Founded in 2004 as specialized recycler of EPS - Expanded Polystyrene, commonly known as Styrofoam™ - scrap material, RecycleTech Corp. has set up its first processing facility in Lakeland, Florida in 2005. In a partnership with the Solid Waste Division of Polk County, some 4,000 lbs of material is processed daily from the post-industrial "loose foam" scrap received from the local organizations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

79 views6 pagesSolutions For Recycling Elmwood Park

Uploaded by

recycletechnoRecycleTech Corporation is an innovation-driven company utilizing the latest technology to provide solutions for recycling and waste reduction. Founded in 2004 as specialized recycler of EPS - Expanded Polystyrene, commonly known as Styrofoam™ - scrap material, RecycleTech Corp. has set up its first processing facility in Lakeland, Florida in 2005. In a partnership with the Solid Waste Division of Polk County, some 4,000 lbs of material is processed daily from the post-industrial "loose foam" scrap received from the local organizations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Solutions for Recycling Elmwood Park

RecycleTech Corporation is an innovation-driven company

utilizing the latest technology to provide solutions for recycling

and waste reduction. Founded in 2004 as specialized recycler of

EPS - Expanded Polystyrene, commonly known as Styrofoam

- scrap material, RecycleTech Corp. has set up its first

processing facility in Lakeland, Florida in 2005. In a partnership

with the Solid Waste Division of Polk County, some 4,000 lbs

of material is processed daily from the post-industrial "loose

foam" scrap received from the local organizations. In 2008, an

Innovative Waste Reduction and Recycling Grant was awarded

to RecycleTech to stop the flow of EPS waste into

landfills. Through the grant RecycleTech has placed its EPS

processing machines in several counties and businesses

throughout the State of Florida.

Current Operations Locations

RecycleTech has its epuipment installed and running at over 100 client locations

throughout U.S. & Canada.

RT's clients list include many major electric, apliance, motor, and retailing companies.

Reverse Vending Machines

RVMs - are automated machines that utilize advanced technology to identify, sort,

collect and process used beverage containers. RecycleTech's cutting edge Reverse

Vending Machines have unique features that will effectively promote recycling among

the public, especially the younger generations.

MT-500 Reverse Vending Machine can do much more than just crushing cans and

bottles.

MT-500 Reverse

Vending Machine

has 42" LCD video

display for ads and

campaign

messages.

Video Player

Personalized magnetic/IC chip

card system issues the users

reward points. The system may

be integrated with other types

of personal accounts, i.e. school

ID or library card.

Reward Point System

MT 500

Waste to Energy Systems

The system processes waste materials

thermo-plastics, waste tires, synthetic fibers,

etc. by applying heat in the absence of

oxygen, triggering chemical endothermic

reaction that breaks down the carbon chains

inside: The materials are decomposed into

carbonized hydrogen chemical compounds

from which gaseous, solid, and liquid fuels

are extracted.

It's not science fiction any more. RecycleTech's high molecular pyrolysis Waste-to-

Energy system can produce fuel from waste.

Virtually Self-sustaining System (Output gas

used as fuel for operation)

Minimal CO2 Footprint

No Polluting Emissions

High Efficiency & Profitability

Plastic Foam Densifiers

Plastic Foam Densifier XT 200

XT 200 Specifications

Weight: 1,400 lbs

Capacity: 200 lbs/hour

Overall Dimensions (w/ safety guard):

47"(W) x 43"(L) x 65 "(H)

Hopper Opening: 25" x 20"

Power Requirements:

220 Volt / 3 Phase / 16~40 Amp

(60 Amp circuit breaker required)

Why XT200

Competitively priced / Cost effective Convenient and Safe for

public use Easy to move around (Can be mounted on a truck to

form a Mobile EPS Recycling Station) Easy to maintain.

Applications

Small to mid-sized warehouses/

retail stores

Small to mid-sized electronic

recycle & repair centers

Schools or Government Offices

For more information please visit

http://www.recycletechno.com

Headquarters & Sales Office

418 Falmouth Ave.,

Elmwood Park, NJ 07407.

Telephone: 201-475-5000

Fax: 201-475-5001

E-mail: info@recycletechno.com

U.S. South East Operation

Bartow Municipal Airport Blvd 104

Bartow, FL 33830

Telephone: 863-665-3755

FAX: 863-665-3866

E-mail: info@recycletechno.com

You might also like

- OverviewDocument17 pagesOverviewbillNo ratings yet

- The Clean Tech Revolution: Winning and Profiting from Clean EnergyFrom EverandThe Clean Tech Revolution: Winning and Profiting from Clean EnergyRating: 4 out of 5 stars4/5 (2)

- Oracle World Wide: Your Sourcing PartnerDocument13 pagesOracle World Wide: Your Sourcing PartnerabioduncityNo ratings yet

- Case Study 3 Cynar Plastics To Fuel FINALDocument8 pagesCase Study 3 Cynar Plastics To Fuel FINALParth Garg100% (1)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Ecoreco CompanyDocument6 pagesEcoreco CompanyYogendra ShastriNo ratings yet

- Polystyrene Recycling System - StyromeltDocument2 pagesPolystyrene Recycling System - StyromeltDuncan HarrisonNo ratings yet

- Design For Recycling (DFR) : How Does It Work?Document14 pagesDesign For Recycling (DFR) : How Does It Work?NguyenHuanNo ratings yet

- CynarPlc - Turning Plastic Waste To FuelDocument3 pagesCynarPlc - Turning Plastic Waste To FuelShubham ArawkarNo ratings yet

- Eco RecoDocument8 pagesEco RecokittuiyerNo ratings yet

- Green MarketingDocument25 pagesGreen MarketinggeetukumariNo ratings yet

- Effluent Treatment PlantDocument68 pagesEffluent Treatment PlantSegun Olatayo100% (2)

- ITC Other BusinessDocument24 pagesITC Other BusinessArihant JainNo ratings yet

- Process DescriptionDocument9 pagesProcess Descriptionsonhai937No ratings yet

- EERC Gasifier FactsheetDocument1 pageEERC Gasifier FactsheetMag FhearadhaighNo ratings yet

- EFFECTIVE WASTE MANAGEMENT PROJECT FinalDocument18 pagesEFFECTIVE WASTE MANAGEMENT PROJECT FinalIkram KhanNo ratings yet

- Thermo Fuel ProcessDocument9 pagesThermo Fuel ProcessSpoiler Alert100% (1)

- Waste ExchangeDocument24 pagesWaste Exchangeminorona2409No ratings yet

- Business Plan On Plastic RecycleDocument25 pagesBusiness Plan On Plastic RecycleShailendra Joshi83% (6)

- ppt tejuDocument17 pagesppt tejuTejas JawanjalNo ratings yet

- Pyrolysis of Plastic Waste - Opportunities and ChallengesDocument17 pagesPyrolysis of Plastic Waste - Opportunities and Challengesgavin meadeNo ratings yet

- EPS Cold Compactor Parameter GreenMax - C200-WDSSDocument2 pagesEPS Cold Compactor Parameter GreenMax - C200-WDSSintcopanNo ratings yet

- Abstract For E-WasteDocument3 pagesAbstract For E-WasteRuchithaNo ratings yet

- Fuel From Waste PlasticDocument13 pagesFuel From Waste PlasticAnonymous VTbmrkb13bNo ratings yet

- Pyrolysis FPDocument6 pagesPyrolysis FPReymarkMachoNo ratings yet

- Project Report On Pet Granules From Pet Bottles Then Making Pet PreformDocument8 pagesProject Report On Pet Granules From Pet Bottles Then Making Pet PreformEIRI Board of Consultants and PublishersNo ratings yet

- Thermalysis-Converting Waste Plastic To DieselDocument8 pagesThermalysis-Converting Waste Plastic To DieselRavi KumarNo ratings yet

- Chintan Fact Sheet Green Your Electronic FootprintDocument2 pagesChintan Fact Sheet Green Your Electronic FootprintShruti BansalNo ratings yet

- Recycling PlasticsDocument13 pagesRecycling PlasticsSushan KottariNo ratings yet

- E WasteDocument15 pagesE WasteRachel PrestoNo ratings yet

- Itc PSPD UnitsDocument7 pagesItc PSPD UnitsDheena NagarajanNo ratings yet

- Circular Economy: Economic System Aimed at Eliminating Waste and The Continual Use of ResourcesDocument27 pagesCircular Economy: Economic System Aimed at Eliminating Waste and The Continual Use of Resourcesendang dian lestariNo ratings yet

- T-Technology Pintér WorksDocument5 pagesT-Technology Pintér Worksmig232323No ratings yet

- Midterm Exam Project Climate Action: Business EthicsDocument20 pagesMidterm Exam Project Climate Action: Business EthicsSofija JovchevaNo ratings yet

- 20121123003140!business Plan For Website2Document24 pages20121123003140!business Plan For Website2Harshith GowdaNo ratings yet

- Waste Paper and CardboardDocument4 pagesWaste Paper and CardboardHajar YounesNo ratings yet

- OTE Filtration Solutions For 2nd and 3rd GeneratioDocument4 pagesOTE Filtration Solutions For 2nd and 3rd GeneratioHermawan Dwi AriyantoNo ratings yet

- What Is Polypropylene (PP) ?: ? Ecycling PP Environmental Benefits of RDocument4 pagesWhat Is Polypropylene (PP) ?: ? Ecycling PP Environmental Benefits of Rفهد العتيبيNo ratings yet

- 01 EREMA Image 2013 09 ENDocument15 pages01 EREMA Image 2013 09 ENcarlos4770No ratings yet

- Training Programme On "Plastics"Document12 pagesTraining Programme On "Plastics"Deejay ShivNo ratings yet

- Obtaining Fuels From Plastic Waste PDFDocument3 pagesObtaining Fuels From Plastic Waste PDFurfi ramadhani100% (1)

- DELTA Plastics Recycling: Industry Description and OutlookDocument19 pagesDELTA Plastics Recycling: Industry Description and OutlookprospereducationNo ratings yet

- MLGRCMPPTDocument43 pagesMLGRCMPPTapi-264489033No ratings yet

- Ecodek - WPC DeckingDocument3 pagesEcodek - WPC DeckingEcodekNo ratings yet

- Thesis On Industrial Wastewater TreatmentDocument6 pagesThesis On Industrial Wastewater TreatmentCollegePaperWritingServiceCanada100% (2)

- Environmental Management: Ecological Innovations in OrganizationsDocument23 pagesEnvironmental Management: Ecological Innovations in OrganizationsvimalNo ratings yet

- Presentation of EntrepreneurshipDocument24 pagesPresentation of Entrepreneurshipharis khanNo ratings yet

- Plastic Sorters Comparison ParametersDocument24 pagesPlastic Sorters Comparison Parametersjustakash0% (1)

- EconomiserDocument2 pagesEconomiserChirag RakhashiyaNo ratings yet

- Review of Related LiteratureDocument6 pagesReview of Related LiteratureMontzo Diana BaltonadoNo ratings yet

- DSEU PUSA CAMPUS Environmental Studies ProjectDocument17 pagesDSEU PUSA CAMPUS Environmental Studies ProjectSanjeev KumarNo ratings yet

- New Magnetic Technology Reduces Costs and PollutionDocument7 pagesNew Magnetic Technology Reduces Costs and PollutionPeter KulishNo ratings yet

- Molo06 Jankunaite Pulp and Paper Industry in SwedenDocument35 pagesMolo06 Jankunaite Pulp and Paper Industry in SwedenjnmanivannanNo ratings yet

- Digital Assignment-3: Rohan Avachat 15bem0102 C2 Dr. Pundlik BhagatDocument14 pagesDigital Assignment-3: Rohan Avachat 15bem0102 C2 Dr. Pundlik BhagatjasonNo ratings yet

- SBIR Phase III-HighlightDocument9 pagesSBIR Phase III-HighlightAnthony D.No ratings yet

- T-Technology Brochure - Zbigniew TokarzDocument1 pageT-Technology Brochure - Zbigniew Tokarzmig232323No ratings yet

- E-Waste Management System in IndiaDocument37 pagesE-Waste Management System in IndiaKunal VermaNo ratings yet

- PLASTICS CIRCULAR ECONOMY TECHNOLOGY CONVERTING WASTEDocument6 pagesPLASTICS CIRCULAR ECONOMY TECHNOLOGY CONVERTING WASTEJasmine PutriNo ratings yet

- Smart Sketch GuideDocument690 pagesSmart Sketch Guidesenthilsp3d100% (1)

- Wilson Sporting Goods V Rawlings Sporting GoodsDocument38 pagesWilson Sporting Goods V Rawlings Sporting GoodsDarren Adam HeitnerNo ratings yet

- Conclusion and RecommendationDocument2 pagesConclusion and RecommendationKholidi ChooNo ratings yet

- Abhishek Kumar SinghDocument3 pagesAbhishek Kumar SinghAshutosh UpadhyayNo ratings yet

- Mechanical Engineer Resume For FresherDocument5 pagesMechanical Engineer Resume For FresherIrfan Sayeem SultanNo ratings yet

- Edexcel GCE: Decision Mathematics D1 Advanced/Advanced SubsidiaryDocument24 pagesEdexcel GCE: Decision Mathematics D1 Advanced/Advanced SubsidiarymizmellNo ratings yet

- Upper West Side Town House Construction SetDocument34 pagesUpper West Side Town House Construction SethannahchiaroniclarkeNo ratings yet

- Building EstimateDocument16 pagesBuilding EstimateMrinal TalukdarNo ratings yet

- STROBEL 3100 Mechanics InstructionsDocument40 pagesSTROBEL 3100 Mechanics InstructionsHadi KurniawanNo ratings yet

- Nota - 2245047 - Pre Manual Implementation StepsDocument13 pagesNota - 2245047 - Pre Manual Implementation StepsCarlos Manoel SouzaNo ratings yet

- Tower Signal BoqDocument2 pagesTower Signal Boqrafael velardeNo ratings yet

- 2004 E60 530D Glowplug Controller ReplacedDocument16 pages2004 E60 530D Glowplug Controller ReplacedAlexandru Bogdan OvidenieNo ratings yet

- Crane Safety Program EssentialsDocument11 pagesCrane Safety Program Essentialssekhargm100% (1)

- OSS ReferenceDocument336 pagesOSS ReferenceMonish R Nath50% (2)

- E PKS: Control Builder Parameter ReferenceDocument3,341 pagesE PKS: Control Builder Parameter ReferenceAnkoosh MandanNo ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFDocument42 pagesModule 7 (Maintenance Practices) Sub Module 7.1 (Safety Precautions-Aircraft and Workshop) PDFshareyhou100% (1)

- Method Statement For Installation of Aftercooler Compressor E-2180Document11 pagesMethod Statement For Installation of Aftercooler Compressor E-2180Anyanele Nnamdi FelixNo ratings yet

- Timber-framed homes guideDocument44 pagesTimber-framed homes guideMtkNo ratings yet

- Rai Quo NK 001 0124Document5 pagesRai Quo NK 001 0124yudii.hidayatNo ratings yet

- Export PDS To Smart 3D User's GuideDocument6 pagesExport PDS To Smart 3D User's Guidedaisyduck2013No ratings yet

- Durga's Interview QuestionsDocument22 pagesDurga's Interview QuestionsRaJu SinGh82% (11)

- Cable Laying Equipment: CCC (Underwater Engineering) SalDocument5 pagesCable Laying Equipment: CCC (Underwater Engineering) Sallaleye_olumideNo ratings yet

- Flipkart's Big Billion Day Sale IT FailuresDocument21 pagesFlipkart's Big Billion Day Sale IT FailuresManisha KumariNo ratings yet

- Oracle Complex PO RetainageDocument19 pagesOracle Complex PO RetainageabiyeasamenewNo ratings yet

- Instruction Manual: SpecificationsDocument16 pagesInstruction Manual: SpecificationsJorge L. ContrerasNo ratings yet

- Siebel Field ServiceDocument4 pagesSiebel Field ServicesubbaraocrmNo ratings yet

- 487 - 1 - MSSL Press Release-August 2018Document2 pages487 - 1 - MSSL Press Release-August 2018Varun SidanaNo ratings yet

- Eeca QB PDFDocument6 pagesEeca QB PDFJeevanandam ShanmugaNo ratings yet

- Project Management For Construction - The Design and Construction ProcessDocument3 pagesProject Management For Construction - The Design and Construction ProcessMark Alvin L. AcordaNo ratings yet

- STD1 Crimping Chart March 2020 Final 2Document1 pageSTD1 Crimping Chart March 2020 Final 2Bernd RichterNo ratings yet

- The Voice of God: Experience A Life Changing Relationship with the LordFrom EverandThe Voice of God: Experience A Life Changing Relationship with the LordNo ratings yet

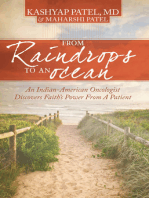

- From Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientFrom EverandFrom Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientRating: 1 out of 5 stars1/5 (1)